- 2005 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2004 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 1999 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 1998 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2000 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2011 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 1996 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2012 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2007 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2002 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2001 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2008 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2009 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 1997 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- 2006 Nissan Quest Owners Manuals

- Nissan Quest Owners Manuals

- Download PDF Manual

-

7-12

CAUTION

Be sure to use the correct socket to remove the plugs. An incorrect socket can cause damage.

Z X

information’’ section.) Adjust quired.

it as re-

4. Fit the new plugs, one at a time, into the spark plug socket and install them. Turn each plug several full turns by hand, then tighten with a spark plug socket to the correct torque. Do not overtighten. Spark plug tightening torque:

14 to 22 ft-lb (20 to 29 Nzm)

5. Holding the boot, re-connect each high tension cable to its proper spark plug by pushing it on until you feel a snap.

AIR CLEANER HOUSING FILTER

ADI0579

The filter should not be cleaned and reused. Replace it according to the maintenance intervals shown in the ‘‘Maintenance sched- ule’’ section. When replacing the filter, un- clip the four clamps and remove the filter. Wipe the inside of the air cleaner housing and the cover with a damp cloth when replacing filter.

7-13

Z X

DI1017M

1. Disconnect the spark plug cables from

the spark plugs.

When disconnecting, always hold the boots, not the cables. 2. Remove the spark plugs with a spark plug socket. The plug socket has a rub- ber seal that holds the spark plug so it does not fall when it is pulled out. Make sure each spark plug is snugly fitted into the plug socket.

3. Check the gap on each new spark plug with a feeler gauge. (The spark plug gap is shown in the ‘‘Technical and consumer

WIPER BLADES

WARNING

Operating the engine with the air cleaner off can cause you or others to be burned. The air cleaner not only cleans the air, it stops flame if the engine backfires. If it isn’t there and the engine backfires, you could be burned. Don’t drive with it off, and be careful working on the engine with the air cleaner off.

DI1018M

cleaning the blades and using the wipers, replace the blades. REPLACEMENT 1. Lift the wiper arm away from the wind-

shield.

2. Push the lock pin, then remove the wiper

blade.

3. Insert the new wiper blade to the wiper

arm until it clicks into place.

CLEANING If your windshield is not clear after using the windshield washer or if the wiper blade chatters when running, wax or other mate- rial may be on the blade or windshield. Clean the outside of the windshield with a washer solution or a mild detergent. Your windshield is clean if beads do not form when rinsing with clear water. Clean the blade by wiping it with a cloth soaked in a washer solution or a mild deter- gent. Then, rinse the blade with clear water. If your windshield is still not clear after

7-14

Z X

CAUTION

c After wiper blade replacement, re- turn the wiper arm to its original position.

c Otherwise it may be damaged when

the engine hood is opened.

c Make sure the wiper blade contacts the glass, otherwise the arm may be damaged from wind pressure.

ADI0581

Rear wiper blade replacement 1. Lift the wiper arm away from the wind-

shield.

2. Push in the lock pin with a suitable tool,

then pull up on the blade.

3. Insert a new wiper blade onto the wiper arm and press down until the blade clicks into place.

7-15

Z X

PARKING BRAKE CHECK

BRAKE PEDAL

ADI0062

ADI0027

From the released position, push the park- ing brake foot lever down. If the number of clicks is out of the range listed above, see your NISSAN dealer.

With the engine running, check the distance between the upper surface of the pedal and the floor. If it is out of the range shown above, see your NISSAN dealer. Self-adjusting brakes Your vehicle is equipped with self-adjusting brakes. The front disc-type brakes self-adjust every time the brake pedal is applied. The rear drum-type brakes also self-adjust every time the brake pedal is applied. If the brake pedal goes down farther than normal, see your NISSAN dealer

7-16

WARNING

See your NISSAN dealer and have it checked if the brake pedal height does not return to normal.

Brake pad wear indicators The disc pads on your vehicle have audible wear indicators. When a brake pad requires replacement, it makes a high pitched scrap- ing or screeching sound when the vehicle is in motion whether or not the brake pedal is depressed. Have the brakes checked as soon as possible if the wear indicator sound is heard. Under some driving or climate conditions, occasional brake squeak, squeal or other noise may be heard. Occasional brake noise during light to moderate stops is nor- mal and does not affect the function or performance of the brake system. The rear drum brakes (if so equipped) do not have audible wear indicators. Should you ever hear an unusually loud noise from the rear drum brakes, have them inspected as soon as possible by your NISSAN dealer.

Z X

Proper brake inspection intervals should be followed. For more information regard- ing brake inspections, see the appropriate maintenance schedule information in the ‘‘Maintenance schedule’’ section of this manual.

BRAKE BOOSTER

FUSES

Check the brake booster function as fol- lows: 1. With the engine off, press and release times. When the brake pedal several brake pedal movement (distance of travel) remains the same from one pedal application to the next, continue on to the next step.

2. While depressing the brake pedal, start the engine. The pedal height should drop a little.

3. With the brake pedal depressed, turn the engine off. Keep the pedal depressed for about 30 seconds; the pedal height should not change.

4. Run the engine for one minute without depressing the brake pedal, then turn it off. Depress the brake pedal several times. The pedal travel distance will de- crease gradually with each depression as the vacuum is released from the booster.

If the brakes do not operate properly, see your NISSAN dealer.

