- 2011 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2005 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2006 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2004 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2013 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2009 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2008 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2012 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2010 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- 2007 Jeep Wrangler Owners Manuals

- Jeep Wrangler Owners Manuals

- Download PDF Manual

-

continuous speeds above 75 mph (120 km/h).

446 STARTING AND OPERATING Radial-Ply Tires

WARNING!

Combining radial ply tires with other types of tires on your vehicle will cause your vehicle to handle poorly. The instability could cause a collision. Al- ways use radial tires in sets of four. Never combine them with other types of tires.

Cuts and punctures in radial tires are repairable only in the tread area because of sidewall flexing. Consult your authorized dealer for radial tire repairs. Spare Tire Matching Original Equipped Tire And Wheel – If Equipped Your vehicle may be equivalent with a spare tire and wheel in look and function as the original equipment tire and wheel found on the front or rear axle of your vehicle. This spare tire may be used in the tire rotation for your

vehicle. If your vehicle has this option refer to an authorized tire dealer for the recommended tire rotation pattern. If your vehicle is not equipped with an original equip- ment tire and wheel as a spare, a non-matching tempo- rary emergency use spare may be equipped with your vehicle. Temporary use spares are engineered to be used only with your vehicle. Your vehicle may be equipped with one of the following types of non-matching tempo- rary use spares; compact, full size, or limited-use. Do not install more than one non-matching temporary use spare tire/wheel on the vehicle at any given time.

CAUTION!

Because of the reduced ground clearance, do not take your vehicle through an automatic car wash with a compact, full size or limited-use temporary spare installed. Damage to the vehicle may result.

Compact Spare Tire – If Equipped The compact spare is for temporary emergency use only. You can identify if your vehicle is equipped with a compact spare by looking at the spare tire description on the Tire and Loading Information Placard located on the driver’s side door opening or on the sidewall of the tire. Compact spare tire descriptions begin with the letter “T” or “S” preceding the size designation. Example: T145/ 80D18 103M. T, S = Temporary Spare Tire Since this tire has limited tread life the original equip- ment tire should be repaired (or replaced) and reinstalled on your vehicle at the first opportunity. Do not install a wheel cover or attempt to mount a conventional tire on the compact spare wheel, since the wheel is designed specifically for the compact spare tire. Do not install more than one compact spare tire and wheel on the vehicle at any given time

STARTING AND OPERATING 447

WARNING!

Compact spares are for temporary emergency use only. With these spares, do not drive more than 50 mph (80 km/h). Temporary use spares have limited tread life. When the tread is worn to the tread wear indicators, the temporary use spare tire needs to be replaced. Be sure to follow the warnings, which apply to your spare. Failure to do so could result in spare tire failure and loss of vehicle control.

Full Size Spare – If Equipped The full size spare is for temporary emergency use only. This tire may look like the original equipped tire on the front or rear axle of your vehicle, but it is not. This spare tire may have limited tread life. When the tread is worn to the tread wear indicators, the temporary use full size spare tire needs to be replaced. Since it is not the same as

448 STARTING AND OPERATING your original equipment tire, replace (or repair) the original equipment tire and reinstall on the vehicle at the first opportunity. Limited-Use Spare – If Equipped The limited-use spare tire is for temporary emergency use only. This tire is identified by a label located on the limited-use spare wheel. This label contains the driving limitations for this spare. This tire may look like the original equipped tire on the front or rear axle of your vehicle, but it is not. Installation of this limited-use spare tire affects vehicle handling. Since it is not the same as your original equipment tire, replace (or repair) the original equipment tire and reinstall on the vehicle at the first opportunity.

WARNING!

Limited-use spares are for emergency use only. In- stallation of this limited-use spare tire affects vehicle handling. With this tire, do not drive more than the speed listed on the limit-use spare wheel. Keep inflated to the cold tire inflation pressure listed on your Tire and Loading Information Placard located on the driver’s side door opening. Replace (or repair) the original equipment tire at the first opportunity and reinstall it on your vehicle. Failure to do so could result in loss of vehicle control.

Tire Spinning When stuck in mud, sand, snow, or ice conditions, do not spin your vehicle’s wheels above 30 mph (48 km/h).

WARNING!

Fast spinning tires can be dangerous. Forces gener- ated by excessive wheel speeds may cause tire dam- age or failure. A tire could explode and injure some- one. Do not spin your vehicle’s wheels faster than 30 mph (48 km/h) when you are stuck, and do not let anyone near a spinning wheel no matter what the speed.

Tread Wear Indicators Tread wear indicators are in the original equipment tires to help you in determining when your tires should be replaced.

STARTING AND OPERATING 449

1 — Worn Tire 2 — New Tire These indicators are molded into the bottom of the tread grooves. They will appear as bands when the tread depth becomes 1/16 in (2 mm). When the tread is worn to the tread wear indicators, the tire should be replaced.

450 STARTING AND OPERATING Life Of Tire The service life of a tire is dependent upon varying factors including but not limited to: • Driving style • Tire pressure • Distance driven

WARNING!

Tires and the spare tire should be replaced after six years, regardless of the remaining tread. Failure to follow this warning can result in sudden tire failure. You could lose control and have a collision resulting in serious injury or death.

Keep unmounted tires in a cool, dry place with as little exposure to light as possible. Protect tires from contact with oil, grease and gasoline.

Replacement Tires The tires on your new vehicle provide a balance of many characteristics. They should be inspected regularly for wear and correct cold tire inflation pressure. The manu- facturer strongly recommends that you use tires equiva- lent to the originals in size, quality and performance when replacement is needed (see the paragraph on tread wear indicators). Refer to the “Tire and Loading Infor- mation” placard for the size designation of your tire. The Load Index and Speed Symbol for your tire will be found on the original equipment tire sidewall. See the Tire Sizing Chart example found in the Tire Safety Informa- tion section of this manual for more information relating to the Load Index and Speed Symbol of a tire. It is recommended to replace the two front tires or two rear tires as a pair. Replacing just one tire can seriously affect your vehicle’s handling. If you ever replace a wheel, make sure that the wheel’s specifications match those of the original wheels.

It is recommended you contact your original equipment or an authorized tire dealer with any questions you may have on tire specifications or capability. Failure to use equivalent replacement tires may adversely affect the safety, handling, and ride of your vehicle.

WARNING!

• Do not use a tire, wheel size or rating other than that specified for your vehicle. Some combinations of unapproved tires and wheels may change sus- pension dimensions and performance characteris- tics, resulting in changes to steering, handling, and braking of your vehicle. This can cause unpredict- able handling and stress to steering and suspen- sion components. You could lose control and have a collision resulting in serious injury or death. Use only the tire and wheel sizes with load ratings approved for your vehicle.

(Continued)

STARTING AND OPERATING 451

WARNING! (Continued)

• Never use a tire with a smaller load index or capacity, other than what was originally equipped on your vehicle. Using a tire with a smaller load index could result in tire overloading and failure. You could lose control and have a collision. • Failure to equip your vehicle with tires having adequate speed capability can result in sudden tire failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different size may result in false speedometer and odometer read- ings.

452 STARTING AND OPERATING TIRE CHAINS Tire chains may be installed on all models except the Sahara and Rubicon. Install chains on rear tires only. Follow these recommendations to guard against damage and excessive tire and chain wear: • Use chains on P225/75R16 rear tires only. P255/75R17, P255/70R18, and LT255/75R17 tires do not provide adequate clearance. • Use SAE class “S” tire chains or traction devices only.

CAUTION!

To avoid damage to your vehicle or tires, observe the following precautions:

(Continued)

CAUTION! (Continued)

• Because of restricted chain clearance between tires and other suspension components, it is important that only chains in good condition are used. Bro- ken chains can cause serious damage. Stop the vehicle immediately if noise occurs that could indicate chain breakage. Remove the damaged parts of the chain before further use. • Install chains on the rear wheels as tightly as possible and then retighten after driving about 1⁄2

mile (0.8 km).• Do not exceed 30 mph (48 km/h). • Drive cautiously and avoid severe turns and large • Do not drive for prolonged period on dry pave-

bumps, especially with a loaded vehicle.

ment.

(Continued)

CAUTION! (Continued)

• Observe the tire chain manufacturer’s instructions on the method of installation, operating speed, and conditions for use. Always use the lower suggested operating speed of the chain manufac- turer if different from the speed recommended by the manufacture.

