- 2000 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 1999 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2010 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2003 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2009 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 1996 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 1998 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2006 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2002 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 1997 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2005 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2011 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2001 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2007 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2012 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2008 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- 2004 Nissan Sentra Owners Manuals

- Nissan Sentra Owners Manuals

- Download PDF Manual

-

engine and move the vehicle at a low speed in forward or reverse. When the ‘‘self-test’’ occurs, you may hear a ‘‘clunk’’ noise and/ or feel a ‘‘pulsation’’ in the brake pedal. This is normal and is not an indication of any malfunction. the computer senses any malfunction, it switches the anti-lock brake system OFF and turns on the ABS brake warning light in the dashboard. The brake system then operates normally, but without anti-lock assistance. If the light comes on during the self check, or while driving, take your vehicle to your NISSAN dealer for repair at your earliest convenience.

If

WARNING

The anti-lock brake system is a sophis- ticated device, but it cannot prevent accidents resulting from careless or dangerous driving techniques. It can help maintain vehicle control during braking on slippery surfaces, but re- member that the stopping distance on slippery surfaces will be longer than on normal surfaces, even with the anti- lock system. Stopping distances may also be longer on rough, gravel or snow covered roads, or if you are using tire chains. Always maintain a safe dis- tance from the vehicle in front of you. Ultimately, the responsibility for safety of self and others rests in the hands of the driver. Tire type and condition may also affect braking effectiveness. c When replacing tires,

the specified size of tires on all 4 wheels. c When installing a spare tire, make sure it is the proper size and type as speci- fied on the tire placard. For tire placard location information, refer to ‘‘Tire placard’’ in the Owner’s Manual index.

install

4-17

Z X

COLD WEATHER DRIVING CAUTIONS

Freeing a frozen door lock To prevent a door lock from freezing, apply de-icer or glycerin to it through the key hole. If the lock becomes frozen, heat the key before inserting it into the key hole. Anti-freeze In the winter when it is anticipated that the temperature will drop below 32°F (0°C), check the anti-freeze (ethylene glycol base) to assure proper winter protection. For de- tails, see ‘‘Engine cooling system’’ in the ‘‘Do-it-yourself operations’’ section. Battery If fully charged during extremely cold weather conditions, the bat- tery fluid may freeze and damage the bat- tery. To maintain maximum efficiency, the battery should be checked regularly. For details, see ‘‘Battery’’ in the ‘‘Do-it-yourself operations’’ section. Draining of coolant water If the vehicle is to be left outside without anti-freeze, drain the cooling system by opening the drain valves located under the radiator and on the engine block. Refill

the battery is not

before operating the vehicle. See ‘‘Chang- ing Engine Coolant’’ in the ‘‘Do-it-yourself operations’’ section. Tire equipment 1. The SUMMER tires are of a tread design to provide superior performance on dry pavement. However, the performance of these tires will be substantially reduced in snowy and icy conditions. If you oper- ate your vehicle on snowy or icy roads, NISSAN recommends the use of MUD & SNOW or ALL SEASON TIRES on all four wheels. Please consult your NIS- SAN dealer for the tire type, size, speed rating and availability information.

2. For additional traction on icy roads, stud- ded tires may be used. However, some provinces and states prohibit their use. Check local, state and provincial laws before installing studded tires.

Skid and traction capabilities of studded snow tires on wet or dry surfaces may be poorer than that of non-studded snow tires. 3. Snow chains may be used if desired. Make sure they are of proper size for the tires on your vehicle and are installed

4-18

according to the chain manufacturer’s suggestions. Use of tire chains may be prohibited according to location. Check the local laws before installing tire chains. When installing tire chains, make sure they are of proper size for the tires on your vehicle and are installed according to the chain manufacturer’s suggestions. Use only SAE Class “S” chains. Use chain ten- sioners when recommended by the tire chain manufacturer to ensure a tight fit. Loose end links of the tire chain must be secured or removed to prevent the pos- sibility of whipping action damage to the fenders or underbody. If possible, avoid fully loading your vehicle when using tire chains. In addition, drive at a reduced speed, otherwise, your vehicle may be damaged and/or vehicle handling and performance may be adversely affected. Never install tire chains on T-type and small size spare tires. Do not use the chains on dry roads.

Special winter equipment It is recommended that the following items be carried in the vehicle during winter:

Z X

c Allow greater following distances on

slippery roads.

c Watch for slippery spots (glare ice). These may appear on an otherwise clear road in shaded areas. If a patch of ice is seen ahead, brake before reaching it. Try not to brake while actually on the ice, and avoid any sudden steering maneuvers.

Engine block heater

WARNING

Do not use your heater (if so equipped) with an ungrounded electrical system or two-pronged (cheater) adapters. You can be injured by an electrical shock if you use an ungrounded connection.

1. A scraper and stiff-bristled brush to re- move ice and snow from the windows and wiper blades.

2. A sturdy, flat board to be placed under

the jack to give it firm support.

3. A shovel to dig the vehicle out of snow-

drifts.

4. Extra window washer fluid to refill the

reservoir tank.

Driving on snow or ice c Wet ice (32°F, 0°C and freezing rain), very cold snow or ice can be slick and very hard to drive on. The vehicle will have a lot less traction or ‘‘grip’’ under these conditions. Try to avoid driving on wet ice until the road is salted or sanded.

c Whatever the condition, drive with caution and accelerate gently. If accel- erated too fast, the drive wheels will spin and will lose even more traction. c Allow more stopping distance under these conditions. Braking should be started sooner than on dry pavement.

4-19

Z X

MEMO

4-20

Z X

5 In case of emergency

Flat tire ................................................................. 5-2

Jump starting........................................................ 5-7

Push starting ........................................................ 5-8

If your vehicle overheats ...................................... 5-9

Tow truck towing ................................................ 5-10Z X

FLAT TIRE

If you have a flat tire, follow the instructions below. Stopping the vehicle 1. Safely move the vehicle off

the road

away from traffic.

2. Turn on the hazard warning flashers. 3. Park on a level surface and apply the park- ing brake. Shift the manual transmission into reverse (automatic transmission in P).

