- 2008 Jeep Grand Cherokee SRT8 Owners Manuals

- Jeep Grand Cherokee SRT8 Owners Manuals

- 2012 Jeep Grand Cherokee SRT8 Owners Manuals

- Jeep Grand Cherokee SRT8 Owners Manuals

- 2010 Jeep Grand Cherokee SRT8 Owners Manuals

- Jeep Grand Cherokee SRT8 Owners Manuals

- 2013 Jeep Grand Cherokee SRT8 Owners Manuals

- Jeep Grand Cherokee SRT8 Owners Manuals

- 2009 Jeep Grand Cherokee SRT8 Owners Manuals

- Jeep Grand Cherokee SRT8 Owners Manuals

- 2006 Jeep Grand Cherokee SRT8 Owners Manuals

- Jeep Grand Cherokee SRT8 Owners Manuals

- 2007 Jeep Grand Cherokee SRT8 Owners Manuals

- Jeep Grand Cherokee SRT8 Owners Manuals

- Download PDF Manual

-

can also provide the driver with more control during passing, city driving, mountain driving, trailer towing, and many other situations.

240 STARTING AND OPERATING

Autostick Operation By placing the shift lever in the D (Drive) position the lever can be moved from side to side. This allows the driver to engage the AutoStick mode. Moving the shift lever to the right (+) or the left (-) will engage the Autostick mode. In normal driving mode (Boxed “D” displayed in the PRNDL), moving the shift lever to the right (+) will engage the Autostick mode putting the transmission in the cur- rently engaged gear. Moving the shift lever to the Left (-) will engage the Autostick mode and downshift the trans- mission 1 gear. For example, the transmission is in Normal Mode and is currently operating in 3rd gear, a boxed D is displayed in the PRNDL, a push to the right will engage the Autostick mode in 3rd and a Boxed 3 will be displayed in the PRNDL. A push to the left (-) will engage Autostick mode and downshift to 2nd gear and a Boxed 2 will be displayed in the PRNDL. Once Autostick mode is engaged a move to the Right (+) or left (-) will trigger a upshift (+) or trigger a downshift (-).

In the Autostick mode, the transmission will NOTE: only shift up and down when Left or Right (D-/D+) is manually selected by the driver. The transmission will not honor a downshift command if the downshift would result in a engine overspeed condi- tion. The transmission will always honor a upshift com- mand from 1st to 2nd gear, however 2nd - 3rd, 3rd - 4th, and 4th – 5th upshift commands will not be honored if the vehicle speed is to low to maintain operation in the commanded gear. The transmission will automatically downshift as the vehicle slows to a stop. When in the Autostick mode, as the engine RPM nears the engine maximum speed, an “UPSHIFT” message will appear in the Electronic Vehicle Information Center (EVIC) portion of your instrument cluster. This message appears in order to alert the driver that the engine speed is approaching it’s maximum value and a upshift to the next gear is required. In the event that the driver does not

upshift, the engine control system will limit the engine speed to protect the engine. Refer to “Electronic Vehicle Information Center” in Section 4 of this manual. Shifting into or out of the Autostick mode can be done at any time without taking your foot off the accelerator pedal. When the driver wishes to engage Autostick, simply move the shift lever to the Left or Right (D-/D+) position while in D (Drive). Hold the shift lever to the right for at least one second to disengage Autostick. The transmission will now operate automatically; shifting between the five available gears. Autostick General Information • You can start out in first or second gear. The system will ignore attempts to upshift at too low of a vehicle speed.

STARTING AND OPERATING 241

conditions.

gear when coming to a stop.

• The transmission will automatically downshift to first • Starting out in second gear is helpful in snowy or icy • Avoid using speed control when Autostick is engaged. • The transmission will not automatically shift up when maximum engine speed is reached while Autostick is engaged. • Transmission shifting will be more noticeable when

Autostick is engaged.

PARKING BRAKE To set the parking brake, pull the lever up as firmly as possible. When the parking brake is applied with the ignition ON, the “Brake Warning Light” in the instru- ment cluster will light.

242 STARTING AND OPERATING

NOTE: The instrument cluster “Brake Warning Light” indicates only that the parking brake is applied. It does not indicate the degree of brake application.

Before leaving the vehicle parked on a hill, you must make sure the parking brake is fully applied and place the gear selector in the P (Park) position. Make certain the transfer case is in gear. Failure to do so may cause the vehicle to roll and cause damage or injury. When parking on a hill, it is important to set the parking brake before placing the gear selector in P (Park), other- wise the load on the transmission locking mechanism may make it difficult to move the selector out of P (Park). The parking brake should always be applied when the driver is not in the vehicle.

Parking Brake

WARNING!

• Leaving children unattended in a vehicle is dan- gerous for a number of reasons. A child or others could be injured. Children should be warned not to touch the parking brake or the gear selector lever. Don’t leave the keys in the ignition. A child could operate power windows, other controls, or move the vehicle. • Do not leave children or animals inside parked vehicles in hot weather. Interior heat build up may cause serious injury or death.

STARTING AND OPERATING 243

NOTE: Parking brake adjustment and maintenance should be performed by your authorized dealer.

ANTI-LOCK BRAKE SYSTEM The Anti-Lock Brake System (ABS) is designed to aid the driver in maintaining vehicle control under adverse braking conditions. The system operates with a separate computer to modulate hydraulic pressure to prevent wheel lock-up and help avoid skidding on slippery surfaces. All vehicle wheels and tires must be the same size and type and tires must be properly inflated to produce accurate signals for the computer.

To release the parking brake, pull up slightly, press the center button, then lower the lever completely. Be sure the parking brake is fully disengaged before driving. Failure to do so can lead to brake failure.

WARNING!

Significant over or under inflation of tires can lead to loss of braking effectiveness.