7-17

ADI0583

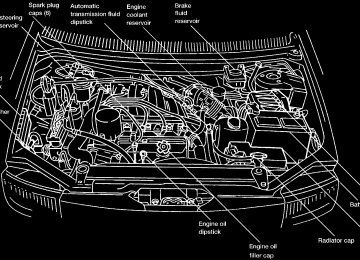

Engine compartment (headlight fuses)

CAUTION

Never use a fuse of a higher amperage rating than that specified on the fuse box cover. This could damage the elec- trical system or cause a fire.

If a headlight does not come on, check for an open fuse: The left headlight (driver’s side) fuse is located in the right-hand fuse box, found in

Z X

the right-front corner of the engine compart- ment. The right headlight (passenger side) fuse is located in the left-hand fuse box, near the radiator cap.

FUSIBLE LINKS

If the electrical equipment does not operate and fuses are in good condition, check the fusible links. If any of these fusible links are melted, replace only with genuine NISSAN parts. If the new fusible link melts again, have the system checked and repaired by your NISSAN dealer.

ADI0584

1. Turn the headlight switch to the OFF

position.

2. Open the engine hood. 3. Remove the appropriate fuse box cover. 4. Remove the fuse with the fuse puller attached to the passenger compartment fuse box cover.

5. If the fuse is open, replace it with a new

fuse.

6. If a new fuse opens again, have the electrical system checked and repaired by your NISSAN dealer.

7-18

Z X

LIGHT BULBS

Passenger compartment CAUTION

Never use a fuse of a higher amperage rating than that specified on the fuse box cover. This could damage the elec- trical system or cause a fire.

If the electrical equipment does not operate, check for an open fuse: 1. Remove the key from the ignition. 2. Open the fuse box cover. Refer to the fuse label on the fuse box cover to locate

ADI0580

AEL076-A

the fuse in question.

3. Remove the fuse with the fuse puller. 4. If the fuse is open, replace it with a new

fuse.

5. If a new fuse opens again, have the electrical system checked and repaired by your NISSAN dealer.

HEADLIGHTS The headlight is a semi-sealed beam type which uses a replaceable headlight (halo- gen) bulb. A bulb can be replaced from inside the engine compartment without re- moving the headlight assembly.

CAUTION

c High pressure halogen gas is sealed inside the halogen bulb. The bulb may break if the glass envelope is scratched or the bulb is dropped.

7-19

Z X

CAUTION

DO NOT TOUCH THE BULB. c Use the same number and wattage

as originally installed: Wattage 65/45

Bulb no. 9004c Aiming is not necessary after replac- ing the bulb. When aiming adjust- ment is necessary, contact your NISSAN dealer.

c Do not leave the bulb out of the headlight reflector for a long period of time as dust, moisture and smoke may enter the headlight body and affect the performance of the head- light.

c When handling the bulb, do not

touch the glass envelope.

Removing the headlight bulb 1. Disconnect the negative (-) battery cable. 2. Disconnect the electrical connector from

the rear end of the bulb.

3. Turn the bulb retaining ring counterclock- it is free from the headlight

wise until reflector, then remove it.

4. Remove the headlight bulb by pulling it straight out. Do not shake or rotate the bulb when removing it.

Replacing the headlight bulb 1. Insert the bulb into the headlight reflector with the flat side of the plastic base facing upward.

2. Install the bulb retaining ring and turn it

clockwise until it stops.

3. Push the electrical connector into the bulb plastic base until it snaps and stops.

7-20

Z X

BULB REPLACEMENT

Item

Wattage (W)

Bulb No.

Headlight (semi-sealed beam)

High/Low

Front combination light:

Front side marker light

Parking/Cornering

Front turn signal light

Rear combination light:

Turn signal

Stop/Tail

Back-up light

Rear side marker light

License plate light

High-mounted stop light

Interior lights

Personal reading light

Luggage compartment light

Steplight

Spotlight

65/45

3.8

8.25/27

27

27

27

27

3.8

3.8

12.8

12

9.8

12

3.8

10

9004

194

3157

3475

1156NA

1157

3156

194

194

912

211-2

208

211-2

194

—

7-21

Z X

ADI0044

Replacement procedures All lights (except for headlights) are either type A, B, C or D. When replacing a bulb, first remove the lens and/or cover.

ADI0577

7-22

Z X

7-23

ADI0049

Z X

7-24

ADI0574

Z X

WHEELS AND TIRES

DI1033M

If you have a flat tire, see the ‘‘In case of emergency’’ section. Maximum inflation pressure Do not exceed the maximum inflation pres- sure shown on the side wall of the tire. Tire inflation pressure Periodically check the tire pressure (includ- ing spare). Incorrect tire pressure may ad- versely affect tire life and vehicle handling. Tire pressure should be checked when tires are COLD. Tires are considered COLD after the vehicle has been parked for three or

Z X

ADI0578

7-25

more hours, or driven less than 1 mile (1.6

km). COLD tire pressures are shown on the tire placard affixed to the glove box door.WARNING

c The vehicle capacity weight is indi- cated on the tire placard. Do not load your vehicle beyond this capacity. Overloading your vehicle may result in reduced tire life, unsafe operating con- ditions due to premature tire failure, or unfavorable handling characteristics and could also lead to a serious acci- dent. Loading beyond the specified ca- pacity may also result in failure of other vehicle components.

c Before taking a long trip, or whenever you have loaded your vehicle heavily, use a tire pressure gauge to ensure that the tire pressure is at the speci- fied level.

c Do not drive your vehicle over 85

MPH (140 km/h) unless it is equipped with high speed capability tires. Driving faster than 85 MPH (140

km/h) may result in tire failure, loss of control and possible injury.Types of tires

CAUTION

When changing or replacing tires, be sure all four tires are of the same type (i.e., Summer, All Season or Snow) and con- struction. Your NISSAN dealer may be able to help you with information about tire type, size, speed rating and availabil- ity. Replacement tires may have a lower speed rating than the factory equipped tires, and may not match the potential maximum vehicle speed. Never exceed the maximum speed rating of the tire.

