- 2008 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- 2007 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- 2004 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- 2005 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- 2006 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- 2003 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- 2009 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- 2002 Mini Cooper Owners Manuals

- Mini Cooper Owners Manuals

- Download PDF Manual

-

the clutch carefully during this initial period.

Parking the vehicle Condensation forms in the air conditioner system during operation, and then exits under the vehicle. Traces of condensed water under the vehicle are therefore normal.

Brakes

Do not rest your foot on the brake pedal while driving. Even light but

consistent pedal pressure can lead to high temperatures, brake wear and possibly even brake failure.<

Hydroplaning

When driving on wet or slushy roads, reduce road speed. If you do not, a

wedge of water can form between tires and road surface. This phenomenon is charac- terized by a partial or complete loss of contact between the tires and the road surface. The ultimate results are loss of steering and braking control.<

76

GENERAL DRIVING NOTES

REFUELING

Driving through water

Do not drive through water on the road if it is deeper than 1 ft (30 cm),

and then only at walking speed at the most. Otherwise, the vehicle’s engine, the electrical systems and the transmission may be damaged.<

Clothes hooks

When suspending clothing from the hooks, ensure that they will not

obstruct the driver’s vision. Do not hang heavy objects on the hooks. If you do so, they could cause personal injury during braking or evasive maneuvers.<

High temperatures

High temperatures occur in any vehicle equipped with a catalytic

converter. Do not remove the heat protec- tion plates fitted in the area of the exhaust system and do not apply body-cavity protectant to this area. When driving, standing at idle or when parking, take precautions to avoid contact between the hot exhaust system and easily flammable materials (grass, hay or leaves, for example). Such contact could lead to a fire, resulting in serious personal injury and property damage.<

Always switch off the engine before refueling. If you do not, fuel cannot

be filled into the tank and the "Service Engine Soon" lamp may come on.<

1. Open the fuel filler door 2. Turn the filler cap counterclockwise 3. Put the filler cap in the bracket attached

to the fuel filler door.

Always observe all applicable precau- tions and regulations when handling

fuels. Never carry spare fuel containers in your vehicle. Whether empty or full, these containers can leak, cause an explosion, and lead to fire in the event of a collision.<

Simple and environmentally friendly

Always observe all safety precautions posted at the service station when

handling fuel.<

When refueling, insert the filler nozzle completely into the filler pipe. Pulling the nozzle out of the pipe during refueling > results in premature pump shutoff > and will reduce the effect of the fuel vapor recovery system on the pump.

As long as the filler nozzle is used properly, the fuel tank is full whenever the nozzle shuts off the first time. Tank capacity: approx. 13.2 gallons (50 liters).

Close the fuel cap carefully after refuelling until a "click" is heard.

While closing, be sure not to squeeze the strap which is fastened to the filler cap. A loose or missing cap will activate the "Service Engine Soon" warning lamp.<

Refill early to avoid damaging the catalytic converter; never attempt to

drive to the last drop of fuel in the tank.<

77

FUEL SPECIFICATIONS

ANTILOCK BRAKE SYSTEM (ABS)

The engine uses lead-free gasoline only. Required fuel: > Premium Unleaded Gasoline, min. 91 AKI. AKI = Anti Knock Index.

Do not use leaded fuels. The use of leaded fuels will cause permanent

damage to the emissions-control system’s oxygen sensor and the catalytic converter.<

The concept The ABS keeps the wheels from locking while braking, thereby enhancing active driving safety. ABS also includes Electronic Brake Force Distribution (EBV).

Braking with ABS To achieve optimal performance from ABS when reacting to critical situations you should apply maximum pressure to the brake pedal ("panic stop"). Since the vehicle maintains steering responsiveness, you can nevertheless avoid possible obstacles with a minimum of steering effort. Pulsation of the brake pedal in conjunction with the sound of hydraulic regulation indi- cates to you that you are driving at the limit and reminds you to readapt your vehicle’s speed to road surface conditions.

78

Brake pads

For your own safety: use only brake pads that the manufacturer has

released for your particular vehicle model. The manufacturer cannot evaluate non- approved brake pads to determine if they are suited for use, and therefore cannot ensure the operating safety of the vehicle if they are installed.<

BRAKE SYSTEM

Brake fluid level If the brake fluid level is too low and brake pedal travel has become longer, there may be a defect in one of the brake system’s hydraulic circuits.

Proceed to the nearest MINI center. Higher brake application pressure

may be necessary under these conditions, there may be slight "pull" to one side, and brake pedal travel may be longer. Please remember to adapt your driving style accordingly.<

Disc brakes When the vehicle is driven only occasion- ally, during extended periods when the vehicle is not used at all, and in operating conditions where brake applications are less frequent, there is an increased tendency for corrosion of the brake rotors and accumulation of contamination on the brake pads. This occurs because the minimal pressure that must be exerted by the pads to clean the rotors by brake appli- cations is not reached. Corrosion on brake rotors is signaled by a running or pulsation during braking; even extended subsequent braking will not cure this phenomenon.

