- 2009 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2010 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2004 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 1999 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2001 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 1996 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2015 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2013 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2007 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2000 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2012 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 1998 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 1997 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2003 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- 2019 Toyota Corolla Owners Manuals

- Toyota Corolla Owners Manuals

- Download PDF Manual

-

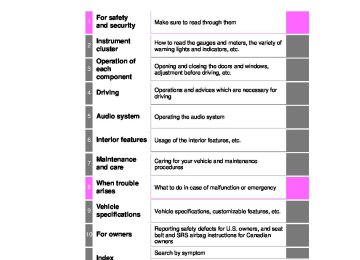

COROLLA_TMMMS_TMMC_U (OM12F00U)

534

8-2. Steps to take in an emergency

■Starting the engine when the battery is discharged

The engine cannot be started by push-starting.

■To prevent battery discharge

●Turn off the headlights and the audio system while the engine is off. ●Turn off any unnecessary electrical components when the vehicle is running

at a low speed for an extended period, such as in heavy traffic.

■Charging the battery

The electricity stored in the battery will discharge gradually even when the vehicle is not in use, due to natural discharge and the draining effects of cer- tain electrical appliances. If the vehicle is left for a long time, the battery may discharge, and the engine may be unable to start. (The battery recharges automatically during driving.)

■When recharging or replacing the battery

●Vehicles with a smart key system: In some cases, it may not be possible to unlock the doors using the smart key system when the battery is dis- charged. Use the wireless remote control or the mechanical key to lock or unlock the doors.

●The engine may not start on the first attempt after the battery has recharged

but will start normally after the second attempt. This is not a malfunction.

●Vehicles with a smart key system: The engine switch mode is memorized by the vehicle. When the battery is reconnected, the system will return to the mode it was in before the battery was discharged. Before disconnecting the battery, turn the engine switch off. If you are unsure what mode the engine switch was in before the battery dis- charged, be especially careful when reconnecting the battery.

●Make sure that the key is not inside the vehicle when recharging or replac- ing the battery. The key may be locked in the vehicle if the alarm is acti- vated. (P. 69)

COROLLA_TMMMS_TMMC_U (OM12F00U)

8-2. Steps to take in an emergency

535

CAUTION

■Avoiding battery fires or explosions

Observe the following precautions to prevent accidentally igniting the flam- mable gas that may be emitted from the battery: ●Make sure each jumper cable is connected to the correct terminal and that it is not unintentionally in contact with any other than the intended terminal. ●Do not allow the other end of the jumper cable connected to the “+” termi- nal to come into contact with any other parts or metal surfaces in the area, such as brackets or unpainted metal.

●Do not allow the + and - clamps of the jumper cables to come into contact

with each other.

●Do not smoke, use matches, cigarette lighters or allow open flame near

the battery.

■Battery precautions

The battery contains poisonous and corrosive acidic electrolyte, while related parts contain lead and lead compounds. Observe the following pre- cautions when handling the battery: ●When working with the battery, always wear safety glasses and take care not to allow any battery fluids (acid) to come into contact with skin, clothing or the vehicle body.

●Do not lean over the battery. ●In the event that battery fluid comes into contact with the skin or eyes, immediately wash the affected area with water and seek medical attention. Place a wet sponge or cloth over the affected area until medical attention can be received.

●Always wash your hands after handling the battery support, terminals, and

other battery-related parts.

●Do not allow children near the battery.

NOTICE

■When handling jumper cables

When connecting the jumper cables, ensure that they do not become entan- gled in the cooling fan or engine drive belt.

COROLLA_TMMMS_TMMC_U (OM12F00U)

536

8-2. Steps to take in an emergency

If your vehicle overheats

The following may indicate that your vehicle is overheating.

● Vehicles with a drive monitor display: The high engine coolant tem- perature warning light (P. 491) comes on or a loss of power is experienced. Vehicles with a multi-information display: The engine coolant tem- perature gauge (P. 82) enters the red zone or a loss of power is experienced.

● Steam comes out from under the hood.

Correction procedures

Stop the vehicle in a safe place and turn off the air conditioning sys- tem, and then stop the engine. If you see steam: Carefully lift the hood after the steam subsides. If you do not see steam: Carefully lift the hood. After the engine has cooled down sufficiently, inspect the hoses and radiator core (radia- tor) for any leaks.

Radiator Cooling fan If a large amount of coolant leaks, immediately contact your Toyota dealer.

COROLLA_TMMMS_TMMC_U (OM12F00U)

8-2. Steps to take in an emergency

537

The coolant level is satisfactory if it is between the “F” and “L” lines on the reservoir.