4. Turn off the engine.

WARNING

c Make sure that the parking brake is securely applied and the manual transmission is shifted into reverse (automatic transmission in P).

c Never change tires when the vehicle is on a slope, ice or slippery areas. This is dangerous.

c Never change tires if oncoming traffic is close to your vehicle. Wait for pro- fessional road assistance.

c Raise the hood to warn other traffic, and to signal professional road assis- tance need assistance.

personnel

that

you

c Have all passengers get out of the vehicle and stand in a safe place, away from traffic and clear of the vehicle.

CE1050MA

ACE0601

5-2

Z X

Getting the spare tire and tools 1. Open the trunk. Lift the trunk floor carpet- ing and spare tire cover. Remove the tool bag and the spare tire. Use either end of the jack rod (found in the tool bag) to loosen the spare tire hold-down bolt. Push the two release clips on the jack access door.

2. Pull the jack access door open. To re- move the jack, turn the jack screw coun- terclockwise. Use either end of the jack rod (found in the tool bag) to loosen the jack from its storage position.

3. Close the jack access door. 4. When the spare tire is installed on the vehicle, place the damaged tire in the storage area. Put the jack rod in the tool bag and place the tool bag in the storage area.

5. Place the spare tire cover and the trunk

floor carpeting over the damaged tire.

6. Install the jack in its storage area and

tighten the jack screw.

7. Close the jack access door. Close the

trunk.

MCE0001

Blocking wheels Place suitable blocks at both the front and back of the wheel diagonally opposite the flat tire to prevent the vehicle from rolling when it is jacked up.

WARNING

Be sure to block the wheel as the ve- hicle may move and could cause per- sonal injury.

5-3

CE1053M

Removing wheel cover

WARNING

Do not use your hands to pry off wheel covers. Doing so could result in per- sonal injury.

Use caution not to scratch the wheel cover.

Z X

The jack should be used on level firm ground.

CE1069M

Jacking up the vehicle and remov- ing the wheel To help avoid personal injury, carefully read the caution label attached to the jack body and follow these instructions. 1. Place the jack directly under the jack-up point as illustrated above so that the top of the jack contacts the vehicle at the jack-up point. Align the center of both the jack head and the notch at the jack-up point as shown. Also fit the notched portion of the vehicle in the groove of the jack head as shown.

5-4

Z X

c Never jack up the vehicle more than

necessary.

c Never use blocks on or under the

jack.

c Do not start or run engine while ve- hicle is on the jack as it may cause the vehicle to move.

c Do not allow passengers to stay in

the vehicle while it is on the jack.

c Do not raise the vehicle using a

bumper jack.

c Never run the engine with a wheel off the ground. It may cause the vehicle to move. This is especially true for models equipped with limited slip differen- tial carrier.

2. Loosen each wheel nut one or two turns by turning counterclockwise with the wheel nut wrench. Do not remove the wheel nuts until the tire is off the ground.

3. Carefully raise the vehicle until the tire clears the ground. Remove the wheel nuts, and then remove the wheel.

CAUTION

c Never get under the vehicle while it is

supported only by the jack.

SCE0002

c Use the jack provided with your ve- hicle. Do not use the jack provided with your vehicle on other vehicles. The jack is designed only for lifting your vehicle during a tire change.

c To lift the vehicle, securely hold the jack lever and rod with both hands as shown above.

c Use the correct jack-up points; never use any other part of the vehicle for jack support.

5-5

Z X

CE1005M

Installing wheel The T-type spare tire is designed for emergency use. See specific instruc- tions under the heading ‘‘Wheels and tires’’ in the ‘‘Do-it- yourself operations’’ section. 1. Clean any mud or dirt from the surface

between the wheel and hub.

2. Carefully put the wheel on and tighten

the wheel nuts finger tight.

3. With the wheel nut wrench, tighten wheel nuts alternately and evenly until they are tight.

4. Lower the vehicle slowly until

the tire touches the ground. Then, with the wheel nut wrench, tighten the wheel nuts se- curely in the sequence as illustrated.

CAUTION

c As soon as possible tighten the wheel nuts to the specified torque with a torque wrench. Wheel nut tightening torque:

72 to 87 ft-lb (98 to 118 N†m) tire pressure to the COLD

c Adjust

pressure.

SCE0005

COLD pressure: After vehicle has been parked for three hours or more or driven less than 1 mile (1.6 km). COLD tire pressures are shown on the

5-6

Z X

tire placard affixed to the driver side center pillar. c Retighten the wheel nuts when the vehicle has been run for 600 miles (1,000 km).

5. Securely store the spare tire and jacking

equipment in the vehicle.

WARNING

c Always make sure that the spare tire and jacking equipment are properly secured after use. The jack rod may be used to securely tighten the hold- down bolts. Such items can become dangerous projectiles in an accident or sudden stop.

c The T-type spare tire and small size spare tire are designed for emer- gency use. See specific instructions under the heading ‘‘Wheels and tires’’ in the ‘‘Do-it-yourself opera- tions’’ section.

JUMP STARTING

To start your engine with a booster battery, the instructions and precautions below must be followed.

CAUTION

c If done incorrectly, jump starting can

be hazardous.

c Explosive hydrogen gas is always present in the vicinity of the battery. Keep all sparks and flames away from the battery.

c Do not allow battery fluid to come into contact with eyes, skin, cloth or painted surfaces. Battery fluid is a corrosive sulfuric acid solution which can cause severe burns. If the fluid should come into contact with anything, immediately flush the contacted area with water.

c A battery rated at above 12 volts

should not be used for a booster.

c Whenever working on or near a bat- tery, always wear suitable eye protec- tors (e.g., goggles or industrial safety spectacles) and remove rings, metal bands, or any other metal jewelry.

c Keep battery out of the reach of chil-

dren.

5-7

Always follow the instructions below. Failure to do so could result in damage to the charging system and cause per- sonal injury. 1. If the booster battery is in another vehicle, position the two vehicles to bring their batteries into close proximity to each other. Do not allow the two vehicles to touch. 2. Apply the parking brake. Move the shift lever to Neutral (On automatic transmis- sion models, move the lever to P). Switch off all unnecessary electrical systems (lights, heater, air conditioner, etc.).

3. Remove vent caps on the battery (if so equipped). Cover the battery with an old cloth to reduce explosion hazard.

4. Connect jumper cables in the sequence

as illustrated.

CAUTION

c Always connect positive (+) to posi- tive (+) and negative (−) to body ground (e.g., strut mounting bolt, etc. — not to the battery).