All Season tires NISSAN specifies All Season tires to pro- vide good performance all year, including snowy and icy road conditions. All Season Tires are identified by ‘‘ALL SEASON’’ and/or ‘‘M&S’’ on the tire sidewall. Snow tires have better snow traction than All Season tires and may be more appropriate in some areas. Snow tires If snow tires are needed, it is necessary to select tires equivalent in size and load rating

7-26

to the original equipment tires. If you do not, it can adversely affect the safety and han- dling of your vehicle. Generally, snow tires have lower speed ratings than factory equipped tires and may not match the potential maximum vehicle speed. Never exceed the maximum speed rating of the tire. For additional traction on icy roads, studded tires may be used. However, some states and provinces prohibit their use. Check lo- cal, state and provincial laws before install- ing studded tires. Skid and traction capabili- ties of studded snow tires on wet or dry surfaces may be poorer than that of non- studded snow tires. Tire chains Use of tire chains may be prohibited accord- ing to location. Check the local laws before installing tire chains. When installing tire chains, make sure they are of proper size for the tires on your vehicle and are installed according to the chain manufacturer’s sug- gestions. Use only SAE Class ‘‘S’’ chains. Other types may damage your vehicle. Use chain tensioners when recommended by the tire chain manufacturer to ensure a tight

Z X

fit. Loose end links of the tire chain must be secured or removed to prevent the possibil- ity of whipping action damage to the fenders or undercarriage. If possible, avoid fully loading your vehicle when using tire chains. In addition, drive at a reduced speed. Do not exceed maximum speed suggested by the chain manufacturer. Otherwise, your ve- hicle may be damaged and/or vehicle han- dling and performance may be adversely affected. Never install tire chains on T-type and small size spare tires. Do not use tire chains on dry roads.

WARNING

c After rotating the tires, adjust the tire

pressure.

c Retighten the lug nuts after

the wheels have been run for the first 600 miles (1,000 km) (also in cases of a flat tire, etc.).

c Do not include the T-type spare tire or any other small size spare tire in the tire rotation.

ADI0656

Tire rotation NISSAN recommends rotating the tires every 7,500 miles (12,000 km). Tighten wheel nuts to 72 to 87 ft-lb (98 to 118 Nzm). See ‘‘Flat tire’’ in the ‘‘In case of emergency’’ section for tire replacing procedures.

7-27

Z X

DI1035M

Tire wear and damage

WARNING

c Tires should be periodically in- spected for wear, cracking, bulging, or objects caught in the tread. If excessive wear, cracks, bulging, or deep cuts are found, the tire should be replaced. c The original

tires have a built-in tread wear indicator. When the wear indicator is visible, the tire should be replaced.

c Improper service for a T-type spare tire may result in serious personal injury. If it is necessary to repair the T-type spare tire, contact your NISSAN dealer.

Changing tires and wheels When replacing a tire, use the same size, speed rating and load carrying capacity as originally equipped. Recommended types and sizes are shown in ‘‘Wheels and tires’’ in the ‘‘Technical and consumer informa- tion’’ section.

WARNING

c The use of tires other than those recommended or the mixed use of tires of different brands, construc- tion (bias, bias-belted or radial), or tread patterns can adversely affect the ride, braking, handling, ground clearance, body-to-tire clearance, snow chain clearance, speedometer calibration, aim and bumper height. Some of these ef- fects may lead to accidents and could result in serious personal injury.

headlight

7-28

c If the wheels are changed for any reason, always replace with wheels which have the same offset dimen- sion. Wheels of a different offset could cause early tire wear, possibly degraded vehicle handling charac- teristics and/or interference with the brake discs/drums. Such interfer- ence can lead to decreased braking efficiency and/or early brake pad/ shoe wear.

c Do not install a deformed wheel or tire even if it has been repaired. Such wheels or tires could have structural damage and could fail without warn- ing.

Wheel balance Unbalanced wheels may affect vehicle han- dling and tire life. Even with regular use, wheels can get out of balance. Therefore, they should be balanced as required. Wheel balance service should be performed with the wheels off the vehicle. Spin balanc- ing the front wheels on the vehicle could lead to transmission damage.

Z X

CAUTION

c Do not use tire chains on a T-type spare tire. Tire chains will not fit properly on the T-type spare tire and may cause damage to the vehicle.

c Because the T-type spare tire is smaller than the original tire, ground clearance is reduced. To avoid dam- age to the vehicle do not drive over obstacles. Also do not drive the ve- hicle through an automatic car wash since it may get caught.

Care of wheels c Wash the wheels when washing the ve-

hicle to maintain their appearance.

c Clean the inner side of the wheels when the wheel is changed or the underside of the vehicle is washed.

c Do not use abrasive cleaners when

washing the wheels.

c Inspect wheel rims regularly for dents or corrosion. Such damage may cause loss of pressure or poor seal at the tire bead. c NISSAN recommends waxing the road wheels to protect against road salt in areas where it is used during winter.

Spare tire (T-type spare tire) Observe the following precautions if the T-type spare tire must be used, otherwise your vehicle could be damaged or involved in an accident.