Reservoir “F” line “L” line Radiator cap

Add engine coolant if neces- sary. Water can be used in an emer- gency if engine coolant is unavail- able.

Start the engine to check that the radiator cooling fan operate and to check for coolant leaks from the radiator or hoses.

COROLLA_TMMMS_TMMC_U (OM12F00U)

538

8-2. Steps to take in an emergency

If the fan is not operating: Stop the engine immediately and contact your Toyota dealer. If the fan is operating: Have the vehicle inspected at the nearest Toyota dealer.

CAUTION

■When inspecting under the hood of your vehicle

Observe the following precautions. Failure to do so may result in serious injury such as burns. ●If steam is seen coming from under the hood, do not open the hood until

the steam has subsided. The engine compartment may be very hot.

●Keep hands and clothing (especially a tie, a scarf or a muffler) away from

the fan and belts.

●Do not loosen the radiator cap and the coolant reservoir cap while the engine and radiator are hot. High could spray out.

temperature steam or coolant

COROLLA_TMMMS_TMMC_U (OM12F00U)

8-2. Steps to take in an emergency

539

NOTICE

■When adding engine coolant

Add coolant slowly after the engine has cooled down sufficiently. Adding cool coolant to a hot engine too quickly can cause damage to the engine.

■To prevent damage to the cooling system

Observe the following precautions: ●Avoid contaminating the coolant with foreign matter (such as sand or dust

etc.).

●Do not use any coolant additives.

COROLLA_TMMMS_TMMC_U (OM12F00U)

540

8-2. Steps to take in an emergency

If the vehicle becomes stuck

Carry out the following procedures if the tires spin or the vehicle becomes stuck in mud, dirt or snow:

Stop the engine. Set the parking brake and shift the shift lever to P (automatic transmission or continuously variable transmission) or N (manual transmission). Remove the mud, snow or sand from around the front wheels. Place wood, stones or some other material under the front wheels to help provide traction. Restart the engine. Shift the shift lever to D or R (automatic transmission or continu- ously variable transmission) or 1 or R (manual transmission) and release the parking brake. Then, while exercising caution, depress the accelerator pedal.

COROLLA_TMMMS_TMMC_U (OM12F00U)

8-2. Steps to take in an emergency

541

■When it is difficult to free the vehicle (vehicles with a TRAC system)

Press

to turn off TRAC.

CAUTION

■When attempting to free a stuck vehicle

If you choose to push the vehicle back and forth to free it, make sure the surrounding area is clear to avoid striking other vehicles, objects or people. The vehicle may also lunge forward or lunge back suddenly as it becomes free. Use extreme caution.

■When shifting the shift lever

Be careful not to shift the shift lever with the accelerator pedal depressed. This may lead to unexpected rapid acceleration of the vehicle that may cause an accident resulting in death or serious injury.

NOTICE

■To avoid damaging the transmission and other components

●Avoid spinning the front wheels and depressing the accelerator pedal

more than necessary.

●If the vehicle remains stuck even after these procedures are performed,

the vehicle may require towing to be freed.

COROLLA_TMMMS_TMMC_U (OM12F00U)

542

8-2. Steps to take in an emergency

COROLLA_TMMMS_TMMC_U (OM12F00U)

543

Vehicle specifications

9-1. Specifications

Maintenance data (fuel, oil level, etc.).......... 544

Fuel information ................ 554

Tire information ................. 5579-2. Customization

Customizable features ...... 570

9-3. Items to initialize

Items to initialize ............... 577

COROLLA_TMMMS_TMMC_U (OM12F00U)

544

9-1.Specifications

Maintenance data (fuel, oil level, etc.)

182.6 in. (4639 mm) 69.9 in. (1776 mm) 57.3 in. (1455 mm) 106.3 in. (2700 mm) 60.3 in. (1531 mm)*2

59.8 in. (1519 mm)*3

60.4 in. (1534 mm)*2

59.9 in. (1522 mm)*3865 lb. (390 kg)

Dimensions and weights

Overall length Overall width Overall height*1

WheelbaseTread

Front

Rear

Vehicle capacity weight (occupants + luggage)

*1: Unladen vehicles *2: 195/65R15 tires *3: P205/55R16 and P215/45R17 tires Vehicle identification ■ Vehicle identification number

The vehicle identification number (VIN) is the legal identifier for your vehicle. This is the primary identification number for your Toyota. It is used in registering the ownership of your vehicle. This number is stamped on the top left of the instrument panel.

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

545

This number is also on the Certifi- cation Label on the driver’s side center pillar.