Z X

PUSH STARTING

CAUTION

c Automatic transmission models can- not be push started. This may cause transmission damage. catalytic

converter equipped models should not be started by pushing since the three way catalyst may be damaged.

c Three-way

c Never try to start the vehicle by tow- ing it; when the engine starts, the forward surge could cause the ve- hicle to collide with the tow vehicle.

ACE0602

c Make sure that cables do not touch moving parts in the engine compart- ment and that clamps do not contact any other metal.

5. Start the engine of the booster vehicle

and let it run for a few minutes.

CAUTION

Do not keep the starter motor engaged for more than 10 seconds. If the engine does not start right away, turn the key off and wait 3 to 4 seconds before trying again.

6. Keep the engine speed of the booster vehicle at about 2,000 rpm, and start your engine in the normal manner.

7. After starting your engine, carefully dis- connect the negative cable and then the positive cable.

8. Replace the vent caps (if so equipped). Be sure to dispose of the cloth used to cover the vent holes as it may be con- taminated with corrosive acid.

5-8

Z X

IF YOUR VEHICLE OVERHEATS

If your vehicle is overheating (indicated by an extremely high temperature gauge read- ing), or if you feel a lack of engine power, detect abnormal noise, etc., take the follow- ing steps:

WARNING

To avoid the danger of being scalded, never remove the radiator cap while the engine is still hot. When the radiator cap is removed, pressurized hot water will spurt out, possibly causing serious injury.

1. Move the vehicle safely off

the road, apply the parking brake and move the gearshift (automatic transmission to P). Do not stop the engine.

to Neutral

lever

2. Turn off the air conditioning. Open all the windows, move the heater or air condi- tioner temperature control to maximum hot and fan control to high speed.

3. Get out of the vehicle. Look and listen for steam or coolant escaping from the ra- diator before opening the hood. Wait until no steam or coolant can be seen before proceeding.

4. Open the engine hood.

WARNING

If steam or water is coming from the engine, stand clear to prevent getting burned.

7. After the engine cools down, check the coolant level in the reservoir tank with the engine running. Add coolant to the res- ervoir tank if necessary. Have your ve- hicle repaired at the nearest NISSAN dealer.

5. If engine overheating is caused by climb- ing a long hill on a hot day, run the engine at a fast idle (approximately 1,500 rpm) until the temperature gauge indication returns to normal.

6. Visually check drive belts for damage or looseness. Also check if the cooling fan is running. The radiator hoses and radia- tor should not leak water.

WARNING

c Be careful not to allow your hands, hair or clothing to come into contact with, or to get caught in, the running fan, belts, or fan motor. The fan motor can start at any time when the cool- ant temperature is high.

c If coolant is leaking, the water pump belt is missing or loose, or the cool- ing fan does not run, stop the engine.

5-9

Z X

TOW TRUCK TOWING

When towing your vehicle, all State (Provin- cial in Canada) and local regulations for towing must be followed. Incorrect towing equipment could damage your vehicle. Towing instructions are available from your NISSAN dealer. Local service operators are generally familiar with the applicable laws and procedures for towing. To assure proper towing and to prevent accidental damage to your vehicle, NISSAN recom- mends having a service operator tow your vehicle. It is advisable to have the service operator carefully read the following precau- tions.

CAUTION

c When towing, make sure that

the transmission, axles, steering system and powertrain are in working condi- tion. If any unit is damaged, a dolly must be used.

c When towing with the front wheels on

the ground: Turn the ignition key to the ‘‘OFF’’ position and secure the steering wheel in a straight ahead position with a rope or similar device. Never place the ignition key in the ‘‘LOCK’’

position. This will result in damage to the steering lock mechanism. Move the gearshift lever to the Neu- tral (‘‘N’’) position. On automatic transmission models, to move the shift lever to the Neutral (‘‘N’’) position turn the ignition key to the ‘‘ACC’’ position. After moving the shift lever to the Neutral (‘‘N’’) position, be sure to turn the ignition key to the ‘‘OFF’’ position.

c When towing with the rear wheels on release the parking

the ground, brake. On automatic transmission models, to move the shift lever to the Neutral (‘‘N’’) position, turn the ignition key to the ‘‘ACC’’ position. After moving the shift lever to the Neutral position, be sure to turn the ignition key to the ‘‘OFF’’ position.

c Attach safety chains for all towing.

5-10

CE1051

NISSAN recommends that your vehicle be towed with the driving (front) wheels off the ground as illustrated. c Speed: Below 70MPH (115 km/h) c Distance: Less than 500 miles (800

km)

Z X

on the vehicle at a sideways angle.

c Pulling devices such as ropes or canvas straps are not recommended for use in vehicle towing or recovery.

If you have to tow an automatic transmission model with four wheels on ground Observe the following restricted towing speeds and distances. c Speed: Below 30 MPH (50 km/h) c Distance: Less than 40 miles (65 km)

CAUTION

Never tow an automatic transmission model from the rear (i.e., backward) with four wheels on the ground as this may cause serious and expensive dam- age to the transmission.

VEHICLE RECOVERY (Freeing a stuck vehicle) c Tow chains or cables must be attached only to the main structual members of the vehicle.

c Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or cooling systems.

c Always pull the cable straight out from the front or rear of the vehicle. Never pull

5-11

CE1052

Towing an automatic transmission model with rear wheels raised (with front wheels on the ground)

CAUTION

Never tow an automatic transmission model with the rear wheels raised (with the front wheels on the ground) as this may cause serious and expensive dam- age to the transmission. If it is neces- sary to tow the vehicle with the rear wheels raised, always use a towing dolly under the front wheels.

Z X

MEMO

5-12

Z X

6 Appearance and interior care

Cleaning exterior and interior............................... 6-2

Corrosion protection ............................................. 6-5Z X

CLEANING EXTERIOR AND INTERIOR

MAI0001

In order to maintain the appearance of your vehicle, it is important to take proper care of it. In the following cases, please wash your vehicle as soon as possible to protect the paint surface. c After a rainfall c After driving on coastal roads c When things such as soot, bird drop- pings, tree sap, metal particles or bugs get on the paint surface

c When dust or mud builds up on the

surface

Whenever possible, store or park your ve- hicle inside a garage or in a covered area. When it is necessary to park outside, park in a shady area or protect the vehicle with a body cover. Be careful not to scratch the paint sur- face when putting on or removing the body cover. Washing Wash dirt off with a wet sponge and plenty of water. Clean the vehicle thoroughly using a mild soap or detergent (a special vehicle soap or general purpose dish-washing liq- uid) mixed with clean, lukewarm (never hot) water.