WARNING

c The T-type spare tire should be used only for emergency. It should be re- placed by the standard tire at the first opportunity.

c Drive carefully while the T-type spare tire is installed. Avoid sharp turns and abrupt braking while driving.

c Periodically check tire inflation pres- sure, and always keep it at 60 psi (420 kP, 4.2 bar).

c Do not drive your vehicle at speeds

faster than 50 MPH (80 km/h).

c When driving on roads covered with snow or ice, the T-type spare tire should be used on the rear wheel and the original tire used on the front wheels (drive wheels). Use tire chains only on the front two original tires.

c Tire tread of the T-type spare tire will wear at a faster rate than the original tire. Replace the T-type spare tire as soon as the tread wear indicators appear.

c Do not use the T-type spare tire on

other vehicles.

c Do not use more than one T-type

spare tire at the same time.

c Do not tow a trailer while the T-type

spare tire is installed.

7-29

Z X

Z X

8 Maintenance schedule

General maintenance.............................................8-2

Outside the vehicle ................................................8-2

Inside the vehicle ...................................................8-3

Under the hood and vehicle...................................8-4Periodic maintenance schedules ...........................8-5

Schedule 1 .............................................................8-5

Schedule 2 .............................................................8-5

Explanation of maintenance items.......................8-10Z X

Your new NISSAN has been designed to have minimum maintenance requirements with longer service intervals to save you both time and money. However, some day- to-day and regular maintenance is essential to maintain your NISSAN’s good mechani- cal condition, as well as its emission and engine performance. It is the owner’s responsibility to make sure the specified maintenance, as well as gen- eral maintenance, is performed. As the vehicle owner, you are the only one who can ensure that your vehicle receives the proper maintenance care. You are a vital link in the maintenance chain. General maintenance General maintenance includes those items which should be checked during normal day-to-day operation of the vehicle. They are essential if your vehicle is to continue to operate properly. It is your responsibility to perform these procedures regularly as pre- scribed. These checks or inspections can be done by yourself, a qualified technician or, if you prefer, your NISSAN dealer.

Periodic maintenance The maintenance items listed in this section must be serviced at regular intervals. However, under severe driving conditions, additional or more frequent maintenance is required. Where to go for service If maintenance service is required or your vehicle appears to malfunction, have the systems checked and tuned by an autho- rized NISSAN dealer. NISSAN technicians are well-trained spe- cialists and are kept up to date with the latest service information through technical bulletins, service tips, and in-dealership training programs. They are completely qualified to work on NISSAN’s vehicles be- fore they work on your vehicle, rather than after they have worked on it. You can be confident that your NISSAN dealer’s service department performs the best job to meet the maintenance require- ments on your vehicle — in a reliable and economic way.

8-2

GENERAL MAINTENANCE

During the normal day-to-day operation of the vehicle, general maintenance should be performed regularly as prescribed in this section. If you detect any unusual sounds, vibrations or smells, be sure to check for the cause or have your NISSAN dealer do it promptly. In addition, you should notify your NISSAN dealer if you think repairs are re- quired. When performing any checks or mainte- nance work, closely observe the precau- tions in the ‘‘Do-it-yourself operations’’ sec- tion. Additional information on the following items with ‘‘*’’ can be found in the ‘‘Do-it- yourself operations’’ section. OUTSIDE THE VEHICLE The maintenance items listed here should be performed from time to time, unless otherwise specified. Tires* — Check the pressure with a gauge periodically when at a service station, in- cluding the spare, and adjust to the speci- fied pressure if necessary. Check carefully for damage, cuts or excessive wear. Wheel nuts* — When checking the tires,

Z X

make sure no nuts are missing, and check for any loose nuts. Tighten if necessary. Tire rotation* — Tires should be rotated every 7,500 miles (12,000 km). Wheel alignment and balance — If the vehicle should pull to either side while driv- ing on a straight and level road, or if you detect uneven or abnormal tire wear, there may be a need for wheel alignment. If the steering wheel or seat vibrates at normal highway speeds, wheel balancing may be needed. Windshield wiper blades* — Check for cracks or wear if they do not wipe properly. Doors and engine hood — Check that all doors and the engine hood operate prop- erly. Also ensure that all latches lock se- curely. Lubricate hinges, latches, rollers and links if necessary. Make sure the secondary latch keeps the hood from opening when the primary latch is released. When driving in areas using road salt or other corrosive materials, check lubrication frequently.

sure

lights

all warning

INSIDE THE VEHICLE The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle, etc. Lights* — Make sure the headlights, stop lights, tail lights, turn signal lights, and other lights are all operating properly and installed securely. Also check headlight aim. Warning lights and buzzers/chimes — Make and buzzers/chimes are operating properly. Windshield wiper and washer* — Check that the wipers and washer operate properly and that the wipers do not streak. Windshield defroster — Check that the air comes out of the defroster outlets properly and in sufficient quantity when operating the heater or air conditioner. Steering wheel — Check for changes in the steering conditions, such as excessive freeplay, hard steering or strange noises. Seats — Check seat position controls such as seat adjusters, seatback recliner, etc. to ensure they operate smoothly and all latches lock securely in every position.