■ Engine number

The engine number is stamped on the engine block as shown.

COROLLA_TMMMS_TMMC_U (OM12F00U)

546

9-1. Specifications

Engine

Model Type Bore and stroke Displacement

Drive belt tension

1.8 L 4-cylinder (2ZR-FE and 2ZR-FAE) engines 4 cylinder in line, 4 cycle, gasoline 3.17 3.48 in. (80.5 88.3 mm) 109.7 cu. in. (1798 cm3) 2ZR-FE* 143 ± 22 lbf (650 ± 100 N, 65 ± 10 kgf) 2ZR-FAE Automatic adjustment

Valve clearance (engine cold) Intake Exhaust *: Drive belt tension measured with Borroughs drive belt tension gauge No.

Automatic adjustment

BT-33-73F (used belt), lbf

Fuel

Fuel type Octane rating Fuel tank capacity (Reference)

Lubrication system

Oil capacity (Drain and refill reference*) With filter Without filter

Unleaded gasoline only 87 (Research Octane Number 91) or higher

13.2 gal. (50 L, 10.9 Imp. gal.)

4.4 qt. (4.2 L, 3.7 Imp. qt.) 4.1 qt. (3.9 L, 3.4 Imp. qt.)

*: The engine oil capacity is a reference quantity to be used when changing the engine oil. Warm up and turn off the engine, wait more than 5 minutes, and check the oil level on the dipstick.

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

547

■ Engine oil selection

“Toyota Genuine Motor Oil” is used in your Toyota vehicle. Use Toyota approved “Toyota Genuine Motor Oil” or equivalent to sat- isfy the following grade and viscosity. Oil grade: ILSAC GF-5 multigrade engine oil Recommended viscosity: SAE 0W-20

SAE 0W-20 is the best choice for good fuel economy and good start- ing in cold weather. If SAE 0W-20 is not available, SAE 5W-20 oil may be used. However, it must be replaced with SAE 0W- 20 at the next oil change.Outside temperature

Oil viscosity (0W-20 is explained here as an example): • The 0W in 0W-20 indicates the characteristic of the oil which allows cold startability. Oils with a lower value before the W allow for easier starting of the engine in cold weather.

• The 20 in 0W-20 indicates the viscosity characteristic of the oil when the oil is at high temperature. An oil with a higher viscosity (one with a higher value) may be better suited if the vehicle is operated at high speeds, or under extreme load conditions. How to read oil container label The International Lubricant Specification Advisory Committee (ILSAC) Certification Mark is added to some oil containers to help you select the oil you should use.

COROLLA_TMMMS_TMMC_U (OM12F00U)

548

9-1. Specifications

Cooling system

Capacity (Reference)

Coolant type

Ignition system

Spark plug Make Gap

NOTICE

5.8 qt. (5.5 L, 4.8 Imp. qt.) Use either of the following.

• “Toyota Super Long Life Coolant” • Similar high-quality ethylene glycol-based non-silicate, non-amine, non-nitrite, and non- borate coolant with long-life hybrid organic acid technology

Do not use plain water

DENSO SC20HR11

0.043 in. (1.1 mm)■Iridium-tipped spark plugs

Use only iridium-tipped spark plugs. Do not adjust spark plug gap.

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

549

12.6 12.8 V Fully charged 12.2 12.4 V Half charged 11.8 12.0 V Discharged (Voltage checked 20 minutes after the engine and all the lights turned off) 5 A max.

2.5 qt. (2.4 L, 2.1 Imp. qt.)

Use either of the following:

• “TOYOTA Genuine Manual Transmission

• Other gear oil that meets API GL-4 and SAE

Gear Oil LV”

75W specifications

Electrical system

Battery

Open voltage at 68F (20C):

Charging rates

Manual transaxle

Gear oil capacity (Reference)

Gear oil type

NOTICE

■Manual transmission gear oil

Please be aware that depending on the particular characteristics of the gear oil used or the operating conditions, idle sound, shift feeling and/or fuel effi- ciency may be different or affected. Toyota recommends to use “TOYOTA Genuine Manual Transmission Gear Oil LV” to achieve optimal perfor- mance.

COROLLA_TMMMS_TMMC_U (OM12F00U)

550

9-1. Specifications

Automatic transaxle

Fluid capacity (Reference) Fluid type

6.9 qt. (6.5 L, 5.7 Imp. qt.) Toyota Genuine ATF WS

NOTICE

■Automatic transmission fluid type

Using automatic transmission fluid other than “Toyota Genuine ATF WS” may cause deterioration in shift quality, locking up of your transmission accompanied by vibration, and ultimately damage the transmission of your vehicle.