It is a good idea to periodically dry the brakes with a gentle application when driving in rain and on wet roads. Monitor traffic conditions to ensure that this maneuver does not endanger other road users. The heat generated in this process helps dry the brake pads and rotors to ensure that your brake system will respond with undiminished efficiency when you need it. Extended or steep mountain descents should be driven in the gear or in the driving position in which only minimal peri- odic brake application is required. This helps avoid placing excessive loads on the brake system. Stay within the allowable speed range, refer to page 55.

Do not coast with the clutch pressed or with the transmission or selector

lever in Neutral. Do not coast with the engine switched off. The engine provides no braking effect when the transmisson is in neutral and there is no power-assist for braking when the engine is switched off.<

79

TIRE INFLATION PRESSURE

Information for your safety The factory-approved radial tires are matched to the vehicle and have been selected to provide optimum safety and driving comfort if used properly. It is not merely the tire’s service life, but also driving comfort and — above all else — driving safety that depend on the condition of the tires and the maintenance of the specified tire pressure. Incorrect inflation pressure is a frequent cause of tire damage. It also significantly influences the roadholding ability of your MINI.

Inflation pressures are on a sticker attached to the B-pillar and visible with the driver’s door open.

Check tire inflation pressures regularly — at least every two weeks and before

beginning a longer trip. Failure to observe these precautions can result in incorrect tire pressures, which cause instable handling response as well as tire damage, and can ultimately lead to an accident. Also check the inflation pressure on the space-saver spare tire.<

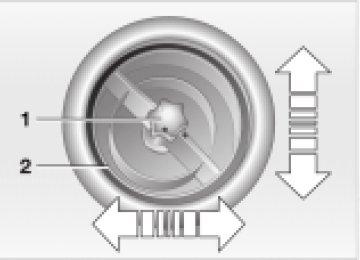

Checking tire inflation pressures All pressures are specified in the standard units of pressure for your country (bar, psi, kilopascal), and apply to cold tires (tires at ambient temperature). Vehicles with Flat Tire Monitor: After correcting the tire inflation pressure, reinitialize the Flat Tire Monitor, see page 62.

Comply with tire approval specifications The specified pressures apply to the tire brands recommended by the manufacturer, which your MINI center can provide for you.

80

Checking the inflation pressure on the space-saver spare tire* There is a valve extension accessible from the outside on the bumper for checking the inflation pressure.

Safety (run-flat) tires* Safety tires are an optional extra consisting of self-contained tires and special rims. The tire reinforcement ensures that the tire retains residual safety in the event of pres- sure drop and driving remains possible to a restricted degree. The vehicle is equipped with a Flat Tire Monitor which indicates a flat-tire. More information, see pages 62, 110.

TIRE INFLATION PRESSURE

Model

Tires

MINI COOPER

MINI COOPER S

Pressures specified in bar (kPa/psi) 175/65 R 15

195/55 R 16

205/45 R 17

175/60 R 16

All winter tires Space-saver spare tire 195/55 R 16

205/45 R 17

195/55 R 16 M+S 205/45 R 17 M+S 175/60 R 16 M+S2.1 (210/30) 2.1 (210/30)

2.4 (240/35) 2.4 (240/35)

2.1 (210/30) 2.1 (210/30)

2.4 (240/35

2.4 (240/35

2.3 (230/33) 2.3 (230/33)

2.6 (260/38) 2.6 (260/38)

4.2 (420/61) 4.2 (420/61) 2.1 (210/30) 2.1 (210/30)

4.2 (420/61) 4.2 (420/61) 2.4 (240/35) 2.4 (240/35)

2.3 (230/33) 2.3 (230/33)

2.6 (260/38) 2.6 (260/38)

2.5 (250/36) 2.5 (250/36)

2.8 (280/41) 2.8 (280/41)

In the case of all-season tires, the tire inflation pressure for summer tires applies. This data only applies to tires approved and/or recommended by the manufacturer, about which your MINI center will be glad to provide information.

81

TIRE CONDITION

Tire tread/tire damage Inspect your tires frequently for tread wear, signs of damage and for foreign objects lodged in the tread. Check the tread depth.

The tread depth should not fall below 0.12 in (3 mm), although e. g. European legislation only prescribes a minimum tread depth of 0.063 in (1.6 mm). Below 0.12 in (3 mm) tread pattern depth, there is an increased risk of hydroplaning, even at relatively moderate speeds and with only small amounts of water on the road. Wear indicators in the tread-groove base, see arrow, are spread around the circum- ference of the tire and are marked on the side wall of the tire with TWI — Tread Wear Indicator. The indicators in the tread indicate at 0.063 in (1.6 mm) tread depth that the legally permitted wear limit has been reached.

