- 2009 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2002 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 1999 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2004 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2003 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 1997 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2010 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 1996 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2005 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 1998 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2008 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2007 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2001 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2000 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2011 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2012 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- 2006 Nissan Altima Owners Manuals

- Nissan Altima Owners Manuals

- Download PDF Manual

-

If skin contact

c Keep coolant out of reach of children

and pets.

DI1349

CHANGING ENGINE COOLANT c Major cooling system repairs should be performed by an authorized NISSAN dealer. The service procedures can be found in an appropriate NISSAN Service Manual.

Perform the following procedure to open the heater water cock: 1. Turn the ignition switch ON and set the lever to the maxi- temperature control mum hot position. Wait 10 seconds, then turn the switch OFF.

2. Open the radiator drain plug. Open the

8-6 Do-it-yourself

Z X

down, refill the radiator up to the filler opening. Fill the reservoir tank up to the MAX level.

10. Open and close the air release plug to release air. Then fill the radiator again and install the radiator cap.

drain plug on the engine water pipe.

3. Open the radiator cap to drain the cool-

ant. c Waste coolant must be disposed of

properly.

c Check your local regulations.

4. Flush the cooling system by running

fresh water through the radiator.

5. Close the radiator drain plug and the drain plug on the engine water pipe se- curely.

6. See the ‘‘Technical and consumer infor- mation’’ section for cooling system ca- pacity. Fill the radiator slowly with the proper mixture of coolant and water. Fill the reservoir tank up to the MAX level.

7. Open and close the air release plug to release air. Then fill the radiator again and install the radiator cap.

8. Start the engine and let it idle until

it reaches normal operating temperature. Then race the engine 2 or 3 times under no load. Watch the engine coolant tem- perature gauge for signs of overheating. 9. Stop the engine. After it completely cools

AMA098

11. Check the radiator drain plug and the drain plug on the engine water pipe for any sign of leakage, tighten if neces- sary.

Do-it-yourself

8-7

Z X

ENGINE OIL

DI1299

DI1300

DI1301

CHECKING ENGINE OIL LEVEL 1. Park the vehicle on a level surface and

apply the parking brake.

2. Start the engine and let it idle until

reaches operating temperature.

it

3. Turn off the engine. Wait a few minutes for the oil to drain back into the oil pan.

4. Remove the dipstick and wipe it clean.

Reinsert it all the way.

level.

5. Remove the dipstick again and check the oil It should be between the H (High) and L (Low) marks. If the oil level is below the L (Low) mark, remove the oil filler cap and pour recommended oil through the opening. Do not overfill. 6. Recheck the oil level with the dipstick. It is normal to add some oil between oil maintenance intervals or during the break-in period, depending on the sever- ity of operating conditions.

8-8 Do-it-yourself

Z X

CAUTION

Oil level should be checked regularly. Operating the engine with an insuffi- cient amount of oil can damage the engine, and such damage is not cov- ered by warranty.

DI1302

CHANGING ENGINE OIL 1. Park the vehicle on a level surface and

apply the parking brake.

2. Start the engine and let it idle until

it reaches operating temperature, then turn it off.

3. Remove the oil filler cap. 4. Place a large drain pan under the drain

plug.

5. Remove the drain plug with a wrench and

completely drain the oil.

If the oil filter is to be changed, remove and replace it at this time. See ‘‘Chang- ing engine oil filter’’ later in this section.

CAUTION

Be careful not to burn yourself. The engine oil may be hot.

c Waste oil must be disposed of properly. c Check your local regulations. 6. Clean and reinstall the drain plug and a new washer. Securely tighten the drain plug with a wrench. Drain plug tightening torque:

22 to 29 ft-lb (29 to 39 Nzm)

Do not overtighten.

7. Refill the engine with a recommended oil through the oil filler opening, then install the oil filler cap securely. See the ‘‘Technical and consumer informa- tion’’ section for drain and refill capacity.

The drain and refill capacity depends on the oil temperature and drain time. Use these specifications for reference only. Always 8-9

Do-it-yourself

Z X

use the dipstick to determine when the proper amount of oil is in the engine. 8. Start

leakage around the drain plug. Correct as re- quired.

the engine. Check for

9. Turn the engine off and wait several level with the

minutes. Check the oil dipstick. Add engine oil if necessary.

WARNING

c Prolonged and repeated contact with used engine oil may cause skin can- cer.

c Try to avoid direct skin contact with used oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

c Keep used engine oil out of reach of

children.

8-10 Do-it-yourself

CAUTION

Be careful not to burn yourself. The engine oil may be hot.

5. Wipe the engine oil filter mounting sur-

face with a clean rag. Be sure to remove any old gasket mate- rial remaining on the mounting surface of the engine.

6. Coat the gasket on the new filter with

clean engine oil.

7. Screw on the oil filter until a slight resis- tance is felt, then tighten an additional 2/3 turn.

8. Start the engine and check for leakage around the oil filter. Correct as required. 9. Turn the engine off and wait several minutes. Check the oil level. Add engine oil if necessary.

DI1303

CHANGING ENGINE OIL FILTER 1. Park the vehicle on a level surface and

apply the parking brake.

2. Turn the engine off. 3. Place a large drain pan under the oil

filter.

4. Loosen the oil

filter wrench. Then, remove the oil filter by turning it by hand.

filter with an oil

Z X

AUTOMATIC TRANSMISSION FLUID

WDI0013

WARNING

c When the engine is running, keep hands, jewelry and clothing away from any moving parts such as the cooling fan and drive belts.

c Automatic transmission fluid is poi- sonous and should be stored care- fully in marked containers out of the reach of children.

TEMPERATURE CONDITIONS FOR CHECKING c The fluid level should be checked using the HOT range on the dipstick after the following conditions have been met:

— The engine should be warmed up to

operating temperature.

— The vehicle should be driven at least 5

minutes.