Continuously variable transaxle Fluid capacity* Fluid type *: The fluid capacity is a reference quantity.

7.9 qt. (7.5 L, 6.6 Imp. qt.) Toyota Genuine CVTF FE

If replacement is necessary, contact your Toyota dealer.

NOTICE

■Continuously variable transaxle fluid type

Using continuously variable transaxle fluid other than “Toyota Genuine CVTF FE” may cause deterioration in shift quality, locking up of the trans- mission accompanied by vibration and, ultimately, damage to the vehicle’s transmission.

Clutch

Pedal free play Fluid type

0.2 0.6 in. (5 15 mm) SAE J1703 or FMVSS No.116 DOT 3

COROLLA_TMMMS_TMMC_U (OM12F00U)

Brakes

Pedal clearance*1

9-1. Specifications

551

1.8 L 4-cylinder (2ZR-FE) engine

2.9 in. (74 mm)

1.8 L 4-cylinder (2ZR-FAE) engine

2.8 in. (71 mm)

Pedal free play Brake pad wear limit Parking brake lining wear limit Parking brake lever travel*2

Fluid type0.04 0.24 in. (1 6 mm) 0.04 in. (1.0 mm) 0.04 in. (1.0 mm) 6 9 clicks SAE J1703 or FMVSS No.116 DOT 3

*1: Minimum pedal clearance when depressed with a force of 66 lbf (294 N, 30

kgf) while the engine is running

*2: Parking brake lever travel when pulled up with a force of 44 lbf (200 N, 20

kgf)

COROLLA_TMMMS_TMMC_U (OM12F00U)

552

9-1. Specifications

Steering

Free play

Tires and wheels

Type A

Tire size

Tire inflation pressure (Recommended cold tire inflation pressure) Wheel size Wheel nut torque Type B

Less than 1.2 in. (30 mm)

195/65R15 91S, T135/80R16 101M, T135/80D16 101M Front: 35 psi (240 kPa, 2.4 kgf/cm2 or bar) Rear: 35 psi (240 kPa, 2.4 kgf/cm2 or bar) Spare: 60 psi (420 kPa, 4.2 kgf/cm2 or bar) 15 6 J, 16 4T (compact spare) 76 ft•lbf (103 N•m, 10.5 kgf•m)

Tire size

Tire inflation pressure (Recommended cold tire inflation pressure) Wheel size Wheel nut torque

P205/55R16 89H, T135/80R16 101M, T135/80D16 101M Front: 32 psi (220 kPa, 2.2 kgf/cm2 or bar) Rear: 32 psi (220 kPa, 2.2 kgf/cm2 or bar) Spare: 60 psi (420 kPa, 4.2 kgf/cm2 or bar) 16 6 1/2 J, 16 4T (compact spare) 76 ft•lbf (103 N•m, 10.5 kgf•m)

Type C

Tire size

Tire inflation pressure (Recommended cold tire inflation pressure) Wheel size Wheel nut torque

P215/45R17 87W, T135/80R16 101M, T135/80D16 101M Front: 32 psi (220 kPa, 2.2 kgf/cm2 or bar) Rear: 32 psi (220 kPa, 2.2 kgf/cm2 or bar) Spare: 60 psi (420 kPa, 4.2 kgf/cm2 or bar) 17 7 J, 16 4T (compact spare) 76 ft•lbf (103 N•m, 10.5 kgf•m)

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

553

Light bulbs

Light bulbs

Bulb No.

60

9005

7444NA

28/8

7443

921

19

21

21/5

16

3.8

Type

B: Wedge base bulbs (clear) D: H16 halogen bulbs

Headlights

High beam

turn

signal

side marker

Front lights Front turn signal/park- ing lights Front fog lights* Side lights* Rear turn signal lights Stop/tail and rear side marker lights License plate lights Back-up lights Front rior without a moon roof) Front rior with a moon roof) Rear interior light Trunk light

personal/inte- (vehicles

personal/inte- (vehicles

lights

lights

Exterior

Interior

A: HB3 halogen bulbs C: Wedge base bulbs (amber) E: Double end bulbs *: If equipped

COROLLA_TMMMS_TMMC_U (OM12F00U)

554

9-1. Specifications

Fuel information

You must only use unleaded gasoline in your vehicle. Select octane rating 87 (Research Octane Number 91) or higher. Use of unleaded gasoline with an octane rating lower than 87

may result in engine knocking. Persistent knocking can lead to engine damage.■Fuel tank opening for unleaded gasoline

To help prevent incorrect fueling, your vehicle has a fuel tank opening that only accommodates the special nozzle on unleaded fuel pumps.