Do not continue driving on depres- surized (flat) tires, except with safety tires. A flat tire greatly impairs steering and braking response, and can lead to complete loss of control over the vehicle. Avoid overloading the vehicle so that the permitted load on the tires is not exceeded. Overloading can lead to overheating and increases the rate at which damage develops inside the tires. The ultimate result can assume the form of a sudden air loss. Unusual vibrations while driving, e. g. driving over a curb or similar, can indicate tire damage or other damage to the vehicle. This is also true for irregularities in the vehicle’s handling characteristics, such as a pronounced tendency to pull to the left or right. Should this occur, respond by immediately reducing your speed. Proceed carefully to the nearest MINI center or professional tire center, or have the vehicle towed in to have its wheels and tires inspected. Tire damage (up to and including blowouts) can endanger the lives of both the vehicle occupants and other road users.<

82

TIRE REPLACEMENT

To maintain good handling and vehicle response, use only tires of a single tread configuration from a single manufacturer. The manufacturer of your MINI tests and approves wheel and tire combinations.

Do not use retreaded tires, since driving safety may be impaired. This is due to the possible variations in casing structures and, in some cases, to their extreme age, which can lead to a decrease in their durability.<

DOT Quality Grades Tread wear Traction AA A B C Temperature A B C

All passenger car tires must conform to Federal Safety Requirements in

addition to these grades.<

Tread wear The tread wear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear one and one-half (1 g) times as well on the government course as a tire graded 100.

The relative performance of tires depends upon the actual conditions of their use, however, and may depart significantly from the norm due to variations in driving habits, service practices and differences in road characteristics and climate.

Traction The traction grades, from highest to lowest, are AA, A, B, and C. Those grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified govern- ment test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

The traction grade assigned to this tire is based on straight-ahead

braking traction tests, and does not include acceleration, cornering, hydroplaning, or peak traction characteristics.<

Temperature The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel.

Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to a sudden flat tire. The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Car Safety Stan- dard No. 109. Grades B and A represent higher levels of performance on the labora- tory test wheel than the minimum required by law.

The temperature grade for this tire is established for a tire that is properly

inflated and not overloaded. Excessive speed, underinflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.<

Uniform Tire Quality Grading Quality grades can be found where appli- cable on the tire sidewall between tread shoulder and maximum section width. For example: Tread wear 200 Traction AA Temperature A

83

TIRE REPLACEMENT

WHEEL AND TIRE COMBINATIONS

Tire age The date on which the tire was manufac- tured is indicated by the code on the side- wall: DOT ... 1202 indicates that the tire was manufactured in Week 12 of the year 2002. The manufacturer of your MINI recom- mends replacement of all tires — including the space-saver spare tire, after no more than 6 years.

Safety (run-flat) tires*

For replacement, use only safety tires, as in the event of a flat tire there is no

space-saver spare tire. You will recognize safety tires by a circular symbol containing the letters RSC on the side of the tire, see pages 110, 80.<

The right choice The factory-approved normal tires and safety tires are matched to the vehicle and have been selected to provide optimum driving safety and the desired driving comfort.

Never mount wheels and tires that have not been specifically approved by the manufacturer for use on your partic- ular model. Although other wheels and tires may theoretically have the same dimensions, variations in factors such as manufacturing tolerances can result in contact between tire and bodywork, ulti- mately leading to serious accidents. The manufacturer cannot evaluate non- approved wheels and tires to determine if they are suited for use, and therefore cannot ensure the operating safety of the vehicle if they are fitted.<

The manufacturer has tested certain tire brands in each size, categorized them as safe for use on the road, and approved them. Contact your MINI center for more details.

The correct wheel and tire combina- tion affects various systems that would otherwise be impaired, e.g. ABS, ASC+T and DSC. For this reason, use only tires of the same manufacture and tread configuration. In the event of a flat tire, for example, remount the approved wheel and tire combination as soon as possible.<

Storage Store tires in a cool, dry place, protecting them against light whenever possible. Protect the tires against contact with oil, grease and fuel.

Tire changes between axles Depending on individual operating condi- tions, different wear patterns appear on the front and rear axles. In the interests of safety and optimized handling characteris- tics, a change between the axles is not recommended.

84

SNOW CHAINS*

The use of narrow-link snow chains is permitted in pairs only and only on the front wheels with the following tires: 175/65 R 15 175/60 R 16 When fitting, comply with the manufac- turer’s instructions.<

With chains, do not exceed a speed of 30 mph (50 km/h).<

After fitting the snow chains, do not activate the Flat Tire Monitor.