— The automatic transmission fluid should be warmed to between 122° and 176°F (50° to 80°C).

c The fluid can be checked at fluid tem- peratures of 86° to 122°F (30 to 50°C) using the COLD range on the dipstick, after the engine is warmed up and before driving. However, the fluid should be re-checked using the HOT range.

1. Park the vehicle on a level surface and

set the parking brake.

2. Start the engine and then move the shift selector lever through each gear range. Move the shift selector lever to P (Park) after you have moved it through all ranges.

ADI1012

3. Check the fluid level with the engine

idling.

4. Remove the dipstick and wipe it clean

with lint-free paper.

5. Reinsert

the dipstick into the dipstick

tube as far as it will go.

6. Remove the dipstick and note the read- ing. If the level is at the low side of either range, add fluid through the dipstick tube.

Do-it-yourself

8-11

Z X

CAUTION

DO NOT OVERFILL. USE ONLY NISSAN Matic ‘D’ (Continental U.S. and Alaska) or Canada NISSAN Automatic Trans- mission Fluid. Dexron™ III/Mercon™ or equivalent may also be used. Outside the continental United States and Alaska contact an authorized NISSAN dealership for more information re- garding suitable fluids, including rec- ommended of Dexron™ III/Mercon™ Automatic Transmission Fluid.

brand(s)

NOTE: If the vehicle has been driven for a long time at high speeds, or in city traffic in hot weather, or if it is being used to pull a trailer, the accurate fluid level cannot be read. You should wait until the fluid has cooled down (about 30 minutes).

8-12 Do-it-yourself

POWER STEERING FLUID

BRAKE AND CLUTCH FLUID

ADI1117

DI1307

The fluid level should be checked using the HOT MAX range on the power steering fluid reservoir at fluid temperatures of 122° to 176°F (50° to 80°C) or using the COLD MAX range on the power steering fluid reservoir at fluid temperatures of 32° to 86°F (0 to 30°C).

CAUTION

c DO NOT OVERFILL. c Recommended fluid is Genuine NIS-

SAN PSF II or equivalent.

BRAKE FLUID Check the brake fluid level in the reservoir. If the fluid level is below the MIN line or the brake warning light comes on, add Genuine Nissan Brake Fluid or equivalent DOT 3 fluid up to the MAX line. If fluid must be added frequently, the system should be thoroughly checked by an authorized NISSAN dealer.

Z X

WARNING

Use only new fluid from a sealed con- tainer. Old, inferior, or contaminated fluid may damage the brake and clutch systems. The use of improper fluids can damage the brake system and af- fect the vehicle’s stopping ability.

CAUTION

Do not spill the fluid on painted sur- faces. This will damage the paint. If fluid is spilled, immediately wash the surface with water.

DI1348

CLUTCH FLUID Check the clutch fluid level in the reservoir (manual transmission only). If the fluid level is below the MIN line, add Genuine Nissan Brake Fluid or equivalent DOT 3 fluid up to the MAX line. If fluid must be added fre- quently, the system should be thoroughly checked by an authorized NISSAN dealer. For further brake and clutch fluid specifica- tion information, refer to ‘‘Capacities and recommended fuel/lubricants’’ in the ‘‘Tech- nical and consumer information’’ section of this manual.

WINDOW WASHER FLUID

DI1308

To fill the window washer fluid reservoir, lift the cap off the reservoir tank and pour the window washer fluid into the tank opening. Add a washer solvent to the water for better cleaning. In the winter season, add a wind- shield washer antifreeze. Follow the manu- facturer’s instructions for the mixture ratio.

Do-it-yourself

8-13

Z X

For USA Fill the window washer fluid reservoir peri- odically. Perform the refilling operation more often under driving conditions that require an increased amount of window washer fluid. For Canada Add window washer

fluid when the

light comes on.

CAUTION

Do not substitute engine anti-freeze coolant for windshield washer solution. This may result in damage to the paint.

8-14 Do-it-yourself

c Battery posts, terminals and related accessories contain lead and lead compounds. Wash hands after han- dling.

c Keep the battery out of the reach of

children.

BATTERY

c Keep the battery surface clean and dry. Any corrosion should be washed off with a solution of baking soda and water.

c Make certain the terminal connections

are clean and securely tightened.

c If the vehicle is not to be used for 30 days or longer, disconnect the negative (—) battery terminal cable to prevent discharge.

WARNING

c Do not expose the battery to flames or electrical sparks. Hydrogen gas generated by the battery is explo- sive. Do not allow battery fluid to contact your skin, eyes, fabrics, or painted surfaces. After touching a battery or battery cap, do not touch or rub your eyes. Thoroughly wash your hands. If the acid contacts your eyes, skin or clothing, immediately flush with water for at least 15 min- utes and seek medical attention.

c When working on or near the battery, always wear suitable eye protection and remove all jewelry.

Z X

DRIVE BELTS

ADI0500

DI1310

ADI0533

1. To remove the cap, gently pry between the battery cap and cover as illustrated. Use a cloth to protect the battery case.

2. Check the fluid level in each cell.

If it is necessary to add fluid, add only distilled water to bring the level up to the OK level indicator in each filler opening. Do not overfill.

JUMP STARTING If jump starting is necessary, see the ‘‘In case of emergency’’ section of this owner’s manual. If the engine does not start by jump starting, the battery may have to be re- placed. Contact an authorized NISSAN dealer.

WARNING

Be sure the ignition key is in the OFF or LOCK position. The engine could rotate unexpectedly.

1. Visually inspect each belt for signs of unusual wear, cuts, fraying or looseness. If the belt is in poor condition or is loose, have it replaced or adjusted by an autho- rized NISSAN dealer.

2. Have the belts checked regularly for con- dition and tension in accordance with the maintenance schedule found in the ‘‘Maintenance’’ section of this manual.