■Gasoline quality

In very few cases, driveability problems may be caused by the brand of gaso- line you are using. If driveability problems persist, try changing the brand of gasoline. If this does not correct the problem, consult your Toyota dealer.

■Gasoline quality standards

●Automotive manufacturers in the U.S.A., Europe and Japan have developed a specification for fuel quality called the World-Wide Fuel Charter (WWFC), which is expected to be applied worldwide.

●The WWFC consists of four categories that are based on required emission

levels. In the U.S., category 4 has been adopted.

●The WWFC improves air quality by lowering emissions in vehicle fleets, and

improves customer satisfaction through better performance.

■Recommendation of the use of gasoline containing detergent additives ●Toyota recommends the use of gasoline that contains detergent additives to

avoid the build-up of engine deposits.

●All gasoline sold in the U.S.A. contains minimum detergent additives to clean and/or keep clean intake systems, per EPA's lowest additives concen- tration program.

●Toyota strongly recommends the use of Top Tier Detergent Gasoline. For more information on Top Tier Detergent Gasoline and a list of marketers, please go to the official website www.toptiergas.com.

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

555

■Recommendation of the use of cleaner burning gasoline

Cleaner burning gasoline, including reformulated gasoline that contains oxy- genates such as ethanol or MTBE (Methyl Tertiary Butyl Ether) is available in many areas. Toyota recommends the use of cleaner burning gasoline and appropriately blended reformulated gasoline. These types of gasoline provide excellent vehicle performance, reduce vehicle emissions and improve air quality.

■Non-recommendation of the use of blended gasoline

●Use only gasoline containing up to 15%

ethanol. DO NOT use any flex-fuel or gasoline that could contain more than 15% etha- nol, including from any pump labeled E30, E50, E85 (which are only some examples of fuel containing more than 15% ethanol).

DO NOT use gasoline contain- ing more than 15% ethanol.

(30% ethanol)

(50% ethanol)

(85% ethanol)

●If you use gasohol in your vehicle, be sure that it has an octane rating no

lower than 87.

●Toyota does not recommend the use of gasoline containing methanol.

COROLLA_TMMMS_TMMC_U (OM12F00U)

556

9-1. Specifications

■Non-recommendation of the use of gasoline containing MMT

Some gasoline contains an octane enhancing additive called MMT (Methylcy- clopentadienyl Manganese Tricarbonyl). Toyota does not recommend the use of gasoline that contains MMT. If fuel containing MMT is used, your emission control system may be adversely affected. The malfunction indicator lamp on the instrument cluster may come on. If this happens, contact your Toyota dealer for service.

■If your engine knocks

●Consult your Toyota dealer. ●You may occasionally notice light knocking for a short time while accelerat-

ing or driving uphill. This is normal and there is no need for concern.

NOTICE

■Notice on fuel quality

●Do not use improper fuels. If improper fuels are used, the engine will be

damaged.

●Do not use leaded gasoline.

Leaded gasoline can cause damage to your vehicle’s three-way catalytic converters causing the emission control system to malfunction.

●Do not use gasohol other than the type previously stated.

Other gasohol may cause fuel system damage or vehicle performance problems.

●Using unleaded gasoline with an octane number or rating lower than the

level previously stated will cause persistent heavy knocking. At worst, this will lead to engine damage.

■Fuel-related poor driveability

If poor driveability is encountered after using a different type of fuel (poor hot starting, vaporization, engine knocking, etc.), discontinue the use of that type of fuel.

■When refueling with gasohol

Take care not to spill gasohol. It can damage your vehicle’s paint.

COROLLA_TMMMS_TMMC_U (OM12F00U)

Tire information

Typical tire symbols

Full-size tire

Compact spare tire

9-1. Specifications

557

COROLLA_TMMMS_TMMC_U (OM12F00U)

558

9-1. Specifications

10

11

Tire size (P. 560) DOT and Tire Identification Number (TIN)(P. 559) Uniform tire quality grading For details, see “Uniform Tire Quality Grading” that follows. Location of treadwear indicators(P. 448) Tire ply composition and materials Plies are layers of rubber-coated parallel cords. Cords are the strands which form the plies in a tire. Radial tires or bias-ply tires A radial tire has “RADIAL” on the sidewall. A tire not marked “RADIAL” is a bias-ply tire. TUBELESS or TUBE TYPE A tubeless tire does not have a tube and air is directly put into the tire. A tube type tire has a tube inside the tire and the tube maintains the air pressure. Load limit at maximum cold tire inflation pressure (P. 564) Maximum cold tire inflation pressure (P. 564) This means the pressure to which a tire may be inflated. Summer tires or all season tires (P. 452) An all season tire has “M+S” on the sidewall. A tire not marked “M+S” is a summer tire. “TEMPORARY USE ONLY” A compact spare tire is identified by the phrase “TEMPORARY USE ONLY” molded on its sidewall. This tire is designed for temporary emergency use only.

