- 2012 Subaru Tribeca Owners Manuals

- Subaru Tribeca Owners Manuals

- 2008 Subaru Tribeca Owners Manuals

- Subaru Tribeca Owners Manuals

- 2007 Subaru Tribeca Owners Manuals

- Subaru Tribeca Owners Manuals

- 2006 Subaru Tribeca Owners Manuals

- Subaru Tribeca Owners Manuals

- 2010 Subaru Tribeca Owners Manuals

- Subaru Tribeca Owners Manuals

- 2011 Subaru Tribeca Owners Manuals

- Subaru Tribeca Owners Manuals

- 2009 Subaru Tribeca Owners Manuals

- Subaru Tribeca Owners Manuals

- Download PDF Manual

-

11-50

11-50Maintenance schedule

Maintenance precautions

The scheduled maintenance items re- quired to be serviced at regular intervals are shown in the “Warranty and Main- tenance Booklet”.

For details of your maintenance schedule, read the separate “Warranty and Main- tenance Booklet”.

When maintenance and service are re- quired, it is recommended that all work be done by an authorized SUBARU dealer.

If you perform maintenance and service by yourself, you should familiarize yourself with the information provided in this section on general maintenance and service for your SUBARU.

Incorrect or incomplete service could cause improper or unsafe vehicle opera- tion. Any problems caused by improper maintenance and service performed by you are not eligible for warranty coverage.

WARNING

. Testing of an All-Wheel Drive vehicle must NEVER be per- formed on a single two-wheel dynamometer or similar appara- tus. Attempting to do so will result in transmission damage and in uncontrolled vehicle movement and may cause an accident or injuries to persons nearby.

. Always select a safe area when performing maintenance on your vehicle.

Maintenance and service 11-3

. Always be very careful to avoid injury when working on the vehi- cle. Remember that some of the materials in the vehicle may be hazardous if improperly used or handled, for example, battery acid.

. Your vehicle should only be ser- viced by persons fully competent to do so. Serious personal injury may result to persons not experi- enced in servicing vehicles.

. Always use the proper tools and make certain that they are well maintained.

. Never get under the vehicle sup- ported only by a jack. Always use a safety stands to support the vehicle.

. Never keep the engine running in a poorly ventilated area, such as a garage or other closed areas.

. Do not smoke or allow open flames around the fuel or battery. This will cause a fire.

. Because the fuel system is under pressure, replacement of the fuel filter should be performed only by your SUBARU dealer.

. Wear adequate eye protection to

– CONTINUED –

11-4 Maintenance and service

in your eyes,

guard against getting oil or fluids in your eyes. If something does get thoroughly wash them out with clean water. . Do not tamper with the wiring of the SRS airbag system or seat- belt pretensioner system, or at- tempt to take its connectors apart, as that may activate the system or it can render it inop- erative. The wiring and connec- tors of these systems are yellow for easy identification. NEVER use a circuit tester for these wiring. If your SRS airbag or seatbelt pretensioner needs service, con- sult your nearest SUBARU deal- er.

& Before checking or servicing

in the engine compartment

WARNING

. Always stop the engine and set the parking brake firmly to pre- vent the vehicle from moving.

. Always let the engine cool down. Engine parts become very hot when the engine is running and

remain hot for some time after the engine is stopped.

. Do not spill engine oil, engine coolant, brake fluid or any other fluid on hot engine components. This may cause a fire.

. Always remove the key from the ignition switch. When the ignition switch is in the “ON” position, the cooling fan may operate suddenly even when the engine is stopped.

& When you do checking or

servicing in the engine com- partment while the engine is running

WARNING

A running engine can be dangerous. Keep your fingers, hands, clothing, hair and tools away from the cooling fan, belts and any other moving engine parts. Removing rings, watches and ties is advisable.

Engine hood

To open the hood: 1. If the wiper blades are lifted off the windshield, return them to their original positions. 2. Pull the hood release knob under the instrument panel.

Maintenance and service 11-5

WARNING

Always check that the hood is properly locked before you start driving. If it is not, it might fly open while the vehicle is moving and block your view, which may cause an accident and serious bodily in- jury.

CAUTION

When closing the hood, be careful not to pinch your or other person’s hands or anything else in the hood.

3. Release the secondary hood release located under the front grille by moving the lever toward the left. 4. Lift up the hood.

To close the hood: 1. Lower the hood to a point approxi- mately 20 in (50 cm) from the closed position and then give the hood a strong push down to make it drop. 2. After closing the hood, be sure the hood is securely locked.

If this does not close the hood, release it from a slightly higher position. Do not push the hood forcibly to close it. It could deform the metal.

11-6 Maintenance and service

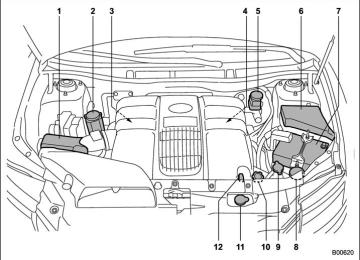

Engine compartment overview

1) Air cleaner element (page 11-14) 2) Power steering fluid reservoir

(page 11-19)

3) Differential gear oil level gauge

(page 11-17)

4) Automatic transmission fluid level gauge

(page 11-15)

Fuse box (page 11-38)

5) Brake fluid reservoir (page 11-20) 6) 7) Battery (page 11-37) 8) Windshield washer tank (page 11-32) 9) Radiator cap (page 11-11) 10) Engine oil filler cap (page 11-7) 11) Engine coolant reservoir (page 11-11) 12) Engine oil level gauge (page 11-7)

Engine oil

NOTE . The engine oil consumption rate is not stabilized, and therefore cannot be determined until the vehicle has tra- veled at least several thousand miles (kilometers). Even after break-in, when the vehicle is used under severe driv- ing conditions such as those men- tioned in the “Warranty and Mainte- nance Booklet”, engine oil is con- sumed or deteriorated more quickly than under normal driving conditions. If you drive your vehicle under these severe conditions, you should check the oil level at least at every second fuel fill-up time, and change the oil more frequently. Please refer to the “Warranty and Maintenance Booklet” for more details. . If the oil consumption rate seems abnormally high after the break-in period, for example more than 1 quart per 1,200 miles or 1 liter per 2,000

kilometers, we recommend that you contact your SUBARU dealer.Maintenance and service 11-7

& Checking the oil level Check the engine oil stop. 1. Park the vehicle on a level surface and stop the engine.

level at each fuel

2. Pull out the dipstick, wipe it clean, and insert it again. 3. Be sure the dipstick is correctly in- it stops with the graphic serted until ” on its top appearing as symbol shown in the illustration.