Do-it-yourself

8-15

Z X

SPARK PLUGS

DI1229M

WDI0005

REPLACING SPARK PLUGS

WARNING

Be sure the engine and ignition switch are off and that the parking brake is engaged securely.

CAUTION

Be sure to use the correct socket to remove the spark plugs. An incorrect socket can damage the spark plugs.

Platinum-tipped spark plugs It is not necessary to replace platinum- tipped spark plugs as frequently as conven- tional type spark plugs because they last much longer. Follow the maintenance schedule, but do not reuse the spark plugs by cleaning or regapping. c Always replace spark plugs with rec-

ommended or equivalent ones.

1. Remove brackets as necessary to give access to the high tension spark plug cables and spark plugs.

8-16 Do-it-yourself

2. Disconnect the spark plug cables from

the spark plugs. When disconnecting, always hold the boots, not the cables. Mark all cables to identify their original locations.

3. Remove the spark plugs with a spark

plug socket. The plug socket has a rubber seal that holds the spark plug so it does not fall when it is pulled out. Make sure each spark plug is snugly fitted into the spark plug socket.

4. Fit the new plugs, one at a time, into the spark plug socket and install them. Use only the specified spark plugs. Turn each plug several full turns by hand, then tighten with the spark plug socket to the correct torque. Do not overtighten. Spark plug tightening torque:

14 to 22 ft-lb (20 to 29 Nzm)

5. Holding the boot, reconnect each high tension cable to its proper spark plug by pushing it on until you feel a snap. 6. Reinstall all brackets as necessary.

Z X

AIR CLEANER

DI1312

The air cleaner filter should not be cleaned and reused. Replace it according to the maintenance intervals shown in the ‘‘Main- tenance’’ section of this manual. When re- placing the filter, wipe the inside of the air cleaner filter housing and the cover with a damp cloth.

WARNING

c Operating the engine with the air cleaner removed can cause you or others to be burned. The air cleaner not only cleans the air, it stops the flame if the engine backfires. If it isn’t there, and the engine backfires, you could be burned. Do not drive with the air cleaner removed, and be careful when working on the engine with the air cleaner removed.

c Never pour fuel into the throttle body or attempt to start the engine with the air cleaner removed. Doing so could result in serious injury.

Do-it-yourself

8-17

Z X

WINDSHIELD WIPER BLADES

CLEANING If your windshield is not clear after using the windshield washer or if a wiper blade chat- ters when running, wax or other material may be on the blade or windshield. Clean the outside of the windshield with a washer solution or a mild detergent. Your windshield is clean if beads do not form when rinsing with clear water. Clean each blade by wiping it with a cloth soaked in a washer solution or a mild deter- gent. Then rinse the blade with clear water. If your windshield is still not clear after 8-18 Do-it-yourself

cleaning the blades and using the wiper, replace the blades. REPLACING 1. Pull the wiper arm away from the wind-

shield.

2. Push the tab, then move the wiper blade

down the wiper arm to remove.

3. Remove the wiper blade. 4. Insert the new wiper blade onto the wiper

arm until it clicks.

ADI1022

CAUTION

c After wiper blade replacement, return the wiper arm to its original position; otherwise it may be damaged when the hood is opened.

c Make sure the wiper blades contact the glass; otherwise the arms may be damaged from wind pressure.

Z X

PARKING BRAKE AND BRAKE PEDAL

ADI1003

DI1020M

CHECKING PARKING BRAKE From the released position, pull the parking brake lever up slowly and firmly. the number of clicks is out of the range listed above, see an authorized NISSAN dealer.

If

CHECKING BRAKE PEDAL With the engine running, check the distance between the upper surface of the pedal and the metal floor. If it is out of the range shown above, see an authorized NISSAN dealer.

ADI0613

If you wax the surface of the hood, be careful not to let wax get into the washer nozzle. This may cause clogging or im- proper windshield washer operation. If wax gets into the nozzle, remove it with a needle or small pin.

Do-it-yourself

8-19

Z X

Self-adjusting brakes Your vehicle is equipped with self-adjusting brakes. The front (and rear, if equipped) disc-type brakes self-adjust every time the brake pedal is applied. The rear drum-type brakes also self-adjust every time the brake pedal is applied. If the brake pedal goes down farther than normal, it may be due to a lack of adjust- ment of the rear drum brakes. To adjust, apply the parking brake several times.

WARNING

See an authorized NISSAN dealer for a brake system check if the brake pedal height does not return to normal.

Brake pad wear indicators The disc brake pads on your vehicle have audible wear indicators. When a brake pad requires replacement, it makes a high pitched scraping or screeching sound when the vehicle is in motion whether or not the brake pedal is depressed. Have the brakes checked as soon as possible if the wear 8-20 Do-it-yourself

indicator sound is heard. Under some driving or climate conditions, occasional brake squeak, squeal or other noise may be heard. Occasional brake noise during light to moderate stops is nor- mal and does not affect the function or performance of the brake system. The rear drum brakes (if so equipped) do not have audible wear indicators. Should you ever hear an unusually loud noise from the rear drum brakes, have them inspected as soon as possible by an authorized NISSAN dealer. Proper brake inspection intervals should be followed. For more information regard- ing brake inspections, see the appropriate maintenance schedule information in the ‘‘Maintenance’’ section of this manual. BRAKE BOOSTER Check the brake booster function as fol- lows: 1. With the engine off, press and release times. When the brake pedal several brake pedal movement (distance of travel) remains the same from one pedal

application to the next, continue on to the next step.

2. While depressing the brake pedal, start the engine. The pedal height should drop a little.

3. With the brake pedal depressed, stop the engine. Keep the pedal depressed for about 30 seconds. The pedal height should not change.

4. Run the engine for one minute without depressing the brake pedal, then turn it off. Depress the brake pedal several times. The pedal travel distance will de- crease gradually with each depression as the vacuum is released from the booster.

If the brakes do not operate properly, see an authorized NISSAN dealer.

