- Download PDF Manual

-

5. Operate the buttons to check its operation.

See a NISSAN dealer if you need any assistance for replacement.

FCC Notice:

This equipment has been tested and found to comply with the limits for a Class B digital device pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful in- stallation. This equipment generates, uses

interference in a residential

8-24 Maintenance and do-it-yourself

Black plate (272,1)

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (273,1)

LIGHTS

Front turn signal light

Front side marker/park light

1. 2. Headlight (high-beam/low-beam) 3. 4. Map light (if so equipped) 5. Ceiling light 6. 7. Side turn signal light 8. High-mounted stop light 9. 10. Rear combination light (stop/tail/turn signal/back-

Front fog light (if so equipped)

License plate light

up light)

11. Cargo light (if so equipped) 12. Rear side marker light

SDI2395

Maintenance and do-it-yourself 8-25

Model "Z12-D" EDITED: 2009/ 1/ 28

HEADLIGHTS Fog may temporarily form inside the lens of the exterior lights in the rain or in a car wash. A temperature difference between the inside and the outside of the lens causes the fog. This is not a malfunction. If large drops of water collect inside the lens, contact a NISSAN dealer.

. Aiming is not necessary after repla- cing the bulb. When aiming adjust- ment is necessary, contact a NISSAN dealer.

Use the same number and wattage as originally installed as shown in the chart.

Replacing

Halogen headlight model:

The headlight is a semi-sealed beam type which uses a replaceable headlight (halogen) bulb.

CAUTION

. Do not leave the bulb out of the headlight reflector for a long period of time. Dust, moisture, smoke, etc. entering the headlight body may affect bulb performance.

. High pressure halogen gas is sealed inside the halogen bulb. The bulb may break if the glass envelope is scratched or the bulb is dropped.

. Only touch the base when handling the bulb. Never touch the glass envelope. Touching the glass envel- ope could significantly affect bulb life and/or headlight performance.

8-26 Maintenance and do-it-yourself

Black plate (274,1)

SDI2396

Disconnect the battery negative cable before replacing bulbs. 1. Remove the connector *A

and the back

cover *B .

2. Unlock the retaining spring *C , and then

remove the bulb.

Model "Z12-D" EDITED: 2009/ 1/ 28

EXTERIOR AND INTERIOR LIGHTS

Item

Headlight high/low beams (Halogen) Front turn signal light* Front fog light (if so equipped)* Front side marker/park light* Side turn signal light* Rear combination light*

turn signal stop/tail back-up

Rear side marker light* License plate light*

Map light (if so equipped) High-mounted stop light* Ceiling light

Cargo light (if so equipped)

Wattage (W)

60/55

21

3521

21/5

18

18Bulb No.

HB2

PY21W

H8

W5W WY5W

PY21W W21/5W W16W W5W W5W

—

W16W

—

—

*: See a NISSAN dealer for replacement. NOTE: Always check with the Parts Department at a NISSAN dealer for the latest information about parts.

Black plate (275,1)

SDI2306

: REMOVE

INSTALL

Replacement procedures All other lights are either type A, B, C, D or E. When replacing a bulb, first remove the lens and/or cover.

Maintenance and do-it-yourself 8-27

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (276,1)

WHEELS AND TIRES

If you have a flat tire, see “FLAT TIRE” in the “6. In case of emergency” section.

TIRE PRESSURE Tire Pressure Monitoring System (TPMS) This vehicle is equipped with the Tire Pressure Monitoring System (TPMS). It monitors tire pressure of all tires except the spare. When the low tire pressure warning light is lit, one or more of your tires is significantly under-inflated.

The TPMS will activate only when the vehicle is driven at speeds above 16 MPH (25 km/h). Also, this system may not detect a sudden drop in tire pressure (for example a flat tire while driving).

For more details, see “Low tire pressure warning light” in the “2. Instruments and controls” section, “TIRE PRESSURE MONITORING SYS- TEM (TPMS)” in the “5. Starting and driving” section and “TIRE PRESSURE MONITORING SYSTEM (TPMS)” in the “6. In case of emergency” section.

Tire inflation pressure Check the pressure of the tires (including the spare) often and always prior to long distance trips. The recommended tire pressure specifications are shown on the Tire and Loading Information label under the “Cold Tire Pressure” heading. The Tire

Model "Z12-D" EDITED: 2009/ 1/ 28

Map light

Cargo light

SDI2391

SDI2392

Ceiling light

SDI1845

8-28 Maintenance and do-it-yourself

and Loading Information label is affixed to the driver side center pillar. Tire pressures should be checked regularly because: . Most tires naturally lose air over time. . Tires can lose air suddenly when driven over potholes or other objects or if the vehicle strikes a curb while parking.

The tire pressures should be checked when the tires are cold. The tires are considered COLD after the vehicle has been parked for 3 or more hours, or driven less than 1 mile (1.6 km) at moderate speeds.

Incorrect tire pressure, including un- der inflation, may adversely affect tire life and vehicle handling.

WARNING

Improperly inflated tires can fail suddenly and cause an accident. . The Gross Vehicle Weight rating (GVWR) is located on the F.M.V. S.S./C.M.V.S.S. certification la- bel. The vehicle weight capacity is indicated on the Tire and Loading Information label. Do

not load your vehicle beyond this capacity. Overloading your vehicle may result in reduced tire life, unsafe operating condi- tions due to premature tire fail- ure, or unfavorable handling characteristics and could also lead to a serious accident. Load- ing beyond the specified capa- city may also result in failure of other vehicle components.

. Before taking a long trip, or whenever you heavily load your vehicle, use a tire pressure gauge to ensure that the tire pressures are at the specified level.

. For additional

information re- garding tires, refer to “Important Tire Safety Information” (US) or “Tire Safety Information” (Cana- da) in the Warranty Information Booklet.

Black plate (277,1)

Maintenance and do-it-yourself 8-29

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (278,1)

*4 Cold tire pressure: Inflate the tires to this pressure when the tires are cold. Tires are considered COLD after the vehicle has been parked for 3 or more hours, or driven less than 1 mile (1.6 km) at moderate speeds. The recommended cold tire inflation is set by the manufacturer to provide the best balance of tire wear, vehicle handling, driveability, tire noise, etc., up to the vehicle’s GVWR.