CAUTION

Do not use strong household soap, strong chemical detergents, gasoline or solvents.

Inside flanges, seams and folds on the doors, hatches and hood are particularly vulnerable to the effects of road salt. There- fore, these areas must be regularly cleaned. Take care that the drain holes in the lower edge of the door are open. Spray water under the body and in the wheel wells to loosen the dirt and wash away road salt. A damp chamois can be used to dry the vehicle to avoid water spots. Waxing Regular waxing protects the paint surface and helps retain new vehicle appearance. After waxing, polishing is recommended to remove built-up residue and to avoid a ‘‘weathered’’ appearance. Your NISSAN dealer can assist you in choosing the proper product. c Wax your vehicle only after a thorough washing. Follow the instructions supplied with the wax.

c Do not use a wax containing any abra- sives, cutting compounds or cleaners that may damage the vehicle finish.

Rinse the vehicle thoroughly with plenty of clean water.

c If the surface does not polish easily, use

a “road tar” remover and wax again.

6-2

Z X

Machine compounding or aggressive pol- ishing on a base coat/clear coat paint finish may dull the finish or leave swirl marks. Only use black wax or black shoe polish on black urethane or polypropylene bumpers. Removing spots Remove tar and oil spots, industrial dust, insects, and tree sap as quickly as possible from the surface of the paint to avoid lasting damage or staining. Special cleaning prod- ucts are available at your NISSAN dealer or any automotive accessory store. Underbody In areas where road salt is used in winter, the underbody must be cleaned regularly. This prevents dirt and salt from building up and causing underbody and suspension corrosion. Before winter and again in the spring, the underseal must be checked and, if necessary, re-treated.

AAI0601

Cleaning glass When cleaning the rear window, it may be easier to clean if the high-mounted stop light is removed first. Be careful when removing the high- mounted stop light to reduce the risk of damaging the high-mounted stop light wires. The high-mounted stop light must be prop- erly reinstalled before driving your vehicle. Use glass cleaner to remove smoke and dust film from the glass surfaces. It is nor- mal for glass to become coated with a film

6-3

after the vehicle is parked in the hot sun. Glass cleaner and a soft cloth easily remove this film.

CAUTION

When cleaning the inside of the win- dow, do not use sharp-edged tools, abrasive cleaners or chlorine based disinfectant cleaners. They could dam- age electrical conductors or rear win- dow defogger elements.

Cleaning alloy wheels Wash the wheels regularly, especially dur- ing winter months in areas where road salt is used. If not removed, road salt could discolor the wheels. Chrome parts Clean all chrome parts regularly with a non-abrasive chrome polish to maintain the finish. Plastic parts Plastic parts can be cleaned with a mild soap solution. If the dirt cannot be easily removed, use a plastic cleaner. Do not use solvents.

Z X

Cleaning interior Occasionally remove loose dust from the interior trim and seats using a vacuum cleaner or soft brush. Wipe the vinyl and leather surfaces with a clean, soft cloth dampened in mild soap solution, then wipe clean with a dry soft cloth. Before using any fabric protector, read the manufacturer’s recommendations. Some fabric protectors contain chemicals that may stain or bleach the seat material.

CAUTION

c Never use benzine, thinner, or any

similar material.

c The leather seats should be regularly coated with a leather wax like saddle soap. Never use car wax.

c Never use fabric protectors unless recommended by the manufacturer.

AAI0500

Floor mat positioning aid (Driver side only) All models include a front floor mat bracket to act as a floor mat positioning aid. NIS- SAN floor mats have been specially de- signed for your vehicle model. The driver’s side floor mat has a grommet hole incorpo- rated in it. Simply position the mat by plac- ing the floor mat bracket hook through the floor mat grommet hole while centering the mat in the floor pan contour. Periodically check to make certain the mats are properly positioned. 6-4

Floor mats The use of genuine NISSAN floor mats can extend the life of your vehicle carpet and make it easier to clean the interior. No matter what mats are used, be sure they are fitted for your vehicle and are properly posi- tioned in the footwell to prevent interference with pedal operation. Mats should be main- tained with regular cleaning and replaced if they become excessively worn. Seat belts The seat belts can be cleaned by wiping them with a sponge dampened in a mild soap solution. Allow the belts to dry com- pletely before using them. Do not allow wet belts to roll up in the retractor. NEVER use bleach, dye, or chemical solvents since these may severely weaken the seat belt webbing.

Z X

ment by washing it out with a hose. Remove dirt with a vacuum cleaner or broom.

c Never allow water or other liquids to come in contact with electronic com- ponents inside the vehicle.

CORROSION PROTECTION

Most common factors contributing to vehicle corrosion: 1. The accumulation of moisture-retaining dirt and debris in body panel sections, cavities, and other areas.

2. Damage to paint and other protective coatings caused by gravel and stone chips or minor traffic accidents.

Environmental factors influence the rate of corrosion: Moisture Accumulation of sand, dirt and water on the vehicle body underside can accelerate cor- rosion. Wet floor coverings will not dry com- pletely inside the vehicle, and should be removed for drying to avoid floor panel corrosion. Relative humidity Corrosion will be accelerated: c In areas of high relative humidity c especially in those areas where the tem-

peratures stay above freezing

c where atmospheric pollution exists

c where road salt is used Temperature A temperature increase accelerates the rate of corrosion to those parts which are not well ventilated. Air pollution Industrial pollution, the presence of salt in the air in coastal areas, or heavy road salt use accelerates the corrosion process. Road salt also accelerates the disintegra- tion of paint surfaces. To protect your vehicle from corrosion: c Wash and wax your vehicle often to keep

the vehicle clean.

c Always check for minor damage to the paint and repair it as soon as possible. c Keep drain holes at the bottom of the doors open to avoid water accumulation. c Check the underbody for accumulation of sand, dirt or salt. If present, wash with water as soon as possible.