When driving with snow chains, it can be helpful to switch off the ASC+T or DSC for a brief period, see pages 60, 61.<

WINTER TIRES

Choosing the right tire The manufacturer recommends winter tires (M+S radial tires) for driving in adverse winter road conditions. While so-called all- season tires (M+S designation) provide better winter traction than summer tires with the load ratings S, T, H, V, W, they do not achieve the performance of winter tires. In the interest of safe tracking and steering response, install winter tires made by the same manufacturer having the same tread configuration on all four wheels. Before purchasing winter tires, check whether your MINI is fitted with safety tires. You will recognize safety tires by a circular symbol containing the letters RSC on the side of the tire, see page 110. In this case, use only safety tires, as in the event of a flat tire there is no space-saver spare tire. Only winter tires recommended by the manufacturer of your MINI should be fitted. Any MINI center will be glad to advise you on the selection of the right winter tires for the relevant operating conditions.

Observing speeds

Never exceed the maximum speed for which the tires are rated.

Unprofessional attempts by laymen to service tires can lead to damage and acci- dents. Have this work performed by skilled profes- sionals only. Your MINI center will be glad to assist you with both their expertise and the proper equipment for your vehicle.<

Tire condition, tire inflation pressure

Once the tire wears to below 0.16 in (4 mm), winter tires display a percep- tible decrease in their ability to cope with winter driving conditions, and should be replaced in the interest of safety.<

Comply with the specified tire inflation pressures and be sure to have the wheel and tire assemblies balanced every time you change the tires.

85

HOOD

Do not attempt to service your vehicle if you do not have the

required technical background. Before working in the engine compartment, switch off the engine and allow it to cool down. Before working on the electrical system, always disconnect the battery first. For all work on the vehicle, comply with the appropriate information and instructions. Failure to work in an informed, professional manner when servicing components and materials constitutes a safety hazard for vehicle occupants and other road users. If you are not familiar with the guidelines, please have the operations performed by your MINI center.<

86

To unlock Pull the lever in the right door area beneath the instrument panel.

To open 1. Reach under the hood 2. Pull the release lever 3. Open the hood.

To close Allow the hood to fall from a height of about 12 in (30 cm).

To avoid injuries, be sure that the travel path of the hood is clear when

it is closed, as with all closing procedures. If it is determined that the hood is not completely closed while driving, stop immediately and close it securely, see also page 16.<

ENGINE COMPARTMENT — MINI COOPER

1 Reservoir for windshield washer

system 89

2 Coolant expansion tank 91

3 Engine oil filler neck 90

4 Battery 111

5 Brake fluid reservoir 926 Reservoir for headlamp cleaning

system 89

7 Engine oil dipstick 89

87

ENGINE COMPARTMENT — MINI COOPER S

1 Reservoir for windshield washer

system 89

3 Engine oil filler neck 90

4 Auxiliary terminal for jump-2 Coolant expansion tank 91

starting 113

6 Reservoir for headlamp cleaning

system 89

7 Engine oil dipstick 89

5 Brake fluid reservoir 92

88

WASHER FLUID

ENGINE OIL

The oil volume between the two marks on the dipstick ("MIN", "MAX") corresponds to approx. 1.1 quarts (1 liter). Do not fill beyond the upper notch on the dipstick. Excess oil will damage the engine.

Measuring the oil level 1. Park the vehicle on a level surface 2. Switch off the warmed-up engine 3. Pull the dipstick out after approx.

5 minutes and wipe it off with a lint-free cloth, paper towel, or similar material 4. Carefully push the dipstick all the way

into the guide tube and pull it out again. The oil level must be between the two marks on the dipstick.

As with fuel economy, oil consumption is directly influenced by your driving style and vehicle operating conditions.

Headlamp* and windshield washer system Capacity approx. 2.6 quarts (2.5 liters) per reservoir. Fill with water and — if required — with anti- freeze (according to manufacturer’s recom- mendations).

We recommend that you mix the washer fluid before adding it to the

reservoir.<

Antifreeze agent for the washer systems is flammable. Always keep it

well away from sparks and open flames, and store it in tightly closed containers well out of the reach of children. Always observe the instructions for use provided on the container.<

89

Continuous exposure to used oil has caused cancer in laboratory testing. For this reason, any skin areas that come into contact with oil should be thoroughly washed with soap and water. Always store oil, grease, etc., out of reach of children. Comply with all warning labels and information on lubricant containers.<

Comply with the applicable environ- mental laws regulating the disposal

of used oil.<

Approved engine oils The quality of the engine oil selected has critical significance for the operation and service life of an engine. Based on extensive testing, the manufacturer approves only certain grades of engine oil.