Check that the head restraints move up and down smoothly and the locks hold securely in all latched positions. Check that the seat leg latches lock securely in every anchor position for the folding down rear seat and detachable rear seat (if so equipped). Seat belts — Check that all parts of the seat belt system (e.g. buckles, anchors, adjust- ers and retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for cuts, fraying, wear or damage. Accelerator pedal — Check the pedal for smooth operation and make sure the pedal does not catch or require uneven effort. Keep the floor mats away from the pedal. Brakes — Check that the brakes do not pull the vehicle to one side when applied. Brake pedal* — Check the pedal for smooth operation and make sure it has the proper distance under it when depressed fully. Check the brake booster function. Be certain to keep floor mats away from the pedal. Parking brake* — Check that the pedal is adjusted to specification and confirm that your vehicle is held securely on a fairly

8-3

Z X

the end of winter,

stances, otherwise rust forms on the floor lines and around the ex- pan, frame, fuel haust system. At the underbody should be thoroughly flushed with plain water, being careful to clean those areas where mud and dirt may accu- mulate. See the ‘‘Appearance and interior care’’ section for additional information. Fluid leaks — Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has been parked for a while. Water dripping from the air conditioner after use is normal. If you should notice any leaks or if gasoline fumes are evident, check for the cause and have it corrected immediately.

steep hill with only the parking brake ap- plied. Automatic transmission ‘‘Park’’ mecha- nism — On a fairly steep hill check that your vehicle is held securely with the selector lever in the P (Park) position without apply- ing any brakes. UNDER THE HOOD AND VEHICLE The maintenance items listed here should be checked periodically, for example, each time you check the engine oil or refuel. Windshield washer fluid* — Check that there is adequate fluid in the tank. Engine coolant level* — Check the cool- ant level when the engine is cold. Radiator and hoses — Check the front of the radiator and clean off any dirt, insects, leaves, etc., that may have accumulated. Make sure the hoses have no cracks, de- formation, rot, or loose connections. Brake fluid level* — Make sure the brake fluid level is between the MAX and MIN lines on the reservoir. Battery* — Check the fluid level

in each

cell. It should be between the MAX and MIN lines. Engine drive belts* — Make sure no belts are frayed, worn, cracked or oily. Engine oil level* — Check the level after parking the vehicle on a level surface and turning off the engine. Power steering fluid level* and lines — Check the level when the fluid is cold and the engine is turned off. Check the lines for proper attachment, leaks, cracks, etc. Automatic transmission fluid level* — Check the level after putting the selector lever in P (Park) with the engine idling. Exhaust system — Make sure there are no cracks, holes, loose joints or supports. If the sound of the exhaust seems unusual or there is a smell of exhaust fumes, immedi- ately have the exhaust system inspected by a qualified individual. (See the carbon mon- oxide warning in the ‘‘Starting and driving’’ section.) Underbody — The underbody is frequently exposed to corrosive substances such as those used on icy roads or to control dust. It to remove these sub- is very important 8-4

Z X

c Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

c Driving in dusty conditions. c Driving on rough, muddy, or salt

spread roads.

c Towing a trailer, using a camper or a

car-top carrier. SCHEDULE 2

Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown in Schedule 1 apply to your driving habits.PERIODIC MAINTENANCE SCHEDULES

To ensure smooth, trouble-free, safe and economical driving, NISSAN provides two different maintenance schedules that may be used, depending upon the conditions in which you usually drive. These schedules contain both distance and time intervals, up to 60,000 miles (96,000 km)/48 months. For most people, the odometer reading indi- cates when service is needed. However, if you drive very little, your vehicle should be serviced at the regular time intervals shown in the schedule. After 60,000 miles (96,000

km) or 48 months, continue periodic maintenance at the same mileage/time intervals. SCHEDULE 1

Follow Periodic Maintenance Schedule 1 if your driving habits frequently include one or more of the following driving conditions: c Repeated short trips of less than 5miles (8 km).

c Repeated short trips of less than 10

miles (16 km) with outside tempera- tures remaining below freezing.c Operating in hot weather in stop-

and-go ‘‘rush hour’’ traffic.

8-5

Z X

Schedule 1

Abbreviations: R = ReplaceMAINTENANCE OPERATION

Perform at number of miles, kilometers or months, whichever comes first.

I = Inspect. Correct or replace if necessary.

]: At the mileage intervals only

MAINTENANCE INTERVAL

Miles × 1,000

(km × 1,000) Months3.75 7.5 11.25

(18) (6)(12)

15 18.75 22.5 26.25

(42) (24) 12

21(30) 15

(36) 18

30 33.75 37.5 41.25

(66) (48) 24

33(60) 30

(54) 27

45 48.75 52.5 56.25

(90) (72) 36

45(78) 39

(84) 42

Emission control system maintenance Drive belts Air cleaner filter Vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter (Use NISSAN Premium type or equivalent.) Spark plugs Timing belt

See NOTE (1). See NOTE (2).

See NOTE (3)*.

[R] I* I*

Replace every 30,000 miles (48,000 km) or 36 months.*

[R]

Replace every 105,000 miles (168,000 km).

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required. (3) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or

extremely high, the filters might become clogged. In such an event, replace them immediately.

* Maintenance items and intervals with ‘‘*’’ are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-6

Z X

60

(96) 48I* [R] I* I*

[R]

Abbreviations: I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATION

Perform at number of miles, kilometers or months, whichever comes first.

Chassis and body maintenance

Brake lines & cables

Brake pads, discs, drums & linings

Automatic transmission fluid

See NOTE (1).

Steering gear & linkage, axle & suspension parts

Steering linkage ball joints & front suspension ball joints

Exhaust system

Front drive shaft boots

Supplemental air bag system

See NOTE (2).

MAINTENANCE INTERVAL

Miles × 1,000

(km × 1,000)

Months

7.5

(12)

15

(24)

12

22.5

(36)

18

30

(48)

24

37.5

(60)

30

45

(72)

36

52.5

(84)

42

60

(96)

48

NOTE: (1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) fluid at every

(2) Inspect the supplemental air bag system 10 years after the date of manufacture as noted on the F.M.V.S.S. certification label located

30,000 miles (48,000 km) or 24 months.

on the left center pillar.

8-7

Z X

Schedule 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary.MAINTENANCE OPERATION

Perform at number of miles, kilometers or months, whichever comes first.