Z X

CLUTCH PEDAL

FUSES

ADIO528

ADI1021

CHECKING CLUTCH PEDAL Press the pedal by hand and be sure the free travel is within the limits shown above. If the range shown above, see an authorized NISSAN dealer.

free travel

is out of

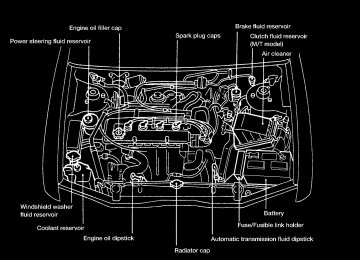

ENGINE COMPARTMENT

CAUTION

Never use a fuse of a higher amperage rating than specified on the fuse box cover. This could damage the electrical system or cause a fire.

If the electrical equipment does not come on, check for an open fuse. 1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the engine hood.

3. Remove the fuse box cover. 4. Remove the fuse with the fuse puller located in the passenger compartment fuse box.

5. If the fuse is open, replace it with a new

fuse.

6. If a new fuse also opens, have the elec- trical system checked and repaired by an authorized NISSAN dealer.

Fusible links If the electrical equipment does not operate and fuses are in good condition, check the fusible links. If any of these fusible links are melted, replace only with genuine NISSAN parts.

Do-it-yourself

8-21

Z X

PASSENGER COMPARTMENT

CAUTION

Never use a fuse of a higher amperage rating than specified on the fuse box cover. This could damage the electrical system or cause a fire.

3. Remove the fuse with the fuse puller. 4. If the fuse is open, replace it with a new

fuse.

5. If a new fuse also opens, have the elec- trical system checked and repaired by an authorized NISSAN dealer.

WDI0053

If any electrical equipment does not oper- ate, check for an open fuse. 1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the fuse box cover.

8-22 Do-it-yourself

Z X

MULTI-REMOTE CONTROLLER BATTERY REPLACEMENT

the

button is pressed,

controller operation. Each time the hazard lights flash once. If the battery is removed for any reason other than replacement, perform step 4. c An improperly disposed battery can hurt the environment. Always confirm local regulations for battery disposal. c The multi-remote controller is water- resistant; however, if it does get wet, immediately wipe completely dry.

Replace the battery in the multi-remote con- troller as follows: 1. Open the lid using a coin. 2. Replace the battery with a new one.

APD1026

Recommended battery: Sanyo CR2025 or equivalent. 3. Close the lid securely. 4. Press the button two or three times to check the multi-remote

button, then the

c The operational range of the multi- remote controller extends to approxi- mately 33 ft (10 m) from the vehicle. This range may vary with conditions.

FCC Notice: Changes or modifications not expressly approved by the manufacturer for com- pliance could void the user’s authority to operate the equipment. This device complies with part 15 of the FCC Rules and RSS-210 of Industry Canada.

Do-it-yourself

8-23

Z X

c High pressure halogen gas is sealed inside the halogen bulb. The bulb may break if the glass envelope is scratched or the bulb is dropped.

c Use the same number and wattage

as originally installed: Wattage 65/55

Bulb no. 9007(HB5)c Aiming is not necessary after replac- ing the bulb. When aiming adjust- ment is necessary, contact an autho- rized NISSAN dealer.

1. Disconnect the negative (-) battery cable.

LDI0009

2. Remove the four screws from the bottom of the front fender protector (see above illustration) and position the fender pro- tector aside to allow access to the head- lamp mounting fasteners.

LIGHTS

HEADLIGHTS The headlamp is a semi-sealed beam type which uses a replaceable halogen bulb. Because the headlamp assembly must be removed from the vehicle for bulb replace- ment, it is recommended that your vehicle be taken to an authorized NISSAN Dealer. Replacing the headlight bulb

CAUTION

c Do not leave the headlamp assembly open without a bulb installed for a long period of time. Dust, moisture, smoke, etc. entering the headlamp body may affect bulb performance. Remove the bulb from the headlamp assembly just before a replacement bulb is installed.

c Only touch the plastic base when handling the bulb. Never touch the glass envelope. Touching the glass could significantly affect bulb life and/or headlamp performance.

8-24 Do-it-yourself

Z X

LDI0010

LDI0011

3. Remove the three nuts and one bolt mounting the headlamp assembly (see above illustration).

5. Disconnect the harness connector from the back side of the bulb socket (see above illustration).

4. Pull the headlamp assembly evenly away from the front of the vehicle to access the bulb sockets.

6. Turn the bulb retaining ring counter- clockwise until it is free from the head- lamp assembly and then remove it.

7. Remove the bulb by pulling it straight out of the lamp assembly. Do not shake the bulb when removing it.

8. Follow the instructions in reverse order to

install new bulb.

Headlamp mounting nuts and bolt torque: 36 to 47 in-lb (4.1 to 5.3 Nzm)

Adjusting the headlight aim Before performing aiming adjustment, make sure of the following: a. Use an aiming wall screen. b. Keep all of the tires inflated to the correct

pressure.

c. Place the vehicle and screen on level

ground.

d. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and that the spare tire, jack, and tools are stored). Have the driver or an equivalent weight placed in the driver’s seat.

Low beam 1. Open the hood. Turn headlamp low

beam on.

2. Adjust

the vertical aim by turning the

adjusting screw.

c Cover the opposite lamp and ensure the fog lamps (if so equipped) are turned off. c Adjust beam pattern until cutoff line is positioned at the same height off ground as bulb center (on H-line).

Do-it-yourself

8-25

Z X

If the vehicle front body has been repaired and/or the headlight assembly has been replaced, check aiming. Use the aiming chart shown in the illustration. c Basic illuminating area should be within the range shown. Adjust headlamps ac- cordingly.