“

1) Upper level 2) Lower level

4. Pull out the dipstick again and check the oil level on it. If it is below the lower level, add oil to bring the level up to the upper level.

CAUTION

. Use only engine oil with the recommended grade and vis- cosity.

– CONTINUED –

11-8 Maintenance and service

. Be careful not to spill engine oil when adding it. If oil touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If engine oil gets on the exhaust pipe, be sure to wipe it off.

If you check the oil level just after stopping the engine, wait a few minutes for the oil to drain back into the oil pan before checking the level. To prevent overfilling the engine oil, do not add any additional oil above the upper level when the engine is cold. & Changing the oil and oil filter Change the oil and oil filter according to the maintenance schedule in the “War- ranty and Maintenance Booklet”. filter must be The engine oil and oil changed more frequently than listed in the maintenance schedule when driving on dusty roads, when short trips are frequently made, or when driving in extremely cold whether. 1. Warm up the engine by letting the engine idle for approximately 10 minutes to ease draining the engine oil. 2. Park the vehicle on a level surface and stop the engine. 3. Remove the oil filler cap.

4. Drain out the engine oil by removing the drain plug while the engine is still warm. The used oil should be drained into an appropriate container and disposed of properly.

6. Open the access cover by removing the five clips and turning the access cover counterclockwise. The oil filter will be exposed.

WARNING

Be careful not to burn yourself with hot engine oil.

5. Wipe the seating surface of the drain plug with a clean cloth and tighten it securely with a new sealing washer after the oil has completely drained out.

7. Remove the oil filter with an oil filter wrench.

8. Clean the rubber seal seating area of the bottom of engine and install the oil filter by hand turning. Be careful not to twist or damage the seal. filter by the amount 9. Tighten the oil indicated in the following table after the seal makes contact with the bottom of engine.

Oil filter color Part number Amount of ro-

tation

Black

15208AA031

3/4 rotation

CAUTION

. Never over tighten the oil filter because that can result in an oil leak.

. Thoroughly wipe off any engine oil that has spilled over the exhaust pipe and/or under-cover. If left unremoved, the oil could catch fire.

10. Reinstall the cover under the oil filter. 11. Pour engine oil through the filler neck.

Oil capacity (Guideline):

6.7 US qt (6.3 liters, 5.5 Imp qt)

The oil quantity indicated above is only a guideline. The necessary quantity of oil depends on the quantity of oil that has been drained. The quantity of drained oil differs slightly depending on the tempera- ture of the oil and the time the oil is left flowing out. After refilling the engine with oil, therefore, you must use the dipstick to confirm that the level is correct. 12. Start the engine and make sure that no oil leaks appear around the filter’s rubber seal and drain plug. 13. Run the engine until it reaches the normal operating temperature. Then stop the engine and wait a few minutes to allow the oil drain back. Check the oil level again and if necessary, add more engine oil.

& Recommended grade and

viscosity

CAUTION

Use only engine oil with the recom- mended grade and viscosity.

Maintenance and service 11-9

Oil grade:

ILSAC GF-4, which can be identified with the ILSAC certification mark (Starburst mark) or API classification SM with the words “ENERGY CONSERVING”

These recommended oil grades can be identified by looking for either or both of the following marks displayed on the oil container.

ILSAC Certification Mark (Starburst Mark)

– CONTINUED –

11-10 Maintenance and service

API classification SM (or SL):

SAE viscosity No.:

30, 40, 10W-50, 20W-40, 20W-50

API Service label 1)

Indicates the oil quality by API designa- tions Indicates the SAE oil viscosity grade Indicates that capabilities

the oil has fuel saving

2) 3)

In choosing an oil, you want the proper quality and viscosity, as well as one that will add to fuel economy. The following table lists the recommended viscosities and applicable temperatures. When adding oil, different brands may be used together as long as they are the same API classification and SAE viscosity as those recommended by SUBARU.

SAE viscosity number and applicable temperature *:

5W-30 is recommended.

Engine oil viscosity (thickness) affects fuel economy. Oils of lower viscosity provide better in hot weather, oil of higher viscosity is required to properly lubricate the engine.

fuel economy. However,

& Recommended grade and

viscosity under severe driv- ing conditions

If the vehicle is used in desert areas, in areas with very high temperatures, or used for heavy-duty applications such as towing a trailer, use of oil with the following grade and viscosities is recommended.

Cooling system

WARNING

Never attempt to remove the radia- tor cap until the engine has been shut off and has cooled down completely. Since the coolant is under pressure, you may suffer serious burns from a spray of boil- ing hot coolant when the cap is removed.

CAUTION

. The cooling system has been filled at the factory with a high quality, corrosion-inhibiting, year-around coolant which pro- vides protection against freezing down to −338F (−368C). Subaru engines use aluminum components that require the anti-corrosive and anti-freeze properties of Subaru Genuine Coolant, which is specifically formulated for the Subaru cool- ing system. Failure to use Subaru Genuine Coolant along with Subaru Cooling System Condi- tioner at the recommended main-

tenance intervals may result in problems, including, but not lim- ited to shortened life of engine components and cooling system clogging, coolant leaks and en- gine damage from overheating. Problems caused by the failure to use Subaru Genuine Coolant and Subaru Cooling System Condi- tioner at recommended intervals are not covered under the Subaru Limited Warranty. While there may be other generic products that may provide the required protection, they have not been tested for compatibility with Subaru engines and cooling system components, and there- fore not recommended.

. Do not splash the engine coolant over painted parts. The alcohol contained in the engine coolant may damage the paint surface.

& Hose and connections Your vehicle employs an electric cooling fan which is thermostatically controlled to operate when the engine coolant reaches a specific temperature. If the radiator cooling fan does not operate

Maintenance and service 11-11

even when the engine coolant tempera- ture gauge exceeds the normal operating range, the cooling fan circuit may be defective. Check the fuse and replace it if necessary. If the fuse is not blown, have the cooling system checked by your SUBARU dealer.

If frequent addition of coolant is neces- sary, there may be a leak in the engine cooling system. It is recommended that the cooling system and connections be checked for leaks, damage, or looseness.