c NEVER remove dirt, sand or other debris from the passenger compart-

6-5

Z X

MEMO

6-6

Z X

7 Do-it-yourself operations

Maintenance precautions ..................................... 7-2

Engine compartment check locations .................. 7-3

Engine cooling system ......................................... 7-5

Engine oil ............................................................ 7-8

Automatic transmission fluid .............................. 7-11

Power steering fluid............................................ 7-13

Brake fluid .......................................................... 7-13

Window washer fluid .......................................... 7-14

Battery ................................................................ 7-15

Drive belts .......................................................... 7-17

Spark plug replacement ..................................... 7-18

Air cleaner housing filter .................................... 7-19Wiper blades ...................................................... 7-20

Parking brake check........................................... 7-21

Brake pedal ........................................................ 7-21

Brake booster ..................................................... 7-22

Clutch pedal ....................................................... 7-23

Fuses.................................................................. 7-23

Light bulbs .......................................................... 7-25

Headlight aiming adjustment.............................. 7-26

Bulb replacement ............................................... 7-26

Wheels and tires ................................................ 7-32Z X

MAINTENANCE PRECAUTIONS

When performing any inspection or mainte- nance work on your vehicle, always take care to prevent serious accidental injury to yourself or damage to the vehicle. The following are general precautions which should be closely observed. c Park the vehicle on a level surface, apply the parking brake securely and block the wheels to prevent the ve- hicle from moving. Move the gearshift control lever to Neutral (N).

c Be sure the ignition key is OFF when performing any parts replacement or repairs.

c Do not work under the hood while the engine is hot. Turn the engine off and wait until it cools down.

c Be sure to turn the ignition key to the

OFF or LOCK position. When the ignition key is in the ON or ACC position, the cooling fan may start to operate suddenly even when the engine is not running.

c If you must work with the engine run- ning, keep your hands, clothing, hair and tools away from moving fans, belts and any other moving parts.

c It is advisable to remove ties and any jewelry, such as rings, watches, etc., before working on your vehicle.

c If you must run the engine in an en- closed space such as a garage, be sure there is proper ventilation for exhaust gases.

c Never get under the vehicle while it is supported only by a jack. If it is nec- essary to work under the vehicle, sup- port it with safety stands.

c Keep smoking materials, flame and

sparks away from fuel and battery.

c Never connect or disconnect either the battery or any transistorized com- ponent connector while the ignition is on.

c On gasoline engine models with the Multiport Fuel Injection (MFI) system, the fuel filter or fuel lines should be serviced by a NISSAN dealer because the fuel lines are under high pressure even when the engine is off.

c Failure to follow these or other com- mon sense guidelines may lead to serious injury or vehicle damage.

7-2

c Improperly disposed motor oil and/or other vehicle fluids can hurt the envi- ronment. Always conform to local regulations for disposal of vehicle fluid. Avoid contact with used motor oil.

This ‘‘Do-it-yourself operations’’ section gives instructions regarding only those items which are relatively easy for an owner to perform. You should be aware that incomplete or improper servicing may result in operating difficulties or excessive emissions, and could affect your warranty coverage. If in doubt about any servicing, have it done by your NISSAN dealer.

Z X

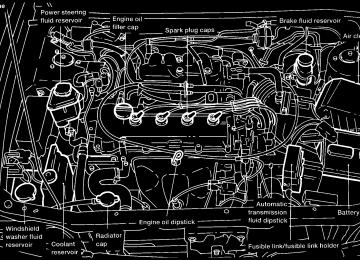

ENGINE COMPARTMENT CHECK LOCATIONS

7-3

ADI0620

Z X

7-4

ADI0621

Z X

ENGINE COOLING SYSTEM

The engine cooling system is filled at the factory with a high-quality, year-round, anti- freeze coolant solution. The anti-freeze so- lution contains rust and corrosion inhibitors, therefore additional cooling system addi- tives are not necessary.

caused by high pressure fluid escaping from the radiator. Wait until the engine and radiator cool down. See precautions in ‘‘If your ve- hicle overheats’’ found in the ‘‘In Case Of Emergency’’ section.

CAUTION

When adding or replacing coolant, be sure to use only an ethylene glycol anti-freeze with the proper mixture ra- tio. Examples are shown below:

Outside tempera- ture down to

°C

−35

°F

−30

Anti- freeze

Soft wa- ter

50%

50%

The use of other types of coolant solu- tions may damage your cooling system. The radiator is equipped with a pressure cap. Use a genuine NISSAN cap or its equivalent when replacement is re- quired. Never remove the radiator cap when the engine is hot. Serious burns could be

DI1210M

CHECKING ENGINE COOLANT LEVEL With coolant reservoir Check the coolant level in the reservoir tank when the engine is cold. If the coolant level is below MIN, add coolant up to the MAX level. If the reservoir tank is empty, check the coolant level in the radiator when the engine is cold. If there is insufficient cool- ant the radiator with coolant up to the filler opening and also add it to the reservoir tank up to the MAX level.

in the radiator,

fill

7-5

Z X

If the cooling system frequently requires coolant, have cooling system checked by your NISSAN dealer.

the

c Improper servicing can result in reduced heater performance and engine over- heating.

WARNING

c To avoid the danger of being scalded, never change the coolant when the engine is hot.

c Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pressure fluid escaping from the radiator.

DI1211M

CHANGING ENGINE COOLANT c Major cooling system repairs should be performed by your NISSAN dealer. The service procedures can be found in the appropriate NISSAN Service Manual.

7-6

Z X

3. Open the radiator cap to drain the cool-

ant.

4. Flush the cooling system by running

fresh water through the radiator.

ADI0632

1. Move the heater or air conditioner tem- perature control dial to the maximum hot position.

2. Open the radiator drain plug. Open the

drain plug on the engine block.

ADI0615

5. Close the drain plugs on the radiator and

the engine block securely.

6. See the ‘‘Technical and consumer infor- mation’’ section for cooling system ca- pacity. Fill the radiator slowly with the proper mixture of coolant and water. Fill the reservoir tank up to the MAX level.

7. Open and close the air release plug(s) to release air. Then fill the radiator again and install the radiator cap.

8. Start the engine, and warm it up until it reaches normal operating temperature. Then race the engine 2 or 3 times under no load. Watch the coolant temperature gauge for signs of overheating.

7-7

Z X

ENGINE OIL

DI1249M

DI1217M

DI1251M

9. Stop the engine. After

it completely cools down, refill the radiator up to the filler opening. Fill the reservoir tank up to the MAX level.