8-26 Do-it-yourself

Z X

WDI0006

Do-it-yourself

8-27

Z X

FRONT TURN SIGNAL LAMP Replacing the front turn signal lamp bulb 1. Disconnect the negative (-) battery cable. 2. Reach between the grille and radiator to

access the turn signal bulb socket.

3. Rotate the socket counter-clockwise and pull it out of the headlamp assembly. Do not shake the bulb socket when remov- ing it.

4. Pull the bulb out of the socket. 5. Follow the instructions in reverse order to

install new bulb.

FRONT PARKING AND CORNER- ING LAMP Replacing the front parking and cor- nering lamp bulb 1. Disconnect the negative (-) battery cable.

8-28 Do-it-yourself

LDI0009

LDI0010

2. Remove the four screws from the bottom of the front fender protector (see above illustration) and position the fender pro- tector aside to allow access to the head- lamp mounting fasteners.

3. Remove the three nuts and one bolt mounting the headlamp assembly (see above illustration).

4. Pull the headlamp assembly evenly away from the front of the vehicle to access the bulb sockets.

5. Rotate the socket counter-clockwise and pull it out of the headlamp assembly. Do not shake the bulb socket when remov- ing it.

6. Pull the bulb out of the socket. 7. Follow the instructions in reverse order to

install new bulb.

Z X

Headlamp mounting nuts and bolt torque: 36 to 47 in-lb (4.1 to 5.3 Nzm) FRONT SIDEMARKER LAMP Replacing the front sidemarker lamp bulb 1. Disconnect the negative (-) battery cable.

LDI0009

LDI0010

2. Remove the four screws from the bottom of the front fender protector (see above illustration) and position the fender pro- tector aside to allow access to the head- lamp mounting fasteners.

3. Remove the three nuts and one bolt mounting the headlamp assembly (see above illustration).

4. Pull the headlamp assembly evenly away from the front of the vehicle to access the bulb sockets.

5. Rotate the socket counter-clockwise and pull it out of the headlamp assembly. Do not shake the bulb socket when remov- ing it.

6. Pull the bulb out of the socket. 7. Follow the instructions in reverse order to

install new bulb.

Do-it-yourself

8-29

Z X

Headlamp mounting nuts and bolt torque: 36 to 47 in-lb (4.1 to 5.3 Nzm) FOG LIGHTS Replacing the fog light bulb

8-30 Do-it-yourself

WDI0003

Z X

EXTERIOR AND INTERIOR LIGHTS

Item

Wattage (W)

Bulb No.

Headlamp assembly

High/Low Front turn signal Parking and cornering Side marker

Front fog light Rear combination light:

Turn signal: Stop/Tail

Back-up License plate light High-mounted stop light

inside spoiler (if so equipped)

Interior light Map light Trunk light Glove box light (if so equipped)

65/55

30

27/8

3.8

37.527

27/8

1818

See an authorized NISSAN dealer for assistance 10

3.4

1.1HB5 (9007) 3457AK 3157K 194

881L3156K 3157K 921

168921

68

578

158

658Do-it-yourself

8-31

Z X

8-32 Do-it-yourself

ADI1049

Replacement procedures All other lights are either type A, B, C or D. When replacing a bulb, first remove the lens and/or cover.

WDI0052

Z X

WDI0008

Do-it-yourself

8-33

Z X

8-34 Do-it-yourself

WDI0007

Z X

WHEELS AND TIRES

DI1033M

If you have a flat tire, see the ‘‘In case of emergency’’ section of this manual. TIRE PRESSURE Maximum inflation pressure Do not exceed the maximum inflation pres- sures shown on the side wall of the tire. Tire inflation pressure Periodically check the tire pressure (including the spare). tire pressure may ad- versely affect tire life and vehicle handling. Tire pressure should be checked when tires are COLD. Tires are considered COLD after the vehicle has been parked for three or more

Incorrect

hours, or driven less than 1 mile (1.6 km). COLD tire pressures are shown on the tire placard affixed to the driver’s door center pillar.

WARNING

c Improperly inflated tires can fail sud-

denly and cause an accident.

c The vehicle weight capacity is indi- cated on the tire placard. Do not load your vehicle beyond this capacity. Overloading your vehicle may result in reduced tire life, unsafe operating conditions due to premature tire fail- ure, or unfavorable handling charac- teristics and could also lead to a seri- ous accident. Loading beyond the specified capacity may also result in failure of other vehicle components.

c Before taking a long trip, or when- ever you heavily load your vehicle, use a tire pressure gauge to ensure that the tire pressures are at the specified level.

c Do not drive your vehicle over 85

MPH (140 km/h) unless it is equipped with high speed rated tires. Driving faster than 85 MPH (140 km/h) may result in tire failure, loss of control and possible injury.TYPES OF TIRES

WARNING

When changing or replacing tires, be sure all four tires are of the same type (i.e., summer, all season or snow) and construction. An authorized NISSAN dealer may be able to help you with information about tire type, size, speed rating and availability. Replacement tires may have a lower speed rating than the factory equipped tires, and may not match the potential maximum vehicle speed. Never exceed the maxi- mum speed rating of the tire.

All Season tires NISSAN specifies All Season tires on some models to provide good performance for use all year around, including snowy and icy road conditions. All Season Tires are iden- tified by ALL SEASON and/or M&S on the tire sidewall. Snow tires have better snow traction than All Season tires and may be more appropriate in some areas.