& Engine coolant ! Checking the coolant level

Check the coolant level at each fuel stop. 1. Check the coolant level on the outside of the reservoir while the engine is cool. – CONTINUED –

11-12 Maintenance and service

2. If the level is close to or lower than the “LOW” level mark, add coolant up to the “FULL” level mark. If the reserve tank is empty, remove the radiator cap and refill as required.

3. After refilling the reserve tank and the radiator, reinstall the caps and check that the rubber gaskets inside the radiator cap are in the proper position.

CAUTION

. Be careful not

to spill engine coolant when adding it. If coolant touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If engine coolant gets on the exhaust pipe, be sure to wipe it off.

. Do not splash the engine coolant over painted parts. The alcohol contained in the engine coolant may damage the paint surface.

3. Loosen the radiator cap to drain the coolant from the radiator. Then drain the coolant from the reserve tank. Tighten the drain plug securely.

! Changing the coolant Always add genuine Subaru cooling sys- tem conditioner whenever the coolant is replaced. Change the engine coolant and add genuine Subaru cooling system condi- tioner using the following procedures according to the maintenance schedule in the “Warranty and Maintenance Book- let”. 1. Remove the under cover.

WARNING

Never attempt to remove the radia- tor cap until the engine has been shut off and has cooled down completely. Since the coolant is under pressure, you may suffer serious burns from a spray of boil- ing hot coolant when the cap is removed.

4.

Install the under cover.

2. Place a proper container under the drain plug and loosen the drain plug.

5. Slowly pour the coolant and fill up to

1)

Fill up to here

Maintenance and service 11-13

8. Start and run the engine for more than five minutes at 2,000 to 3,000 rpm. 9. Stop the engine and wait until the coolant cools down (122 to 1408F [50 to 608C]). If there is any loss of coolant, add coolant to the radiator’s filler neck and to the reserve tank’s “FULL” level. 10. Put the radiator cap and reservoir cap back on and tighten firmly.

just below the filler neck, allowing enough room to add genuine Subaru cooling system conditioner in the radiator. Add genuine Subaru cooling system condi- tioner until the coolant level reaches the filler neck. Do not pour the coolant too quickly, as this may lead to insufficient air bleeding and trapped air in the system.

Coolant capacity (Guideline):

8.0 US qt (7.6 liters, 6.7 Imp qt)

CAUTION

. Be careful not

to spill engine coolant when adding it. If coolant touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If engine coolant gets on the exhaust pipe, be sure to wipe it off.

. Do not splash the engine coolant over painted parts. The alcohol contained in the engine coolant may damage the paint surface.

6. Pour the coolant and fill to the reser- voir tank’s “FULL” level mark.

7. Put the radiator cap back on and tighten firmly. At this time, make sure that the rubber gasket in the radiator cap is correctly in place.

11-14 Maintenance and service

Air cleaner element

WARNING

Do not operate the engine with the air cleaner element removed. The air cleaner element not only filters intake air but also stops flames if the engine backfires. the air cleaner element installed when the engine backfires, you could be burned.

is not

If

CAUTION

When replacing the air cleaner ele- ment, use a genuine SUBARU air cleaner element. If it is not used, there is the possibility of causing a negative effect to the engine.

The air cleaner element functions as a filter screen. When the element is perfo- rated or removed, engine wear will be excessive and engine life shortened.

The air cleaner element is a dry type. It is unnecessary to clean or wash the ele- ment.

& Replacing the air cleaner

element

Replace the air cleaner element according to the maintenance schedule in the “Warranty and Maintenance Booklet”. Un- der extremely dusty conditions, replace it more frequently. It is recommended that you always use genuine SUBARU parts.

1. Unsnap the two clamps holding the air cleaner case cover.

Install a new air cleaner element.

2. Open the air cleaner case cover and remove the air cleaner element. 3. 4. To install the air cleaner case cover, snap the two clamps on the air cleaner case cover.

Spark plugs

Drive belts

It may be difficult to replace the spark plugs. It is recommended that you have the spark plugs replaced by your SUBARU dealer.

The spark plugs should be replaced according to the maintenance schedule in the “Warranty and Maintenance Book- let”.

& Recommended spark plugs

SILFR6A (NGK)

The alternator, power steering pump, and air conditioner compressor depend on drive belts. Satisfactory performance re- quires that belt tension be correct. It tension is unnecessary to check belt periodically because your engine is equipped with an automatic belt tension adjuster. However, replacement of the belt should be done according to the main- tenance schedule in the “Warranty and Maintenance Booklet”. Consult your SUBARU dealer for replacement. If a belt is loose, cracked, or worn, contact your SUBARU dealer.

Maintenance and service 11-15

Automatic transmission fluid & Checking the fluid level The automatic transmission fluid expands largely as its temperature rises; the fluid level differs according to fluid temperature. Therefore, there are two different scales for checking the level of hot fluid and cold fluid on the dipstick.

Though the fluid level can be checked without warming up the fluid on the “COLD” range, we recommend checking the fluid level when the fluid is at operating temperature. ! Checking the fluid level when the

fluid is hot

Check the fluid level monthly. 1. Drive the vehicle several miles to raise the temperature of the transmission fluid up to normal operating temperature; 158

to 1768F (70 to 808C) is normal. 2. Park the vehicle on a level surface and set the parking brake. 3. First shift the selector lever in each position. Then shift it in the “P” position, and run the engine at idling speed.– CONTINUED –

11-16 Maintenance and service

1) Yellow handle

1) HOT range 2) COLD range 3) Upper level Lower level 4)

& Recommended fluid

Use one of the following types of auto- matic transmission fluid.

Genuine Subaru Automatic Transmis- sion Fluid Type-HP IDEMITSU ATF HP Castrol Transmax J

NOTE Using any non-specified type of auto- matic transmission fluid could result in damage inside the transmission. When replacing the automatic transmission fluid, be sure to use a fluid of the types specified above.

4. Pull out the dipstick and check the fluid level on the gauge. If it is below the lower level on the “HOT” range, add the recom- mended automatic transmission fluid up to the upper level.

! Checking the fluid level when the

fluid is cold

When the fluid level has to be checked without time to warm up the automatic transmission, check to see that the fluid level is between the lower level and upper level on the “COLD” range. If it is below that range, add fluid up to the upper level. Be careful not to overfill.