10. Open and close the air release plug(s) to release air. Then fill the radiator again and install the radiator cap.

11. Check the drain plugs on the radiator and the engine block for any sign of leakage. Also check the air release plug for any sign of leakage.

CHECKING ENGINE OIL LEVEL 1. Park the vehicle on a level surface and

apply the parking brake.

2. Run the engine until it reaches operating

temperature.

3. Turn off the engine. Wait a few minutes for the oil to drain back into the oil pan.

4. Remove the dipstick and wipe it clean.

Reinsert it all the way.

5. Remove the dipstick again and check the oil level. It should be between the H and L marks. If the oil is below the L mark, remove the oil filler cap and pour recommended oil through the opening. Do not overfill.

level

7-8

Z X

If the oil filter is to be changed, remove and replace it at this time. See ‘‘Chang- ing engine oil filter’’ in this section.

WARNING

c Prolonged and repeated contact with used engine oil may cause skin cancer.

c Try to avoid direct skin contact with used oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

c Keep used engine oil out of reach of

children.

DI1252M

DI1221M

6. Recheck oil level with dipstick.

CAUTION

c Oil level should be checked regularly. Operating with insufficient amount of oil can damage the engine, and such damage is not covered by warranty. c It is normal to add some oil between oil maintenance intervals or during the break-in period, depending on the severity of operating conditions.

CHANGING ENGINE OIL 1. Park the vehicle on a level surface and

apply the parking brake.

2. Run the engine until it reaches operating

temperature, and then turn it off.

3. Place a large drain pan under the drain

plug.

4. Remove the oil filler cap. 5. Remove the drain plug with a wrench and

completely drain the oil.

7-9

Z X

Drain plug tightening torque:

22 to 29 ft-lb (29 to 39 N†m) Do not overtighten.

7. Refill engine with recommended oil and

install the cap securely. See the ‘‘Technical and consumer infor- mation’’ section for refill capacity.

8. Start the engine.

Check for leakage around the drain plug and oil filter. Correct as required.

WARNING

DI1151

9. Turn the engine off and wait several level with the

minutes. Check the oil dipstick. Add engine oil if necessary.

Be careful not to burn yourself, as the engine oil is hot.

CAUTION

c Waste oil must be disposed of prop-

erly. Check your local regulations.

c Avoid direct contact with used en-

gine oil.

6. Clean and re-install the drain plug and washer. Securely tighten the drain plug with a wrench.

DI1222M

CHANGING ENGINE OIL FILTER 1. Park the vehicle on a level surface and

apply the parking brake.

2. Turn the engine off. 3. Loosen the oil filter with an oil filter wrench. (Depending on the engine model, a special cap type wrench may be required. See your NISSAN dealer if in doubt.) Remove the oil filter by turning it by hand.

WARNING

Be careful not to burn yourself, as the engine oil may be hot.

7-10

Z X

AUTOMATIC TRANSMISSION FLUID

8. Turn the engine off and wait several minutes. Check the oil level. Add engine oil if necessary.

DI1154

4. Wipe the engine oil filter mounting sur-

face with a clean rag. Be sure to remove any old rubber gasket remaining on the mounting surface of the engine.

5. Coat the rubber gasket on the new filter

with clean engine oil.

6. Screw in the oil filter until a slight resis- tance is felt, then tighten an additional 2/3 turn.

7. Start the engine and check for leakage around the oil filter. Correct as required.

ADI0614

WARNING

c When engine is running, keep hands and clothing away from any moving parts such as cooling fan and drive belts.

c Automatic transmission fluid is poi- sonous and should be stored care- fully in marked containers out of the reach of children.

7-11

Z X

the continental United States and Alaska contact a Nissan dealership for more information regarding suit- able fluids, including recommended brand(s) of Dexron® III/Mercon® or Dexron® Automatic Transmission Fluid.

IIE/Mercon®

NOTE: If the vehicle has been driven for a long time at high speeds, or in city traffic in hot weather, or if it is being used to pull a trailer, the accurate fluid level cannot be read. You should wait until the fluid has cooled down (about 30 minutes) be- fore checking fluid level.

c The fluid can be checked at fluid tem- peratures of 86 to 122°F (30 to 50°C) using the COLD range on the dipstick after the engine is warmed up and before driving. However, the fluid should be re-checked using the HOT range.

1. Park the vehicle on a level surface and

set the parking brake.

2. Start the engine and then move the shift lever through each gear range, ending in P.

3. Check the fluid level with the engine

idling.

4. Remove the dipstick and wipe it clean

with lint-free paper.

5. Reinsert the dipstick into the charging

pipe as far as it will go.

6. Remove the dipstick and note the read- ing. If the level is at the low side of either range, add fluid to the charging pipe. DO NOT OVERFILL. Use ONLY Nissan Matic ‘D’ (Continen- tal U.S. and Alaska) or Genuine Nis- san Automatic Transmission Fluid (Canada). Dexron® III/Mercon® or equivalent may also be used. Outside

7-12

ADI0626

Temperature conditions for check- ing c The fluid level should be checked using the HOT range on the dipstick after the following conditions have been met:

— The engine should be warmed up to

operating temperature.

— The vehicle should be driven at least 5

minutes.

— The automatic transmission fluid should be warmed to between 122 and 176°F (50 and 80°C).

Z X

POWER STEERING FLUID

BRAKE FLUID

Check the power steering fluid level. The fluid level should be checked using the HOT range on the side of the fluid reservoir at fluid temperatures of 122 to 176°F (50 to 80°C) or using the COLD range on the side of the fluid reservoir at fluid temperatures of 32 to 86°F (0 to 30°C).

CAUTION

c Do not overfill. c The recommended fluid is type

DEXRONTMII or equivalent.

ADI0611

DI1226M

Check the brake fluid level in the reservoir. If the fluid is below the minimum (MIN) line or the brake warning light comes on, add DOT 3 fluid up to the maximum (MAX) line. If fluid must be added frequently, the system should be thoroughly checked by your NIS- SAN dealer.

CAUTION

c Use only new fluid from a sealed container. Old, inferior, or contami- nated fluid may damage the brake system. The use of improper fluids can damage the brake system and affect the vehicle’s stopping ability.