Do-it-yourself

8-35

Z X

Summer tires NISSAN specifies summer tires on some models to provide superior performance on dry roads. Summer tire performance in snow and ice is substantially reduced. Sum- mer tires do not have the tire traction rating M&S on the tire sidewall. If you plan to operate your vehicle in snowy or icy conditions, NISSAN recommends the use of SNOW or ALL SEASON tires on all four wheels. Snow tires If snow tires are needed, it is necessary to select tires equivalent in size and load rating to the original equipment tires. If you do not, it can adversely affect the safety and han- dling of your vehicle. Generally, snow tires have lower speed ratings than factory equipped tires and may not match the potential maximum vehicle speed. Never exceed the maximum speed rating of the tire. For additional traction on icy roads, studded tires may be used. However, some U.S States and Canadian Provinces prohibit their use. Check local, state and provincial 8-36 Do-it-yourself

laws before installing studded tires. Skid and traction capabilities of studded snow tires on wet or dry surfaces may be poorer than that of non-studded snow tires. TIRE CHAINS Use of tire chains may be prohibited accord- ing to location. Check the local laws before installing tire chains. When installing tire chains, make sure they are of proper size for the tires on your vehicle and are installed according to the chain manufacturer’s sug- gestions. Use only SAE class ‘‘S’’ chains. Other types may damage your vehicle. Use chain tensioners when recommended by the tire chain manufacturer to ensure a tight fit. Loose end links of the tire chain must be secured or removed to prevent the possibil- ity of whipping action damage to the fenders or underbody. If possible, avoid fully loading your vehicle when using tire chains. In ad- dition, drive at a reduced speed. Otherwise, your vehicle may be damaged and/or ve- hicle handling and performance may be adversely affected. Never install tire chains on TEMPORARY USE ONLY spare tires. Do not use tire chains on dry roads.

ADI1115

Tire chains must be installed only on the front wheels and not on the rear wheels. CHANGING TIRES AND WHEELS Tire rotation Tires should be rotated every 7,500 miles (12,000 km). See ‘‘Flat tire’’ in the ‘‘In case of emergency’’ section for tire replacing procedures. As soon as possible, tighten the wheel nuts to the specified torque with a nut tightening torque:

72 to 87 ft-lb (98 to 118 Nzm)

Z X

The wheel nuts must be kept tightened to specifications at all times. It is recom- mended that wheel nuts be tightened to specification at each rotation interval.

WARNING

c After rotating the tires, check and

adjust the tire pressure.

c Retighten the wheel nuts when the vehicle has been driven for 600 miles (1,000 km) (also in cases of a flat tire, etc.).

c Do not include the spare tire in the

tire rotation.

DI1035M

Tire wear and damage

WARNING

c Tires should be periodically in- spected for wear, cracking, bulging, or objects caught in the tread. If excessive wear, cracks, bulging, or deep cuts are found, the tire(s) should be replaced.

c The original

tires have a built-in tread wear indicator. When the wear indicator is visible, the tire(s) should be replaced.

c Improper service of the spare tire may result in serious personal in- jury. If it is necessary to repair the spare tire, contact an authorized NISSAN dealer.

Replacing wheels and tires When replacing a tire, use the same size, tread design, speed rating and load carrying capacity as originally equipped. Recom- mended types and sizes are shown in ‘‘wheels/tire size’’ in the ‘‘Technical and con- sumer information’’ section of this manual.

WARNING

c The use of tires other than those rec- ommended, or the mixed use of tires of different brands, construction (bias, bias-belted, radial), or tread patterns can adversely affect the ride, braking, handling, ground clearance, body-to- tire clearance, tire chain clearance, speedometer calibration, headlight aim and bumper height. Some of these effects may lead to accidents and could result in serious personal injury.

Do-it-yourself

8-37

Z X

handling

c If the wheels are changed for any rea- son, always replace with wheels which have the same off-set dimension. Wheels of a different off-set could cause pre-mature tire wear, degrade vehicle characteristics and/or interference with the brake discs/drums. Such interference can lead to decreased braking efficiency and/or early brake pad/shoe wear. Re- fer to ‘‘Wheel/tire size’’ in the ‘‘Techni- cal and consumer information’’ sec- tion of this manual for wheel off-set dimensions.

c Do not install a deformed wheel or tire even if it has been repaired. Such wheels or tires could have unknown structural damage and could fail without warning.

c The use of retread tires is not recom-

mended.

Wheel balance Unbalanced wheels may affect vehicle han- dling and tire life. Even with regular use, wheels can get out of balance. Therefore, they should be balanced as required. 8-38 Do-it-yourself

Wheel balance service should be per- formed with the wheels off the vehicle. Spin balancing the front wheels on the vehicle could lead to transmission damage. Care of wheels c Wash the wheels when washing the ve-

hicle to maintain their appearance.

c Clean the inner side of the wheels when the wheel is changed or the underside of the vehicle is washed.

c Do not use abrasive cleaners when

washing the wheels.

c Inspect wheel rims regularly for dents or corrosion. Such damage may cause loss of pressure or poor seal at the tire bead. c NISSAN recommends waxing the road in

wheels to protect against road salt areas where it is used during winter.

Spare tire (TEMPORARY USE ONLY spare tire) Observe the following precautions if the TEMPORARY USE ONLY spare tire must be used, otherwise your vehicle could be damaged or involved in an accident:

WARNING

c The spare tire should be used for emergency use only. It should be replaced with the standard tire at the first opportunity to avoid possible tire or differential damage.

c Drive carefully while the TEMPO- RARY USE ONLY spare tire is in- stalled. Avoid sharp turns and abrupt braking while driving.

c Periodically check spare tire infla- tion pressure. Always keep the pres- sure of the TEMPORARY USE ONLY spare tire at 60 psi (420 kPa, 4.2 bar). c With the TEMPORARY USE ONLY spare tire installed do not drive the vehicle at speeds faster than 50 MPH (80 km/h).

c When driving on roads covered with snow or ice, the TEMPORARY USE ONLY spare tire should be used on the rear wheels and the original tire used on the front wheels (drive wheels). Use tire chains only on the front (original) tires.

Z X

c Tire tread of the TEMPORARY USE ONLY spare tire will wear at a faster rate than the standard tire. Replace the spare tire as soon as the tread wear indicators appear.

c Do not use the spare tire on other

vehicles.

c Do not use more than one spare tire

at the same time.

c Do not tow a trailer when the TEM- PORARY USE ONLY spare tire is installed.