CAUTION

Be careful not to spill automatic transmission fluid when adding it. If automatic transmission fluid touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If automatic transmission fluid gets on the exhaust pipe, be sure to wipe it off.

Front differential gear oil & Checking the oil level

1) Yellow handle

1. Park the vehicle on a level surface and stop the engine. 2. Pull out the dipstick, wipe it clean, and insert it again.

1) Upper level 2) Lower level

3. Pull out the dipstick again and check the oil level on it. If it is below the lower level, add oil to bring the level up to the upper level.

CAUTION

Be careful not to spill front differ- ential gear oil when adding it. If oil touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If oil gets on the exhaust pipe, be sure to wipe it off.

Maintenance and service 11-17

& Recommended grade and

viscosity

Each oil manufacturer has its own base oils and additives. Never use different brands together.

Oil grade:

API classification GL-5

SAE viscosity No. and applicable tempera- ture

it off.

. If the vehicle requires frequent refilling, there may be an oil leak. If you suspect a problem, have the vehicle checked at your SUBARU dealer.

& Recommended grade and

viscosity

Each oil manufacturer has its own base oils and additives. Never use different brands together.

Oil grade:

API classification GL-5

11-18 Maintenance and service

Rear differential gear oil & Checking the gear oil level Your vehicle may be equipped with a rear differential protector. The differential pro- tector provides protection to the rear differential assembly during off-road use. Removal of the rear differential protector is not required when checking the oil level.

1) Filler plug 2) Drain plug

1) Filler hole 2) Drain hole 3) Oil level

Remove the plug from the filler hole and check the oil level. The oil level should be kept even with the bottom of the filler hole. If the oil level is below the bottom edge of the hole, add oil through the filler hole to raise the level.

CAUTION

. Be careful not to spill rear differ- ential gear oil when adding it. If rear differential gear oil touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If rear differential gear oil gets on the exhaust pipe, be sure to wipe

SAE viscosity No. and applicable tempera- ture

Power steering fluid & Checking the fluid level

WARNING

Be careful not because the fluid may be hot.

to burn yourself

CAUTION

. When power steering fluid is being added, use only clean fluid, and be careful not to allow any dirt into the tank. And never use different brands together.

. Avoid spilling fluid when adding

it in the tank.

Maintenance and service 11-19

. Be careful not

to spill power steering fluid when adding it. If power steering fluid touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If power steering fluid gets on the exhaust pipe, be sure to wipe it off.

The power steering fluid expands greatly as its temperature rises; the fluid level differs according to fluid temperature. Therefore, tank has two different checking ranges for hot and cold fluids.

the reservoir

Check the power steering fluid level monthly. 1. Park the vehicle on a level surface, and stop the engine. 2. Check the fluid level of the reservoir tank. When the fluid is hot after the vehicle has been run: Check that is between “HOT MIN” and “HOT MAX” on the surface of the reservoir tank. When the fluid is cool before the vehicle is run: Check that the oil is between “COLD MIN” and “COLD MAX” on the surface of the reservoir tank. 3. applicable “MIN”

than the line, add the recom-

the fluid level

is lower

the oil

level

level

If

– CONTINUED –

11-20 Maintenance and service

mended fluid as necessary to bring the level between the “MIN” and “MAX” line. If is extreme low, it may indicate possible leakage. Consult your SUBARU dealer for inspection.

the fluid level

& Recommended fluid

Use one of the following types of auto- matic transmission fluid.

Genuine Subaru Automatic Transmis- sion Fluid Type-HP “Dexron III” Type Automatic Transmis- sion Fluid

Brake fluid & Checking the fluid level

WARNING

to your eyes.

. Never let brake fluid contact your eyes because brake fluid can be harmful If brake fluid gets in your eyes, immedi- ately flush them thoroughly with clean water. For safety, when performing this work, wearing eye protection is advisable.

. Brake fluid absorbs moisture from the air. Any absorbed moist- ure can cause a dangerous loss of braking performance.

. If the vehicle requires frequent refilling, there may be a leak. If you suspect a problem, have the vehicle checked at your SUBARU dealer.

CAUTION

. Never use different brands of brake fluid together. Also, avoid mixing DOT 3 and DOT 4 brake fluids even if they are of the same brand.

. When adding brake fluid, be care- ful not to allow any dirt into the reservoir.

. Never splash the brake fluid over painted surfaces or rubber parts. Alcohol contained in the brake fluid may damage them.

. Be careful not to spill brake fluid when adding it. If brake fluid touches the exhaust pipe, it may cause a bad smell, smoke, and/or a fire. If brake fluid gets on the exhaust pipe, be sure to wipe it off.

Check the fluid level monthly.

Check the fluid level on the outside of the reservoir. If the level is below “MIN”, add the recommended brake fluid to “MAX”.

Use only brake fluid from a sealed container.

Brake booster

Brake pedal

Maintenance and service 11-21

& Recommended brake fluid

FMVSS No. 116, fresh DOT 3 or 4 brake fluid

If the brake booster does not operate as described in the following, have it checked by your SUBARU dealer. 1. With the engine off, depress the brake pedal several times, applying the same pedal force each time. The distance the pedal travels should not vary. 2. With the brake pedal depressed, start the engine. The pedal should move slightly down to the floor. 3. With the brake pedal depressed, stop the engine and keep the pedal depressed for 30 seconds. The pedal height should not change. 4. Start the engine again and run for approximately one minute then turn it off. Depress the brake pedal several times to check the brake booster. The brake booster operates properly if the pedal stroke decreases with each depression.

Check the brake pedal free play and reserve distance according to the main- tenance schedule in the “Warranty and Maintenance Booklet”.

& Checking the brake pedal

free play

1)

0.02 – 0.08 in (0.5 – 2.0 mm)

Stop the engine and firmly depress the brake pedal several times. Lightly pull the brake pedal up with one finger to check the free play with a force of less than 2 lbs (10 N, 1 kg). the free play is not within proper If specification, contact your SUBARU deal- er.

– CONTINUED –

11-22 Maintenance and service

& Checking the brake pedal

reserve distance

Replacement of brake pad and lining

CAUTION

If you continue to drive despite the scraping noise from the audible brake pad wear indicator, it will result in the need for costly brake rotor repair or replacement.