244 STARTING AND OPERATING

The Anti-Lock Brake System conducts a low-speed self- test at about 12 mph (20 km/h). If you have your foot lightly on the brake while this test is occurring you may feel slight pedal movement. The movement can be more apparent on ice and snow. This is normal. The Anti-Lock Brake System pump motor runs during the self-test at 12 mph (20 km/h) and during an ABS stop. The pump motor makes a low humming noise during operation, which is normal.

WARNING!

Pumping of the Anti-Lock Brakes will diminish their effectiveness and may lead to an accident. Pumping makes the stopping distance longer. Just press firmly on your brake pedal when you need to slow down or stop.

WARNING!

• The Anti-Lock Brake System (ABS) cannot pre- vent the natural laws of physics from acting on the vehicle, nor can it increase braking or steering efficiency beyond that afforded by the condition of the vehicle brakes and tires or the traction afforded.

• The ABS cannot prevent accidents,

including those resulting from excessive speed in turns, following another vehicle too closely, or hydro- planing. Only a safe, attentive, and skillful driver can prevent accidents. • The capabilities of an ABS equipped vehicle must never be exploited in a reckless or dangerous manner which could jeopardize the user’s safety or the safety of others.

CAUTION!

The Anti-Lock Brake System is subject to possible detrimental effects of electronic interference caused by improperly installed after-market radios or tele- phones.

NOTE: During severe braking conditions, a pulsing sensation may occur and a clicking noise will be heard. This is normal, the Anti-Lock Brake System is functioning.

indicating that

WARNING!

To use your brakes and accelerator more safely, follow these tips:

STARTING AND OPERATING 245

• Do not “ride” the brakes by resting your foot on the pedal. This could overheat the brakes and result in longer stopping dis- unpredictable braking action, tances, or brake damage. • When descending mountains or hills, repeated brak- ing can cause brake fade with loss of braking control. Avoid repeated heavy braking by downshifting the transmission or locking out overdrive whenever pos- sible. • Engines may idle at higher speeds during warm-up, which could cause rear wheels to spin and result in loss of vehicle control. Be especially careful while driving on slippery roads, in close-quarter maneuver- ing, parking or stopping.

246 STARTING AND OPERATING

• Do not drive too fast for road conditions, especially when roads are wet or slushy. A wedge of water can build up between the tire tread and the road. This hydroplaning action can cause loss of traction, braking ability, and control. • After going through deep water or a car wash, brakes may become wet, resulting in decreased performance and unpredictable braking action. Dry the brakes by gentle, intermittent pedal action while driving at very slow speeds.

POWER STEERING The standard power steering system will give you good vehicle response and increased ease of maneuverability in tight spaces. The system will provide mechanical steering capability if power assist is lost.

If for some reason, the power assist is interrupted, it will still be possible to steer your vehicle. Under these condi- tions you will observe a substantial increase in steering effort, especially at very low vehicle speeds and during parking maneuvers. Increased noise levels at the end of the steering NOTE: wheel travel are considered normal and does not indicate that there is a problem with the power steering system. Upon initial start-up in cold weather, the power steering pump may make noise for a short period of time. This is due to the cold, thick fluid in the steering system. This noise should be considered normal, and does not in any way damage the steering system.

WARNING!

Continued operation with reduced power steering assist could pose a safety risk to yourself and others. Service should be obtained as soon as possible.

CAUTION!

Prolong operation of the steering system at the end of the steering wheel travel will increase the steering fluid temperature and should be avoided when possible. Damage to the power steering pump may occur.

STARTING AND OPERATING 247

TIRE SAFETY INFORMATION

Tire Markings

NOTE: • P (Passenger)-Metric tire sizing is based on U.S. design standards. P-Metric tires have the letter “P” molded into the sidewall preceding the size designation. Ex- ample: P215/65R15 95H.

248 STARTING AND OPERATING

• European Metric tire sizing is based on European design standards. Tires designed to this standard have the tire size molded into the sidewall beginning with the section width. The letter ⬙P⬙ is absent from this tire size designation. Example: 215/65R15 96H • LT (Light Truck)-Metric tire sizing is based on U.S. design standards. The size designation for LT-Metric tires is the same as for P-Metric tires except for the letters “LT” that are molded into the sidewall preced- ing the size designation. Example: LT235/85R16.

• Temporary Spare tires are high pressure compact spares designed for temporary emergency use only. Tires designed to this standard have the letter “T” molded into the sidewall preceding the size designa- tion. Example: T145/80D18 103M. • High Flotation tire sizing is based on U.S. design standards and begins with the tire diameter molded into the sidewall. Example: 31x10.5 R15 LT.

Tire Sizing Chart

Size Designation:

EXAMPLE:

P = Passenger car tire size based on U.S. design standards ⴖ....blank....ⴖ = Passenger car tire based on European design standards LT = Light Truck tire based on U.S. design standards T = Temporary Spare tire 31 = Overall Diameter in Inches (in) 215 = Section Width in Millimeters (mm) 65 = Aspect Ratio in Percent (%)

—Ratio of section height to section width of tire.

10.5 = Section Width in Inches (in) R = Construction Code

—⬙R⬙ means Radial Construction. —⬙D⬙ means Diagonal or Bias Construction.

15 = Rim Diameter in Inches (in)

STARTING AND OPERATING 249

250 STARTING AND OPERATING

Service Description:

95 = Load Index

EXAMPLE:

—A numerical code associated with the maximum load a tire can carry.

H = Speed Symbol

—A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions. —The maximum speed corresponding to the Speed Symbol should only be achieved un- der specified operating conditions. (i.e. tire pressure, vehicle loading, road conditions and posted speed limits).