*5 Tire size — see “TIRE LABELING”

later in this section.

*6 Spare tire size or compact spare tire

size (if so equipped)

Model "Z12-D" EDITED: 2009/ 1/ 28

Tire and Loading Information label *1 Seating capacity: The maximum num- ber of occupants that can be seated in the vehicle.

*2 Vehicle load limit: See “VEHICLE 8-30 Maintenance and do-it-yourself

SDI2340

LOADING INFORMATION” in the “9. Technical and consumer information” section.

*3 Original size: The size of the tires originally installed on the vehicle at the factory.

tion shown on the Tire and Loading Information label.

5. Add air to the tire as needed.

If too much air is added, press the core of the valve stem briefly with the tip of the gauge stem to release pressure. Re- check the pressure and add or release air as needed.

6.

Install the valve stem cap.

7. Check the pressure of all other tires,

including the spare.

SIZE

P195/60R15

87H P195/55R16

86V P195/60R15

87H P195/55R16

86VT125/70D15

COLD TIRE INFLATION PRESSURE 230 kPa, 33 PSI 230 kPa, 33 PSI 230 kPa, 33 PSI 230 kPa, 33 PSI 420 kPa, 60 PSI

FRONT

ORIGINAL

TIRE

REAR

ORIGINAL

TIRE

SPARE

TIRE

SDI1949

Checking the tire pressure 1. Remove the valve stem cap from the

tire.

2. Press the pressure gauge squarely onto the valve stem. Do not press too hard or force the valve stem sideways, or air will escape. the hissing sound of air escaping from the tire is heard while checking the pressure, reposition the gauge to eliminate this leakage.

If

3. Remove the gauge.

4. Read the tire pressure on the gauge stem and compare it to the specifica-

Black plate (279,1)

SDI1575

TIRE LABELING

Example

Federal law requires tire manufacturers to place standardized information on the side- wall of all tires. This information identifies and describes the fundamental character- istics of the tire and also provides the tire identification number (TIN) for safety stan- dard certification. The TIN can be used to identify the tire in case of a recall.

Maintenance and do-it-yourself 8-31

Model "Z12-D" EDITED: 2009/ 1/ 28

5. Two-digit number (16): This number is

the wheel or rim diameter in inches.

6. Two- or three-digit number (94): This number is the tire’s load index. It is a measurement of how much weight each tire can support. You may not find this information on all tires because it is not required by law.

7. H: Tire speed rating. You should not drive the vehicle faster than the tire speed rating.

*1 Tire size (example: P215/60R16

Example

SDI1606

94H)

1. P: The “P” indicates the tire is designed tires

for passenger vehicles. (Not all have this information.)

2. Three-digit number (215): This number gives the width in millimeters of the tire from sidewall edge to sidewall edge.

3. Two-digit number (60): This number, known as the aspect ratio, gives the tire’s ratio of height to width.

4. R: The “R” stands for radial.

8-32 Maintenance and do-it-yourself

Black plate (280,1)

SDI1607

Example

*2 TIN (Tire Identification Number) for a new tire (example: DOT XX XX XXX XXXX)

1. DOT: Abbreviation for the “Department of Transportation”. The symbol can be placed above, below or to the left or right of the Tire Identification Number.

2. Two-digit code: Manufacturer’s identifi-

cation mark

3. Two-digit code: Tire size

4. Three-digit code: Tire type code (Op-

tional)

Model "Z12-D" EDITED: 2009/ 1/ 28

5. Three-digit code: Date of Manufacture

6. Four numbers represent the week and year the tire was built. For example, the numbers 3103 means the 31st week of 2003. If these numbers are missing, then look on the other sidewall of the tire.

*3 Tire ply composition and material

layers or plies of

The number of rubber-coated fabric in the tire. Tire manufacturers also must indicate the materials in the tire, which include steel, nylon, polyester, and others.

*4 Maximum permissible inflation pres-

sure This number is the greatest amount of air pressure that should be put in the tire. Do not exceed the maximum permissible inflation pressure.

*5 Maximum load rating

This number indicates the maximum load in kilograms and pounds that can be carried by the tire. When replacing the tires on the vehicle, always use a tire that has the same load rating as the factory installed

Black plate (281,1)

tire.

*6 Term of “tubeless” or “tube type”

Indicates whether the tire requires an inner tube (“tube type”) or not (“tubeless”).

*7 The word “radial”

The word “radial” is shown, if the tire has radial structure.

*8 Manufacturer or brand name

Manufacturer or brand name is shown.

Other tire-related terminology:

In addition to the many terms that are defined throughout this section, Intended Outboard Sidewall is (1) the sidewall that contains a whitewall, bears white lettering or bears manufacturer, brand and/or model name molding that is higher or deeper than the same molding on the other sidewall of the tire, or (2) the outward facing sidewall of an asymmetrical tire that has a particular side that must always face outward when mounted on a vehicle.

TYPES OF TIRES

WARNING

. When changing or replacing tires, be sure all four tires are of the same type (Example: Summer, All Season or Snow) and construction. A NISSAN dealer may be able to help you with information about tire type, size, speed rating and availability.

. Replacement tires may have a lower speed rating than the factory equipped tires, and may not match the potential maximum vehicle speed. Never exceed the maximum speed rating of the tire.

. Replacing tires with those not ori- ginally specified by NISSAN could affect the proper operation of the TPMS.

. For additional information regard- ing tires, refer to “Important Tire Safety Information” (US) or “Tire Safety Information” (Canada) in the Warranty Information Booklet.

Maintenance and do-it-yourself 8-33

Model "Z12-D" EDITED: 2009/ 1/ 28

All season tires NISSAN specifies all season tires on some models to provide good performance all year, including snowy and icy road conditions. All Season tires are identified by ALL SEASON and/or M&S (Mud and Snow) on the tire sidewall. Snow tires have better snow traction than All Season tires and may be more appro- priate in some areas.

Summer tires NISSAN specifies summer tires on some models to provide superior performance on dry roads. Summer tire performance is substantially reduced in snow and ice. Summer tires do not have the tire traction rating M&S on the tire sidewall.

If you plan to operate your vehicle in snowy or icy conditions, NISSAN recommends the use of SNOW tires or ALL SEASON tires on all four wheels.

Snow tires If snow tires are needed, it is necessary to select tires equivalent in size and load rating to the original equipment tires. it can adversely affect the safety and handling of your vehicle.