1) More than 2.16 in (55 mm)

Depress the pedal with a force of approxi- mately 66 lbs (294 N, 30 kg) and measure the distance between the upper surface of the pedal pad and the floor. When the measurement is smaller than the specification, or when the pedal does not operate smoothly, contact with your SUBARU dealer.

The front disc brake and the right rear disc brake have audible wear indicators on the brake pads. If the brake pads wear close to their service limit, the wear indicator makes a very audible scraping noise when the brake pedal is applied.

If you hear this scraping noise each time

you apply the brake pedal, have the brake pads serviced by your SUBARU dealer as soon as possible.

& Breaking-in of new brake

pads and linings

When replacing the brake pad or lining, use only genuine SUBARU parts. After replacement, the new parts must be broken in as follows: ! Brake pad and lining While maintaining a speed of 30 to 40

mph (50 to 65 km/h), step on the brake pedal this five or more times. ! Parking brake lininglightly. Repeat

WARNING

A safe location and situation should be selected for break-in driving.

CAUTION

Pressing the parking brake pedal too forcefully may cause the rear wheels to lock. To avoid this, be certain to press the pedal slowly and gently.

1. Drive the vehicle at a speed of approximately 22 mph (35 km/h). 2. Press the parking brake pedal SLOWLY and GENTLY. (Pressing with a force of approximately 34 lbs [150 N, 15

kg].) 3. Drive the vehicle for approximately 220 yards (200 meters) in this condition. 4. Wait 5 to 10 minutes for the parking brake to cool down. Repeat this proce- dure. 5. Check the parking brake stroke. If the parking brake stroke is out of the specified range, adjust it by turning the adjusting nut located on the parking brake pedal.Parking brake stroke:

5 – 6 notches / 67 lbs (300 N, 30 kg)

Parking brake stroke

Check the parking brake stroke according to the maintenance schedule in the “Warranty and Maintenance Booklet”. When the parking brake is properly adjusted, braking power is fully applied by pressing the pedal five to six notches gently but firmly (approximately 67 lbs, 300 N, 30 kg). If the parking brake pedal stroke is not within the specified range, have the brake system checked and adjusted at your SUBARU dealer.

Maintenance and service 11-23

Tires and wheels & Types of tires You should be familiar with type of tires present on your vehicle. ! All season tires The factory-installed tires on your new vehicle are all season tires. All season tires are designed to provide an adequate measure of traction, handling and braking performance in year-round driving including snowy and icy road conditions. However all season tires do not offer as much traction performance as winter (snow) tires in heavy or loose snow or on icy roads. All season tires are identified by “ALL SEASON” and/or “M+S” (Mud & Snow) on the tire sidewall. ! Summer tires Summer tires are high-speed capability tires best suited for highway driving under dry conditions. Summer tires are inadequate for driving on slippery roads such as on snow- covered or icy roads. If you drive your vehicle on snow-covered or icy roads, we strongly recommend the use of winter (snow) tires. When installing winter tires, be sure to

– CONTINUED –

11-24 Maintenance and service

replace all four tires. ! Winter (snow) tires Winter tires are best suited for driving on snow-covered and icy roads. However winter tires do not perform as well as summer tires and all season tires on roads other than snow-covered and icy roads.

& Tire pressure monitoring

system (TPMS)

The tire pressure monitoring system pro- vides the driver with a warning message by sending a signal from a sensor that is installed in each wheel when tire pressure is severely low. The tire pressure monitor- ing system will activate only when the vehicle is driven. Also, this system may not react immediately to a sudden drop in tire pressure (for example, a blow-out caused by running over a sharp object).

If you adjust the tire pressures in a warm garage and will then drive the vehicle in cold outside air, the resulting drop in tire pressures may cause the low tire pressure warning light to come on. To avoid this problem when adjusting the tire pressures in a warm garage, inflate the tires to pressures higher than those shown on the tire placard. Specifically, inflate them by an extra 1 psi (6.9 kPa, 0.07 kgf/cm2) for every difference of 108F (5.68C) between

the temperature in the garage and the temperature outside. By way of example, the following table shows the required tire pressures that correspond to various out- side temperatures when the temperature in the garage is 608F (15.68C). Standard tire pressures: Front: 33 psi (230 kPa, 2.3 kgf/cm2) Rear: 32 psi (220 kPa, 2.2 kgf/cm2) Garage temperature: 608F (15.68C)

Outside

temperature

Adjusted pressure [psi (kPa, kgf/cm2)] front rear

308F (−18C)

36 (250, 2.5)

35 (240, 2.4)

108F (−128C)

38

(265, 2.65)

37

(255, 2.55)

−108F (−238C)

40 (280, 2.8)

39 (270, 2.7)

If the low tire pressure warning light comes on when you drive the vehicle in cold outside air after adjusting the tire pressures in a warm garage, re-adjust the tire pressures using the method described above. Then, increase the vehicle speed to at least 20 mph (32 km/h) and check to see that the low tire pressure warning light goes off a few minutes later. If the low tire pressure warning light does not go off, the tire pressure monitoring system may not

be functioning normally. In this event, go to a SUBARU dealer to have the system inspected as soon as possible.

While the vehicle is driven, friction be- tween tires and the road surface causes the tires to warm up. After illumination of the low tire pressure warning light, any increase in the tire pressures caused by an increase in the outside air temperature or by an increase in the temperature in the tires can cause the low tire pressure warning light to go off.

System resetting is necessary when the wheels are changed (for example, a switch to snow tires) and new TPMS valves are installed on the newly fitted wheels. Have this work performed by a SUBARU dealer following wheel replace- ment.

It may not be possible to install TPMS valves on certain wheels that are on the market. Therefore, if you change the wheels (for example, a switch to snow tires), use wheels that have the same part number as the standard-equipment wheels. Without four operational TPMS valve/sensors on the wheels, the TPMS will not fully function and the warning light in the instrument panel will illuminate steadily after blinking for approximately one minute.

When a tire is replaced, adjustments are necessary to ensure continued normal operation of the tire pressure monitoring system. As with wheel replacement, there- fore, you should have the work performed by a SUBARU dealer.