Emission control system maintenance Drive belts Air cleaner housing filter Vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter (Use NISSAN Premium type, or equivalent.) Spark plugs Timing belt

]: At the mileage intervals only

MAINTENANCE INTERVAL

Miles × 1,000

(km × 1,000) Months7.5

(12)15

(24) 1222.5

(36) 18See NOTE (1).

37.5

(60) 3045

(72) 3652.5

(84) 4230

(48) 24[R] I* I*

See NOTE (2)*.

Replace every 30,000 miles (48,000 km) or 36 months.*

[R]

Replace every 105,000 miles (168,000 km).

60

(96) 48I* [R] I* I*

[R]

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or

extremely high, the filters might become clogged. In such an event, replace them immediately.

* Maintenance items and intervals with ‘‘*’’ are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-8

Z X

Abbreviations: I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Perform at number of miles, kilome- ters or months, whichever comes first.

Miles × 1,000

(km × 1,000) Months7.5

(12)15

(24) 1222.5

(36) 1830

(48) 2437.5

(60) 3045

(72) 3652.5

(84) 4260

(96) 48Chassis and body maintenance

Brake lines & cables

Brake pads, discs, drums & linings

Automatic transmission oil

Steering gear linkage, axle & suspension parts

Exhaust system

Front drive shaft boots

See NOTE (1).

Supplemental air bag system

See NOTE (2).

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) Inspect the supplemental air bag system 10 years after the date of manufacture as noted on the F.M.V.S.S. certification label located

on the left center pillar.

8-9

Z X

EXPLANATION OF MAINTENANCE ITEMS

Additional information on the following items with ‘‘*’’ is found in the ‘‘Do-it- yourself operations’’ section. Emission control system maintenance Drive belts* — Check drive belts for wear, fraying or cracking and also for proper ten- sion. Replace the drive belts if found dam- aged. Air cleaner filter — Under normal driving conditions, the air cleaner filter should be replaced in accordance with the mainte- nance schedule. However, driving the ve- hicle in dusty areas may cause more rapid clogging of the element. Consequently, the element may have to be replaced more frequently. Vapor lines — Check vapor lines and con- nections for failure or looseness. If leaks are found, replace them. Fuel lines — Check the fuel hoses, piping and connections for leaks, looseness or deterioration. Replace any parts if they are damaged. Fuel filter — If the vehicle is operated under extremely adverse weather condi-

tions or in areas where ambient tempera- tures are either extremely low or extremely high, the filter might become clogged. In such an event, replace the filter immedi- ately. Engine coolant* — Changing engine cool- ant can be performed by your NISSAN dealer or procedures can be found in the Improper air relief after Service Manual. changing coolant can result in reduced heater performance and overheating. Engine oil & oil filter* — Under normal driving conditions, the engine oil and oil filter should be replaced in accordance with the maintenance schedule. However, under se- vere driving conditions, they may have to be replaced more frequently. Spark plugs* — Replace with new plugs having the correct heat range. Timing belt — Replace the timing belt for driving the camshaft. Chassis and body maintenance Brake lines & cables — Check the brake lines and hoses (including brake booster vacuum hoses, connections & check valve) and parking brake cables for proper attach-

8-10

ment, leaks, cracks, chafing, abrasion, de- terioration, etc. Brake pads, discs, drums & linings — Check these and the other neighboring brake components for wear, deterioration and leaks. Under severe driving conditions, they may have to be inspected more fre- quently. Automatic transmission fluid* — Check the fluid level and visually inspect for signs of leakage. Under severe driving conditions, the fluid should be replaced at the specified interval. Steering gear & linkage, axle & suspen- sion parts, and drive shaft boots — Check for damage, looseness and leakage of oil or grease. Under severe driving con- ditions, more frequent inspection should be performed. Steering linkage ball joints & front sus- pension ball joints — Check the ball joints for damage, looseness and grease leakage.

Z X

Exhaust system — Visually check the ex- haust pipes, muffler, and hangers for proper attachment, leaks, cracks, chafing, abra- sion, deterioration, etc. Under severe driv- ing conditions, inspection should be per- formed more frequently. Supplemental air bag system — Check the supplemental air bag system compo- nents for proper attachment, damage, de- formities, cracks, rust, etc. Work around and on the supplemental air bag system should be done by an authorized NISSAN dealer.

8-11

Z X

Z X

9 Technical and consumer information

Capacities and recommended fuel/lubricants........9-2

Fuel recommendation.............................................9-2

Engine oil and oil filter recommendation................9-4

Recommended SAE viscosity number...................9-6

Air conditioner system refrigerant and lubricant recommendations ....................................9-6

Engine ....................................................................9-7

Wheel/tire size........................................................9-8

Dimensions and weights ........................................9-8

Registering your vehicle in another country ..........9-9

Vehicle identification ..............................................9-9

Vehicle identification number (VIN) plate...............9-9

Engine serial number .............................................9-9F.M.V.S.S. certification label................................9-10

Emission control information label .......................9-10

Tire placard ..........................................................9-11

Air conditioner specification label.........................9-11

Installing the license plate....................................9-11

Vehicle loading information..................................9-12

Trailer towing........................................................9-13

Uniform tire quality grading..................................9-18

Emission control system warranty .......................9-19

Reporting safety defects (USA) ...........................9-19

Readiness for inspection/maintenance (I/M) test........................................................................9-20Z X

CAPACITIES AND RECOMMENDED FUEL/LUBRICANTS

The following are approximate capacities. The actual refill capacities may be a little different. When refilling, follow the procedure instructed in the ‘‘Do-it-yourself’’ section to determine the proper refill capacity.