You can find out from your MINI center which individual oils have been approved by the manufacturer.<

Alternative oil specifications If you are unable to obtain one of these oils, you may use small volumes of other oils between oil changes in exceptional cases. One of the following oil specifications must be on the oil package: > Preferred: BMW Longlife-01

> Alternative: BMW Longlife-98,BMW Longlife or ACEA A3.

ENGINE OIL

Adding engine oil Only top up oil when the oil level has dropped to just above the lower notch of the dipstick, but before it goes below this mark.

MINI engines are designed to operate without oil additives; the use of addi- tives could lead to damage in some cases. This also applies to the CVT, the manual transmission, and the differential.<

The manufacturer recommends that you have the oil changed only at your MINI center.

90

COOLANT

Do not add coolant to the cooling system when the engine is hot.

Escaping coolant can cause burns. To avoid the possibility of damage later on, never use anything other than factory- approved, nitrite and amino-free extended- duty antifreeze with corrosion inhibitor. Every MINI center is aware of these. Antifreeze and anti-corrosion agents are hazardous to health. Always store these agents in tightly-closed original containers kept well away from the reach of children. Extended-duty antifreeze with corrosion inhibitor contains the flammable substance ethylene-glycol. For this reason, do not spill extended-duty antifreeze with corrosion inhibitor on hot engine parts. It could catch fire and cause serious burns.<

Comply with the applicable environ- mental laws regulating the disposal

of extended-duty antifreeze with corrosion inhibitor.<

The illustration shows an example of the coolant tank on the MINI COOPER.

Checking coolant level Correct coolant level for cold engine (approx. 68 7/20 6): Up to the mark "MAX" of the transparent expansion tank.

Only open the cap of the expansion tank when the engine has cooled

down. The needle on the coolant tempera- ture gauge in the instrument cluster must be no higher than in the first quarter, otherwise there is a danger of scalding.<

To add coolant MINI COOPER: 1. Slowly open the cap by turning it with the tab to allow accumulated pressure toescape.

2. Pull open the cap completely. 3. If the coolant is low, slowly add coolant until the correct level is reached — do not overfill.

MINI COOPER S: 1. Open the cap by turning it slightly coun- terclockwise to allow accumulated pres- sure to escape.

2. Unscrew the cap completely and open. 3. If the coolant is low, slowly add coolant until the correct level is reached — do not overfill.

The coolant consists of water and extended-duty antifreeze with corrosion inhibitor. The mixing ratio of 50 to 50 must be maintained all the year round due to the required corrosion resistance. No other additives are required. Replace the coolant every 4 years.

91

BRAKE FLUID

Warning lamp

If the brake warning lamp comes on with the parking brake released: The brake fluid level is too low, see

page 15.

Brake warning lamp for Canadian models.

Adding brake fluid To add brake fluid or to determine and correct the cause of brake fluid loss, consult your MINI center. Your MINI center is familiar with the specifications for factory- approved brake fluids (DOT 4).

92

Brake fluid loss may result in extended brake pedal travel. If this occurs, refer to the information on page 79.

Brake fluid is hygroscopic, that is, it absorbs moisture from the air over

time. In order to ensure the brake system’s safety and reliability, have the brake fluid changed every two years by a MINI center, see also page 57 and the Service and Warranty Information Booklet (US models)/ Warranty and Service Guide Booklet (Cana- dian models). Brake fluid is toxic and also damages vehicle paintwork. Always store brake fluid in tightly-closed original containers kept well away from the reach of children. Do not spill the brake fluid and do not fill the brake fluid reservoir beyond the "MAX" mark. The brake fluid could ignite upon contact with hot engine parts and cause serious burns.<

Comply with the applicable environ- mental laws regulating the disposal

of brake fluid.<

MINI MAINTENANCE SYSTEM

The MINI Maintenance System has been designed as a reliable means of providing maximum driving and operating safety — and as cost-effectively as possible for you. Please bear in mind that regular mainte- nance is not only necessary for the safety of your vehicle, but also plays a significant role in maintaining the resale value of the vehicle.

Service Interval Display While conventional systems specify main- tenance according to rigid distances driven, the MINI Maintenance System takes account of the operating conditions of the vehicle, for distances can be driven in many different ways: From the point of view of maintenance, 60.000 miles (100.000 km) of short- distance driving cannot be regarded in the same way as 60.000 miles (100.000 km) of long-distance highway travel. The condition-based MINI Maintenance System includes the Engine Oil Service and Inspections I and II. Determining the maintenance intervals according to the actual use of the vehicle covers every kind of operating situation. People who drive very little — much less than 6.000 miles (10.000 km) per year — should have the engine oil changed at least every 2 years since oil deteriorates over time, regardless of use. For more information on the Service Interval Display, see page 57.