WARNING

If the low tire pressure warning light does not come on briefly after the ignition switch is turned ON or the light illuminates steadily after blink- ing for approximately one minute, you should have your Tire Pressure Monitoring System checked at a SUBARU dealer as soon as possi- ble. If this light comes on while driving, never brake suddenly and keep driving straight ahead while gradu- ally reducing speed. Then slowly pull off the road to a safe place. Otherwise an accident involving serious vehicle damage and serious personal injury could occur. If this light still comes on while driving after adjusting the tire pres- sure, a tire may have significant damage and a fast leak that causes the tire to lose air rapidly. If you have a flat tire, replace it with a spare tire

as soon as possible. When a spare tire is mounted or a wheel rim is replaced without the original pressure sensor/transmitter being transferred, the low tire pres- sure warning light will illuminate steadily after blinking for approxi- mately one minute. This indicates the TPMS is unable to monitor all four road wheels. Contact your SUBARU dealer as soon as possible for tire and sensor replacement and/ or system resetting. the light illuminates steadily after blinking for approximately one minute, promptly contact a SUBARU dealer to have the system inspected.

If

& Tire inspection Check on a daily basis that the tires are free from serious damage, nails, and stones. At the same time, check the tires for abnormal wear. Contact your SUBARU dealer ately if you find any problem. NOTE . When the wheels and tires strike curbs or are subjected to harsh treat- ment as when the vehicle is driven on a rough surface, they can suffer damage

immedi-

Maintenance and service 11-25

that cannot be seen with the naked eye. This type of damage does not become evident until time has passed. Try not to drive over curbs, potholes or on other rough surfaces. If doing so is unavoidable, keep the vehicle’s speed down to a walking pace or less, and approach the curbs as squarely as possible. Also, make sure the tires are not pressed against the curb when you park the vehicle. . If you feel unusual vibration while driving or find it difficult to steer the vehicle in a straight line, one of the tires and/or wheels may be damaged. Drive slowly to the nearest authorized SUBARU dealer and have the vehicle inspected.

& Tire pressures and wear Maintaining the correct tire pressures helps to maximize the tires’ service lives and is essential for good running perfor- mance. Check and, if necessary, adjust the pressure of each tire (including the spare) at least once a month (for example, during a fuel stop) and before any long journey.

– CONTINUED –

. Correct evenly)

tire pressure (tread worn

NOTE . The air pressure in a tire increases by approximately 4.3 psi (30 kPa, 0.3

kgf/cm2) when the tire becomes warm. . The tires are considered cold when the vehicle has been parked for at least three hours or has been driven less than one mile (1.6 km).WARNING

Do not let air out of warm tires to adjust pressure. Doing so will result in low tire pressure.

Incorrect tire pressures detract from con- trollability and ride comfort, and they cause the tires to wear abnormally.

Roadholding is good, and steering is responsive. Rolling resistance is low, so fuel consumption is also lower.

11-26 Maintenance and service

Check the tire pressures when the tires are cold. Use a pressure gauge to adjust the tire pressures to the values shown on the tire placard. The tire placard is located on the door pillar on the driver’s side.

Driving even a short distance warms up the tires and increases the tire pressures. Also, the tire pressures are affected by the outside temperature. It is best to check tire pressure outdoors before driving the vehicle.

When a tire becomes warm, the air inside it expands, causing the tire pressure to increase. Be careful not to mistakenly release air from a warm tire to reduce its pressure.

. Abnormally low tire pressure (tread worn at shoulders)

. Abnormally high tire pressure (tread worn in center)

Rolling resistance is high, so fuel con- sumption is also higher.

is poor. Also,

the tire Ride comfort magnifies the effects of road-surface bumps and dips, possibly resulting in vehicle damage.

WARNING

Driving at high speeds with exces- sively low tire pressures can cause the tires to deform severely and to rapidly become hot. A sharp in- crease in temperature could cause tread separation, and destruction of the tires. The resulting loss of vehicle control could lead to an accident.

Maintenance and service 11-27

that

& Wheel balance Each wheel was correctly balanced when your vehicle was new, but the wheels will become unbalanced as the tires become worn during use. Wheel imbalance causes the steering wheel to vibrate slightly at certain vehicle speeds and detracts from the vehicle’s straight-line stability. It can also cause steering and suspension sys- tem problems and abnormal tire wear. If you suspect the wheels are not correctly balanced, have them checked and adjusted by your SUBARU dealer. Also have them adjusted after tire repairs and after tire rotation. NOTE Loss of correct wheel alignment* causes the tires to wear on one side and reduces the vehicle’s running stability. Contact your SUBARU dealer if you notice abnormal tire wear. *: The suspension system is designed to hold each wheel at a certain alignment (relative to the other wheels and to the road) for optimum straight-line stability and cornering perfor- mance.

– CONTINUED –

11-28 Maintenance and service

& Wear indicators

cause the vehicle to hydroplane. The resulting loss of vehicle control can lead to an accident.

the direction mark facing forward.

& Tire rotation

NOTE For safety, inspect the tire tread reg- ularly and replace the tires before their tread wear indicators become visible.

& Tire rotation direction mark

1) New tread 2) Worn tread 3)

Tread wear indicator

Each tire incorporates a tread wear indicator, which becomes visible when the depth of the tread grooves decreases to 0.071 in (1.8 mm). A tire must be replaced when the tread wear indicator appears as a solid band across the tread.

WARNING

When a tire’s tread wear indicator becomes visible, the tire is worn beyond the acceptable limit and must be replaced immediately. With a tire in this condition, driving at high speeds in wet weather can

Example of tire rotation direction mark 1)

Front

the tire has the rotation direction the tire rotation direction

If specification, mark is placed on its sidewall. When you install a tire that has the tire rotation direction mark, install the tire with

Vehicles equipped with 4 non-unidirec- tional tires 1)

Front

& Tire replacement The wheels and tires are important and integral parts of your vehicle’s design; they cannot be changed arbitrarily. The tires fitted as standard equipment are optimally matched to the characteristics of the vehicle and were selected to give the best possible combination of running performance, ride comfort, and service life. It is essential for every tire to have a size and construction matching those shown on the tire placard and to have a speed symbol and load index matching those shown on the tire placard.

Using tires of a non-specified size detracts from controllability, ride comfort, braking performance, speedometer accuracy and odometer accuracy. It also creates incor- rect body-to-tire clearances and inappro- priately changes the vehicle’s ground clearance.

All four tires must be the same in terms of manufacturer, brand (tread pattern), con- struction, and size. You are advised to replace the tires with new ones that are identical to those fitted as standard equip- ment.