If you do not,

Generally, snow tires will have lower speed ratings than factory equipped tires and may not match the potential maximum vehicle speed. 8-34 Maintenance and do-it-yourself

Never exceed the maximum speed rating of the tire.

If you install snow tires, they must be the same size, brand, construction and tread pattern on all four wheels.

For additional traction on icy roads, studded tires may be used. However, some U.S. states and Canadian provinces prohibit their use. Check local, state and provincial laws before installing studded tires. Skid and traction cap- abilities of studded snow tires, on wet or dry surfaces, may be poorer than that of non- studded snow tires.

TIRE CHAINS Use of tire chains may be prohibited according to location. Check the local laws before instal- ling tire chains. When installing tire chains, make sure they are the proper size for the tires on your vehicle and are installed according to the chain manufacturer’s suggestions. Use only SAE Class S chains. Class “S” chains are used on vehicles with restricted tire to vehicle clearance. Vehicles that can use Class “S” chains are designed to meet the SAE standard minimum clearances between the tire and the closest vehicle suspension or body component required to accommodate the use of a winter traction device (tire chains or cables). The minimum clearances are determined using the factory equipped tire size. Other types may damage

Black plate (282,1)

your vehicle. Use chain tensioners when re- commended by the tire chain manufacturer to ensure a tight fit. Loose end links of the tire chain must be secured or removed to prevent the possibility of whipping action damage to the fenders or underbody. If possible, avoid fully loading your vehicle when using tire chains. In addition, drive at a reduced speed. Otherwise, your vehicle may be damaged and/or vehicle handling and performance may be adversely affected.

Tire chains must be installed only on the front wheels and not on the rear wheels.

Never install tire chains on a TEMPORARY USE ONLY spare tire.

Do not use tire chains on dry roads. Driving with tire chains in such conditions can cause damage to the various mechanisms of the vehicle due to some overstress.

Model "Z12-D" EDITED: 2009/ 1/ 28

Wheel nut tightening torque:

80 ft-lb (108 N·m)

The wheel nuts must be kept tigh- tened to the specification at all times. It is recommended that wheel nuts be tightened to the specification at each tire rotation interval.

WARNING

. After rotating the tires, check

and adjust the tire pressure.

. Retighten the wheel nuts when the vehicle has been driven for 600 miles (1,000 km) (also in cases of a flat tire, etc.).

. Do not include the spare tire or any other small size spare tire in the tire rotation.

. For additional

information re- garding tires, refer to “Important Tire Safety Information” (US) or “Tire Safety Information” (Cana- da) in the Warranty Information Booklet.

SDI1662

CHANGING WHEELS AND TIRES Tire rotation NISSAN recommends rotating the tires every 7,500 miles (12,000 km). (See “FLAT TIRE” in the “6. In case of emergency” section for tire replacing procedures.)

As soon as possible, tighten the wheel nuts to the specified torque with a torque wrench.

Black plate (283,1)

SDI1663

1. Wear indicator 2. Wear indicator location mark Tire wear and damage

WARNING

. Tires should be periodically in- spected for wear, cracking, bul- ging or objects caught in the tread. If excessive wear, cracks, bulging or deep cuts are found, the tire(s) should be replaced.

. The original tires have built-in tread wear indicators. When

Maintenance and do-it-yourself 8-35

Model "Z12-D" EDITED: 2009/ 1/ 28

.

WARNING

The use of tires other than those recommended or the mixed use of tires of different brands, construc- tion (bias, bias-belted or radial), or tread patterns can adversely affect the ride, braking, handling, ground clearance, body-to-tire clearance, tire chain clearance, speedometer calibration, headlight aim and bum- per height. Some of these effects may lead to accidents and could result in serious personal injury.

If the wheels are changed for any reason, always replace with wheels which have the same off-set dimen- sion. Wheels of a different off-set could cause premature tire wear, degrade vehicle handling character- istics and/or interference with the brake discs/drums. Such interfer- ence can lead to decreased braking efficiency and/or early brake pad/ shoe wear. See “WHEELS AND TIRES” in the “9. Technical and consumer information” section of this manual for wheel off-set dimen- sions.

Black plate (284,1)

. When a spare tire is mounted or a wheel is replaced, the TPMS will not function and the low tire pressure warning light will flash for approxi- mately 1 minute. The light will remain on after 1 minute. Contact your NISSAN dealer as soon as possible for tire replacement and/ or system resetting.

. Replacing tires with those not ori- ginally specified by NISSAN could affect the proper operation of the TPMS.

. Do not install a damaged or de- formed wheel or tire even if it has been repaired. Such wheels or tires could have structural damage and could fail without warning.

The use of retread tire is not re- commended.

. For additional information regard- ing tires, refer to “Important Tire Safety Information” (US) or “Tire Safety Information” (Canada) in the Warranty Information Booklet.

Model "Z12-D" EDITED: 2009/ 1/ 28

wear indicators are visible, the tire(s) should be replaced.

. Tires degrade with age and use. Have tires, including the spare, over 6 years old checked by a qualified technician, because some tire damage may not be obvious. Replace the tires as necessary to prevent tire failure and possible personal injury. Improper service of the spare tire may result in serious perso- nal injury. If it is necessary to repair the spare tire, contact a NISSAN dealer. . For additional

information re- garding tires, refer to “Important Tire Safety Information” (US) or “Tire Safety Information” (Cana- da) in the Warranty Information Booklet.

Replacing wheels and tires When replacing a tire, use the same size, tread design, speed rating and load carrying capacity as originally equipped. (See “SPECIFICA- TIONS” in the “9. Technical and consumer information” section for recommended types and sizes of tires and wheels.) 8-36 Maintenance and do-it-yourself

Wheel balance Unbalanced wheels may affect vehicle handling and tire life. Even with regular use, wheels can get out of balance. Therefore, they should be balanced as required.

Wheel balance service should be per- formed with the wheels off the vehicle. Spin balancing the wheels on the vehicle could lead to mechanical damage.

For additional information regarding tires, refer to “Important Tire Safety Information” (US) or “Tire Safety Information” (Canada) in the War- ranty Information Booklet.

Care of wheels See “CLEANING EXTERIOR” in the “7. Ap- pearance and care” section for details about care of the wheels.