Service and Warranty Information Booklet (US models)/Warranty and Service Guide Booklet (Canadian models) For additional information on maintenance intervals and procedures, please refer to the Service and Warranty Information Booklet (US models) or the Warranty and Service Guide Booklet (Canadian models). As a precaution against rust, it is advisable to have the body checked for damage from rocks or gravel at the same time, depending upon operating conditions.

Have your vehicle’s maintenance and repairs performed at your MINI

center. Be sure that all maintenance work is confirmed in the Service and Warranty Information Booklet (US models) or the Warranty and Service Guide Booklet (Cana- dian models). These entries are your proof that the vehicle has received regular main- tenance. They are also a requirement for warranty claims.<

93

CARING FOR YOUR VEHICLE

Suitable car-care products

Rod antenna

Use the cleaning and car-care prod- ucts available at your MINI center.<

Washing your vehicle You can wash your new MINI from the outset in automatic car washes, though you should use brushless car washes.

When using steam jets or high-pres- sure washers, ensure that you keep

the jets sufficiently far away from the vehicle. If the jet is too close or the pressure is too high, this can lead to damage or initial damage that can develop into more serious damage. Water that enters vehicle components can lead to damage over the long term.<

After washing the vehicle, apply the brakes briefly to dry them, otherwise

water can reduce braking efficiency over the short term and the brake rotors can corrode. <

Switch the rain sensor off when passing through an automatic car wash, see page 51. Failure to do so could result in damage caused by undesired wiper activation.<

If necessary, before entering a car wash or garage with elevator ramp for example, remove the rod antenna. To do so, grip the rod antenna at the base and unscrew it from the antenna foot by turning it to the left.<

Headlamps

When cleaning the headlamps, please observe the following: do not clean by wiping with a dry cloth (scratches). Never use abrasives or strong solvents to clean the covers. Remove dirt and contami- nation (such as insects) by soaking with shampoo and then rinsing with plenty of water. Always use a deicer spray to remove accumulated ice and snow — never use a scraper.<

Vehicle paintwork Regular care contributes greatly to driving safety and value retention. Environmental influences varying from one region to the next can affect the vehicle paintwork. Please base the frequency and scope of car care on these various influ- ences.

Care of upholstery Depressions that come about on the uphol- stery material of the seats in daily use can be brushed out using a slightly damp brush against the grain. The fact that velour lays down is not a quality defect, but rather is inevitable in the case of home textiles or clothing mate- rials. In the case of strong sunlight and longer parking periods, cover the seats or all windows to prevent discoloration.

Care of special parts > Light-alloy wheels:

Use wheel cleaner especially during the winter months, but do not use any aggressive, acidic, strong alkali or rough cleansers or steam jets above 140 7 (60 6) (observe the manufacturer’s operating instructions)

> Chrome parts* such as cooler grille, door

handles, etc.: Especially if exposed to road salt, care- fully clean these parts with plenty of water and possibly with a shampoo addi- tive. For additional treatment, use chrome polish

94

CARING FOR YOUR VEHICLE

> Rubber parts:

Treat only with water or rubber care products

> Plastic parts, imitation leather surfaces, headliner, lamp glass, covering glass for the instrument cluster, as well as matt black molded parts: Clean with water and, if necessary, plastic care products. Do not dampen seats and the headliner. Never use solvents such as lacquer thinner, heavy- duty grease remover, fuel or similar

> Safety belts:

Only clean using mild soap, leaving the belts fitted; do not dry clean, as the fabric can be destroyed. Always unroll automatic safety belts when dry. Dirty safety belts prevent unrolling and thus negatively affect safety

> Floor carpets and floor mats*:

If heavily soiled, clean using interior cleaner. Floor mats can be removed to allow the interior to be cleaned

> Wiper blades:

Clean with soapy water. Replace wiper blades twice a year, before and after the cold season. This is particularly impor- tant on vehicles fitted with a rain sensor.

Cleaning agents can contain hazardous or health-damaging

substances. For this reason, always observe the warnings on the package. For interior cleaning, always open the doors or windows of the vehicle. Do not use any products (e.g. solvents) that are not intended for cleaning the vehicle.<

Use only wiper blades which have been approved by the manufac-

turer.<

Leather care The leather* used by the manufacturer is a high-quality natural product processed using state-of-the-art methods, and it will retain its quality level for many years if cared for appropriately. Regular cleaning and care are necessary, as dust and road dirt scratches in pores and creases and lead to heavy wear as well as premature brittleness of the leather surface. This is why you should use a cloth or vacuum cleaner to remove dust from the leather on a regular basis. As dirt and grease can slowly affect the protective layer of the leather, the cleaned leather surfaces must be treated with leather care agent. This also helps to avoid electrostatic charges.