Load Identification:

ⴖ....blank....ⴖ = Absence of any text on sidewall of the tire indicates a Standard Load (SL) Tire Extra Load (XL) = Extra Load (or Reinforced) Tire Light Load = Light Load Tire C,D,E = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load — Maximum Load indicates the maximum load this tire is designed to carry. Maximum Pressure — Maximum Pressure indicates the maximum permissible cold tire inflation pressure for this tire.

Tire Identification Number (TIN) The TIN may be found on one or both sides of the tire however the date code may only be on one side. Tires with white sidewalls will have the full TIN including date code located on the white sidewall side of the tire.

STARTING AND OPERATING 251

Look for the TIN on the outboard side of black sidewall tires as mounted on the vehicle. If the TIN is not found on the outboard side then you will find it on the inboard side of the tire.

DOT = Department of Transportation

—This symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire safety standards, and is approved for highway use.

EXAMPLE:

DOT MA L9 ABCD 0301

MA = Code representing the tire manufacturing location. (2 digits) L9 = Code representing the tire size. (2 digits) ABCD = Code used by tire manufacturer. (1 to 4 digits) 03 = Number representing the week in which the tire was manufactured. (2 digits)

—03 means the 3rd week.

01 = Number representing the year in which the tire was manufactured. (2 digits)

—01 means the year 2001. —Prior to July 2000, tire manufacturers were only required to have 1 number to represent the year in which the tire was manufactured. Example: 031 could represent the 3rd week of 1981 or 1991.

252 STARTING AND OPERATING

Tire Loading and Tire Pressure

Tire Placard Location NOTE: The proper cold tire inflation pressure is listed on either the face of the driver’s door or the driver’s side “B” pillar.

Tire and Loading Information Placard

Tire and Loading Information

This placard tells you important information about the: 1) number of people that can be carried in the vehicle 2) the total weight your vehicle can carry

Tire Placard Location

3) the tire size designed for your vehicle 4) the cold tire inflation pressures for the front, rear and spare tires. Loading The vehicle maximum load on the tire must not exceed the load carrying capacity of the tire on your vehicle. You will not exceed the tire’s load carrying capacity if you adhere to the loading conditions, tire size, and cold tire inflation pressures specified on the “Tire and Loading Information” placard and in the “Vehicle Loading” sec- tion of this manual. NOTE: Under a maximum loaded vehicle condition, gross axle weight ratings (GAWR’s) for the front and rear axles must not be exceeded. For further information on GAWR’s, vehicle loading, and trailer towing, refer to the “Vehicle Loading” section of this manual.

STARTING AND OPERATING 253

To determine the maximum loading conditions of your vehicle, locate the statement “The combined weight of occupants and cargo should never exceed XXX kg or XXX lbs.” on the Tire and Loading Information placard. The combined weight of occupants, cargo/luggage and trailer tongue weight (if applicable) should never exceed the weight referenced here. Steps for Determining Correct Load Limit 1. Locate the statement “The combined weight of occu- pants and cargo should never exceed XXX pounds” on your vehicle’s placard. 2. Determine the combined weight of the driver and passengers that will be riding in your vehicle. 3. Subtract the combined weight of the driver and pas- sengers from XXX kilograms or XXX pounds.

254 STARTING AND OPERATING

4. The resulting figure equals the available amount of cargo and luggage load capacity. For example, if “XXX” amount equals 1400 lbs. and there will be five 150 lb. passengers in your vehicle, the amount of available cargo and luggage load capacity is 650 lb. (since 5 x 150 = 750, and 1400 – 750 = 650 lb.) 5. Determine the combined weight of luggage and cargo being loaded on the vehicle. That weight may not safely exceed the available cargo and luggage load capacity calculated in step 4. 6. If your vehicle will be towing a trailer, load from your trailer will be transferred to your vehicle. Consult this

manual to determine how this reduces the available cargo and luggage load capacity of your vehicle. NOTE: The following table shows examples on how to calculate total load, cargo/luggage and towing capacities of your vehicle with varying seating configurations and number and size of occupants. This table is for illustra- tion purposes only and may not be accurate for the seating and load carry capacity of your vehicle. NOTE: For the following example the combined weight of occupants and cargo should never exceed 865 lbs. (392

Kg).STARTING AND OPERATING 255

256 STARTING AND OPERATING

WARNING!

WARNING!

Overloading of your tires is dangerous. Overloading can cause tire failure, affect vehicle handling, and increase your stopping distance. Use tires of the recommended load capacity for your vehicle. Never overload them.

Do not exceed 55 mph (88 km/h) if the “Tire Pressure Monitoring Telltale Light” is illuminated. Vehicle handling and braking may be reduced. You could have an accident and be severely or fatally injured.

TIRES — GENERAL INFORMATION

Run Flat Tires This vehicle is equipped with run flat tires. Although the tires are designed with a “run flat” feature that allows the vehicle to be driven about 50 miles (80 km) at 55 mph (88

km/h), immediate service should be obtained.NOTE: The “run flat” feature eliminates the need for a spare tire or jack. This vehicle is not equipped with either a spare tire or jack.

Tire Pressure Proper tire inflation pressure is essential to the safe and satisfactory operation of your vehicle. Three primary areas are affected by improper tire pressure:

1. Safety—

WARNING!

STARTING AND OPERATING 257

Improperly inflated tires are dangerous and can cause accidents. • Under inflation increases tire flexing and can result in tire failure. • Over inflation reduces a tire’s ability to cushion shock. Objects on the road and chuck holes can cause damage that results in tire failure. • Unequal tire pressures can cause steering prob- lems. You could lose control of your vehicle. • Overinflated or under inflated tires can affect vehicle handling and can fail suddenly, resulting in loss of vehicle control. • Unequal tire pressures from one side of the vehicle to the other can cause the vehicle to drift to the right or left. Always drive with each tire properly inflated.