In order to avoid damage to tires, chains, and NOTE: your vehicle do not drive for a prolonged period on dry pavement. Observe the tire chain manufacturer’s instruc- tions on method of installation, operating speed, and conditions for usage. Always use the lower suggested operating speed if both the chain manufacturer and vehicle manufacturer sug- gest a maximum speed. This notice applies to all chain traction devices, including link and cable (radial) chains.

STARTING AND OPERATING 453

TIRE ROTATION RECOMMENDATIONS The tires on the front and rear of your vehicle operate at different loads and perform different steering, handling, and braking functions. For these reasons, they wear at unequal rates. These effects can be reduced by timely rotation of tires. The benefits of rotation are especially worthwhile with aggressive tread designs such as those on On/Off Road type tires. Rotation will increase tread life, help to main- tain mud, snow, and wet traction levels, and contribute to a smooth, quiet ride. Refer to the “Maintenance Schedule” for the proper maintenance intervals. More frequent rotation is permis- sible if desired. The reasons for any rapid or unusual wear should be corrected prior to rotation being per- formed.

454 STARTING AND OPERATING The suggested rotation method is the “forward-cross” shown in the following diagram.

Tire Rotation

TIRE PRESSURE MONITOR SYSTEM (TPMS) The Tire Pressure Monitoring System (TPMS) will warn the driver of a low tire pressure based on the vehicle recommended cold placard pressure. The tire pressure will vary with temperature by about 1 psi (6.9 kPa) for every 12°F (6.5°C). This means that when the outside temperature decreases, the tire pressure will decrease. Tire pressure should always be set based on cold inflation tire pressure. This is defined as the tire pressure after a vehicle has not been driven for more than three hours, or driven less than 1 mile (1.6 km) after a three-hour period. Refer to “Tires – General Informa- tion” in “Starting and Operating” for information on how to properly inflate the vehicle’s tires. The tire pressure will also increase as the vehicle is driven; this is normal and there should be no adjustment for this increased pressure.

The TPMS will warn the driver of a low tire pressure if the tire pressure falls below the low pressure warning threshold for any reason, including low temperature effects, or natural pressure loss through the tire. The TPMS will continue to warn the driver of low tire pressure as long as the condition exists, and will not turn off until the tire pressure is at or above recommended cold placard pressure. Once the “Tire Pressure Monitor- ing Telltale Light” has been illuminated, the tire pressure must be increased to the recommended cold placard pressure in order for the “Tire Pressure Monitoring Telltale Light” to be turned OFF. The system will auto- matically update and the “Tire Pressure Monitoring Telltale Light” will extinguish once the updated tire pressures have been received. The vehicle may need to be driven for up to 20 minutes above 15 mph (24 km/h) to receive this information.

STARTING AND OPERATING 455

For example, your vehicle may have a recommended cold (parked for more than three hours) air pressure of 35 psi (241 kPa). If the ambient temperature is 68°F (20°C) and the measured tire pressure is 30 psi (207 kPa), a temperature drop to 20°F (-7°C) will decrease the tire pressure to approximately 26 psi (179 kPa). This tire pressure is sufficiently low enough to turn ON the “Tire Pressure Monitoring Telltale Light.” Driving the vehicle may cause the tire pressure to rise to approximately 30 psi (207 kPa), but the “Tire Pressure Monitoring Telltale Light” will still be ON. In this situation, the “Tire Pressure Monitoring Telltale Light” will turn OFF only after the tires have been inflated to the vehicle’s recom- mended cold placard pressure value.456 STARTING AND OPERATING

CAUTION!

• The TPMS has been optimized for the original equipment tires and wheels. The TPMS pressures have been established for the tire size equipped on your vehicle. Undesirable system operation or sensor damage may result when using replace- ment equipment that is not of the same size, type, and/or style. Aftermarket wheels can cause sensor damage. Do not use aftermarket tire sealants or balance beads if your vehicle is equipped with a TPMS, as damage to the sensors may result. • After inspecting or adjusting the tire pressure, always reinstall the valve stem cap. This will prevent moisture and dirt from entering the valve stem, which could damage the Tire Pressure Moni- toring Sensor.

while adjusting your tire pressure.

NOTE: • The TPMS is not intended to replace normal tire care and maintenance, nor to provide warning of a tire failure or condition. • The TPMS should not be used as a tire pressure gauge • Driving on a significantly under-inflated tire causes the tire to overheat and can lead to tire failure. Under-inflation also reduces fuel efficiency and tire tread life, and may affect the vehicle’s handling and stopping ability. • The TPMS is not a substitute for proper tire mainte- nance, and it is the driver’s responsibility to maintain correct tire pressure, even if under-inflation has not reached the level to trigger illumination of the “Tire Pressure Monitoring Telltale Light.”

• Seasonal temperature changes will affect tire pressure, and the TPMS will monitor the actual tire pressure in the tire.

Base System The Tire Pressure Monitor System (TPMS) uses wireless technology with wheel rim-mounted electronic sensors to monitor tire pressure levels. Sensors, mounted to each wheel as part of the valve stem, transmit tire pressure readings to the Receiver Module. It is particularly important for you to check the NOTE: tire pressure in all of your tires regularly and to maintain the proper pressure. The Tire Pressure Monitor System (TPMS) consists of the following components: • Receiver Module • Four Tire Pressure Monitoring Sensors

STARTING AND OPERATING 457

• Tire Pressure Monitoring Telltale Light A tire pressure monitoring sensor is located in the spare wheel if the vehicle is equipped with a matching full size spare wheel and tire assembly. The matching full size spare tire can be used in place of any of the four road tires. A low spare tire will not cause the “Tire Pressure Monitoring Telltale Light” to illuminate or the chime to sound.

The “Tire Pressure Monitoring Telltale Light” will illuminate in the instrument cluster,, a “LOW TIRE PRESSURE” message will display in the EVIC, and an audible chime will be activated when one or more of the four active road tire pressures are low. Should this occur, you should stop as soon as possible, check the inflation pressure of each tire on your vehicle, and inflate each tire to the vehicle’s recommended cold placard pressure value. The system will automatically update and the “Tire Pressure Monitoring Telltale Light” will

458 STARTING AND OPERATING extinguish once the updated tire pressures have been received. The vehicle may need to be driven for up to 20 minutes above 15 mph (24 km/h) to receive this information. The “Tire Pressure Monitoring Telltale Light” will flash on and off for 75 seconds, and will remain on solid when a system fault is detected. The system fault will also sound a chime. If the ignition key is cycled, this sequence will repeat, providing the system fault still exists. A system fault can occur by any of the following scenarios: 1. Jamming due to electronic devices or driving next to facilities emitting the same Radio Frequencies as the TPM sensors. 2. Installing some form of aftermarket window tinting that affects radio wave signals. 3. Lots of snow or ice around the wheels or wheel housings.

4. Using tire chains on the vehicle. 5. Using wheels/tires not equipped with TPM sensors. NOTE: • If your vehicle is equipped with a matching full-size spare wheel and tire assembly, it has a tire pressure monitoring sensor, and can be monitored by the Tire Pressure Monitoring System (TPMS). In the event that the matching full-size spare tire is swapped with a low pressure road tire, the next ignition key cycle will still show the “Tire Pressure Monitoring Telltale Light” to be ON, and a chime to sound. Driving the vehicle for up to 20 minutes above 15 mph (24 km/h) will turn OFF the “Tire Pressure Monitoring Telltale Light” as long as none of the road tires are below the low pressure warning threshold. • If your vehicle is not equipped with a matching full-size spare wheel and tire assembly, it does not have a tire pressure monitoring sensor in the spare tire.

The TPMS will not be able to monitor the tire pressure. If you install the spare tire in place of a road tire that has a pressure below the low-pressure warning limit, upon the next ignition key cycle, a chime will sound and the “Tire Pressure Monitoring Telltale Light” will turn ON. After driving the vehicle for up to 20 minutes above 15 mph (24 km/h), the “Tire Pressure Monitor- ing Telltale Light” will flash on and off for 75 seconds and then remain on solid. For each subsequent ignition key cycle, a chime will sound and the “Tire Pressure Monitoring Telltale Light” will flash on and off for 75 seconds and then remain on solid. Once you repair or replace the original road tire, and reinstall it on the vehicle in place of the spare tire, the TPMS will update automatically and the “Tire Pressure Monitoring Tell- tale Light” will turn OFF, as long as no tire pressure is below the low-pressure warning limit in any of the four active road tires. The vehicle may need to be

STARTING AND OPERATING 459

driven for up to 20 minutes above 15 mph (24 km/h) in order for the TPMS to receive this information.General Information This device complies with part 15 of the FCC rules and RSS 210 of Industry Canada. Operation is subject to the following conditions: • This device may not cause harmful interference. • This device must accept any interference received, including interference that may cause undesired operation.