95

VEHICLE IMMOBILIZATION

OBD INTERFACE SOCKET

TECHNICAL MODIFICATIONS

Your MINI center will be glad to advise you on what is important if the vehicle is to be decommissioned for longer than three months.

Any MINI center will be glad to inform you of the advisability, legal regulations and factory recommendations for technical modifications to the vehicle. To do so, they require the vehicle identification number from your vehicle documents.

The interface for onboard diagnostics is located on the driver’s side, behind a cover located beneath the instrument panel. The cover has the letters "OBD" on it. This interface makes it possible to access data on emissions-related components using special equipment.

96

CALIFORNIA PROPOSITION 65 WARNING

California laws require us to state the following warning:

Engine exhaust, some of its constitu- ents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.<

97

98

OVERVIEW

CONTROLS

OPERATION, CARE, MAINTENANCE

OWNER SERVICE PROCEDURES

TECHNICAL DATA

INDEX

99

Repairs

ONBOARD TOOL KIT

WINDSHIELD WIPER BLADES

Storage location The illustration shows an example of the tire change set. Depending on the level of equipment, your MINI is fitted with a special onboard tool kit stored at the following locations: Tire change set for space-saver spare tire: In the luggage compartment under the floor mat. Tool bag for safety tires: In the left of the luggage compartment, behind the side trim panel beside the first- aid kit, see page 113.

Windshield wiper 1. Rotate the wiper arm completely out

Rear window wiper 1. Rotate the wiper arm completely out

from the windshield

2. Set the wiper blade at an angle 3. Press the securing spring (arrow) 4. Unhook the wiper blade towards the

windshield

from the windshield

2. Turn the wiper blade as far as it will go

to the rear, see arrow

3. Press the wiper blade against the limit

and thus out of the mounting

5. Pull the wiper blade past the wiper arm

4. Press the new wiper blade into the

mounting.

toward the top

6. Insert the new wiper blade 7. Press into position until you hear it

engage.

Use only wiper blades which have been approved by the manufac-

turer.<

100

LAMPS AND BULBS

Proceed carefully when handling lamps and bulbs. If you are not familiar with any of the procedures, consult your MINI center.

Do not touch the glass portion of a new bulb with your bare hands since even small amounts of impurities burn into the surface and reduce the service life of the bulb. Use a clean cloth, paper napkin, or a similar material, or hold the bulb by its metallic base.<

Replacement bulbs are available from your MINI center.

1 Low beams H7 bulb, 55 Watts

Whenever working on the electrical system, switch off the electrical

accessory you are working on or disconnect the cable from the negative terminal of the battery. Failure to do this could result in short circuits. To prevent injuries and damage, comply with any instructions provided by the bulb manufacturer.<

2 High beams H7 bulb, 55 Watts

The H7 bulb is pressurized. Therefore, wear safety glasses and protective

gloves. Failure to observe these precautions can result in physical injury if the bulb breaks.<

1. Pull off the cover panel of the corre-

sponding lamp

2. Press the securing wire outwards 3. Fold the securing wire downwards 4. Remove and replace the bulb.

When cleaning the headlamps, please observe the following: do not clean by wiping with a dry cloth (scratches). Never use abrasives or strong solvents to clean the covers. Remove dirt and contami- nation (such as insects) by soaking with shampoo and then rinsing with plenty of water. Always use a deicer spray to remove accumulated ice and snow — never use a scraper.<

Xenon lamps* The service life of these bulbs is very long and the probability of a failure is very low, provided that they are not switched on and off an unusual number of times. If one of these bulbs should nevertheless fail, it is possible to continue driving with great caution using the fog lamps, provided traffic laws in your area do not prohibit this.

Because of the extremely high volt- ages involved, any work on the xenon

lighting system should be carried out by technically-qualified personnel only. Other- wise, there is a risk of fatal injury.<

101

LAMPS AND BULBS

Fog lamps* H7 bulb, 55 Watts Please contact a MINI center in case of a malfunction.

Side turn signal indicators 5 Watt bulb 1. Press the bulb towards the rear of the

vehicle and remove

2. Remove and replace the bulb.

Side marker lamps Side marker lamps in the wheelhouse paneling of the bumper. Please contact a MINI center in case of a malfunction.