COROLLA_TMMMS_TMMC_U (OM12F00U)

Typical DOT and Tire Identification Number (TIN)

9-1. Specifications

559

DOT symbol* Tire Identification Number (TIN) Tire manufacturer’s identifica- tion mark Tire size code Manufacturer’s optional type code (3 or 4 letters) Manufacturing week Manufacturing year

tire

*: The DOT symbol certifies that the tire conforms to applicable Federal Motor Vehicle Safety Standards.

COROLLA_TMMMS_TMMC_U (OM12F00U)

560

9-1. Specifications

Tire size ■ Typical tire size information

The illustration indicates typical tire size.

Tire use (P = Passenger car, T = Temporary use) Section width (millimeters) Aspect ratio (tire height to section width) Tire construction code (R = Radial, D = Diagonal) Wheel diameter (inches) Load index (2 digits or 3 digits) Speed symbol (alphabet with one letter)

■ Tire dimensions Section width Tire height Wheel diameter

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

561

Tire section names

10

11

Bead Sidewall Shoulder Tread Belt Inner liner Reinforcing rubber Carcass Rim lines Bead wires Chafer

COROLLA_TMMMS_TMMC_U (OM12F00U)

562

9-1. Specifications

Uniform Tire Quality Grading

This information has been prepared in accordance with regulations issued by the National Highway Traffic Safety Administration of the U.S. Department of Transportation. It provides the purchasers and/or prospective purchasers of Toyota vehicles with information on uniform tire quality grading.

Your Toyota dealer will help answer any questions you may have as you read this information.

■ DOT quality grades

All passenger vehicle tires must conform to Federal Safety Require- ments in addition to these grades. Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width.

For example: Treadwear 200 Traction AA Temperature A

■ Treadwear

The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a speci- fied government test course.

For example, a tire graded 150 would wear one and a half (1 - 1/2) times as well on the government course as a tire graded 100. The relative performance of tires depends upon the actual condi- tions of their use. Performance may differ significantly from the norm due to variations in driving habits, service practices and differences in road characteristics and climate.

■ Traction AA, A, B, C

The traction grades, from highest to lowest, are AA, A, B and C, and they represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete.

A tire marked C may have poor traction performance. Warning: The traction grade assigned to this tire is based on braking (straight ahead) traction tests and does not include cornering (turn- ing) traction.

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

563

■ Temperature A, B, C

The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissi- pate heat when tested under controlled conditions on a specified indoor laboratory test wheel.

Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. Grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Stan- dard No. 109. Grades B and A represent higher levels of performance on the labo- ratory test wheel than the minimum required by law. Warning: The temperature grades of a tire assume that it is properly inflated and not overloaded. Excessive speed, underinflation, or excessive loading, either sepa- rately or in combination, can cause heat buildup and possible tire failure.

COROLLA_TMMMS_TMMC_U (OM12F00U)

564

9-1. Specifications

Glossary of tire terminology

Tire related term

Meaning

Cold tire inflation pres- sure

Maximum pressure

inflation

Recommended tion pressure

infla-

Accessory weight

Curb weight

Maximum loaded vehi- cle weight

Normal weight

occupant

Occupant distribution

Tire pressure when the vehicle has been parked for three hours or more, or has not been driven more than 1 mile or 1.5 km under that condition The maximum cold inflated pressure to which a tire may be inflated, shown on the sidewall of the tire Cold tire inflation pressure recommended by a manufacturer The combined weight (in excess of those stan- dard items which may be replaced) of auto- matic transmission, power steering, power brakes, power windows, power seats, radio and heater, to the extent that these items are available as factory-installed equipment (whether installed or not) The weight of a motor vehicle with standard equipment, including the maximum capacity of fuel, oil and coolant, and if so equipped, air conditioning and additional weight optional engine The sum of: (a) Curb weight (b) Accessory weight (c) Vehicle capacity weight (d) Production options weight 150 lb. (68 kg) times the number of occupants specified in the second column of Table 1* that follows Distribution of occupants in a vehicle as speci- fied in the third column of Table 1* below