For safe vehicle operation, SUBARU recommends replacing all tires at the same time.

four

Maintenance and service 11-29

WARNING

. All four tires must be the same in terms of manufacturer, brand (tread pattern), construction, de- gree of wear, speed symbol, load index and size. Mixing tires of different types, sizes or degrees of wear can result in damage to the vehicle’s powertrain. Use of different types or sizes of tires can also dangerously reduce controllability and braking per- formance and can lead to an accident.

. Use only radial tires. Do not use radial tires together with belted bias tires and/or bias-ply tires. Doing so can dangerously re- duce controllability, resulting in an accident.

& Wheel replacement When replacing wheels due, for example, to damage, make sure the replacement wheels match the specifications of the wheels that are fitted as standard equip- ment. Replacement wheels are available from SUBARU dealers.

– CONTINUED –

Vehicles equipped with unidirectional tires 1)

Front

Tire wear varies from wheel to wheel. To maximize the life of each tire and ensure that the tires wear uniformly, it is best to rotate the tires every 7,500 miles (12,000

km). Move the tires to the positions shown in the illustration each time they are rotated. Replace any damaged or unevenly worn tire at tire the tire pressures and rotation, adjust make sure the wheel nuts are correctly tightened.rotation. After

the time of

After driving approximately 600 miles (1,000 km), check the wheel nuts again and retighten any nut that has become loose.

11-30 Maintenance and service

WARNING

Use only those wheels that are specified for your vehicle. Wheels not meeting specifications could interfere with brake caliper opera- tion and may cause the tires to rub against the wheel well housing dur- ing turns. The resulting loss of vehicle control could lead to an accident.

Aluminum wheels . Aluminum wheels can be scratched and damaged easily. Handle them care- fully to maintain their appearance, perfor- mance, and safety.

1)

The length of the wheel nut wrench

CAUTION

There are 2 types of wheel nut wrenches that apply to different lengths. For an aluminum wheel vehicle, the 11.2-inch (285 mm) wheel nut wrench is equipped as a mainte- nance tool. And for a chrome plated wheel vehicle, the 13.2-inch (335

mm) wheel nut wrench is equippedas well. Always use a wheel nut wrench for an aluminum wheel. If you use a wrench for a chrome plated wheel, you cannot tighten it to the specified torque.

. When any of the wheels are removed and replaced for tire rotation or to change a flat tire, always check the tightness of the wheel nuts after driving approximately 600 miles (1,000 km). If any nut is loose, tighten it to the following specified torque. A tightening sequence specification for the wheel nuts can be found in the “Flat tires” in chapter 9. Wheel nuts tightening torque for alu- minum wheel: 74 to 89 lbf·ft (100 to 120 N·m, 10 to 12

kgf·m) This torque is equivalent to applying approximately 88 to 110 lbs (40 to 50 kg) at the top of the wheel nut wrench. . Never apply oil to the threaded parts, wheel nuts, or the wheel. . Never let the wheel rub against sharp protrusions or curbs. . Be sure to fit tire chains on uniformly and completely around the tire, otherwise the chains may scratch the wheel. . When wheel nuts, balance weights, ortapered surface of

the center cap is replaced, be sure to replace them with genuine SUBARU parts designed for aluminum wheels.

Chrome plated wheels (if equipped)

1)

The length of the wheel nut wrench

CAUTION

There are 2 types of wheel nut wrenches that apply to different lengths. For an aluminum wheel vehicle, the 11.2-inch (285 mm) wheel nut wrench is equipped as a mainte- nance tool. And for a chrome plated wheel vehicle, the 13.2-inch (335

mm) wheel nut wrench is equipped as well. Always use a wheel nut wrench for a chrome plated wheel. If you use a wrench for an aluminumMaintenance and service 11-31

wheel, you cannot tighten it to the specified torque.

. When any of the wheels are removed and replaced for tire rotation or to change a flat tire, always check the tightness of the wheel nuts after driving approximately 600 miles (1,000 km). If any nut is loose, tighten it to the following specified torque. A tightening sequence specification for the wheel nuts can be found in the “Flat tires” in chapter 9. Wheel nuts tightening torque for chrome plated wheel: 89 to 111 lbf·ft (120 to 150 N·m, 12 to 15

kgf·m) This torque is equivalent to applying approximately 86 to 108 lbs (39 to 49 kg) at the top of the wheel nut wrench. . Never apply oil to the threaded parts, wheel nuts, or the wheel. . Never let the wheel rub against sharp protrusions or curbs. . Be sure to fit tire chains on uniformly and completely around the tire, otherwise the chains may scratch the wheel. . When wheel nuts, balance weights, or the center cap is replaced, be sure to replace them with genuine SUBARU parts designed for chrome plated wheels.tapered surface of

11-32 Maintenance and service

Windshield washer fluid

CAUTION

Never use engine coolant as washer fluid because it could cause paint damage.

If you spray washer fluid on the windshield but the windshield washer fluid warning light comes on or the supply of washer fluid drops, check the level of washer fluid in the tank.

level gauge. After adding fluid, make sure the wind- shield washer fluid warning light has gone out. Use windshield washer fluid. If windshield washer fluid is unavailable use clean water. In areas where water freezes in winter, use an anti-freeze type windshield washer fluid. SUBARU Windshield Washer Fluid contains 58.5% methyl alcohol and 41.5% surfactant, by volume. Its freezing tem- perature varies according to how much it is diluted, as indicated in the following table.

Washer Fluid Concentration

30%

50%

100%

Freezing

Temperature 10.48F (−128C) −48F (−208C) −498F (−458C)

CAUTION

Washer fluid level gauge

Remove the washer tank filler cap, then check the fluid level indicated by the level gauge (attached to the inside of the cap). is near the “Low” mark, add If the level fluid until it reaches the “Hi” level on the

Never use engine coolant as washer fluid because it could cause paint damage.

In order to prevent freezing of washer fluid, check the freezing temperatures in the table above when adjusting the fluid

concentration to the outside temperature. If you fill the reservoir tank with a fluid with a different concentration from the one used previously, purge the old fluid from the piping between the reservoir tank and washer nozzles by operating the washer for a certain period of time. Otherwise, if the concentration of the fluid remaining in the piping is too low for the outside temperature, it may freeze and block the nozzles.

CAUTION

Adjust the washer fluid concentra- tion appropriately for the outside temperature. If the concentration is inappropriate, sprayed washer fluid may freeze on the windshield and obstruct your view, and the fluid may freeze in the reservoir tank.