7-13

Z X

WINDOW WASHER FLUID

c Do not spill the fluid on painted sur- faces. This will damage the paint. If fluid is spilled, wash with water.

Canada Only Add fluid when the low washer fluid warning light comes on. Add a washer solvent to the water for better cleaning. In the winter sea- son, add a windshield washer anti-freeze. Follow the manufacturer’s instructions for the mixture ratio.

CAUTION

Do not substitute engine anti-freeze coolant for windshield washer solution. This may result in damage to the paint.

ADI0618

For USA Fill the window washer fluid reservoir peri- odically. Perform the refilling operation more often under driving conditions that require an increased amount of window washer fluid. To fill the window washer fluid reservoir, lift the cap off the reservoir tank and pour the window washer fluid into the tank opening. Add a washer solvent to the water for better cleaning. In the winter season, add a wind- shield washer anti-freeze. Follow the manu- facturer’s instructions for the mixture ratio.

7-14

Z X

BATTERY

c Keep the battery surface clean and dry. Any corrosion should be washed off with a solution of baking soda and water.

c Make certain the terminal connections

are clean and securely tightened.

c If the vehicle is not to be used for 30 days or longer, disconnect the negative (−) battery terminal cable to prevent dis- charge.

WARNING

Do not expose the battery to flames or electrical sparks. Hydrogen gas gener- ated by battery action is explosive. Do not allow battery fluid to contact your skin, eyes, fabrics, or painted surfaces. After touching a battery or battery cap, do not touch or rub your eyes. Thor- oughly wash your hands. If the acid contacts your eyes, skin or clothing, immediately flush with water for at least 15 minutes and seek medical attention.

ADI0616

ADI0617

Type 1

1. To remove the cap, gently pry between the battery cap and cover as illustrated. Use a cloth to protect the battery case.2. Check the fluid level in each cell.

If it is necessary to add fluid, add only distilled water to bring the level up to the OK level indicator in each filler opening. Do not overfill.

7-15

Z X

JUMP STARTING If jump starting is necessary, see the ‘‘In case of emergency’’ section. If the engine does not start by jump starting, the battery may have to be replaced. Contact your NISSAN dealer.

ADI0641

Type 2

1. To remove the caps, use a screwdriver. 2. Check the fluid level in each cell.If it is necessary to add fluid, add only distilled water to bring the level up to the OK indicator in each filler opening. Do not overfill.

7-16

Z X

DRIVE BELTS

WARNING

Be sure the ignition key is ‘‘OFF’’.

1. Visually inspect each belt for signs of unusual wear, cuts, fraying or looseness. If the belt is in poor condition or loose, have it replaced or adjusted by your NISSAN dealer.

2. Have the belts checked regularly for con- dition and tension in accordance with the maintenance schedule in this manual.

ADI0627

7-17

Z X

SPARK PLUG REPLACEMENT

DI1229M

WARNING

Be sure the engine and ignition switch are off and that the parking brake is engaged securely.

CAUTION

Be sure to use the correct socket to remove the plugs. An incorrect socket can cause damage.

GA16DE Engine 1. Remove brackets as necessary to give access to the high tension cables and spark plugs.

2. Disconnect the spark plug cables from

the spark plugs.

When disconnecting, always hold the boots, not the cables. Mark all cables to identify their original locations.

DI1017M

3. Remove the spark plugs with a spark

plug socket. The spark plug socket has a rubber seal that holds the spark plug so it does not fall when it is pulled out. Make sure each spark plug is snugly fitted into the plug socket.

4. On conventional spark plugs, check the gap on each new spark plug with a feeler gauge. (The spark plug gap is shown in the ‘‘Technical and consumer information’’ section.) Adjust the gap as required.

7-18

Z X

5. Fit the new plugs, one at a time, into the spark plug socket and install them. Turn each plug in several full turns by hand, then tighten with a spark plug socket to the correct torque. Do not overtighten. Spark plug tightening torque:

14 to 22 ft-lb (20 to 29 N†m)

6. Holding the boot, re-connect each high tension cable to its proper spark plug by pushing it on until you feel a snap.

7. Re-install all brackets as necessary.

AIR CLEANER HOUSING FILTER

DI0205

SR20DE Engine Platinum-tipped spark plug It is not necessary to replace the platinum- tipped spark plugs as frequently as the conventional type spark plugs since they last much longer. Follow the maintenance schedule, but do not reuse the spark plugs by cleaning or regapping. Blue rings on the ceramic portion indicate that the plugs are platinum-tipped. c Always replace spark plugs with rec-

ommended or equivalent ones.

ADI0631

The air cleaner filter should not be cleaned and reused. Replace it according to the maintenance intervals shown in the ‘‘Main- tenance schedule’’ section. When replacing the filter, wipe the inside of the air cleaner housing and the cover with a damp cloth.WARNING

Operating the engine with the air cleaner off can cause you or others to be burned. The air cleaner not only cleans the air, it stops flame if the engine backfires. If it isn’t there, and the engine back- fires, you could be burned. Don’t drive with it off, and be careful working on the engine with the air cleaner off.

7-19

Z X

WIPER BLADES

Make sure the wiper blade contacts the glass, otherwise the arm may be dam- aged from wind pressure.

1) CLEANING

If your windshield is not clear after using the windshield washer or if the wiper blade chatters when running, wax or other material may be on the blade or windshield. Clean the outside of the windshield with a washer solution or a mild detergent. Your windshield is clean if beads do not form when rinsing with clear water. Clean the blade by wiping it with a cloth soaked in a washer solution or a mild detergent. Then rinse the blade with clear water. If your windshield is still not clear after cleaning the blades and using

ADI0650

the wiper, replace the blades.

2) REPLACEMENT 1. Pull the wiper arm. 2. Lift the tab, then remove the wiper blade. 3. Insert the new wiper blade to the wiper

arm until a click sounds.

CAUTION

After wiper blade replacement, return the wiper arm to its original position. Otherwise it may be damaged when the engine hood is opened.

7-20

Z X

PARKING BRAKE CHECK

BRAKE PEDAL

the hood, be If you wax the surface of careful not to let wax get into the washer nozzle. This may cause clogging or im- proper windshield washer operation. If wax gets into the nozzle, remove it with a needle or small pin.