Capacity (Approximate)

US

measure

Imp

measure

Liter

20 gal

16-5/8 gal 75.7

Recommended Fluids & Lubricants

Unleaded gasoline with an octane rat- ing of at least 87 AKI (RON 91)(1)

4-1/4 qt 3-7/8 qt

3-1/2 qt 3-1/8 qt

4.0

3.6API SG or SH and Energy Conserving II (2) API Certification Mark (2)

Fuel

Engine oil (Refill)

With oil filter

Without oil filter

Cooling system

With reservoir tank With rear heater Without rear heater

Reservoir

12-3/4 qt 11-3/8 qt

3/4 qt

10-5/8 qt 9-3/8 qt 5/8 qt

12.1

10.7

0.7Anti-freeze coolant (Ethylene glycol base)

Automatic transaxle fluid

Power steering fluid

Brake fluid

Refill to the proper oil level according to the instructions in the ‘‘Do-it-yourself’’ section.

NISSAN matic ‘D’ (Continental U.S. and Alaska) or Genuine Nissan Automatic Transmission Fluid (Canada).(3) Type F automatic transmission fluid or equivalent Genuine NISSAN Brake Fluid(4) or equivalent DOT 3 (US FMVSS No. 116) NLGI No. 2 (Lithium complex) HFC-134a (R-134a)(5)

— —

Multi-purpose grease Air conditioning system refrigerant (1): For further details, see ‘‘Fuel recommendation’’. (2): For further details, see ‘‘Recommended SAE engine oil viscosity’’. (3): DexronT III/MerconT or equivalent may also be used. Outside the Continental United States and Alaska contact a NISSAN dealership for more information regarding suitable fluids, including recommended brand(s) of DexronT III/MerconT Automatic Transmission Fluid.

— —

— —

(4): Available in mainland U.S.A. through an authorized NISSAN dealer. (5): For further details, see ‘‘Air conditioner specification label’’.

FUEL RECOMMENDATION All models are designed to operate on unleaded gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research octane number 91).

CAUTION

c Using a fuel other than that specified could adversely affect the emission control devices and systems, and could also affect warranty coverage. c Under no circumstances should a leaded gasoline be used, since this will damage the three way catalyst.

Reformulated gasoline Some fuel suppliers are now producing re- formulated gasolines. These gasolines are specially designed to reduce vehicle emis- sions. NISSAN supports efforts towards cleaner air and suggests that you use refor- mulated gasoline when available.

9-2

Z X

Gasoline containing oxygenates Some fuel suppliers sell gasoline containing oxygenates such as ethanol, MTBE and methanol with or without advertising their presence. NISSAN does not recommend the use of fuels of which the oxygenate content and the fuel compatibility for your NISSAN cannot be readily determined. If in doubt, ask your service station manager. If you use oxygenate-blend gasoline, please take the following precautions as the usage of such fuels may cause vehicle perfor- mance problems and/or fuel system dam- age. c The fuel should be unleaded and have an octane rating no lower than that recommended for unleaded gasoline. c If an oxygenate-blend, excepting a methanol blend, it should contain no more than 10% oxygenate. (MTBE may, however, be added up to 15%.)

is used,

c If a methanol blend is used, it should contain no more than 5% methanol (methyl alcohol, wood alcohol). It should also contain a suitable amount of appropriate cosolvents and corro-

sion inhibitors. If not properly formu- lated with appropriate cosolvents and corrosion inhibitors, such methanol blends may cause fuel system dam- age and/or vehicle performance prob- lems. At this time, sufficient data is not available to ensure that all metha- nol blends are suitable for use in NISSAN vehicles.

are

after

experienced

If any undesirable driveability problems such as engine stalling and difficult hot- starting using oxygenate-blend fuels, immediately change to a non-oxygenate fuel or a fuel with a low blend of MTBE. Take care not to spill gasoline during refueling. Gasoline containing oxygen- ates can cause paint damage. Aftermarket fuel additives NISSAN does not recommend the use of any fuel additives (i.e.: fuel injector cleaner, octane booster, intake valve deposit remov- ers, etc.) which are sold commercially. Many of these additives intended for gum, varnish or deposit removal may contain active solvents or similar ingredients that

9-3

to the fuel system and

can be harmful engine. Octane rating tips In most parts of North America, you should use unleaded gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) num- ber. However, you may use unleaded gaso- line with an octane rating as low as 85 AKI (Anti-Knock Index) in high altitude areas (over 4,000 ft [1,219 m]) such as: Colorado, Montana, New Mexico, Utah, Wyoming, northeastern Nevada, southern Idaho, western South Dakota, western Nebraska, and the part of Texas which is directly south of New Mexico. Using unleaded gasoline with an octane rating lower than stated above can cause persistent, heavy ‘‘spark knock.’’ (‘‘Spark knock’’ is a metallic rapping noise.) If severe, this can lead to engine damage. If you detect a persistent heavy spark knock even when using gasoline of the stated octane rating, or if you hear steady spark knock while holding a steady speed on level roads, have an authorized dealer correct the condition. Failure to correct the condition is misuse of the vehicle, for which NISSAN is not respon- sible.

Z X

Incorrect ignition timing may result in spark knock, after-run, and/or overheating, which may cause excessive fuel consumption or engine damage. If any of the above symp- toms are encountered, have your vehicle checked at an authorized NISSAN dealer or other competent service facility. However, now and then you may notice light spark knock for a short time while accelerating or driving up hills. This is no cause for concern, because you get the greatest fuel benefit when there is light spark knock for a short time under heavy engine load.