258 STARTING AND OPERATING

2. Economy— Improper inflation pressures can cause uneven wear patterns to develop across the tire tread. These abnormal wear patterns will reduce tread life resulting in a need for earlier tire replacement. Under inflation also increases tire rolling resistance and results in higher fuel consump- tion. 3. Ride Comfort and Vehicle Stability— Proper tire inflation contributes to a comfortable ride. Over inflation produces a jarring and uncomfortable ride. Both under inflation and over inflation affect the stability of the vehicle and can produce a feeling of sluggish response or over responsiveness in the steering. Unequal tire pressures can cause erratic and unpredict- able steering response. Unequal tire pressure from side to side may cause the vehicle to drift left or right.

Tire Inflation Pressures The proper cold tire inflation pressure is listed on either the face of the driver’s door, or the driver’s side “B” pillar.

Tire Placard Location

The pressure should be checked and adjusted as well as inspecting for signs of tire wear or visible damage at least once a month. Use a good quality pocket-type gauge to

check tire pressure. Do not make a visual judgement when determining proper inflation. Radial tires may look properly inflated even when they are under inflated.

CAUTION!

After inspecting or adjusting the tire pressure al- ways reinstall the valve stem cap–if equipped. This will prevent moisture and dirt from entering the valve stem, which could damage the valve stem.

Inflation pressures specified on the placard are always “cold tire inflation pressure”. Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been driven for at least 3 hours, or driven less than 1 mile (1 km) after a 3 hour period. The cold tire inflation pressure must not exceed the maximum inflation pres- sure molded into the tire side wall.

STARTING AND OPERATING 259

Check tire pressures more often if subject to a wide range of outdoor temperatures, as tire pressures vary with temperature changes. Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air temperature change. Keep this in mind when checking tire pressure inside a garage especially in the winter. Example: If garage temperature = 68° F (20° C) and the outside temperature = 32° F (0° C) then the cold tire inflation pressure should be increased by 3 psi (21 kPa), which equals 1 psi (7 kPa) for every 12° F (7° C) for this outside temperature condition. Tire pressure may increase from 2 to 6 psi (13 to 40 kPa) during operation. DO NOT reduce this normal pressure build up or your tire pressure will be too low.

260 STARTING AND OPERATING

Tire Pressures for High Speed Operation The manufacturer advocates driving at safe speeds within posted speed limits. Where speed limits or condi- tions are such that the vehicle can be driven at high speeds, maintaining correct tire inflation pressure is very important. Increased tire pressure and reduced vehicle loading may be required for high speed vehicle opera- tion. Refer to original equipment or an authorized tire dealer for recommended safe operating speeds, loading and cold tire inflation pressures.

WARNING!

High speed driving with your vehicle under maxi- mum load is dangerous. The added strain on your tires could cause them to fail. You could have a serious accident. Don’t drive a vehicle loaded to the maximum capacity at continuous speeds above 75

mph (120 km/h).Radial-Ply Tires

WARNING!

Combining radial ply tires with other types of tires on your vehicle will cause your vehicle to handle poorly. The instability could cause an accident. Al- ways use radial tires in sets of four. Never combine them with other types of tires.

Cuts and punctures in radial tires are repairable only in the tread area because of sidewall flexing. Consult your dealer for radial tire repairs.

STARTING AND OPERATING 261

Tire Spinning When stuck in mud, sand, snow, or ice conditions, do not spin your vehicle’s wheels above 35 mph (55 km/h).

WARNING!

Fast spinning tires can be dangerous. Forces gener- ated by excessive wheel speeds may cause tire dam- age or failure. A tire could explode and injure someone. Do not spin your vehicle’s wheels faster than 35 mph (55 km/h) when you are stuck, and do not let anyone near a spinning wheel no matter what the speed.

262 STARTING AND OPERATING

Tread Wear Indicators Tread wear indicators are in the original equipment tires to help you in determining when your tires should be replaced.

These indicators are molded into the bottom of the tread grooves and will appear as bands when the tread depth becomes 1/16 inch (2 mm). When the indicators appear in 2 or more adjacent grooves, the tire should be replaced. Many states have laws requiring tire replacement at this point. Life of Tire The service life of a tire is dependent upon varying factors including but not limited to: • Driving style • Tire pressure • Distance driven

WARNING!

All tires should be replaced after six years, regard- less of the remaining tread. Failure to follow this warning can result in sudden tire failure. You could lose control and have an accident resulting in serious injury.

Keep unmounted tires in a cool, dry place with as little exposure to light as possible. Protect tires from contact with oil, grease and gasoline.

STARTING AND OPERATING 263

Replacement Tires The tires on your new vehicle provide a balance of many characteristics. They should be inspected regularly for wear and correct cold tire inflation pressure. The manu- facturer strongly recommends that you use tires equiva- lent to the originals in size, quality and performance when replacement is needed (see the paragraph on tread wear indicators). Refer to the Tire and Loading Informa- tion placard for the size designation of your tire. The service description and load identification will be found on the original equipment tire. Failure to use equivalent replacement tires may adversely affect the safety, han- dling, and ride of your vehicle. We recommend that you contact your original equipment or an authorized tire dealer with any questions you may have on tire specifi- cations or capability.

264 STARTING AND OPERATING

WARNING!

• Do not use a tire, wheel size or rating other than that specified for your vehicle. Some combina- tions of unapproved tires and wheels may change suspension dimensions and performance charac- teristics, resulting in changes to steering, han- dling, and braking of your vehicle. This can cause unpredictable handling and stress to steering and suspension components. You could lose control and have an accident resulting in serious injury or death. Use only the tire and wheel sizes with load ratings approved for your vehicle. • Never use a tire with a smaller load index or capacity, other than what was originally equipped on your vehicle. Using a tire with a smaller load index could result in tire overloading and failure. You could lose control and have an accident. • Failure to equip your vehicle with tires having adequate speed capability can result in sudden tire failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different size may result in false speedometer and odometer read- ings.