ADI0629

DI1020M

From the released position, pull the parking brake lever up slowly and firmly. the number of clicks is out of the range listed above, see your NISSAN dealer.

If

With the engine running, check the distance between the upper surface of the pedal and the metal floor. If it is out of the range shown above, see your NISSAN dealer. Self-adjusting brakes Your vehicle is equipped with self-adjusting brakes. The front (and rear, if equipped) disc-type brakes self-adjust every time the brake pedal is applied. The rear drum-type brakes also self-adjust every time the brake pedal is applied. If the brake pedal goes down farther than

7-21

Z X

the rear drum brakes, have them inspected as soon as possible by your NISSAN dealer. Proper brake inspection intervals should be followed. For more information regard- ing brake inspections, see the appropriate maintenance schedule information in the ‘‘Maintenance Schedule’’ section of this manual.

normal, it may be due to a lack of adjust- ment of the rear drum brakes. Apply the parking brake several times.

WARNING

See your NISSAN dealer and have it checked if the brake pedal height does not return to normal.

Brake pad wear indicators The disc brake pads on your vehicle have audible wear indicators. When a brake pad requires replacement, it makes a high pitched scraping or screeching sound when the vehicle is in motion whether or not the brake pedal is depressed. Have the brakes checked as soon as possible if the wear indicator sound is heard. Under some driving or climate conditions, occasional brake squeak, squeal or other noise may be heard. Occasional brake noise during light to moderate stops is nor- mal and does not affect the function or performance of the brake system. The rear drum brakes (if so equipped) do not have audible wear indicators. Should you ever hear an unusually loud noise from

BRAKE BOOSTER

Check the brake booster function as fol- lows: 1. With the engine off, press and release times. When the brake pedal several brake pedal movement (distance of travel) remains the same from one pedal application to the next, continue on to the next step.

2. While depressing the brake pedal, start the engine. The pedal height should drop a little.

3. With the brake pedal depressed, stop the engine. Keeping the pedal depressed for about 30 seconds, the pedal height should not change.

4. Run the engine for one minute without depressing the brake pedal, then turn it off. Depress the brake pedal several times. The pedal travel distance will de- crease gradually with each depression as the vacuum is released from the booster.

If the brakes do not operate properly, see your NISSAN dealer.

7-22

Z X

CLUTCH PEDAL

FUSES

5. If the fuse is open, replace it with a new

fuse.

Never use a fuse of higher amperage rating than that specified on the fuse box cover. 6. If a new fuse opens again, have the electrical system checked and repaired by your NISSAN dealer.

If the electrical equipment does not operate and fuses are in good condition, check the fusible links. If any of these fusible links are melted, replace only with genuine NISSAN parts.

ADI0630

ADI0628

Press the pedal by hand and be sure the free travel is within the limits shown above. If the range shown above, see your NISSAN dealer.

free travel

is out of

(Headlight

compartment

Engine fuses) If a headlight does not come on, check for an open fuse. 1. Be sure the ignition key and the headlight

switch are OFF.

2. Open the engine hood. 3. Remove the fuse box cover. 4. Remove the fuse with the fuse puller provided (inside the passenger compart- ment fuse panel cover).

7-23

Z X

Passenger compartment If the electrical equipment does not operate, check for an open fuse. 1. Be sure the ignition key and the headlight

switch are OFF.

2. Open the fuse box lid. 3. Remove the fuse with the fuse puller

provided.

4. If the fuse is open, replace it with a new

fuse.

Never use a fuse of higher amperage rating than that specified on the fuse box cover. 5. If a new fuse opens again, have the electrical system checked and repaired by your NISSAN dealer.

ADI0652

7-24

Z X

LIGHT BULBS

HEADLIGHTS The headlight is a semi-sealed beam type which uses a replaceable headlight (halo- gen) bulb. A bulb can be replaced from inside the engine compartment without re- moving the headlight assembly.

CAUTION

High pressure halogen gas is sealed inside the halogen bulb. The bulb may break if the glass envelope is scratched or the bulb is dropped. Hold the plastic base when handling the bulb. Never touch the glass enve- lope.

Removing the headlight bulb 1. Open the hood. 2. Disconnect the negative battery cable. 3. If removing the right-hand (passenger side) headlight bulb, it is necessary to first reposition the engine coolant reser- voir.

ADI0607

4. Disconnect the electrical connector from

the rear end of the bulb.

7-25

5. Push down spring retainer. 6. Pull out the headlight bulb and socket as an assembly. Do not shake or rotate the bulb when removing it. Do not handle the glass envelope.

Replacing the headlight bulb 1. Insert the bulb and socket assembly into

the headlight.

2. Install the spring retainer. 3. Push the electrical connector into the bulb plastic base until it snaps and stops. installing the right-hand (passenger side) headlight bulb, be sure to reposition the engine coolant reservoir.

4. If

5. Connect the battery cable. 6. Close the hood.

CAUTION

DO NOT TOUCH THE BULB. c Use the same number and wattage as

originally installed: Type A: Wattage 65/45

Bulb no. 9004Z X

HEADLIGHT AIMING ADJUSTMENT

c Aiming is not necessary after replac- ing the bulb. When aiming adjust- ment is necessary, contact your NIS- SAN dealer.

c Do not leave the bulb out of the head- light reflector for a long period of time as dust, moisture, and smoke may enter the headlight body and affect the performance of the head- light.

ADI0619

the tires are properly inflated,

Before adjusting the headlights, make sure all of the vehicle is on level ground and there is no excess weight in the vehicle that would affect the level of the vehicle. First, open the hood. The vertical adjustment bolt is behind the headlight. Turn the adjustment bolt clock- wise to raise the headlight beam. Turn the adjustment bolt counterclockwise to lower the headlight beam. The horizontal adjustment bolt is also be- hind the headlight.

7-26

To adjust the horizontal level of the headlight, turn the adjustment bolt clockwise to turn the headlight beam left, and turn it counterclock- wise to turn the headlight beam right. BULB REPLACEMENT

Item

Front combination light

Rear combination light

Turn signal

Stop/Tail

Back-up (Sentra)

Back-up (200SX)

License plate light

High-mounted stop light

Trunk lid-mounted stop light

Front fog lamp

Interior light

Trunk light

Wattage

(W)

27/8

27

27/8

13

13

13

35

3.4

Bulb No.

1157NA

1156

1157

912

1156

168