CAUTION

c Do not use tire chains on the TEM- PORARY USE ONLY spare tire. Tire chains will not fit properly and may cause damage to the vehicle.

c Because the TEMPORARY USE ONLY spare tire is smaller than the original tire, ground clearance is re- duced. To avoid damage to the ve- hicle, do not drive over obstacles. Also, do not drive the vehicle through an automatic car wash since it may get caught.

Do-it-yourself

8-39

Z X

MEMO

8-40 Do-it-yourself

Z X

9 Maintenance

Maintenance precautions .......................................9-2

General maintenance.............................................9-2

Explanation of maintenance items ....................9-2

Exterior maintenance.........................................9-2

Interior maintenance..........................................9-3Periodic maintenance schedules ...........................9-5

Schedule 1 ........................................................9-5

Schedule 2 ........................................................9-5

Explanation of maintenance items ..................9-10Z X

MAINTENANCE PRECAUTIONS

Your new NISSAN has been designed to have minimum maintenance requirements with longer service intervals to save you both time and money. However, some day- to-day and regular maintenance is essential to maintain your NISSAN’s good mechani- cal condition, as well as its emission and engine performance. It is the owner’s responsibility to make sure the specified periodic maintenance, as well as general maintenance, is performed. As the vehicle owner, you are the only one who can ensure that your vehicle receives proper maintenance. You are a vital link in the maintenance chain. General maintenance General maintenance includes those items which should be checked during normal day-to-day operation of the vehicle. They are essential if your vehicle is to continue to operate properly. It is your responsibility to perform these maintenance procedures regularly as prescribed. These checks or inspections can be done by yourself, a qualified technician or, if you prefer, an authorized NISSAN dealer. 9-2 Maintenance

Periodic maintenance The maintenance items listed under peri- odic maintenance are required to be ser- viced at regular intervals. However, under severe driving conditions, additional or more frequent maintenance is required. Where to go for service If maintenance service is required or your vehicle appears to malfunction, have the systems checked and tuned by an autho- rized NISSAN dealer. NISSAN technicians are well-trained spe- cialists who are kept up-to-date with the latest service information through technical bulletins, service tips, and in-dealership training programs. They are completely qualified to work on NISSAN vehicles be- fore they work on your vehicle, rather than after they have worked on it. You can be confident that an authorized NISSAN dealer’s service department per- forms the best job to meet the maintenance requirements on your vehicle — in a reliable and economic way.

GENERAL MAINTENANCE

During the normal day-to-day operation of the vehicle, general maintenance should be performed regularly as prescribed in this section. If you detect any unusual sounds, vibrations or smells, be sure to check for the cause or have an authorized NISSAN dealer do it promptly. In addition, you should notify an authorized NISSAN dealer if you think repairs are required. When performing any checks or mainte- nance work, closely observe the precau- tions in the ‘‘Do-it-yourself’’ section of this manual. EXPLANATION OF MAINTENANCE ITEMS Additional information on the items marked with an ‘‘*’’ can be found in the ‘‘Do-it-yourself’’ section of this manual. EXTERIOR MAINTENANCE Outside the vehicle The maintenance items listed here should be performed from time to time, unless otherwise specified. Tires* — Check the pressure with a gauge periodically when at a service station, in-

Z X

cluding the spare, and adjust to the speci- fied pressure if necessary. Check carefully for damage, cuts or excessive wear. Wheel nuts* — When checking the tires, make sure no wheel nuts are missing, and check for any loose wheel nuts. Tighten if necessary. Tire rotation* — Tires should be rotated every 7,500 miles (12,000 km). Wheel alignment and balance — If the vehicle should pull to either side while driv- ing on a straight and level road, or if you detect uneven or abnormal tire wear, there may be a need for a wheel alignment. If the steering wheel or seat vibrates at normal highway speeds, wheel balancing may be needed. Windshield wiper blades* — Check for cracks or wear if they do not wipe properly. Doors and engine hood — Check that all doors and the hood operate properly. Also ensure all latches lock securely. Lubricate hinges, latches, rollers and links if neces- sary. Make sure the secondary latch keeps the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrication frequently. Lights* — Make sure the headlights, stop lights, tail lights, turn signal lights, and other lights are all operating properly and installed securely. Also check headlight aim. INTERIOR MAINTENANCE The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle, etc. Additional information on the following items with an ‘‘*’’ is found in the ‘‘Do-it- yourself’’ section of this manual. Warning lights and chimes — Make sure all warning lights and buzzers/chimes are operating properly. Windshield wiper and washer* — Check that the wipers and washer operate properly and that the wipers do not streak. Windshield defroster — Check that the air comes out of the defroster outlets properly and in sufficient quantity when operating the heater or air conditioner.

Steering wheel — Check for changes in the steering conditions, such as excessive freeplay, hard steering or strange noises. Seats — Check seat position controls such as seat adjusters, seatback recliner, etc. to ensure they operate smoothly and all latches lock securely in every position. Check that the head restraints move up and down smoothly and the locks (if so equipped) hold securely in all latched posi- tions. Seat belts — Check that all parts of the seat belt system (for example, buckles, anchors, adjusters and retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for cuts, fraying, wear or damage. Accelerator pedal — Check the pedal for smooth operation and make sure the pedal does not catch or require uneven effort. Keep the floor mat away from the pedal. Clutch pedal* — Make sure the pedal operates smoothly and check that it has the proper free travel. Brakes — Check that the brakes do not pull the vehicle to one side when applied.