Spare tire When a spare tire is mounted (TEMPORARY USE ONLY), the TPMS will not function.

Observe the following precautions if the TEM- PORARY USE ONLY spare tire must be used, otherwise your vehicle could be damaged or involved in an accident.

WARNING

The TEMPORARY USE ONLY spare tire should be used for emergency use. It should be replaced with the standard tire at the first opportunity to avoid possible tire or differential damage.

. Drive carefully while the TEMPOR- ARY USE ONLY spare tire is in- stalled. Avoid sharp turns and abrupt braking while driving.

. Periodically check spare tire infla- tion pressure. Always keep the pressure of the TEMPORARY USE ONLY spare tire at 60 psi (420 kPa, 4.2 bar).

. With the TEMPORARY USE ONLY spare tire installed do not drive your vehicle at speeds faster than 50

MPH (80 km/h).. When driving on roads covered with snow or ice, the TEMPORARY USE ONLY spare tire should be used on the rear wheels and original tire used on the front wheels (drive wheels). Use tire chains only on the front (original) tires.

Black plate (285,1)

Tire tread of the TEMPORARY USE ONLY spare tire will wear at a faster rate than the standard tire. Replace the spare tire as soon as the tread wear indicators appear.

. Do not use the spare tire on other

vehicles.

. Do not use more than one spare tire

at the same time.

CAUTION

. Do not use tire chains on a TEM- PORARY USE ONLY spare tire. Tire chains will not fit properly and may cause damage to the vehicle.

. Because the TEMPORARY USE ONLY spare tire is smaller than the original tire, ground clearance is reduced. To avoid damage to the vehicle, do not drive over obstacles. Also do not drive the vehicle through an automatic car wash since it may get caught.

Maintenance and do-it-yourself 8-37

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (286,1)

MEMO

8-38 Maintenance and do-it-yourself

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (28,1)

9 Technical and consumer information

Capacities and recommended fuel/lubricants . . . . . . . . . . . . 9-2

Fuel recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Engine oil and oil filter recommendation. . . . . . . . . . . . . . . 9-5

Air conditioning system refrigerant and lubricant recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Wheels and tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8When traveling or registering your vehicle in another country. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Vehicle identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Vehicle Identification Number (VIN) plate . . . . . . . . . . . . . 9-8

Vehicle identification number (chassis number). . . . . . 9-9

Engine serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

F.M.V.S.S./C.M.V.S.S. certification label . . . . . . . . . . . . . . . 9-9

Emission control information label . . . . . . . . . . . . . . . . . . . . 9-10

Tire and loading information label. . . . . . . . . . . . . . . . . . . . . 9-10

Air conditioner specification label (if so equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Installing front license plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Except for Kro¯ m models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11For Kro¯ m models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Vehicle loading information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Vehicle load capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Securing the load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Loading tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Measurement of weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Flat towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Continuously Variable Transmission (CVT) . . . . . . . . . . 9-19

Manual Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Uniform tire quality grading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Treadwear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Traction AA, A, B and C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Temperature A, B and C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Emission control system warranty. . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Reporting safety defects (US only) . . . . . . . . . . . . . . . . . . . . . . . 9-20

Readiness for Inspection/Maintenance (I/M) test. . . . . . 9-21

Event Data Recorders (EDR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Owner’s Manual/Service Manual order information . . . 9-22

In the event of a collision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (288,1)

CAPACITIES AND RECOMMENDED FUEL/LUBRICANTS

The following are approximate capacities. The actual refill capacities may be a little different. When refilling, follow the procedure instructed in the “8. Maintenance and do-it-yourself” section to determine the proper refill capacity.

Capacity (Approximate)

Recommended specifications

Fuel

Engine oil*1

Drain and refill

With oil filter change

Without oil filter change

Cooling system

With reservoir

Reservoir

Continuously Variable Transmission (CVT) fluid

Manual Transmission (MT) gear oil

Brake fluid

Multi-purpose grease

Air conditioning system refrigerant

Air conditioning system lubricants

CVT model MT model

US measure

Imp measure

13-1/4 gal

11 gal

4-3/8 qt

4 qt

7-1/2 qt 7-1/4 qt

3/4 qt

—

—

3-5/8 qt

3-3/8 qt

6-1/4 qt

6 qt

5/8 qt

—

—

Liter

50

4.1

3.8

7.1

6.80.7

—

—

Refill to the proper oil level according to the instructions in the “8. Maintenance and do-it-yourself” section.

—

—

—

—

—

—

—

—

—

4.5

See “FUEL RECOMMENDATION” later in this section.

. Engine oil with API Certification Mark*2

. Viscosity SAE 5W-3050% Genuine NISSAN Long Life Antifreeze/Coolant or equivalent 50% Demineralized or distilled water

Genuine NISSAN CVT Fluid NS-2*3

Genuine NISSAN gear oil (ELF XT4447 M+) 75W-80, Genuine NISSAN gear oil (Chevron Texaco ETL8997B) 75W-80 or equivalent*4

Genuine NISSAN Super Heavy Duty Brake Fluid*5 or equivalent DOT 3

NLGI No. 2 (Lithium soap base)

HFC-134a (R-134a)*6

NISSAN A/C System Oil Type R or exact equivalent

Genuine NISSAN Windshield Washer Concentrate Cleaner & Antifreeze or equivalent

Window washer fluid

1-1/4 gal

1 gal

*1: For additional information, see “ENGINE OIL” in the “8. Maintenance and do-it-yourself” section for changing engine oil. *2: For additional information, see “ENGINE OIL AND OIL FILTER RECOMMENDATION” later in this section. *3: Use only Genuine NISSAN CVT Fluid NS-2. Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the NISSAN new vehicle limited

warranty. If Genuine NISSAN gear oil is not available, API GL-4, Viscosity SAE 75W-80 may be used as a temporary replacement. Replace with Genuine NISSAN gear oil as soon as it is available.

*4: *5: Available in mainland U.S.A. through a NISSAN dealer. *6: For additional information, see “VEHICLE IDENTIFICATION” later in this section for air conditioner specification label.

9-2 Technical and consumer information

Model "Z12-D" EDITED: 2009/ 1/ 28

FUEL RECOMMENDATION Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research octane number 91).