Alignment and Balance Poor suspension alignment may result in: • Fast tire wear. • Uneven tire wear, such as feathering and one-sided • Vehicle pull to right or left. Tires may also cause the vehicle to pull left or right. Alignment will not correct this problem. See your autho- rized dealer for proper diagnosis.

wear.

Improper alignment will not cause vehicle vibration. Vibration may be a result of tire and wheel out-of- balance. Proper balancing will reduce vibration and avoid tire cupping and spotty wear.

TIRE PRESSURE MONITOR SYSTEM (TPMS)

Premium System The Tire Pressure Monitor System (TPMS) uses wireless technology with wheel rim mounted electronic sensors to monitor tire pressure levels. Sensors mounted to each wheel as part of the valve stem transmit tire pressure readings to the Receiver Module. The wheel sensors monitor tire pressure, and status for all four active road tires. It is particularly important, for you to check the NOTE: tire pressure in all of your tires regularly and to maintain the proper pressure.

STARTING AND OPERATING 265

The “Tire Pressure Monitoring Telltale Light” will illuminate in the instrument cluster, and an au- dible chime will be activated when one or more tire pressures is low. The “Tire Pressure Monitoring Telltale Light” will flash on and off for 60 seconds when a system fault is detected. The flash cycle will repeat every ten minutes or until the fault condition is removed and reset. The Tire Pressure Monitoring System (TPMS) consists of the following components: • Receiver Module • 4 Wheel Sensors • 3 Wheel Sensor Trigger Modules • Tire Pressure Monitoring System Display Messages in • Tire Pressure Monitoring Telltale Light

the EVIC

266 STARTING AND OPERATING

The system consists of tire pressure monitoring sensors attached to each wheel through the valve stem mounting hole, a central receiver module, Wheel Sensor Trigger Modules mounted in three of the four wheel wells, various Tire Pressure Monitoring System Display Mes- sages in the EVIC, and a “Tire Pressure Monitoring Telltale Light.” NOTE: For vehicles with optional wheel/tire sizes and significantly different tire placard pressures, the placard pressure value and the low-pressure threshold value is re-programmable at your authorized dealer to accommo- date the customer selected wheel/tire combinations rec- ommended by DaimlerChrysler Corporation. The following ⬙warnings⬙ will cause a text message to be displayed, an audible chime to sound, and the “Tire Pressure Monitoring Telltale Light” to illuminate. The audible chime will occur once every ignition cycle for each ⬙warning⬙ detected. The “Tire Pressure Monitoring

Telltale Light” will illuminate continuously (solid) and shall remain illuminated until the warning condition is removed/reset. When the appropriate conditions exist, the Electronic Vehicle Information Center (EVIC) displays the following messages. LEFT FRONT, LEFT REAR, RIGHT FRONT, RIGHT REAR LOW PRESSURE One or more of these messages will be displayed in the EVIC if a low tire pressure condition exists in one or more tires. Inspect all tires for proper inflation pressure, once the proper tire pressure has been set, the TPMS will reset automatically when the vehicle has been driven for at least 2 minutes at or above 15 mph (24 km/h).

CHECK TPM SYSTEM See your authorized dealer when this message appears in the EVIC. This message indicates that a system fault condition has been detected.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS pressures have been established for the tire size equipped on your vehicle. Undesirable system operation or sensor damage may result when using replacement equip- ment that is not of the same size, type, and/or style. After-market wheels can cause sensor damage. Do not use tire sealant from a can, or balance beads if your vehicle is equipped with a TPMS, as damage to the sensors may result.

STARTING AND OPERATING 267

CAUTION!

After inspecting or adjusting the tire pressure al- ways reinstall the valve stem cap. This will prevent moisture and dirt from entering the valve stem, which could damage the wheel rim sensor.

condition.

NOTE: • The TPMS can inform the driver of a low tire pressure • The TPMS is not intended to replace normal tire care and maintenance, nor to provide warning of a tire failure or condition. • The TPMS should not be used as a tire pressure gauge

while adjusting your tire pressure.

268 STARTING AND OPERATING

General Information This device complies with part 15 of the FCC rules and RSS 210 of Industry Canada. Operation is subject to the following conditions: • This device may not cause harmful interference. • This device must accept any interference received, including interference that may cause undesired op- eration.

The tire pressure sensors are covered under one of the following licenses:

United States . . . . . . . . . . . . . . . . . . . . . KR5S120123

Canada . . . . . . . . . . . . . . . . . . . . . . . . 2671-S120123TIRE ROTATION RECOMMENDATIONS Do not rotate the tires as the wider rear tires will not fit on the front of the vehicle.

FUEL REQUIREMENTS

Your vehicle is designed to meet all emis- sion regulations and provide excellent fuel economy when using high quality pre- mium unleaded gasoline having an octane rating of 91 or higher.

Spark Knock Light spark knock at low engine speeds is not harmful to your engine. However, continued heavy spark knock at high speeds can cause damage and immediate service is required. Poor quality gasoline can cause problems such as hard starting, stalling and hesitations. If you experience these symptoms, try another brand of “premium” gasoline before considering service for the vehicle.

Over 40 automobile manufacturers around the world have issued and endorsed consistent gasoline specifica- tions (the World Wide Fuel Charter, WWFC) to define fuel properties necessary to deliver enhanced emissions, engine performance, and durability for your vehicle. The manufacturer recommends the use of gasolines that meet the WWFC specifications if they are available. Reformulated Gasoline Many areas of the country require the use of cleaner burning gasoline referred to as “Reformulated Gasoline.” Reformulated gasolines contain oxygenates, and are spe- cifically blended to reduce vehicle emissions and im- prove air quality. The manufacturer supports the use of reformulated gaso- lines. Properly blended reformulated gasolines will pro- vide excellent performance and durability of engine and fuel system components.