Maintenance 9-3

Z X

Brake pedal and booster* — Check the pedal for smooth operation and make sure it has the proper distance under it when de- pressed fully. Check the brake booster func- tion. Be certain to keep the floor mat away from the pedal. Parking brake* — Check that the lever has the proper travel and confirm that your vehicle is held securely on a fairly steep hill with only the parking brake applied. Automatic transmission P position mechanism — On a fairly steep hill check that your vehicle is held securely with the shift selector lever in the P (Park) position without applying any brakes. Under the hood and vehicle The maintenance items listed here should be checked periodically, such as each time you check the engine oil or refuel. Additional information on the items marked with an “*” can be found in the “Do-it-yourself’’ section of this manual. Windshield washer fluid* — Check that there is adequate fluid in the tank. Engine oil level* — Check the level after parking the vehicle on a level surface, with 9-4 Maintenance

the engine off. Wait a few minutes for the oil to drain back into the oil pan. Brake and (if so equipped) clutch fluid levels* — Make sure that the brake and clutch fluid level are between the MIN and MAX lines on each reservoir. Power steering fluid level* and lines — Check the level when the fluid is cold and with the engine off. Check the lines for proper attachment, leaks, cracks, etc. Automatic transmission fluid level* — Check the level after putting the shift selec- tor lever in P (Park) with the engine idling at operating temperature. Engine coolant level* — Check the cool- ant level when the engine is cold. Radiator and hoses — Check the front of the radiator and clean off any dirt, insects, leaves, etc., that may have accumulated. Make sure the hoses have no cracks, de- formation, rot or loose connections. Engine drive belts* — Make sure the drive belts are not frayed, worn, cracked or oily. Battery* — Check the fluid level in each cell. It should be between the MAX and MIN lines.

Exhaust system — Make sure there are no cracks, holes, loose joints or supports. If the sound of the exhaust seems unusual or there is a smell of exhaust fumes, immedi- ately have the exhaust system inspected by a qualified individual. (See the carbon mon- oxide warning in the ‘‘Starting and driving’’ section of this manual.) Underbody — The underbody is frequently exposed to corrosive substances such as those used on icy roads or to control dust. It is very important to remove these sub- stances from the underbody, otherwise rust frame, may form on the floor pan, fuel linesand exhaust system. At the end of winter, the underbody should be thoroughly flushed with plain water, especially those areas where mud and dirt may accumulate. See the ‘‘Appearance and care’’ section for additional information. Fluid leaks — Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has been parked for a while. Water dripping from the air conditioner after use is normal. If you should notice any leaks or if gasoline fumes are evident, check for the cause and have it corrected immediately by an authorized NISSAN dealer.

Z X

PERIODIC MAINTENANCE SCHEDULES

To ensure smooth, trouble-free, safe and economical driving, NISSAN provides two periodic maintenance schedules that may be used, depending upon the conditions in which you usually drive. These schedules contain both distance and time intervals, up to 60,000 miles (96,000 km)/48 months. For most people, the odometer reading indi- cates when service is needed. However, if you drive very little, your vehicle should be serviced at the regular time intervals shown in the schedules. After 60,000 miles (96,000 km)/48 months, continue peri- odic maintenance same mileage/time intervals. SCHEDULE 1

Follow Periodic Maintenance Schedule 1 if your driving habits frequently include one or more of the following driving conditions: c Repeated short trips of less than 5the

at

miles (8 km).

c Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

c Driving in dusty conditions. c Driving on rough, muddy, or salt

spread roads.

c Towing a trailer, using a camper or a

car-top carrier. SCHEDULE 2

Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown in Schedule 1 apply to your driving habits.c Repeated short trips of less than 10

miles (16 km) with outside tempera- tures below freezing.c Operating the vehicle in hot weather during in stop-and-go ‘‘rush hour’’ traffic.

Maintenance 9-5

Z X

Schedule 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary.MAINTENANCE OPERATION

Perform at number of miles, kilometers or months, whichever comes first.

Miles x 1,000

(km x 1,000) Months3.75

(6)7.5 11.25

(12) (18)Emission control system maintenance Drive belts Air cleaner filter EVAP vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter Spark plugs (Use PLATINUM-TIPPED type) Intake & exhaust valve clearance

See NOTE (1) See NOTE (2)

See NOTE (3)* See NOTE (4)

See NOTE (5)*

MAINTENANCE INTERVAL

[ ]: At the mileage intervals only

15 18.75 22.5 26.25

(24) (42) 21

12(30) 15

(36) 18

30 33.75 37.5 41.25

(48) (66) 33

24(54) 27

(60) 30

[R] I* I*

45 48.75 52.5 56.25

(72) (90) 45

36(78) 39

(84) 42

60

(96) 48I* [R] I* I*

R*

Replace every 105,000 miles (169,000 km)

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required. (3) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event,

replace the filter.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months. (5) If valve noise increases, inspect valve clearance. * Maintenance items and intervals marked with an ‘‘*’’ are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

9-6 Maintenance

Z X

Schedule 1

Abbreviations: I = Inspect. Correct or replace if necessary.MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Miles x 1,000

(km x 1,000)

Months

7.5

(12)

15

(24)

12

22.5

(36)

18

30

(48)

24

37.5

(60)

30

45

(72)

36

52.5

(84)

42

60

(96)

48

Chassis and body maintenance

Brake lines & cables

Brake pads, rotors, drums & linings

Manual transmission oil & automatic transmission fluid

See NOTE (2)

Steering gear & linkage, axle & suspension parts

Tire rotation

Exhaust system

Drive shaft boots

See NOTE (3)

Supplemental front and side air bag system

See NOTE (1)

Automatic speed control device (ASCD) vacuum hoses

NOTE: (1) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the FMVSS certification label. (2) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect)

oil at every 30,000 miles (48,000 km) or 24 months.

(3) Refer to ‘‘Tire rotation’’ under the ‘‘General Maintenance’’ heading earlier in this section.

Maintenance 9-7

Z X

Schedule 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary.[ ]: At the mileage intervals only

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Emission control system maintenance Drive belts Air cleaner filter EVAP vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter Spark plugs (Use PLATINUM-TIPPED type) Intake & exhaust valve clearance

Miles x 1,000

(km x 1,000) Months