The tire pressure sensors are covered under one of the following licenses:

United States . . . . . . . . . . . . . . . . . . . MRXC4N3MF9

Canada . . . . . . . . . . . . . . . . . . . . . . 2546A-C4N3MF9460 STARTING AND OPERATING FUEL REQUIREMENTS

All engines are designed to meet all emis- sions regulations and provide excellent fuel economy and performance when us- ing high quality unleaded “regular” gaso- line having an octane rating of 87. The use of premium gasoline is not recommended, as it will not provide any benefit over regular gasoline in these engines. Light spark knock at low engine speeds is not harmful to your engine. However, continued heavy spark knock at high speeds can cause damage, and immediate service is required. Poor quality gasoline can cause problems such as hard starting, stalling and hesitations. If you experience these symptoms, try another brand of gasoline before consid- ering service for the vehicle.

Over 40 auto manufacturer’s worldwide have issued and endorsed consistent gasoline specifications (the World- wide Fuel Charter, WWFC) to define fuel properties necessary to deliver enhanced emissions, performance, and durability for your vehicle. The manufacturer recom- mends the use of gasoline that meets the WWFC speci- fications if they are available. Reformulated Gasoline Many areas of the country require the use of cleaner burning gasoline referred to as “Reformulated Gasoline.” Reformulated gasoline contains oxygenates, and are spe- cifically blended to reduce vehicle emissions and im- prove air quality. The manufacturer supports the use of reformulated gaso- line. Properly blended reformulated gasoline will pro- vide excellent performance and durability for the engine and fuel system components.

Gasoline/Oxygenate Blends Some fuel suppliers blend unleaded gasoline with oxy- genates such as Ethanol. Fuels blended with oxygenates may be used in your vehicle.

CAUTION!

DO NOT use gasoline containing Methanol or gaso- line containing more than 10% Ethanol. Use of these blends may result in starting and driveability prob- lems, damage critical fuel system components, cause emissions to exceed the applicable standard, and/or cause the “Malfunction Indicator Light” to illumi- nate. Pump labels should clearly communicate if a fuel contains greater than 10% Ethanol.

Problems that result from using gasoline containing Methanol or gasoline containing more than 10% Ethanol are not the responsibility of the manufacturer and may not be covered under warranty.

STARTING AND OPERATING 461

E-85 Usage In Non-Flex Fuel Vehicles Non-FFV vehicles are compatible with gasoline contain- ing 10% ethanol (E10). Gasoline with higher ethanol content may void the vehicle’s warranty. If a Non-FFV vehicle is inadvertently fueled with E-85

fuel, the engine will have some or all of these symptoms: • operate in a lean mode • OBD II “Malfunction Indicator Light” on • poor engine performance • poor cold start and cold drivability • increased risk for fuel system component corrosion To fix a Non-FFV vehicle inadvertently fueled once with E-85 perform the following: • drain the fuel tank (see your authorized dealer) • change the engine oil and oil filter462 STARTING AND OPERATING

• disconnect and reconnect the battery to reset the

engine controller memory

More extensive repairs will be required for prolonged exposure to E-85 fuel. MMT In Gasoline MMT is a manganese containing metallic additive that is blended into some gasoline to increase the octane num- ber. Gasoline blended with MMT offers no performance advantage beyond gasoline of the same octane number without MMT. Gasoline blended with MMT has shown to reduce sparkplug life and reduce emission system performance in some vehicles. The manufacturer recom- mends that gasoline without MMT be used in your vehicle. The MMT content of gasoline may not be indi- cated on the gasoline pump, therefore, you should ask your gasoline retailer if the gasoline contains MMT.

and California-

It is even more important to look for gasoline without MMT in Canada, because MMT can be used at levels higher than those allowed in the United States. MMT is prohibited in Federal reformulated gasoline. Materials Added To Fuel All gasoline sold in the United States is required to contain effective detergent additives. Use of additional detergents or other additives are not needed under normal conditions and would result in additional cost. Therefore you should not have to add anything to the fuel.

Fuel System Cautions

CAUTION!

Follow these guidelines to maintain your vehicle’s performance: • The use of leaded gasoline is prohibited by Fed- eral law. Using leaded gasoline can impair engine performance, and damage the emission control system. • An out-of-tune engine, or certain fuel or ignition malfunctions, can cause the catalytic converter to overheat. If you notice a pungent burning odor or some light smoke, your engine may be out of tune or malfunctioning and may require immediate service. Contact your authorized dealer for service assistance.

(Continued)

STARTING AND OPERATING 463

CAUTION! (Continued)

• The use of fuel additives which are now being sold as octane enhancers is not recommended. Most of these products contain high concentra- tions of methanol. Fuel system damage or vehicle performance problems resulting from the use of such fuels or additives is not the responsibility of the manufacturer.

NOTE: systems can result against you.

Intentional tampering with emissions control in civil penalties being assessed

464 STARTING AND OPERATING Carbon Monoxide Warnings

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly. Follow the precautions below to prevent carbon monoxide poisoning: • Do not inhale exhaust gases. They contain carbon monoxide, a colorless and odorless gas which can kill. Never run the engine in a closed area, such as a garage, and never sit in a parked vehicle with the engine running for an extended period. If the vehicle is stopped in an open area with the engine running for more than a short period, adjust the ventilation system to force fresh, outside air into the vehicle.

(Continued)

WARNING! (Continued)

• Guard against carbon monoxide with proper maintenance. Have the exhaust system inspected every time the vehicle is raised. Have any abnor- mal conditions repaired promptly. Until repaired, drive with all side windows fully open. • Keep the swing gate closed when driving your vehicle to prevent carbon monoxide and other poisonous exhaust gases from entering the vehicle.

ADDING FUEL

Fuel Filler Cap (Gas Cap) The gas cap is located on the driver’s side of the vehicle. If the gas cap is lost or damaged, be sure the replacement cap is the correct one for this vehicle.

STARTING AND OPERATING 465

CAUTION!

• Damage to the fuel system or emission control system could result from using an improper fuel cap (gas cap). A poorly fitting cap could let impu- rities into the fuel system. Also, a poorly fitting aftermarket cap can cause the “Malfunction Indi- cator Light (MIL)” to illuminate, due to fuel vapors escaping from the system. • To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

• Never have any smoking materials lit in or near the vehicle when the gas cap is removed or the tank is being filled.

Fuel Filler Cap

(Continued)

466 STARTING AND OPERATING

WARNING! (Continued)

• Never add fuel when the engine is running. This is in violation of most state and federal fire regula- tions and may cause the MIL to turn on. • A fire may result if gasoline is pumped into a portable container that is inside of a vehicle. You could be burned. Always place gas containers on the ground while filling.

tank is full.

NOTE: • When the fuel nozzle “clicks” or shuts off, the fuel • Tighten the gas cap about 1/4 turn until you hear one click. This is an indication that the cap is properly tightened. • If the gas cap is not tightened properly, the MIL will come on. Be sure the gas cap is tightened every time the vehicle is refueled.

Loose Fuel Filler Cap Message After fuel has been added, the vehicle diagnostic system can determine if the fuel filler cap is possibly loose, improperly installed, or damaged. If the system detects a malfunction, the “gASCAP” message will display in the odometer display. Tighten the gas cap until a ⬙clicking⬙ sound is heard. This is an indication that the gas cap is properly tightened. Press the odometer reset button to turn the message off. If the problem persists, the message will appear the next time the vehicle is started. This might indicate a damaged cap. If the problem is detected twice in a row, the system will turn on the MIL. Resolving the problem will turn the MIL off.

VEHICLE LOADING

Certification Label As required by National Highway Traffic Safety Admin- istration regulations, your vehicle has a certification label affixed to the driver’s side door or B-Pillar.

This label contains the month and year of manufacture, Gross Vehicle Weight Rating (GVWR), Gross Axle Weight Rating (GAWR) front and rear, and Vehicle Identification Number (VIN). A Month-Day-Hour (MDH) number is included on this label and indicates the month, day, and hour of manufacture. The bar code that appears on the bottom of the label is your VIN. Gross Vehicle Weight Rating (GVWR) The GVWR is the total permissible weight of your vehicle including driver, passengers, vehicle, options, trailer tongue weight, and cargo. The label also specifies maxi- mum capacities of front and rear axle systems (GAWR). Total load must be limited, so GVWR, and front and rear GAWR are not exceeded. Payload The payload of a vehicle is defined as the allowable load weight a truck or any given vehicle can carry, including the weight of the driver, all passengers, options and cargo.