Replacement of wiper blades

Grease, wax, insects, or other materials on the windshield or the wiper blade results in jerky wiper operation and streak- ing on the glass. If you cannot remove the streaks after operating the windshield washer or if the wiper operation is jerky, clean the outer surface of the windshield (or rear window) and the wiper blades using a sponge or soft cloth with a neutral detergent or mild-abrasive cleaner. After cleaning, rinse the windshield and wiper blades with clean water. The windshield is clean if beads do not form when you rinse the windshield with water.

CAUTION

. Do not clean the wiper blades with gasoline or a solvent, such as paint thinner or benzine. This will cause deterioration of the wiper blades.

. When you wish to raise the passenger-side wiper arm, first raise the driver-side wiper arm. Otherwise, the passenger-side wiper assembly and driver-side wiper assembly will touch each other, possibly resulting in scratches.

Maintenance and service 11-33

. Return the passenger-side wiper arm to its original position before returning the driver-side wiper arm to its original position. Otherwise, the passenger-side wiper assembly and driver-side wiper assembly will touch each other, possibly resulting in scratches.

If you cannot eliminate the streaking even after following this method, replace the wiper blades using the following proce- dures. Be sure to use genuine SUBARU wiper blade rubbers as replacements.

& Windshield wiper blade as-

sembly

1. Raise the windshield wiper arm on the driver’s side. 2. Next, raise the windshield wiper arm on the passenger’s side.

– CONTINUED –

11-34 Maintenance and service

wiper arm snap onto the windshield could damage it.

& Windshield wiper blade rub-

ber

1) Stopper

3. Remove the wiper blade assembly by holding its pivot area and pushing it in the direction shown by the arrow while de- pressing the wiper blade stopper. 4. Install the wiper blade assembly to the wiper arm. Make sure that it locks in place. 5. Lower the windshield wiper arm on the passenger’s side slowly while supporting it by hand. 6. Next, lower the windshield wiper arm on the driver’s side slowly while support- ing it by hand.

CAUTION

Do not let go of the wiper arm until it touches the windshield. Letting the

1) Metal support

1. Grasp the locked end of the blade rubber assembly and pull it firmly until the stoppers on the rubber are free of the metal support.

1) Metal spines

2. If the new blade rubber is not provided with two metal spines, remove the metal spines from the old blade rubber and install them in the new blade rubber.

CAUTION

Be sure to install each metal spine so as to fit its groove completely on the center ridge of the blade rubber. Doing otherwise may result in dis- location and breakage of the spine during wiper operation.

Maintenance and service 11-35

end of the metal support between the stoppers on the rubber as shown. If the rubber is not retained properly, the wiper blade may scratch the windshield.

& Rear window wiper blade

assembly

1. Raise the wiper arm off window.

the rear

3. Align the claws of the metal support with the grooves in the rubber and slide the blade rubber assembly into the metal support until it locks.

3. Pull the wiper blade assembly toward you to remove it from the wiper arm.

& Rear window wiper blade

rubber

2. Turn the wiper blade assembly coun- terclockwise.

1) Stopper

4. Be sure to position the claws at the

– CONTINUED –

11-36 Maintenance and service

1. Pull out the end of the blade rubber assembly to unlock it from the plastic support.

3. If the new blade rubber is not provided with two metal spines, remove the metal spines from the old blade rubber and install them in the new blade rubber.

2. Pull the blade rubber assembly out of the plastic support.

4. Align the claws of the plastic support with the grooves in the blade rubber assembly, then slide the blade rubber assembly into place.

Securely retain both ends of the rubber with the stoppers on the plastic support ends. If the rubber is not retained properly, the wiper may scratch the rear window glass. 5. Install the wiper blade assembly to the wiper arm. Make sure that it locks in place. 6. Hold the wiper arm by hand and slowly lower it in position.

1) Metal spines

Maintenance and service 11-37

distilled water.

Battery

WARNING

. Before beginning work on or near any battery, be sure to extinguish all cigarettes, matches, and light- ers. Never expose a battery to an open flame or electric sparks. Batteries give off a gas which is highly flammable and explosive. . For safety, in case an explosion does occur, wear eye protection or shield your eyes when work- ing near any battery. Never lean over a battery.

. Do not let battery fluid contact eyes, skin, fabrics, or paint be- cause battery fluid is a corrosive acid. If battery fluid gets on your skin or in your eyes, immediately flush the area with water thor- oughly. Seek medical help imme- diately if acid has entered the eyes. If battery fluid is accidentally swallowed, immediately drink a large amount of milk or water, and seek medical attention im- mediately.

. To lessen the risk of sparks,

remove rings, metal watchbands, and other metal jewelry. Never allow metal tools to contact the positive battery terminal and any- thing connected to it WHILE you are at the same time in contact with any other metallic portion of the vehicle because a short cir- cuit will result.

. Keep everyone including children

away from the battery.

. Charge the battery in a well-

ventilated area.

. Battery posts, terminals, and re- lated accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Batteries also contain other chemicals known to the State of California to cause can- cer. Wash hands after handling.

CAUTION

Never use more than 10 amperes when charging the battery because it will shorten battery life.

It is unnecessary to periodically check the battery fluid level or periodically refill with

11-38 Maintenance and service

Fuses

CAUTION

Never replace a fuse with one hav- ing a higher rating or with material other than a fuse because serious damage or a fire could result.

The fuses are designed to melt during an overload to prevent damage to the wiring harness and electrical equipment. The fuses are located in two fuse boxes. One is located under the instrument panel behind the fuse box cover on the driver’s seat side.

Open the lid that is located above the hood release knob and pull it toward you to remove it.

The spare fuses are stored in the main fuse box cover in the engine compart- ment.

The other one is housed in the engine compartment.

The fuse puller is stored in the main fuse box in the engine compartment.

Maintenance and service 11-39

Main fuse

Main fuse box

The main fuses are designed to melt during an overload to prevent damage to the wiring harness and electrical equip- ment. Check the main fuses if any electrical component fails to operate (ex- cept the starter motor) and other fuses are good. A melted main fuse must be replaced. Use only replacements with the same specified rating as the melted main fuse. is replaced, have the electrical system checked by your nearest SUBARU dealer.

If a main fuse blows after

it

If

Inspect

the fuse.

4. Pull out the fuse with the fuse puller. 5. it has blown, replace it with a spare fuse of the same rating. 6.