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

565

Tire related term

Meaning

Production weight

options

Rim

Rim diameter (Wheel diameter) Rim size designation

Rim type designation

Rim width Vehicle weight capacity)

capacity load

(Total

Vehicle maximum load on the tire

Vehicle normal load on the tire

Weather side

Bead

Bead separation

The combined weight of installed regular pro- duction options weighing over 5 lb. (2.3 kg) in excess of the standard items which they replace, not previously considered in curb weight or accessory weight, including heavy duty brakes, ride levelers, roof rack, heavy duty battery, and special trim A metal support for a tire or a tire and tube assembly upon which the tire beads are seated

Nominal diameter of the bead seat

Rim diameter and width The industry manufacturer’s designation for a rim by style or code Nominal distance between rim flanges The rated cargo and luggage load plus 150 lb. (68 kg) times the vehicle’s designated seating capacity The load on an individual tire that is deter- mined by distributing to each axle its share of the maximum loaded vehicle weight, and dividing by two The load on an individual tire that is deter- mined by distributing to each axle its share of curb weight, accessory weight, and normal occupant weight (distributed in accordance with Table 1* below), and dividing by two The surface area of the rim not covered by the inflated tire The part of the tire that is made of steel wires, wrapped or reinforced by ply cords and that is shaped to fit the rim A breakdown of the bond between compo- nents in the bead

COROLLA_TMMMS_TMMC_U (OM12F00U)

566

9-1. Specifications

Tire related term

Meaning

Bias ply tire

Carcass

Chunking

Cord

Cord separation

Cracking

CT

Extra load tire

Groove

Innerliner

Innerliner separation

Intended sidewall

outboard

A pneumatic tire in which the ply cords that extend to the beads are laid at alternate angles substantially less than 90 degrees to the centerline of the tread The tire structure, except tread and sidewall rubber which, when inflated, bears the load The breaking away of pieces of the tread or sidewall The strands forming the plies in the tire The parting of cords from adjacent rubber compounds Any parting within the tread, sidewall, or inner- liner of the tire extending to cord material A pneumatic tire with an inverted flange tire and rim system in which the rim is designed with rim flanges pointed radially inward and the tire is designed to fit on the underside of the rim in a manner that encloses the rim flanges inside the air cavity of the tire A tire designed to operate at higher loads and at higher inflation pressures than the corre- sponding standard tire The space between two adjacent tread ribs The layer(s) forming the inside surface of a tubeless tire that contains the inflating medium within the tire The parting of the innerliner from cord material in the carcass (a) The sidewall that contains a whitewall, bears white lettering, or bears manufac- turer, brand, and/or model name molding that is higher or deeper than the same molding on the other sidewall of the tire, or (b) The outward facing sidewall of an asym- metrical tire that has a particular side that must always face outward when mounted on a vehicle

COROLLA_TMMMS_TMMC_U (OM12F00U)

Tire related term

Meaning

9-1. Specifications

567

Light truck (LT) tire

Load rating

Maximum load rating

Maximum permissible inflation pressure

Measuring rim

Open splice

Outer diameter

Overall width

Passenger car tire

Ply

Ply separation

Pneumatic tire

Radial ply tire

Reinforced tire

A tire designated by its manufacturer as pri- marily intended for use on lightweight trucks or multipurpose passenger vehicles The maximum load that a tire is rated to carry for a given inflation pressure The load rating for a tire at the maximum per- missible inflation pressure for that tire The maximum cold inflation pressure to which a tire may be inflated The rim on which a tire is fitted for physical dimension requirements Any parting at any junction of tread, sidewall, or innerliner that extends to cord material The overall diameter of an inflated new tire The linear distance between the exteriors of the sidewalls of an inflated tire, including ele- vations due to labeling, decorations, or protec- tive bands or ribs A tire intended for use on passenger cars, multipurpose passenger vehicles, and trucks, that have a gross vehicle weight rating (GVWR) of 10,000 lb. or less. A layer of rubber-coated parallel cords A parting of rubber compound between adja- cent plies A mechanical device made of rubber, chemi- cals, fabric and steel or other materials, that, when mounted on an automotive wheel, pro- vides the traction and contains the gas or fluid that sustains the load A pneumatic tire in which the ply cords that extend to the beads are laid at substantially 90

degrees to the centerline of the tread A tire designed to operate at higher loads and at higher inflation pressures than the corre- sponding standard tireCOROLLA_TMMMS_TMMC_U (OM12F00U)