STARTING AND OPERATING 269

Gasoline/Oxygenate Blends Some fuel suppliers blend unleaded gasoline with oxy- genates such as 10% ethanol, MTBE, and ETBE. Oxygen- ates are required in some areas of the country during the winter months to reduce carbon monoxide emissions. Fuels blended with these oxygenates may be used in your vehicle.

CAUTION!

DO NOT use gasolines containing Methanol. Use of these blends may result in starting and driveability problems and may damage critical fuel system com- ponents.

Problems that result from using methanol/gasoline blends are not the responsibility of the manufacturer. While MTBE is an oxygenate made from Methanol, it does not have the negative effects of Methanol.

270 STARTING AND OPERATING

MMT In Gasoline MMT is a manganese containing metallic additive that is blended into some gasoline to increase the octane num- ber. Gasolines blended with MMT offer no performance advantage beyond gasolines of the same octane number without MMT. Gasolines blended with MMT have shown to reduce spark plug life and reduce emission system performance in some vehicles. The manufacturer recom- mends using gasolines without MMT. Since the MMT content of gasoline may not be indicated on the pump, you should ask your gasoline retailer whether or not his/her gasoline contains MMT. It is even more important to look for gasolines without MMT in Canada, because MMT can be used at levels higher than those allowed in the United States. MMT is prohibited in Federal and California reformu- lated gasolines.

Materials Added to Fuel All gasoline sold in the United States is required to contain effective detergent additives. Use of additional detergents or other additives are not needed under normal conditions and would result in additional cost. Therefore you should not have to add anything to the fuel. Fuel System Cautions

CAUTION!

Follow these guidelines to maintain your vehicle’s performance: • The use of leaded gas is prohibited by Federal law. Using leaded gasoline can impair engine performance, or damage the emission control system.

• An out-of-tune engine, or certain fuel or ignition malfunctions, can cause the catalytic converter to overheat. If you notice a pungent burning odor or some light smoke, your engine may be out-of-tune or malfunctioning and may require immediate service. Contact your dealer for service assistance. • The use of fuel additives which are now being sold as octane enhancers are not recommended. Most of these products contain high concentrations of methanol. Fuel system damage or vehicle performance problems resulting from the use of such fuels or additives are not the responsibility of the manufacturer.

NOTE: systems can result against you.

Intentional tampering with emissions control in civil penalties being assessed

STARTING AND OPERATING 271

Carbon Monoxide Warnings

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly. Follow the precautions below to prevent carbon monoxide poisoning: • Do not inhale exhaust gases. They contain carbon monoxide, a colorless and odorless gas which can kill. Never run the engine in a closed area, such as a garage, and never sit in a parked vehicle with the engine running for an extended period. If the vehicle is stopped in an open area with the engine running for more than a short period, adjust the ventilation system to force fresh, outside air into the vehicle.

272 STARTING AND OPERATING

• Guard against carbon monoxide with proper mainte- nance. Have the exhaust system inspected every time the vehicle is raised. Have any abnormal conditions repaired promptly. Until repaired, drive with all side windows fully open. • Keep the trunk closed when driving your vehicle to prevent carbon monoxide and other poisonous ex- haust gases from entering the vehicle.

FUEL TANK FILLER CAP (GAS CAP) The fuel cap is located on the left side of the vehicle. If the fuel cap is lost or damaged, be sure the replacement cap is for use with this vehicle.

Fuel Filler Cap Location

STARTING AND OPERATING 273

CAUTION!

CAUTION!

Damage to the fuel system or emission control system could result from using an improper fuel cap (gas cap). A poorly fitting cap could let impurities into the fuel system. Also, a poorly fitting after- market cap can cause the MIL (Malfunction Indica- tor Light) to illuminate, due to fuel vapors escaping from the system. • Turn the engine off. • Rotate the fuel cap to the left to remove. • To replace the cap, insert it into the filler neck and tighten the cap about 1/4 turn until you hear one click. This is an indication that the cap is properly tightened. • Make sure that the fuel cap tether strap is not caught

under the fuel cap.

To avoid fuel spillage and overfilling, do not “top off” the fuel tank after filling.

NOTE: When the fuel nozzle “clicks” or shuts off, the fuel tank is full. Loose Fuel Filler Cap Message If the vehicle diagnostic system determines that the fuel filler cap is loose, improperly installed, or damaged, a “CHECK GAS CAP” message will be displayed in the EVIC (Electronic Vehicle Information Center). Refer to “Electronic Vehicle Information Center” in Section 4 of this manual. Tighten the fuel filler cap properly and press the odometer reset button to turn the message off. If the problem continues, the message will appear the next time the vehicle is started. Refer to “Onboard Diagnostic System — OBDII” in Section 7 of this manual for more information.

274 STARTING AND OPERATING

WARNING!

• Remove the fuel cap (gas cap) slowly to prevent fuel spray from the filler neck which may cause injury. • The volatility of some gasoline may cause a buildup of pressure in the fuel tank that may increase while you drive. This pressure can result in a spray of gasoline and/or vapors when the cap is removed from a hot vehicle. Removing the cap slowly allows the pressure to vent and prevents fuel spray. • Never have any smoking materials lit in or near the vehicle when the fuel cap is removed or the tank filled. • Never add fuel to the vehicle when the engine is

running.

WARNING!

A fire may result if gasoline is pumped into a portable container that is inside of a vehicle. You could be burned. Always place gas containers on the ground while filling.

TRAILER TOWING In this section you will find safety tips and information on limits to the type of towing you can reasonably do with your vehicle. Before towing a trailer carefully re- view this information to tow your load as efficiently and safely as possible. To maintain warranty coverage, follow the requirements and recommendations in this manual concerning ve- hicles used for trailer towing.