STARTING AND OPERATING 467

Gross Axle Weight Rating (GAWR) The GAWR is the maximum permissible load on the front and rear axles. The load must be distributed in the cargo area so that the GAWR of each axle is not exceeded. Each axle’s GAWR is determined by the components in the system with the lowest load carrying capacity (axle, springs, tires, or wheels). Heavier axles or suspension components, sometimes specified by purchasers for in- creased durability, does not necessarily increase the ve- hicle’s GVWR. Tire Size The tire size on the label represents the actual tire size on your vehicle. Replacement tires must be equal to the load capacity of this tire size. Rim Size This is the rim size that is appropriate for the tire size listed.

468 STARTING AND OPERATING Inflation Pressure This is the cold tire inflation pressure for your vehicle for all loading conditions up to full GAWR. Curb Weight The curb weight of a vehicle is defined as the total weight of the vehicle with all fluids, including vehicle fuel, at full capacity conditions, and with no occupants or cargo loaded into the vehicle. The front and rear curb weight values are determined by weighing your vehicle on a commercial scale before any occupants or cargo are added. Loading The actual total weight and the weight of the front and rear of your vehicle at the ground can best be determined by weighing it when it is loaded and ready for operation.

The entire vehicle should first be weighed on a commer- cial scale to ensure that the GVWR has not been ex- ceeded. The weight on the front and rear of the vehicle should then be determined separately to be sure that the load is properly distributed over front and rear axle. Weighing the vehicle may show that the GAWR of either the front or rear axles has been exceeded, but the total load is within the specified GVWR. If so, weight must be shifted from front to rear, or rear to front, as appropriate until the specified weight limitations are met. Store the heavier items down low and be sure that the weight is distributed equally. Stow all loose items securely before driving. Improper weight distributions can have an adverse affect on the way your vehicle steers and handles, and the way the brakes operate.

CAUTION!

Do not load your vehicle any heavier than the GVWR or the maximum front and rear GAWR. If you do, parts on your vehicle can break, or it can change the way your vehicle handles. This could cause you to lose control. Also, overloading can shorten the life of your vehicle.

TRAILER TOWING In this section, you will find safety tips and information on limits to the type of towing you can reasonably do with your vehicle. Before towing a trailer, carefully review this information to tow your load as efficiently and safely as possible. To maintain warranty coverage, follow the requirements and recommendations in this Owner’s Manual concern- ing vehicles used for trailer towing.

STARTING AND OPERATING 469

Common Towing Definitions The following trailer towing-related definitions will as- sist you in understanding the following information: Gross Vehicle Weight Rating (GVWR) The GVWR is the total allowable weight of your vehicle. This includes driver, passengers, cargo and trailer tongue weight. The total load must be limited so that you do not exceed the GVWR. Refer to “Vehicle Loading/Vehicle Certification Label” in “Starting and Operating” for further information. Gross Trailer Weight (GTW) The GTW is the weight of the trailer plus the weight of all cargo, consumables and equipment (permanent or tem- porary) loaded in or on the trailer in its ⬙loaded and ready for operation⬙ condition. The recommended way to measure GTW is to put your fully-loaded trailer on a vehicle scale. The entire weight of the trailer must be supported by the scale.

470 STARTING AND OPERATING Gross Combination Weight Rating (GCWR) The GCWR is the total permissible weight of your vehicle and trailer when weighed in combination. NOTE: The GCWR rating includes a 150 lbs (68 kg) allowance for the presence of a driver. Gross Axle Weight Rating (GAWR) The GAWR is the maximum capacity of the front and rear axles. Distribute the load over the front and rear axles evenly. Make sure that you do not exceed either front or rear GAWR. Refer to “Vehicle Loading/Vehicle Certifica- tion Label” in “Starting and Operating” for further information.

WARNING!

It is important that you do not exceed the maximum front or rear GAWR. A dangerous driving condition can result if either rating is exceeded. You could lose control of the vehicle and have a collision.

Trailer Tongue Weight (TW) The trailer tongue weight is the downward force exerted on the hitch ball by the trailer. In most cases it should not be less than 10% or more than 15% of the trailer load. You must consider this as part of the load on your vehicle. Frontal Area The frontal area is the maximum height multiplied by the maximum width of the front of a trailer. Trailer Sway Control – If Equipped The trailer sway control is a telescoping link that can be installed between the hitch receiver and the trailer tongue. It typically provides adjustable friction associ- ated with the telescoping motion to dampen any un- wanted trailer swaying motions while traveling.

Weight-Carrying Hitch A weight-carrying hitch supports the trailer tongue weight, just as if it were luggage located at a hitch ball or some other connecting point of the vehicle. This kind of hitch is the most popular on the market today and is commonly used to tow small and medium-sized trailers. Weight-Distributing Hitch A weight-distributing hitch system works by applying leverage through spring (load) bars. It is typically used for heavier loads, to distribute trailer tongue weight to the tow vehicle’s front axle and the trailer axle(s). When used in accordance with the manufacturers’ directions, it provides for a more level ride, offering more consistent steering and brake control thereby enhancing towing safety. The addition of a friction/hydraulic sway control also dampens sway caused by traffic and crosswinds, and contributes positively to tow vehicle and trailer

STARTING AND OPERATING 471

stability. Trailer sway control and a weight-distributing (load-equalizing) hitch are recommended for heavier tongue weights (TW) and may be required depending on vehicle and trailer configuration/loading to comply with Gross Axle Weight Rating (GAWR) requirements.WARNING!

• An improperly adjusted weight-distributing hitch system may reduce handling, stability, braking performance, and could result in a collision. • Weight-Distributing Hitch Systems may not be compatible with Surge Brake Couplers. Consult with your hitch and trailer manufacturer or a reputable Recreational Vehicle dealer for addi- tional information.

472 STARTING AND OPERATING Trailer Hitch Classification The following chart provides the industry standard for the maximum trailer weight a given trailer hitch class can tow and should be used to assist you in selecting the correct trailer hitch for your intended towing condition. Refer to the Trailer Towing Weights (Maximum Trailer Weight Ratings) chart for the Max. GTW towable for your given drivetrain.

Trailer Hitch Classification Definitions

Class

Max. Trailer Hitch Industry

Standards

2,000 lbs (907 kg) 3,500 lbs (1 587 kg)

5,000 lbs (2 268 kg) 10,000 lbs (4 540 kg)

Class I - Light Duty Class II - Medium Duty Class III - Heavy Duty Class IV - Extra Heavy Duty Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” chart for the Maximum Gross Trailer Weight (GTW) towable for your given drivetrain. All trailer hitches should be professionally installed on your vehicle.

Trailer Towing Weights (Maximum Trailer Weight Ratings) The following chart provides the maximum trailer weight ratings towable for your given drivetrain.

STARTING AND OPERATING 473

Engine/ Trans- mission 3.6L/ Manual

3.6L/ Manual

3.6L/ Auto- matic 3.6L/ Manual

Axle

Model

GCWR (Gross Combined Wt.

Rating)

Frontal Area

Max. GTW (Gross Trailer

Wt.)

3.21

3.73

3.73

3.21

Two–Door Sport Model

(4WD)

Two–Door Sport Model

(4WD)

Two–Door Sport Model

(4WD)

Two–Door

Sahara Model

(4WD)

5,329 lbs (2 417 kg) 25 sq ft (2.32 sq m)

6,329 lbs (2 871 kg) 25 sq ft (2.32 sq m)

6,353 lbs (2 881 kg) 25 sq ft (2.32 sq m)

5,430 lbs (2 463 kg) 25 sq ft (2.32 sq m)

1,000 lbs (453 kg)

2,000 lbs (907 kg)

2,000 lbs (907 kg)

1,000 lbs (453 kg)

Max. Trailer Tongue Wt. (See Note)

100 lbs (45 kg)

200 lbs (91 kg)

200 lbs (91 kg)

100 lbs (45 kg)

474 STARTING AND OPERATING

Engine/ Trans- mission 3.6L/ Manual

3.6L/ Auto- matic 3.6L/ Manual

3.6L/ Auto- matic 3.6L/ Manual

Axle

Model

GCWR (Gross Combined Wt.