ENGINE OIL AND OIL FILTER RECOMMENDATION Selecting the correct oil

It is essential to chose engine oil with the correct quality and viscosity to ensure sat- isfactory engine life and performance. NIS- SAN recommends the use of a low friction oil (energy conserving oil) in order to im- prove fuel economy and conserve energy. Oils which do not have the specified quality label should not be used as they could cause engine damage.

9-4

ATI0507

Only those engine oils with the American Petroleum Institute (API) CERTIFICATION MARK on the front of the container should be used. This type of oil supersedes the existing API SG or SH and Energy Conserv- ing II categories. If you cannot find engine oil with the CER- TIFICATION MARK, an API SG or SH, an Energy Conserving II oil with the API Ser- vice Symbol may be used. An oil with a single designation SG or SH, or in combi- nation with other categories (for example, SG/CC or SG/CD) may also be used if one with the

Z X

— repeated short distance driving at cold

outside temperatures,

— driving in dusty conditions, — extensive idling, — towing a trailer.

API CERTIFICATION MARK cannot be found. Mineral based or synthetic type oils may be used in your NISSAN vehicle. These oils must, however, meet the API quality and SAE viscosity ratings specified for your ve- hicle. Do not mix mineral based and syn- thetic type oils in the engine. Oil additives NISSAN does not recommend the use of oil additives. The use of an oil additive is not necessary when the proper oil type is used and maintenance intervals are followed. Oil which may contain foreign matter or has been previously used should not be used. Oil viscosity thickness The engine oil viscosity or changes with temperature. Because of this, it is important to select the engine oil viscos- ity based on the temperatures at which the vehicle will be operated before the next oil change. The chart ‘‘Recommended SAE viscosity number’’ shows the recommended oil viscosities for the expected ambient tem- peratures. Choosing an oil viscosity other

than that recommended could cause seri- ous engine damage. Selecting the correct oil filter Your new NISSAN vehicle is equipped with a high- quality genuine NISSAN oil filter. When replacing, use a genuine NISSAN oil filter or its equivalent for the reason de- scribed in ‘‘Change intervals’’. Change intervals The oil and oil filter change intervals for your engine are based on the use of the specified quality oils and filters. Oil and filter other than the specified quality, or oil and filter change intervals longer than recommended could reduce engine life. Damage to the engine caused by improper maintenance or use of incorrect oil and filter quality and/or viscosity is not covered by the new NISSAN vehicle warranties. Your engine was filled with a high quality engine oil when it was built. You do not have to change the oil before the first recom- mended change interval. Oil and filter change intervals depend upon how you use your vehicle. Operation under the following conditions may require more frequent oil and filter changes:

9-5

Z X

RECOMMENDED SAE VISCOSITY NUMBER

ATI0509

c SAE 5W-30 viscosity oil is preferred for all temperatures. SAE 10W-30 vis- cosity oil may be used if the ambient temperature is above 0°F (-18°C).

AIR CONDITIONER SYSTEM REFRIGERANT AND LUBRICANT RECOMMENDATIONS The air conditioning system in this NISSAN vehicle must be charged with the refrigerant HFC-134a (R-134a) and the lubricant, NISSAN type ‘‘PAG F’’ or the exact equivalents.

CAUTION

Use of any other refrigerant or lubricant will cause severe damage and you will need to replace your vehicle’s entire air conditioning system.

The refrigerant HFC-134a (R-134a) in your NISSAN vehicle does not harm the earth’s ozone layer. Although this refrigerant does not affect the earth’s atmosphere, certain government regulations require the recov- ery and recycling of any refrigerant during automative air conditioning system service. An authorized NISSAN dealer has the trained technicians and equipment needed to recover and recycle your air conditioning system refrigerant. Contact an authorized NISSAN dealer when servicing your air conditioning system.

9-6

Z X

ENGINE

Model Type Cylinder arrangement Bore × Stroke Displacement Firing order Idle speed Ignition timing degree (B.T.D.C.) at idle speed CO percentage at idle speed [No air] Spark plug Standard Cold

Spark plug gap Camshaft operation Drive belts [Width × Length] Generator belt Air conditioner compressor Power steering pump

in (mm) cu in (cm3)

rpm

degree/rpm

in (mm)

in (mm)

VG30E

Gasoline, 4-cycle

6-cylinder, V slanted at 60° 3.425 × 3.268 (87.0 × 83.0)

180.62 (2,960)

1,2,3,4,5,6* (See illustration below)

See the ‘‘Important Vehicle Information’’ label on the underside of the hood.

BKR5EY BKR6EY

0.031 to 0.035 (0.8 to 0.9)

Timing belt** (See note below)

0.7008 × 33.66 (17.80 × 855) 0.5606 × 46.65 (14.24 × 1,185) 0.5606 × 40.74 (14.24 × 1,035)

**NOTE: Periodic maintenance is necessary. Refer to the appropriate periodic

maintenance schedule in Chapter 8.

The spark ignition system of this vehicle meets all requirements of the Canadian Interference-Causing Equipment Regulations.

9-7

Z X

WHEEL/TIRE SIZE

DIMENSIONS AND WEIGHTS

Road wheel

Steel

Aluminum

5.5 - JJ × 15

6.5 - JJ × 15

Overall length

in (mm)

189.9 (4,824)

Overall width

in (mm)

73.7 (1,871)

Offset

in (mm)

1.77 (45)

Overall height

in (mm)

67.6 (1,716)

Tire size

Conventional

Cast aluminum*

Spare

*: Option

P205/75R15

P205/75R15

P215/70R15T125/90D16

P205/75R15