CAUTION

. Using a fuel other than that speci- fied could adversely affect the emis- sion control system, and may also affect warranty coverage.

. Under no circumstances should a leaded gasoline be used, because this will damage the three-way cat- alyst.

. Do not use E-85 fuel in your vehicle. Your vehicle is not designed to run on E-85 fuel. Using E-85 fuel can damage the fuel system compo- nents and is not covered by the NISSAN new vehicle limited war- ranty.

Gasoline specifications NISSAN recommends using gasoline that meets the World-Wide Fuel Charter (WWFC) speci- fications where it the automobile manufacturers developed this spe- cification to improve emission control system

is available. Many of

and vehicle performance. Ask your service station manager the gasoline meets the WWFC specifications.

if

Reformulated gasoline Some fuel suppliers are now producing refor- mulated gasolines. These gasolines are specially designed to reduce vehicle emissions. NISSAN supports efforts towards cleaner air and sug- gests that you use reformulated gasoline when available.

Gasoline containing oxygenates Some fuel suppliers sell gasoline containing oxygenates such as ethanol, MTBE and metha- nol with or without advertising their presence. NISSAN does not recommend the use of fuels of which the oxygenate content and the fuel compatibility for your NISSAN cannot be readily determined. If in doubt, ask your service station manager.

If you use oxygenate-blend gasoline, please take the following precautions as the usage of such fuels may cause vehicle performance problems and/or fuel system damage.

The fuel should be unleaded and have an octane rating no lower than that recommended for unleaded gasoline.

If an oxygenate-blend, other than methanol blend is used, it should contain no more than 10% oxygenate.

Black plate (289,1)

(MTBE may, however, be added up to 15%.)

If a methanol blend is used, it should contain no more than 5% methanol (methyl alcohol, wood alcohol) . It should also contain a suitable amount of appropriate cosolvents and corro- sion inhibitors. If not properly formu- lated with appropriate cosolvents and corrosion inhibitors, such methanol blends may cause fuel system damage and/or vehicle performance problems. At this time, sufficient data is not available to ensure that all methanol blends are suitable for use in NISSAN vehicles.

If any driveability problems such as engine stalling and difficult hot-starting are experienced after using oxygenate-blend fuels, immediately change to a non-oxygenate fuel or a fuel with a low blend of MTBE.

Take care not to spill gasoline during refueling. Gasoline containing oxygenates can cause paint damage.

E-85 fuel E-85 fuel is a mixture of approximately 85% fuel ethanol and 15% unleaded gasoline. E-85 can only be used in a Flexible Fuel Vehicle (FFV). Do not use E-85 fuel in your vehicle. U.S. govern- ment regulations require fuel ethanol dispensing Technical and consumer information 9-3

Model "Z12-D" EDITED: 2009/ 1/ 28

If any of

damage. the above symptoms are encountered, have your vehicle checked at a NISSAN dealer.

However, now and then you may notice light spark knock for a short time while accelerating or driving up hills. This is not a cause for concern, because you get the greatest fuel benefit when there is light spark knock for a short time under heavy engine load.

CAUTION

. Your vehicle is not designed to run on E-85 fuel. Using E-85 fuel in a vehicle not specifically designed for E-85 fuel can damage fuel system components and is not covered by the NISSAN new vehicle limited warranty.

. E-85 is a mixture of approximately 85% fuel ethanol and 15% unleaded gasoline.

. U.S. government regulations require ethanol dispensing pumps to be identified by a small, square, orange and black label with the common abbreviation or the appropriate per- centage for that region.

Black plate (290,1)

Model "Z12-D" EDITED: 2009/ 1/ 28

pumps to be identified by a small, square, orange and black label with the common abbreviation or the appropriate percentage for that region.

fuel additives (for example,

Aftermarket fuel additives NISSAN does not recommend the use of any aftermarket fuel injector cleaner, octane booster, intake valve deposit removers, etc.) which are sold commer- cially. Many of these additives intended for gum, varnish or deposit removal may contain active solvent or similar ingredients that can be harmful to the fuel system and engine.

Octane rating tips Using unleaded gasoline with an octane rating lower than recommended can cause persistent, heavy “spark knock”. (Spark knock is a metallic rapping noise.) If severe, this can lead to engine damage. If you detect a persistent heavy spark knock even when using gasoline of the stated octane rating, or if you hear steady spark knock while holding a steady speed on level roads, have a NISSAN dealer correct the condition. Failure to correct the condi- tion is misuse of the vehicle, for which NISSAN is not responsible.

ignition timing will

Incorrect in spark knock, after-run and/or overheating, which may cause excessive fuel consumption or engine 9-4 Technical and consumer information

result

Black plate (291,1)

Oil viscosity The engine oil viscosity or thickness changes with temperature. Because of this, it is important to select the engine oil viscosity based on the temperatures at which the vehicle will be operated before the next oil change. Choosing an oil viscosity other than that recommended could cause serious engine damage.

Selecting the correct oil filter Your new NISSAN vehicle is equipped with a high-quality genuine NISSAN oil filter. When replacing, use a genuine NISSAN oil filter or its equivalent for the reason described in “Change intervals”.

Change intervals The oil and oil filter change intervals for your engine are based on the use of the specified quality oils and filters. Using an engine oil and filter other than the specified quality, or exceed- ing recommended oil and filter change intervals could reduce engine life. Damage to the engine caused by improper maintenance or use of incorrect oil and filter quality and/or viscosity is not covered by the NISSAN new vehicle limited warranty.

Your engine was filled with a high quality engine oil when it was built. You do not have to change the oil before the first recommended change interval. Oil and filter change intervals depend

Technical and consumer information 9-5

Model "Z12-D" EDITED: 2009/ 1/ 28

1. API certification mark 2. API service symbol ENGINE OIL AND OIL FILTER RE- COMMENDATION Selecting the correct oil It to choose the correct grade, quality, and viscosity engine oil to ensure satisfactory engine life and performance, see “CAPACITIES AND RECOMMENDED FUEL/ LUBRICANTS” earlier in this section. NISSAN recommends the use of an energy conserving oil in order to improve fuel economy.

is essential

Select only engine oils that meet the American Petroleum Institute (API) certification or Interna-

STI0505

tional Lubricant Standardization and Approval Committee (ILSAC) certification and SAE vis- cosity standard. These oils have the API certification mark on the front of the container. Oils which do not have the specified quality label should not be used as they could cause engine damage.