Rating)

Frontal Area

Max. GTW (Gross Trailer

Wt.)

3.73

3.73

4.10

4.10

3.21

Two–Door

Sahara Model

(4WD)

Two–Door

Sahara Model

(4WD)

2–Door Rubi- con Model

(4WD)

Two–Door Rubicon

Model (4WD)

Four–Door Sport Model

(4WD)

6,430 lbs (2 916 kg) 25 sq ft (2.32 sq m)

6,454 lbs (2 927 kg) 25 sq ft (2.32 sq m)

6,507 lbs (2 951 kg) 25 sq ft (2.32 sq m)

6,533 lbs (2 963 kg) 25 sq ft (2.32 sq m)

5,742 lbs (2 604 kg) 32 sq ft (2.97 sq m)

2,000 lbs (907 kg)

2,000 lbs (907 kg)

2,000 lbs (907 kg)

2,000 lbs (907 kg)

1,000 lbs (453 kg)

Max. Trailer Tongue Wt. (See Note)

200 lbs (91 kg)

200 lbs (91 kg)

200 lbs (91 kg)

200 lbs (91 kg)

100 lbs (45 kg)

Engine/ Trans- mission 3.6L/ Manual

3.6L/ Auto- matic 3.6L/ Manual

3.6L/ Manual

3.6L/ Auto- matic

Axle

Model

3.73

3.73

3.21

3.73

3.73

Four–Door SportModel

(4WD)

Four–Door Sport Model

(4WD)

Four–Door

Sahara Model

(4WD)

Four–Door

Sahara Model

(4WD)

Four–Door

Sahara Model

(4WD)

STARTING AND OPERATING 475

GCWR (Gross Combined Wt.

Rating)

Frontal Area

8,242 lbs (3 738 kg) 32 sq ft (2.97 sq m)

Max. GTW (Gross Trailer

Wt.)

3,500 lbs (1 587 kg)

8,257 lbs (3 745 kg) 32 sq ft (2.97 sq m)

5,782 lbs (2 623 kg) 32 sq ft (2.97 sq m)

8,282 lbs (3 757 kg) 32 sq ft (2.97 sq m)

8,297 lbs (3 763 kg) 32 sq ft (2.97 sq m)

3,500 lbs (1 587 kg)

1,000 lbs (453 kg)

3,500 lbs (1 587 kg)

3,500 lbs (1 587 kg)

Max. Trailer Tongue Wt. (See Note)

350 lbs (159 kg)

350 lbs (159 kg)

100 lbs (45 kg)

350 lbs (159 kg)

350 lbs (159 kg)

476 STARTING AND OPERATING

Engine/ Trans- mission 3.6L/ Manual

3.6L/ Auto- matic

Axle

Model

4.10

4.10

Four–Door Rubicon

Model (4WD)

Four–Door Rubicon

Model (4WD)

GCWR (Gross Combined Wt.

Rating)

Frontal Area

8,406 lbs (3 813 kg) 32 sq ft (2.97 sq m)

8,431 lbs (3 824 kg) 32 sq ft (2.97 sq m)

Max. GTW (Gross Trailer

Wt.)

3,500 lbs (1 587 kg)

3,500 lbs (1 587 kg)

Max. Trailer Tongue Wt. (See Note)

350 lbs (159 kg)

350 lbs (159 kg)

Refer to local laws for maximum trailer towing speeds. NOTE: The trailer tongue weight must be considered as part of the combined weight of occupants and cargo (ie. the GVWR), and the GVWR should never exceed the weight referenced on the Tire and Loading Infor- mation placard. Refer to “Tire Safety Information” in “Starting and Operating” for further information.

Trailer And Tongue Weight Always load a trailer with 60% to 65% of the weight in the front of the trailer. This places 10% to 15% of the Gross Trailer Weight (GTW) on the tow hitch of your vehicle. Loads balanced over the wheels or heavier in the rear can cause the trailer to sway severely side-to-side which will cause loss of control of vehicle and trailer. Failure to load trailers heavier in front is the cause of many trailer collisions.

STARTING AND OPERATING 477

Consider the following items when computing the weight on the rear axle of the vehicle: • The trailer tongue weight. • The weight of any other type of cargo or equipment • The weight of the driver and all passengers.

put in or on your vehicle.

478 STARTING AND OPERATING NOTE: Remember that everything put into or on the trailer adds to the load on your vehicle. Also, additional factory-installed options, or authorized dealer-installed options, must be considered as part of the total load on your vehicle. Refer to the “Tire Safety Information/Tire and Loading Information Placard” in “Starting and Op- erating” for the maximum combined weight of occupants and cargo for your vehicle. Towing Requirements To promote proper break-in of your new vehicle drive- train components, the following guidelines are recom- mended: NOTE: Trailer towing requires special rear axle lubri- cant. Refer to “Fluids, Lubricants, and Genuine Parts” in “Maintaining Your Vehicle” for the correct fluid type.

CAUTION!

• Do not tow a trailer at all during the first 500 miles (805 km) the new vehicle is driven. The engine, axle or other parts could be damaged. • Then, during the first 500 miles (805 km) that a trailer is towed, do not drive over 50 mph (80 km/h) and do not make starts at full throttle. This helps the engine and other parts of the vehicle wear in at the heavier loads.

WARNING!

Improper towing can lead to a collision. Follow these guidelines to make your trailer towing as safe as possible:

(Continued)

WARNING! (Continued)

• Make certain that the load is secured in the trailer and will not shift during travel. When trailering cargo that is not fully secured, dynamic load shifts can occur that may be difficult for the driver to control. You could lose control of your vehicle and have a collision. • When hauling cargo or towing a trailer, do not overload your vehicle or trailer. Overloading can cause a loss of control, poor performance or dam- age to the brakes, axle, engine, transmission, steer- ing, suspension, chassis structure or tires. • Safety chains must always be used between your vehicle and trailer. Always connect the chains to the frame or hook retainers of the vehicle hitch. Cross the chains under the trailer tongue and allow enough slack for turning corners.

(Continued)

STARTING AND OPERATING 479

WARNING! (Continued)

• Vehicles with trailers should not be parked on a grade. When parking, apply the parking brake on the tow vehicle. Put the tow vehicle automatic transmission in PARK. With a manual transmis- sion, shift the transmission into first gear. And with four-wheel-drive vehicles, make sure the transfer case is not in N (Neutral). Always, block or ⴖchockⴖ the trailer wheels. • GCWR must not be exceeded. • Total weight must be distributed between the tow vehicle and the trailer such that the following four ratings are not exceeded: 1. GVWR 2. GTW 3. GAWR

(Continued)

480 STARTING AND OPERATING

WARNING! (Continued)

4. Tongue weight rating for the trailer hitch utilized (This requirement may limit the ability to always achieve the 10% to 15% range of tongue weight as a percentage of total trailer weight).

Towing Requirements – Tires − Proper tire inflation pressures are essential to the safe and satisfactory operation of your vehicle. Refer to “Tires – General Information” in “Starting and Oper- ating” for proper tire inflation procedures.

− Check the trailer tires for proper tire inflation pres-

sures before trailer usage.

− Check for signs of tire wear or visible tire damage before towing a trailer. Refer to “Tires – General Information” in “Starting and Operating” for the proper inspection procedure.

− When replacing tires, refer to “Tires – General Infor- mation” in “Starting and Operating” for information on replacement tires and for proper tire replacement procedures. Replacing tires with a higher load carry- ing capacity will not increase the vehicle’s GVWR and GAWR limits.

Towing Requirements – Trailer Brakes − Do not interconnect the hydraulic brake system or vacuum system of your vehicle with that of the trailer. This could cause inadequate braking and possible personal injury.

− An electronically-actuated trailer brake controller is required when towing a trailer with electronically actuated brakes. When towing a trailer equipped with a hydraulic surge-actuated brake system, an electronic brake controller is not required.

− Trailer brakes are recommended for trailers over 1,000 lbs (454 kg) and required for trailers in excess of 2,000 lbs (907 kg).

CAUTION!

If the trailer weighs more than 1,000 lbs (454 kg) loaded, it should have its own brakes and they should be of adequate capacity. Failure to do this could lead to accelerated brake lining wear, higher brake pedal effort, and longer stopping distances.

STARTING AND OPERATING 481

WARNING!

• Do not connect trailer brakes to your vehicle’s hydraulic brake lines. It can overload your brake system and cause it to fail. You might not have brakes when you need them and could have an collision. • Towing any trailer will increase your stopping distance. When towing, you should allow for ad- ditional space between your vehicle and the ve- hicle in front of you. Failure to do so could result in a collision.