568

9-1. Specifications

Tire related term

Meaning

Section width

Sidewall

Sidewall separation

Snow tire

Test rim

Tread

Tread rib

Tread separation

Treadwear (TWI)

indicators

Wheel-holding fixture

The linear distance between the exteriors of the sidewalls of an inflated tire, excluding ele- vations due to labeling, decoration, or protec- tive bands That portion of a tire between the tread and bead The parting of the rubber compound from the cord material in the sidewall A tire that attains a traction index equal to or greater than 110, compared to the ASTM E- 1136 Standard Reference Test Tire, when using the snow traction test as described in ASTM F-1805-00, Standard Test Method for Single Wheel Driving Traction in a Straight Line on Snow-and Ice-Covered Surfaces, and which is marked with an Alpine Symbol ( on at least one sidewall The rim on which a tire is fitted for testing, and may be any rim listed as appropriate for use with that tire That portion of a tire that comes into contact with the road around a tire Pulling away of the tread from the tire carcass The projections within the principal grooves designed to give a visual indication of the degrees of wear of the tread The fixture used to hold the wheel and tire assembly securely during testing

tread section running circumferentially

*: Table 1 Occupant loading and distribution for vehicle normal load for

various designated seating capacities

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-1. Specifications

569

Designated seating capacity, Number of

occupants 2 through 4

5 through 10

11 through 15

16 through 20

Vehicle normal load, Number of occupants

Occupant distribution in a normally loaded

vehicle 2 in front

2 in front, 1 in second

seat

2 in front, 1 in second seat, 1 in third seat, 1

in fourth seat

2 in front, 2 in second seat, 2 in third seat, 1

in fourth seat

COROLLA_TMMMS_TMMC_U (OM12F00U)

570

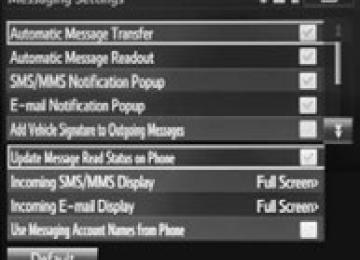

9-2. Customization

Customizable features

Your vehicle includes a variety of electronic features that can be personalized to suit your preferences. Programming these pref- erences requires specialized equipment and may be performed by your Toyota dealer.

Customizing vehicle features ■ Changing by using the navigation system

Press the “APPS” button. Select “Setup” on the “Apps” screen and select “Vehicle”.

Various setting can be changed. Refer to the list of settings that can be changed for details.

■ Changing by using the multimedia system

P. 289

■ Changing by using the door lock switch

P. 103

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-2. Customization

571

Customizable features Some function settings are changed simultaneously with other func- tions being customized. Contact your Toyota dealer for further details. Settings that can be changed using the navigation system/multime- dia system Settings that can be changed by your Toyota dealer

Definition of symbols: O = Available, —=Not available ■ Door lock (P. 97, 106, 534)

Function

Default setting

Customized set-

ting

Unlocking using a key

auto- Speed-detecting matic door lock function (vehicles with a smart key system) Opening driver's door unlocks all doors Shifting gears to P unlocks all doors. (except vehicles with a manual transmis- sion) Shifting gears to position other locks all than P doors. (except vehicles with a manual transmis- sion) Locking/unlocking of the trunk when all doors are locked/unlocked

Driver’s door unlocked in one step, all doors unlocked in two

steps

All doors unlocked

in one step

— O

Off

Off

On

On

On

On

On

Off

Off

Off

O O

O O

— O

COROLLA_TMMMS_TMMC_U (OM12F00U)

572

9-2. Customization

■ Smart key system* and wireless remote control* (P. 97, 106)

Function

Default setting

On

60 seconds

Customized set-

ting Off 1 to 7

Off

Off

30 seconds

120 seconds

O O

O O

O O

On

Off

— O

Operation buzzer volume

Operation signal (emer- gency flashers) Time elapsed before auto- matic door lock function is activated if door is not opened being unlocked Open door warning buzzer (when locking the vehicle) *: If equipped

after

COROLLA_TMMMS_TMMC_U (OM12F00U)

9-2. Customization

573

■ Smart key system* (P. 97, 106, 111)

Function

Default setting

On

Smart key system Number of permissible times of continuous smart lock *: If equipped ■ Wireless remote control* (P. 92, 97, 106)

Twice

Customized set-

ting Off

— O

Unlimited

— O

Function

Default setting

Wireless remote control

On

Unlocking operation

Driver’s door unlocked in one step, all doors unlocked in two

steps

Trunk unlocking operation

Press and hold

(short)

Alarm (panic mode) *: If equipped

On

Customized set-

ting Off