Oil additives NISSAN does not recommend the use of oil additives. The use of an oil additive is not necessary when the proper oil type is used and maintenance intervals are followed.

Oil which may contain foreign matter or has been previously used should not be used.

The refrigerant HFC-134a (R-134a) in your NISSAN vehicle will not harm the earth’s ozone layer. Although this refrigerant does not affect the earth’s atmosphere, certain governmental regulations require the recovery and recycling of any refrigerant during automotive air condition- ing system service. A NISSAN dealer has the trained technicians and equipment needed to recover and recycle your air conditioning system refrigerant.

Contact a NISSAN dealer when servicing your air conditioning system.

upon how you use your vehicle.

Operation under the following conditions may require more frequent oil and filter changes.

repeated short distance driving at cold outside temperatures

driving in dusty conditions

extensive idling

stop and go commuting

Refer to the “NISSAN Service and Maintenance Guide” for the maintenance schedule.

AIR CONDITIONING SYSTEM RE- FRIGERANT AND LUBRICANT RE- COMMENDATIONS The air conditioning system in your NISSAN vehicle must be charged with the refrigerant HFC-134a (R-134a) and the oil, NISSAN A/C system oil Type R or the exact equivalents.

CAUTION

The use of any other refrigerant or oil will cause severe damage to the air conditioning system and will require the replacement of all air conditioner system components.

9-6 Technical and consumer information

Black plate (292,1)

Model "Z12-D" EDITED: 2009/ 1/ 28

SPECIFICATIONS

ENGINE

Model

Type Cylinder arrangement Bore 6 Stroke Displacement Firing order

Idle speed Ignition timing (B.T.D.C.)

Spark plug

Spark plug gap (Normal)

Camshaft operation

MR18DE

Gasoline, 4-cycle, DOHC 4-cylinder, in-line 3.307 6 3.193 (84.0 6 81.1) 109.65 (1,798) 1-3-4-2

No adjustment is necessary.

FXE20HR-11

0.043 (1.1)

Timing chain

in (mm) cu in (cm3)

rpm degree/rpm

Standard

in (mm)

This spark ignition system complies with the Canadian standard ICES-002.

Black plate (293,1)

WHEELS AND TIRES Road wheel

Type

Steel Aluminum

T-type

Tire

Type

Conventional

T-type

Size 15 6 6J 16 6 6J 15 6 4T

Offset in (mm)

1.65 (42) 1.65 (42)

1.38 (35)

Size

P195/60R15

87HP195/55R16

86V T125/70D15Pressure PSI (kPa) [Cold]

33 (230)

60 (420)

Technical and consumer information 9-7

Model "Z12-D" EDITED: 2009/ 1/ 28

WHEN TRAVELING OR REGISTERING YOUR VEHICLE IN ANOTHER COUNTRY

When planning to travel in another coun- try, you should first find out if the fuel available is suitable for your vehicle’s engine.

Using fuel with an octane rating that is too low may cause engine damage. All gasoline vehicles must be operated with unleaded gasoline. Therefore, avoid taking your vehicle to areas where appropriate fuel is not available.

When transferring the registration of your vehicle to another country, state, province or district, it may be necessary to modify the vehicle to meet local laws and regulations.

The laws and regulations for motor vehicle emission control and safety standards vary according to the country, state, province or district; therefore, vehicle specifications may differ.

When any vehicle is to be taken into another country, state, province or district and registered, its modifications, transpor- tation, and registration are the responsi- bility of the user. NISSAN is not responsible for any inconvenience that may result.

DIMENSIONS AND WEIGHTS

Overall length

in (mm) 156.7 (3,980)*1

156.5 (3,975)*2

157.8 (4,010)*1, *3

157.5 (4,000)*2, *3Overall width Overall height

in (mm) 66.7 (1,695) in (mm) 66.1 (1,680)

Front tread Rear tread Wheelbase

Gross Vehicle Weight Rating (GVWR) Gross Axle Weight Rating (GAWR)

Front

Rear

65.0 (1,650)*3

in (mm) 58.1 (1,475) in (mm) 58.3 (1,480) in (mm) 99.6 (2,530)

lb (kg)

lb (kg)

lb (kg)

See the F.M.V.S.S. or C.M.V.S.S. certification label on the driver’s side center pillar.

*1: With front license plate bracket *2: Without front license plate bracket *3: Kro¯ m model

9-8 Technical and consumer information

Black plate (294,1)

VEHICLE IDENTIFICATION

STI0457

VEHICLE IDENTIFICATION NUMBER (VIN) PLATE The vehicle identification number plate is at- tached as shown. This number is the identifica- tion for your vehicle and is used in the vehicle registration.

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (295,1)

STI0637

STI0466

STI0448

VEHICLE IDENTIFICATION NUMBER (chassis number) The vehicle identification number is located as shown.

Remove the cover to access the number.

ENGINE SERIAL NUMBER The number is stamped on the engine as shown.

F.M.V.S.S./C.M.V.S.S. CERTIFICATION LABEL The Federal/Canadian Motor Vehicle Safety Standards (F.M.V.S.S./C.M.V.S.S.) certification label is affixed as shown. This label contains valuable vehicle information, such as: Gross Vehicle Weight Ratings (GVWR), Gross Axle Weight Rating (GAWR), month and year of manufacture, Vehicle Identification Number (VIN), etc. Review it carefully.

Technical and consumer information 9-9

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (296,1)

STI0638

STI0494

STI0639

EMISSION CONTROL INFORMATION LABEL The emission control is at- tached to the underside of the hood as shown.

information label

TIRE AND LOADING INFORMATION LABEL The cold tire pressure is shown on the Tire and Loading Information label affixed to the pillar as shown.

AIR CONDITIONER SPECIFICATION LABEL (if so equipped) The air conditioner specification label is at- tached to the underside of the hood as shown.

9-10 Technical and consumer information

Model "Z12-D" EDITED: 2009/ 1/ 28

INSTALLING FRONT LICENSE PLATE

Black plate (297,1)

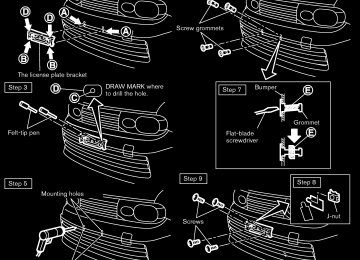

EXCEPT FOR Kro¯ m MODELS Use the following steps to mount the license plate:

Before mounting the license plate, confirm that the following parts are enclosed in the plastic bag.