482 STARTING AND OPERATING Towing Requirements – Trailer Lights And Wiring Whenever you pull a trailer, regardless of the trailer size, stop lights and turn signals on the trailer are required for motoring safety. The Trailer Tow Package will include a four–pin wiring harness. Use a factory-approved trailer harness and connector. NOTE: Do not cut or splice wiring into the vehicles wiring harness. The electrical connections are all complete to the vehicle but you must mate the harness to a trailer connector. Refer to the following illustration.

1 — Female Pins 2 — Male Pin 3 — Ground

Four-Pin Connector 4 — Park 5 — Left Stop/Turn 6 — Right Stop/Turn

Towing Tips Before setting out on a trip, practice turning, stopping and backing the trailer in an area away from heavy traffic. If using a manual transmission vehicle for trailer towing, all starts must be in first gear to avoid excessive clutch slippage. Automatic Transmission – If Equipped The DRIVE range can be selected when towing. How- ever, if frequent shifting occurs while in this range, use the Electronic Range Select (ERS) shift control to select a lower gear range.

STARTING AND OPERATING 483

NOTE: Using a lower gear range while operating the vehicle under heavy operating conditions will improve performance and extend transmission life by reducing excessive shifting and heat build up. This action will also provide better engine braking. The automatic transmission fluid and filter should be changed if you REGULARLY tow a trailer for more than 45 minutes of continuous operation. Refer to “Mainte- nance Schedule” for the proper maintenance intervals. NOTE: Check the automatic transmission fluid level before towing.484 STARTING AND OPERATING Electronic Speed Control – If Equipped − Do not use in hilly terrain or with heavy loads. − When using the speed control, if you experience speed drops greater than 10 mph (16 km/h), disengage until you can get back to cruising speed.

− Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

Cooling System To reduce potential for engine and transmission over- heating, take the following actions: − Highway Driving Reduce speed. − Air Conditioning Turn off temporarily.

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.) Towing This Vehicle Behind Another Vehicle

Towing Condition

Wheels OFF the

Ground

Four-Wheel Drive Models

STARTING AND OPERATING 485

Flat Tow

NONE

See Instructions • Automatic transmission in PARK • Manual transmission in gear (NOT in NEUTRAL (N) • Transfer case in NEUTRAL (N) • Tow in forward direction

Dolly Tow

On Trailer

Front Rear ALL

NOT ALLOWED NOT ALLOWED

OK

486 STARTING AND OPERATING Recreational Towing – Four-Wheel Drive Models

NOTE: The transfer case must be shifted into NEU- TRAL (N), automatic transmission must be shifted into PARK, and manual transmission must be placed in gear (NOT in NEUTRAL) for recreational towing.

CAUTION!

• Front or rear wheel lifts should not be used. Internal damage to the transmission or transfer case will occur if a front or rear wheel lift is used when recreational towing. • Tow only in the forward direction. Towing this vehicle backwards can cause severe damage to the transfer case. • Automatic transmissions must be placed in the

PARK position for recreational towing.

(Continued)

CAUTION! (Continued)

in Neutral) for recreational towing.

• Manual transmissions must be placed in gear (not • Before recreational towing, perform the procedure outlined under “Shifting Into NEUTRAL (N)” to be certain that the transfer case is fully in NEU- TRAL (N). Otherwise, internal damage will result. • Towing this vehicle in violation of the above requirements can cause severe transmission and/or transfer case damage. Damage from improper tow- ing is not covered under the New Vehicle Limited Warranty. • Do not use a bumper-mounted clamp-on tow bar on your vehicle. The bumper face bar will be damaged.

Shifting Into NEUTRAL (N) Use the following procedure to prepare your vehicle for recreational towing.

WARNING!

You or others could be injured if you leave the vehicle unattended with the transfer case in the NEUTRAL (N) position without first fully engaging the parking brake. The transfer case NEUTRAL (N) position disengages both the front and rear drive- shafts from the powertrain and will allow the vehicle to move, even if the transmission is in PARK. The parking brake should always be applied when the driver is not in the vehicle.

STARTING AND OPERATING 487

CAUTION!

It is necessary to follow these steps to be certain that the transfer case is fully in NEUTRAL (N) before recreational towing to prevent damage to internal parts.

1. Bring the vehicle to a complete stop. 2. Turn OFF the engine. 3. Press and hold the brake pedal. 4. Shift the automatic transmission into NEUTRAL or press the clutch pedal on a manual transmission. 5. Shift the transfer case lever into NEUTRAL (N). 6. Start the engine. 7. Shift the transmission into REVERSE.

488 STARTING AND OPERATING 8. Release the brake pedal (and clutch pedal on manual transmissions) for five seconds and ensure that there is no vehicle movement. 9. Repeat steps 7 and 8 with automatic transmission in DRIVE or manual transmission in first gear. 10. Turn OFF the engine. 11. Firmly apply the parking brake. 12. Shift the transmission into PARK or place manual transmission in gear (NOT in Neutral).

CAUTION!

Damage to the transmission may occur if the trans- mission is shifted into PARK with the transfer case in NEUTRAL (N) and the engine running. With the transfer case in NEUTRAL (N) ensure that the engine is OFF prior to shifting the transmission into PARK.

13. Attach the vehicle to the tow vehicle using a suitable tow bar. 14. Release the parking brake. Shifting Out of NEUTRAL (N) Use the following procedure to prepare your vehicle for normal usage. 1. Bring the vehicle to a complete stop, leaving it con- nected to the tow vehicle. 2. Firmly apply the parking brake. 3. Turn the ignition switch to the LOCK/OFF position. 4. Turn the ignition switch to the ON/RUN position, but do not start the engine. 5. Press and hold the brake pedal. 6. Shift the transmission into NEUTRAL. 7. Shift the transfer case lever to the desired position.

NOTE: When shifting out of transfer case NEUTRAL (N), turning the engine OFF may be required to avoid gear clash. 8. Shift the automatic transmission into PARK, or place manual transmission in Neutral. 9. Release the brake pedal. 10. Disconnect vehicle from the tow vehicle.

STARTING AND OPERATING 489

11. Start the engine. 12. Press and hold the brake pedal. 13. Release the parking brake. 14. Shift the transmission into gear, release the brake pedal (and clutch pedal on manual transmissions), and check that the vehicle operates normally.

WHAT TO DO IN EMERGENCIES

CONTENTS

䡵 Hazard Warning Flashers . . . . . . . . . . . . . . . . 492

䡵 If Your Engine Overheats . . . . . . . . . . . . . . . . 492

䡵 Jacking And Tire Changing . . . . . . . . . . . . . . . 493

▫ Jack Location . . . . . . . . . . . . . . . . . . . . . . . 494

▫ Spare Tire Stowage . . . . . . . . . . . . . . . . . . . 495

▫ Preparations For Jacking . . . . . . . . . . . . . . . 495

▫ Jacking Instructions . . . . . . . . . . . . . . . . . . . 496

▫ Road Tire Installation . . . . . . . . . . . . . . . . . 500䡵 Jump-Starting Procedures . . . . . . . . . . . . . . . . 501

▫ Preparations For Jump-Start . . . . . . . . . . . . . 502

▫ Jump-Starting Procedure . . . . . . . . . . . . . . . 503

䡵 Freeing A Stuck Vehicle . . . . . . . . . . . . . . . . . 505

䡵 Emergency Tow Hooks — If Equipped . . . . . . 506

䡵 Shift Lever Override . . . . . . . . . . . . . . . . . . . 507

䡵 Towing A Disabled Vehicle . . . . . . . . . . . . . . . 508

▫ Towing Without The Ignition Key Fob . . . . . 509

▫ Four–Wheel Drive Models . . . . . . . . . . . . . . 510492 WHAT TO DO IN EMERGENCIES HAZARD WARNING FLASHERS The Hazard Warning flasher switch is located on the instrument panel below the climate controls.

Press the switch to turn on the Hazard Warning flasher. When the switch is activated, all directional turn signals will flash on and off to warn oncoming traffic of an emergency. Press the switch a second time to turn off the Hazard Warning flashers. This is an emergency warning system and it should not be used when the vehicle is in motion. Use it when your vehicle is disabled and it is creating a safety hazard for other motorists. When you must leave the vehicle to seek assistance, the Hazard Warning flashers will continue to operate even though the ignition is placed in the OFF position. NOTE: With extended use the Hazard Warning flashers may wear down your battery.