Common Towing Definitions The following trailer towing related definitions will assist you in understanding the following information: Gross Vehicle Weight Rating (GVWR) The GVWR is the total allowable weight of your vehicle. This includes driver, passengers, cargo and tongue weight. The total load must be limited so that you do not exceed the GVWR. Gross Trailer Weight (GTW) The gross trailer weight (GTW) is the weight of the trailer plus the weight of all cargo, consumables and equipment (permanent or temporary) loaded in or on the trailer in its ⬙loaded and ready for operation⬙ condition. The recom- mended way to measure GTW is to put your fully loaded trailer on a vehicle scale. The entire weight of the trailer must be supported by the scale.

STARTING AND OPERATING 275

Gross Combination Weight Rating (GCWR) The gross combination weight rating (GCWR) is the total permissible weight of your vehicle and trailer when weighed in combination. (Note that GCWR ratings in- clude a 150 lbs (68 kg) allowance for the presence of a driver). Gross Axle Weight Rating (GAWR) The GAWR is the maximum capacity of the front and rear axles. Distribute the load over the front and rear axles evenly. Make sure that you do not exceed either front or rear GAWR.

276 STARTING AND OPERATING

WARNING!

It is important that you do not exceed the maximum front or rear GAWR. A dangerous driving condition can result if either rating is exceeded. You could lose control of the vehicle and have an accident.

Tongue Weight (TW) The downward force exerted on the hitch ball by the trailer. In most cases it should not be less than 10% or more than 15% of the trailer load. You must consider this as part of the load on your vehicle. Frontal Area The maximum height and maximum width of the front of a trailer. Trailer Sway Control The trailer sway control is a telescoping link that can be installed between the hitch receiver and the trailer tongue

that typically provides adjustable friction associated with the telescoping motion to dampen any unwanted trailer swaying motions while traveling. Weight-Carrying Hitch A weight-carrying hitch supports the trailer tongue weight, just as if it were luggage located at a hitch ball or some other connecting point of the vehicle. These kind of hitches are the most popular on the market today and they’re commonly used to tow small- and medium-sized trailers. Weight-Distributing Hitch A weight-distributing hitch includes a receiver attached to the tow vehicle, plus a removable hitch head and spring bar assembly that fits into the receiver opening and hook up brackets that connect the spring bars to the trailer frame.

Trailer Hitch Classification Your vehicle may be factory equipped for safe towing of trailers weighing over 2,000 lbs (907 kg) with the optional Trailer Tow Prep Package. See your dealer for package content. The following chart provides the industry standard for the maximum trailer weight a given trailer hitch class can tow and should be used to assist you in selecting the correct trailer hitch for your intended towing condition. Refer to the Trailer Towing Weights (Maximum Trailer Weight Ratings) chart for the Max. GTW towable for your given drivetrain.

STARTING AND OPERATING 277

Trailer Hitch Classification

Class

Max. GTW (Gross Trailer

Wt.)

2,000 lbs (907 kg) 3,500 lbs (1587 kg)

Class I - Light Duty Class II - Medium Duty Class III - Heavy Duty Class IV - Extra Heavy Duty All trailer hitches should be professionally installed on your vehicle.

5,000 lbs (2268 kg) 10,000 lbs (4540 kg)

278 STARTING AND OPERATING

Trailer Towing Weights (Maximum Trailer Weight Ratings) The following chart provides the maximum trailer weight ratings towable for your given drivetrain.

Engine/

Transmission

6.1L Auto-

matic

GVWR (Gross Ve- hicle Wt. Rating) 5,650 lbs (2 563 kg)

GCWR (Gross Com- bined Wt. Rating) 8,800 lbs (3 992 kg)

Frontal Area Max. GTW (Gross

Trailer Wt.)

40 Sq. Ft. (3.72

square meters)3,500 lbs (1 587 kg)

Max. Tongue

Wt. (See Note 1) 350 lbs (159 kg)

Refer to local laws for maximum trailer towing speeds.

Note 1 – The trailer tongue weight must be considered as part of the combined weight of occupants and cargo, and should never exceed the weight referenced on the Tire and Loading Information placard. Refer to the Tire– Safety Information Section in this manual.

Trailer and Tongue Weight Always load a trailer with 60% to 65% of the weight in the front of the trailer. This places 10% to 15% of the Gross Trailer Weight (GTW) on the tow hitch of your vehicle. Loads balanced over the wheels or heavier in the rear can cause the trailer to sway severely side to side which will cause loss of control of vehicle and trailer. Failure to load trailers heavier in front is the cause of many trailer accidents.

Never exceed the maximum tongue weight stamped on your bumper or trailer hitch.

STARTING AND OPERATING 279

put in or on your vehicle.

Consider the following items when computing the weight on the rear axle of the vehicle: • The tongue weight of the trailer. • The weight of any other type of cargo or equipment • The weight of the driver and all passengers. NOTE: Remember that everything put into or on the trailer adds to the load on your vehicle. Also, additional factory-installed options, or dealer-installed options, must be considered as part of the total load on your vehicle. Refer to the Tire and Loading Information plac- ard in the Tire Safety Information Section of this manual for the maximum combined weight of occupants and cargo for your vehicle.

280 STARTING AND OPERATING

Towing Requirements To promote proper break-in of your new vehicle driv- etrain components the following guidelines are recom- mended:

CAUTION!

• Avoid towing a trailer for the first 500 miles (805

km) of vehicle operation. Doing so may damage your vehicle. • During the first 500 miles (805 km) of trailertowing, limit your speed to 50 mph (80 km/h).

Perform the maintenance listed in Section 8 of this manual. When towing a trailer, never exceed the GAWR, or GCWR, ratings.

WARNING!