License plate bracket J-nut 6 2

. Screw 6 2

. Screw grommet 6 21. Park the vehicle on flat, level ground. 2. Locate the center position *A on the lower part of the air duct. Measure straight down from the edge where the bumper and air duct meet to the aligning holes *B , keeping the tape measure lined up with the center position.

3. Mark the holes *B with a felt-tip pen. 4. Carefully drill

the two aligning holes *B using a 0.39 in (10 mm) drill bit at the marked locations. (Be sure that the drill only goes through the bumper fascia.)

5. Line up the bosses *C

or license plate bracket with the holes and hold the license plate bracket in place.

STI0647

Technical and consumer information 9-11

Model "Z12-D" EDITED: 2009/ 1/ 28

6. Mark the center of the holes *D with a felt-

tip pen.

7. Carefully drill the two pilot holes using a 0.39 in (10 mm) drill bit at the marked locations. (Be sure that the drill only goes through the bumper fascia.)

8.

9.

Insert grommets into the hole on the fascia.

Insert a flat-blade screwdriver into the grommet hole to add a 908 turn onto the part *E .

10. Insert a J-nut into the license plate bracket before placing the license plate bracket on the fascia.

11. Install

the license plate bracket with the

screws.

12. Install the license plate with bolts that are

not longer than 0.55 in (14 mm).

9-12 Technical and consumer information

Black plate (298,1)

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (299,1)

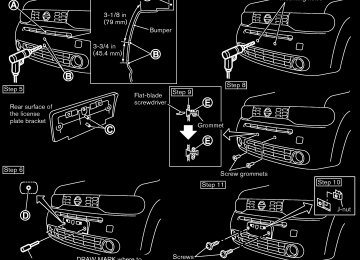

FOR Kro¯ m MODELS Use the following steps to mount the license plate:

Before mounting the license plate, confirm that the following parts are enclosed in the vinyl bag.

License plate bracket J-nut 6 2

. Screw 6 4

. Screw grommet 6 41. Park the vehicle on flat, level ground.

2. Temporarily place the license plate bracket while aligning points *A of the front bumper fascia with holes *B in the license plate bracket.

3. Confirm that points *A and *B are aligned. Hold the license plate bracket and mark the points *C on the bumper facia through the center of the holes *D with a felt-tip pen.

4. Remove the license plate bracket. 5. Carefully drill two shallow pilot holes *A and *C using a 0.39 in (10 mm) drill bit at the marked locations. (Be sure that the drill only goes through the fascia, or damage to the nut may occur.)

STI0648

6.

Insert grommets into the hole on the fascia.

Technical and consumer information 9-13

Model "Z12-D" EDITED: 2009/ 1/ 28

7.

8.

9.

Insert a flat-blade screwdriver into the grommet hole to add a 908 turn onto the part *E . Insert a J-nut into the license plate bracket before placing the license plate bracket on the fascia.

the license plate bracket with the

Install screws.

10. Install the license plate with bolts that are

not longer than 0.55 in (14 mm).

VEHICLE LOADING INFORMATION

WARNING

It is extremely dangerous to ride in a cargo area inside the vehi- cle. In a collision, people riding in these areas are more likely to be seriously injured or killed.

. Do not allow people to ride in any area of your vehicle that is not equipped with seats and seat belts.

. Be sure everyone in your vehicle is in a seat and using a seat belt properly.

TERMS

It is important to familiarize yourself with the following terms before loading your vehicle: . Curb Weight

(actual weight of your vehicle) including: standard and optional equipment, fluids, emergency tools, and spare tire assembly. This weight does not in- clude passengers and cargo.

- vehicle weight

9-14 Technical and consumer information

. GVW (Gross Vehicle Weight) - curb weight plus the combined weight of passengers and cargo.

Black plate (300,1)

. GVWR (Gross Vehicle Weight Rating) - maximum total combined weight of the unloaded vehicle, passengers, luggage, hitch, trailer tongue load and any other optional equipment. This information is located on the F.M.V.S.S./C.M.V.S.S. label.

. GAWR (Gross Axle Weight Rating) - maximum weight (load) limit specified for the front or rear axle. This informa- tion is located on the F.M.V.S.S./C.M.V. S.S. label.

. GCWR (Gross Combined Weight Rat- ing) - The maximum total weight rating of the vehicle, passengers, cargo, and trailer.

limit specified of

. Vehicle Capacity Weight, Load limit, load capacity - maximum total Total weight the load (passengers and cargo) for the vehicle. This is the maximum combined weight of occupants and cargo that can be loaded into the vehicle. If the vehicle is used to tow a trailer, the trailer tongue weight must be included as part of the cargo load. This information is located on the Tire and Loading Information label.

Model "Z12-D" EDITED: 2009/ 1/ 28

. Cargo capacity - permissible weight of cargo, the subtracted weight of occu- pants from the load limit.

VEHICLE LOAD CAPACITY

Do not exceed the load limit of your vehicle shown as “The combined weight of occu- pants and cargo” on the Tire and Loading Information label. Do not exceed the number of occupants shown as “Seating Capacity” on the Tire and Loading Informa- tion label.

To get “the combined weight of occupants and cargo”, add the weight of all occu- pants, then add the total luggage weight. Examples are shown in the following illustration.

Black plate (301,1)

Technical and consumer information 9-15

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (302,1)

if

4. The resulting figure equals the available amount of cargo and luggage load capacity. For example, the XXX amount equals 1400 lbs. and there will be five 150 lb. passengers in your vehicle, the amount of available cargo and luggage load capacity is 650 lbs. (1400 − 750 (5 x 150) = 650 lbs) or (640 − 340 (5 x 70) = 300 kg.)

5. Determine the combined weight of luggage and cargo being loaded on the vehicle. That weight may not safely exceed the available cargo and luggage load capacity calculated in Step 4.

Before driving a loaded vehicle, confirm that you do not exceed the Gross Vehicle Weight Rating (GVWR) or the Gross Axle Weight Rating (GAWR) for your vehicle. (See “MEASUREMENT OF WEIGHTS” later in this section.)