IF YOUR ENGINE OVERHEATS In any of the following situations, you can reduce the potential for overheating by taking the appropriate ac- tion. • On the highways — slow down. • In city traffic — while stopped, shift transmission into

NEUTRAL, but do not increase engine idle speed.

CAUTION!

Driving with a hot cooling system could damage your vehicle. If the temperature gauge reads HOT (H), pull over and stop the vehicle. Idle the vehicle with the air conditioner turned off until the pointer drops back into the normal range. If the pointer remains on HOT (H), and you hear continuous chimes, turn the engine off immediately, and call for service.

NOTE: There are steps that you can take to slow down an impending overheat condition: • If your air conditioner (A/C) is on, turn it off. The A/C system adds heat to the engine cooling system and turning the A/C off can help remove this heat. • You can also turn the temperature control to maximum heat, the mode control to floor and the blower control to high. This allows the heater core to act as a supplement to the radiator and aids in removing heat from the engine cooling system.

WARNING!

You or others can be badly burned by hot engine coolant (antifreeze) or steam from your radiator. If you see or hear steam coming from under the hood, do not open the hood until the radiator has had time to cool. Never try to open a cooling system pressure cap when the radiator or coolant bottle is hot.

JACKING AND TIRE CHANGING

WHAT TO DO IN EMERGENCIES 493

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pull far enough off the road to avoid the danger of being hit when operating the jack or changing the wheel. • Being under a jacked-up vehicle is dangerous. The vehicle could slip off the jack and fall on you. You could be crushed. Never put any part of your body under a vehicle that is on a jack. If you need to get under a raised vehicle, take it to a service center where it can be raised on a lift. • Never start or run the engine while the vehicle is

on a jack.

(Continued)

494 WHAT TO DO IN EMERGENCIES

WARNING! (Continued)

• The jack is designed to be used as a tool for changing tires only. The jack should not be used to lift the vehicle for service purposes. The vehicle should be jacked on a firm level surface only. Avoid ice or slippery areas.

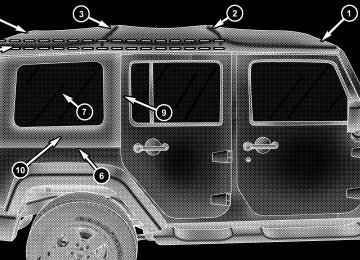

Jack Location

The jack and lug wrench are located in the rear storage compartment.

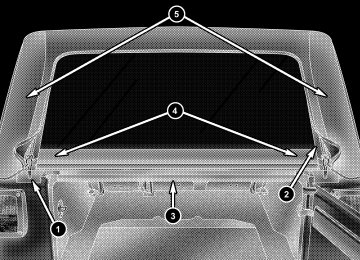

Jack Storage

NOTE: Turn the black plastic wing nut counter clock- wise to loosen the jack from the storage bin.

WHAT TO DO IN EMERGENCIES 495

If you have added aftermarket accessories to the NOTE: spare tire mounted carrier, it cannot exceed a gross weight of 50 lbs (23 kg) including the weight of the spare tire. Preparations For Jacking1. Park on a firm, level surface. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of the vehicle close to moving traffic, pull far enough off the road to avoid being hit when operating the jack or changing the wheel.

2. Turn on the Hazard Warning flasher. 3. Set the parking brake.

Jack Wing Nut

Spare Tire Stowage To remove the spare tire from the carrier, remove the tire cover, if equipped, and remove the lug nuts with the lug wrench turning them counterclockwise.

496 WHAT TO DO IN EMERGENCIES 4. Shift the automatic transmission into PARK, or a manual transmission into REVERSE. 5. Turn the ignition to LOCK.

Jacking Instructions

WARNING!

6. Block both the front and rear of the wheel diagonally opposite of the jack- ing position. For example, if changing the right front tire, block the left rear wheel.

NOTE: Passengers should not remain in the vehicle when the vehicle is being jacked.

Carefully follow these tire changing warnings to help prevent personal injury or damage to your vehicle: • Always park on a firm, level surface as far from the edge of the roadway as possible before raising the vehicle.

• Turn on the Hazard Warning flasher. • Block the wheel diagonally opposite the wheel to • Set the parking brake firmly and set an automatic transmission in PARK; a manual transmission in REVERSE. • Never start or run the engine with the vehicle on a

be raised.

jack.

(Continued)

WARNING! (Continued)

jack.

• Do not let anyone sit in the vehicle when it is on a • Do not get under the vehicle when it is on a jack. • Only use the jack in the positions indicated and • If working on or near a roadway, be extremely • To assure that spare tires, flat or inflated, are securely stowed, spares must be stowed with the valve stem facing the ground.

for lifting this vehicle during a tire change.

careful of motor traffic.

WHAT TO DO IN EMERGENCIES 497

CAUTION!

Do not attempt to raise the vehicle by jacking on locations other than those indicated in the Jacking Instructions for this vehicle.

1. Remove the spare tire, jack and tools from the stored location. 2. Loosen (but do not remove) the wheel lug nuts by turning them to the left one turn while the wheel is still on the ground. 3. Assemble the jack and jacking tools. Connect the jack handle driver to the extension, then to the lug wrench.

Jack Warning Label

498 WHAT TO DO IN EMERGENCIES 4. Operate the jack from the front or the rear of the vehicle. Place the jack under the axle tube, as shown. Do not raise the vehicle until you are sure the jack is fully engaged.

Front Jacking Location

5. Raise the vehicle by turning the jack screw to the right. Raise the vehicle till the tire is raised from the surface of the road. Minimum tire lift provides maximum stability.

Rear Jacking Location

WARNING!

Raising the vehicle higher than necessary can make the vehicle less stable and cause a collision. It could slip off the jack and hurt someone near it. Raise the vehicle only enough to remove the tire.

6. Remove the lug nuts and wheel. 7. Position the spare wheel/tire on the vehicle and install the lug nuts with the cone-shaped end toward the wheel. Lightly tighten the lug nuts clockwise.

WHAT TO DO IN EMERGENCIES 499

Lug Nut Installation

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the wheel nuts fully until the vehicle has been lowered.

500 WHAT TO DO IN EMERGENCIES 8. Lower the vehicle by turning the jack screw to the left, and remove the jack. 9. Finish tightening the lug nuts. Push down on the wrench while tightening for increased leverage. Alternate nuts until each nut has been tightened twice. The correct wheel nut tightness is 95 ft lbs (130 N·m). If in doubt about the correct tightness, have them checked with a torque wrench by your authorized dealer or at a service station. 10. Remove the jack assembly and wheel blocks. 11. Secure the tire, jack, and tools in their proper loca- tions. 12. Remove blocks from wheels.

WARNING!

A loose tire or jack, thrown forward in a collision or hard stop, could endanger the occupants of the ve- hicle. Always stow the jack parts and the spare tire in the places provided.

Road Tire Installation

1. Mount the road tire on the axle. 2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts fully until the vehicle is lowered to the ground.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise. 4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut has been tightened twice. The correct tightness of each lug nut is 95 ft/lbs (130 N·m). If in doubt about the correct tightness, have them checked with a torque wrench by your authorized dealer or service station. 5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

JUMP-STARTING PROCEDURES If your vehicle has a discharged battery it can be jump- started using a set of jumper cables and a battery in another vehicle or by using a portable battery booster pack. Jump-starting can be dangerous if done improperly so please follow the procedures in this section carefully.

WHAT TO DO IN EMERGENCIES 501

NOTE: When using a portable battery booster pack follow the manufacturer’s operating instructions and precautions.CAUTION!

Do not use a portable battery booster pack or any other booster source with a system voltage greater than 12 Volts or damage to the battery, starter motor, alternator or electrical system may occur.

WARNING!

Do not attempt jump-starting if the battery is frozen. It could rupture or explode and cause personal injury.

502 WHAT TO DO IN EMERGENCIES Preparations For Jump-Start The battery in your vehicle is located in the right rear of the engine compartment, behind the Power Distribution Center.

Positive Battery Post

WARNING!

• Take care to avoid the radiator cooling fan when- ever the hood is raised. It can start anytime the ignition switch is on. You can be injured by moving fan blades. • Remove any metal jewelry such as watch bands or bracelets that might make an inadvertent electrical contact. You could be seriously injured. • Batteries contain sulfuric acid that can burn your skin or eyes and generate hydrogen gas which is flammable and explosive. Keep open flames or sparks away from the battery.