Turn signal indicators, front 21 Watt bulb 1. Open the hood 2. Reach into the opening for the turn

signal indicators from above

3. Apply gentle pressure to the bulb holder

while turning it to the left

4. Remove and replace the bulb.

Parking lamps and standing lamps 5 Watt bulb The parking lamps and standing lamps are integrated in the lamp housing of the turn signal indicator. 1. Turn the bulb holder to the left and pull

out

2. Remove and replace the bulb.

102

LAMPS AND BULBS

Tail lamps Rear lamp (3): 21/5 Watt bulb Other bulbs: 21 Watts 1 Rear fog lamp (not active) 2 Turn signal indicator 3 Rear lamp 4 Rear lamp/brake lamp

red yellow red red

Backup lamp Access to the lamp via the rear or underside of the bumper. 1. Press the clips together 2. Push the lamp out of the bumper 3. Apply gentle pressure to the bulb while

turning it to the left

4. Remove and replace the bulb.

To make this clear, the illustration shows a dismantled tail lamp with the bulb holder removed. All of the bulbs are integrated in the bulb holder. To reach the bulb holder, remove the cover of the side trim panel in the luggage compartment.

Replacing bulbs 1. Unplug the power supply 2. Release the bulb holder, see arrow, and

remove

3. Apply gentle pressure to the bulb while

turning it to the left

4. Remove and replace the bulb 5. Plug in the power supply receptacle 6. Press the bulb holder into position until

you hear it engage.

103

LAMPS AND BULBS

Center (high-mount) brake lamp LED strip on the tailgate. Please contact a MINI center in case of a malfunction.

License plate lamps 5 Watt bulb 1. Apply a screwdriver to the recess and

Interior lamps Interior lamp (6 Watt xenon bulb) 1. Press out the lamp cover with a screw-

lever out the lamp cover

2. Replace the bulb.

driver

2. Remove and replace the bulb.

Reading lamps (2 x 6 Watt xenon bulbs) 1. Press out the lamp cover with a screw-

driver

2. Unscrew the entire lamp with a screw-

driver

3. Remove the bulb from above and

replace.

104

LAMPS AND BULBS

Illuminated vanity mirror Lamps in the vanity mirror in the sun visor. Please contact a MINI center in case of a malfunction.

Luggage compartment lamps 5 Watt bulb 1. Press the lamp cover with a screwdriver

to the left and press out

2. Remove and replace the bulb.

Footwell lamps 5 Watt bulb 1. Press out the lamp cover with a screw-

driver

2. Remove and replace the bulb.

Glove compartment lamp 5 Watt bulb 1. Press out the lamp cover with a screw-

driver

2. Remove and replace the bulb.

105

REPAIRING A FLAT TIRE

CHANGING TIRES — MINI WITH SPACE-SAVER SPARE TIRE*

Safety measures in the event of a flat tire:

Stop the vehicle as far as possible from passing traffic. Switch on the hazard warning flashers. Turn the steering wheel to the straight- ahead wheel position and engage the steering lock. Engage the parking brake and shift into 1st or reverse gear (selector lever in P). All passengers should be outside the vehicle and well away from your imme- diate working area (behind a guardrail, for instance). If a warning triangle or portable hazard warning lamp is available, set it up on the roadside at an appropriate distance from the rear of the vehicle. Comply with all safety guidelines and regulations.<

In the event of a flat tire, different proce- dures should be followed depending on the equipment included in your MINI: > Vehicles with space-saver spare tire, see

next column

> Vehicles with safety tires, see page 110.

Additional safety measures in the event of a wheel change: change the wheel only on a level, firm surface which is not slippery. Avoid jacking the vehicle on a soft or slip- pery support surface (snow, ice, loose gravel, etc.), as either the vehicle or the jack could slip sideways. Do not use a wooden block or similar object as a support base for the jack, as this would prevent it from extending to its full support height and reduce its load-carrying capacity. Do not lie under the vehicle or start the engine when the vehicle is supported by the jack — risk of fatal injury.<

To change a space-saver tire, proceed as follows: > Remove the space-saver spare tire, see

page 107

> Prepare the vehicle, see page 108

> Jack up the vehicle, see page 108

> Fit the space-saver spare tire, seepage 109

> Tighten the lug bolts, see page 109

> Drive with space-saver spare tire, seepage 109.

106

Tire change set On vehicles with a space-saver spare tire, the tire change set is stored in the luggage compartment under the floor mat. 1 Chock, folding 2 Hubcap remover 3 Wheel stud wrench 4 Jack 5 Spanner 6 Tow fitting 7 Lifting handle

CHANGING TIRES — MINI WITH SPACE-SAVER SPARE TIRE*

Removing the space-saver spare tire The screw connection of the space-saver spare tire is in the luggage compartment under the floor mat, on the base of the storage compartment for the tire change set. 1. Loosen the screw connection using the

wheel stud wrench

2. Take out the cover panel

3. Screw the lifting handle from the

onboard tool kit onto the thread

4. Raise the lifting handle slightly

5. Squeeze the securing springs 6. The space-saver spare tire is released and must be held by the lifting handle 7. Lower the space-saver spare tire with

the lifting handle

8. Unscrew the lifting handle again