Also check tires for proper inflation pres- sures. See the Tire and Loading Information label.

Model "Z12-D" EDITED: 2009/ 1/ 28

Steps for determining correct load limit 1. Locate the statement “The combined weight of occupants and cargo should never exceed XXX kg or XXX lbs” on your vehicle’s placard.

9-16 Technical and consumer information

STI0447

2. Determine the combined weight of the driver and passengers that will be riding in your vehicle.

3. Subtract the combined weight of the driver and passengers from XXX kg or XXX lbs.

.

a sudden stop or collision, unse- cured cargo could cause personal injury.

The child restraint top tether strap may be damaged by contact with items in the cargo area. Secure any items in the cargo area. Your child could be seriously injured or killed in a collision if the top tether strap is damaged.

. Do not load your vehicle any heavier than the GVWR or the maximum front and rear GAWRs. If you do, parts of your vehicle can break, tire damage could occur, or it can change the way your vehicle han- dles. This could result in loss of control and cause personal injury.

LOADING TIPS . The GVW must not exceed GVWR or GAWR as specified on the F.M.V.S.S./ C.M.V.S.S. certification label.

. Do not load the front and rear axle to the GAWR. Doing so will exceed the GVWR.

SIC4141

SECURING THE LOAD There are tie down hooks located in the cargo area as shown. The tie down hooks can be used to secure cargo with ropes or other types of straps.

Do not apply a total load of more than 7 lb (3 kg) to a single hook *A or 22 lb (10 kg) to a single hook *B when securing cargo.

WARNING

. Properly secure all cargo with ropes or straps to help prevent it from sliding or shifting. Do not place cargo higher than the seatbacks. In

Black plate (303,1)

WARNING

. Properly secure all cargo with ropes or straps to help prevent it from sliding or shifting. Do not place cargo higher than the seatbacks. In a sudden stop or collision, unsecured cargo could cause personal injury.

. Do not load your vehicle any heavier than the GVWR or the m a x i m u m f r o n t a n d r e a r GAWRs. If you do, parts of your vehicle can break, tire damage could occur, or it can change the way your vehicle handles. This could result in loss of control and cause personal injury.

. Overloading not only can short- en the life of your vehicle and the tire, but can cause unsafe vehicle handling and longer braking distances. This may cause a premature tire failure, which could result in a serious accident and personal injury. Failures caused by overloading are not covered by the vehicle’s

Technical and consumer information 9-17

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (304,1)

TOWING A TRAILER

FLAT TOWING

warranty.

Do not tow a trailer with your vehicle.

MEASUREMENT OF WEIGHTS

Secure loose items to prevent weight shifts that could affect the balance of your vehicle. When the vehicle is loaded, drive to a scale and weigh the front and the rear wheels separately to determine axle loads. Individual axle loads should not exceed either of the Gross Axle Weight Ratings (GAWR). The total of the axle loads should not exceed the Gross Vehicle Weight Rating (GVWR). These ratings are given on the vehicle certification label. If weight ratings are exceeded, move or remove items to bring all weights below the ratings.

9-18 Technical and consumer information

Towing your vehicle with all four wheels on the ground is sometimes called flat towing. This method is sometimes used when towing a vehicle behind a recreational vehicle, such as a motor home.

CAUTION

. Failure to follow these guidelines can result in severe transmission damage.

. Whenever flat towing your vehicle, always tow forward, never back- ward.

. DO NOT tow any Continuously Vari- able Transmission (CVT) vehicle with all four wheels on the ground (flat towing). Doing so WILL DA- MAGE internal transmission parts due to lack of transmission lubrica- tion.

. For emergency towing procedures refer to “TOWING YOUR VEHICLE” in the “6. In case of emergency” section of this manual.

Model "Z12-D" EDITED: 2009/ 1/ 28

CONTINUOUSLY VARIABLE TRANS- MISSION (CVT) To tow a vehicle equipped with a Continuously Variable Transmission (CVT), an appropriate vehicle dolly MUST be placed under the towed vehicle’s driving wheels. Always follow the dolly manufacturer’s recommendations when using their product.

MANUAL TRANSMISSION . Always tow with the manual transmission in

Neutral.

. Your vehicle speed should never exceed 70

towing yourMPH (112 km/h) when flat vehicle.

. After towing 500 miles, start and idle the engine with the transmission in Neutral for two minutes. Failure to idle the engine after every 500 miles of towing may cause damage to the transmission’s internal parts.

UNIFORM TIRE QUALITY GRADING

DOT (Department Of Transportation) Quality Grades: All passenger car tires must conform to federal safety requirements in addition to these grades.

Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width. For example:

Treadwear 200 Traction AA Temperature A

TREADWEAR The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear one and one-half (1 1/2) times as well on the government course as a tire graded 100. The relative performance of tires depends upon actual conditions of their use, however, and may depart significantly from the norm due to variations in driving habits, service practices and differences in road char- acteristics and climate.

TRACTION AA, A, B AND C The traction grades, from highest to lowest, are AA, A, B and C. Those grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on spe- cified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

Black plate (305,1)

WARNING

The traction grade assigned to this tire is based on straight-ahead braking traction tests, and does not include acceleration, cornering, hydroplaning, or peak traction characteristics.

TEMPERATURE A, B AND C The temperature grades A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel. Sus- tained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 109. Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law.

WARNING

The temperature grade for this tire is established for a tire that is properly inflated and not overloaded. Excessive speed, under-inflation, or excessive

Technical and consumer information 9-19

Model "Z12-D" EDITED: 2009/ 1/ 28

Black plate (306,1)

EMISSION CONTROL SYSTEM WARRANTY

REPORTING SAFETY DEFECTS (US only)

Your NISSAN is covered by the following emission warranties.

For US: . Emission Defects Warranty . Emissions Performance Warranty

Details of these warranties may be found with other vehicle warranties in your Warranty In- formation Booklet which comes with your NISSAN. receive a Warranty Information Booklet, or it has become lost, you may obtain a replacement by writing to: . Nissan North America, Inc.

If you did not

Consumer Affairs Department P.O. Box 685003

Franklin, TN 37068-5003For Canada:

Emission Control System Warranty

Details of this warranty may be found with other vehicle warranties in your Warranty Information Booklet which comes with your NISSAN. If you