1. Set the parking brake, shift the automatic transmission into PARK (manual transmission in NEUTRAL) and turn the ignition to LOCK. 2. Turn off the heater, radio, and all unnecessary electri- cal accessories.

3. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this could establish a ground connection and personal injury could result.

Jump-Starting Procedure

WARNING!

Failure to follow this procedure could result in per- sonal injury or property damage due to battery ex- plosion.

WHAT TO DO IN EMERGENCIES 503

CAUTION!

Failure to follow these procedures could result in damage to the charging system of the booster vehicle or the discharged vehicle.

1. Connect the positive (+) end of the jumper cable to the positive (+) post of the discharged vehicle. 2. Connect the opposite end of the positive (+) jumper cable to the positive (+) post of the booster battery. 3. Connect the negative end (-) of the jumper cable to the negative (-) post of the booster battery. 4. Connect the opposite end of the negative (-) jumper cable to a good engine ground (exposed metal part of the discharged vehicle’s engine) away from the battery and the fuel injection system.

504 WHAT TO DO IN EMERGENCIES

WARNING!

Do not connect the cable to the negative post (-) of the discharged battery. The resulting electrical spark could cause the battery to explode and could result in personal injury.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery. Once the engine is started, remove the jumper cables in the reverse sequence: 6. Disconnect the negative (-) jumper cable from the engine ground of the vehicle with the discharged battery. 7. Disconnect the negative end (-) of the jumper cable from the negative (-) post of the booster battery.

8. Disconnect the opposite end of the positive (+) jumper cable from the positive (+) post of the booster battery. 9. Disconnect the positive (+) end of the jumper cable from the positive (+) post of the discharged vehicle. If frequent jump-starting is required to start your vehicle you should have the battery and charging system in- spected at your authorized dealer.

CAUTION!

Accessories that can be plugged into the vehicle power outlets draw power from the vehicle’s battery, even when not in use (i.e., cellular phones, etc.). Eventually, if plugged in long enough, the vehicle’s battery will discharge sufficiently to degrade battery life and/or prevent the engine from starting.

FREEING A STUCK VEHICLE If your vehicle becomes stuck in mud, sand or snow, it can often be moved by a rocking motion. Turn your steering wheel right and left to clear the area around the front wheels. Then shift back and forth between DRIVE and REVERSE (with automatic transmission) or 1st gear and REVERSE (with manual transmission). Using mini- mal accelerator pedal pressure to maintain the rocking motion, without spinning the wheels, is most effective.

CAUTION!

Racing the engine or spinning the wheels may lead to transmission overheating and failure. Allow the en- gine to idle with the shift lever in NEUTRAL for at least one minute after every five rocking-motion cycles. This will minimize overheating and reduce the risk of transmission failure during prolonged efforts to free a stuck vehicle.

WHAT TO DO IN EMERGENCIES 505

If your vehicle is equipped with Traction Con- NOTE: trol or Electronic Stability Control (ESC), turn the system OFF before attempting to “rock” the vehicle.CAUTION!

• When “rocking” a stuck vehicle by moving be- tween DRIVE and REVERSE (with automatic transmission) or 1st gear and REVERSE (with manual transmission), do not spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may result. • Revving the engine or spinning the wheels too fast may lead to transmission overheating and failure. It can also damage the tires. Do not spin the wheels above 30 mph (48 km/h) while in gear (no transmission shifting occurring).

506 WHAT TO DO IN EMERGENCIES

WARNING!

Fast spinning tires can be dangerous. Forces gener- ated by excessive wheel speeds may cause damage, or even failure, of the axle and tires. A tire could explode and injure someone. Do not spin your vehi- cle’s wheels faster than 30 mph (48 km/h) or for longer than 30 seconds continuously without stop- ping when you are stuck and do not let anyone near a spinning wheel, no matter what the speed.

WARNING!

• Chains are not recommended for freeing a stuck vehicle. Chains may break, causing serious injury or death. • Stand clear of vehicles when pulling with tow hooks. Tow straps may become disengaged, caus- ing serious injury.

CAUTION!

EMERGENCY TOW HOOKS — IF EQUIPPED If your vehicle is equipped with tow hooks, they are mounted in the front and the rear. NOTE: For off-road recovery, it is recommended to use both of the front tow hooks to minimize the risk of damage to the vehicle.

Tow hooks are for emergency use only, to rescue a vehicle stranded off road. Do not use tow hooks for tow truck hookup or highway towing. You could damage your vehicle. Tow straps are recommended when towing the vehicle, chains may cause vehicle damage.

SHIFT LEVER OVERRIDE If a malfunction occurs and the shift lever cannot be moved out of the PARK position, you can use the following procedure to temporarily move the shift lever: 1. Firmly apply the parking brake. 2. Turn the ignition to the ON/RUN position without starting the engine (engine Off). 3. Using a screwdriver or similar tool, carefully remove the shift lever override access cover, located on the PRNDL bezel.

WHAT TO DO IN EMERGENCIES 507

Shift Lever Override Access Cover

4. Press and maintain firm pressure on the brake pedal. 5. Using the screwdriver or similar tool, reach into the opening and press and hold the shift lever override. 6. Move the shift lever to NEUTRAL. 7. The vehicle may then be started in NEUTRAL. 8. Reinstall the shift lever override access cover.

508 WHAT TO DO IN EMERGENCIES TOWING A DISABLED VEHICLE This section describes procedures for towing a disabled vehicle using a commercial wrecker service. If the transmission and drivetrain are operable, disabled vehicles may also be towed as described under “Recreational Towing” in the “Starting And Operating” section. Towing Condition

Wheels OFF the Ground

Flat Tow

Wheel Lift or Dolly Tow

Flatbed

NONE

Front Rear ALL

4WD MODELS See instructions under “Recreational Towing” • Automatic Transmission in PARK • Manual Transmission in gear ( NOT in Neutral) • Transfer Case in NEUTRAL • Tow in forward direction

NOT ALLOWED NOT ALLOWED BEST METHOD

Proper towing or lifting equipment is required to prevent damage to your vehicle. Use only tow bars and other equipment designed for this purpose, following equip- ment manufacturer’s instructions. Use of safety chains is mandatory. Attach a tow bar or other towing device to main structural members of the vehicle, not to bumpers or associated brackets. State and local laws applying to vehicles under tow must be observed. If you must use the accessories (wipers, defrosters, etc.) while being towed, the ignition must be in the ON/RUN position, not the ACC position. If the vehicle’s battery is discharged, refer to “Shift Lever Override” in “What To Do In Emergencies” for instruc- tions on shifting the automatic transmission out of the PARK position for towing.

WHAT TO DO IN EMERGENCIES 509

CAUTION!

• Do not attempt to use sling type equipment when towing. When securing the vehicle to a flatbed truck, do not attach to front or rear suspension components. Damage to your vehicle may result from improper towing. • If the vehicle being towed requires steering. the ignition switch must be in the ON/RUN or ACC position, not the LOCK/OFF position.

Towing Without The Ignition Key Fob Special care must be taken when the vehicle is towed with the ignition in the LOCK/OFF position. The only approved method of towing without the ignition key is with a flatbed truck. Proper towing equipment is neces- sary to prevent damage to the vehicle.

510 WHAT TO DO IN EMERGENCIES Four–Wheel Drive Models The manufacturer recommends towing with all wheels OFF the ground. Acceptable methods are to tow the vehicle on a flatbed or with one end of the vehicle raised and the opposite end on a towing dolly. If flatbed equipment is not available and the transfer case is operable, the vehicle may be towed (in the forward direction, with ALL wheels on the ground), IF the transfer case is in NEUTRAL and the transmission is in PARK (for automatic transmissions) or in gear ( NOT in NEUTRAL , for manual transmissions). Refer to “Recre- ational Towing” in “Starting And Operating” for detailed instructions.

CAUTION!

• Front or rear wheel lifts should not be used. Internal damage to the transmission or transfer case will occur if a front or rear wheel lift is used when towing. • Failure to follow these towing methods can cause severe damage to the transmission and/or transfer case. Such damage is not covered by the New Vehicle Limited Warranty.

MAINTAINING YOUR VEHICLE

CONTENTS

䡵 Engine Compartment — 3.6L . . . . . . . . . . . . . 513

䡵 Onboard Diagnostic System — OBD II . . . . . . 514

▫ Loose Fuel Filler Cap Message . . . . . . . . . . . 514䡵 Emissions Inspection And Maintenance

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 515