Improper towing can lead to an injury accident. Follow these guidelines to make your trailer towing as safe as possible: Make certain that the load is secured in the trailer and will not shift during travel. When trailering cargo that is not fully secured, dynamic load shifts can occur that may be difficult for the driver to control. You could lose control of your vehicle and have an accident. • When hauling cargo or towing a trailer, do not over- load your vehicle or trailer. Overloading can cause a loss of control, poor performance or damage to brakes, axle, engine, transmission, steering, suspension, chas- sis structure or tires.

• Safety chains must always be used between your vehicle and trailer. Always connect the chains to the frame or hook retainers of the vehicle hitch. Cross the chains under the trailer tongue and allow enough slack for turning corners. • Vehicles with trailers should not be parked on a grade. When parking, apply the parking brake on the tow vehicle. Put the tow vehicle in P (Park). Always, block or ⬙chock⬙ the trailer wheels. • GCWR must not be exceeded. • Total weight must be distributed between the tow vehicle and the trailer such that the following four ratings are not exceeded: 1. GVWR 2. GTW 3. GAWR

STARTING AND OPERATING 281

4. Tongue weight rating for the trailer hitch utilized (This requirement may limit the ability to always achieve the 10% to 15% range of tongue weight as a percentage of total trailer weight).

Towing Requirements — Tires − Proper tire inflation pressures are essential to the safe and satisfactory operation of your vehicle. Refer to “Tires–General Information” for proper tire inflation procedures.

− Also, check the trailer tires for proper tire inflation

pressures before trailer usage.

− Check for signs of tire wear or visible tire damage before towing a trailer. Refer to “Tires–General Infor- mation” for proper inspection procedure.

282 STARTING AND OPERATING

− When replacing tires, refer to “Tires–General Informa- tion” for proper tire replacement procedures. Replac- ing tires with a higher load carrying capacity will not increase the vehicle’s GVWR and GAWR limits.

Towing Requirements — Trailer Brakes − Do not interconnect the hydraulic brake system or vacuum system of your vehicle with that of the trailer. This could cause inadequate braking and possible personal injury.

− An electronically actuated trailer brake controller is required when towing a trailer with electronically actuated brakes. When towing a trailer equipped with a hydraulic surge actuated brake system, an electronic brake controller is not required.

− Trailer brakes are recommended for trailers over 1,000

lbs (454 kg) and required for trailers in excess of 2,000

lbs (907 kg).CAUTION!

If the trailer weighs more than 1,000 lbs (454 kg) loaded, it should have its own brakes and they should be of adequate capacity. Failure to do this could lead to accelerated brake lining wear, higher brake pedal effort, and longer stopping distances.

WARNING!

Do not connect trailer brakes to your vehicle’s hy- draulic brake lines. It can overload your brake sys- tem and cause it to fail. You might not have brakes when you need them and could have an accident. Towing any trailer will increase your stopping dis- tance. When towing you should allow for additional space between your vehicle and the vehicle in front of you. Failure to do so could result in an accident.

Towing Requirements — Trailer Lights & Wiring Whenever you pull a trailer, regardless of the trailer size, stop lights and turn signals on the trailer are required for motoring safety. The Trailer Tow Package may include a 4 and 7 pin wiring harness. Use a factory approved trailer harness and connector.

STARTING AND OPERATING 283

NOTE: Do not cut or splice wiring into the vehicles wiring harness. The electrical connections are all complete to the vehicle but you must mate the harness to a trailer connector. Refer to the following illustrations.

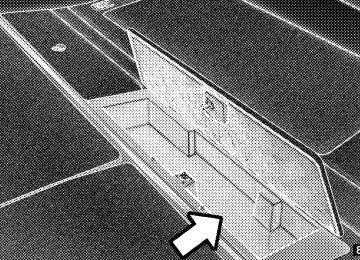

4 - Pin Connector

284 STARTING AND OPERATING

7- Pin Connector

Towing Tips Before setting out on a trip, practice turning, stopping and backing the trailer in an area away from heavy traffic.

Towing Tips — Automatic Transmission The “D” range can be selected when towing. However, if frequent shifting occurs while in this range, the “3” range should be selected. NOTE: Using the “3” range while operating the vehicle under heavy operating conditions will improve perfor- mance and extend transmission life by reducing exces- sive shifting and heat build up. This action will also provide better engine braking. The automatic transmission fluid and filter should be changed if you REGULARLY tow a trailer for more than 45 minutes of continuous operation. See Schedule “B” in section 8 of this manual for transmission fluid change intervals. NOTE: Check the automatic transmission fluid level before towing.

Towing Tips — Electronic Speed Control (If Equipped) − Don’t use in hilly terrain or with heavy loads. − When using the speed control, if you experience speed drops greater than 10 mph (16 km/h), disengage until you can get back to cruising speed.

− Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

Towing Tips — Cooling System To reduce potential for engine and transmission over- heating, take the following actions: − City Driving When stopped for short periods of time, put transmission in neutral and increase engine idle speed.

STARTING AND OPERATING 285

− Highway Driving Reduce speed. − Air Conditioning Turn off temporarily. − refer to Cooling System Operating information in the Maintenance section of this manual for more informa- tion.

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.) Recreational towing is not allowed.

WHAT TO DO IN EMERGENCIES

CONTENTS

䡵 Hazard Warning Flashers . . . . . . . . . . . . . . . . . 288

䡵 If Your Engine Overheats . . . . . . . . . . . . . . . . . 289䡵 Jump Starting Procedure . . . . . . . . . . . . . . . . . . 289

288 WHAT TO DO IN EMERGENCIES

HAZARD WARNING FLASHERS Your vehicle’s hazard warning flasher is an emergency warning system. When you activate it, all front and rear directional signals will flash intermittently. Use it when your vehicle is disabled on or near the road. It warns other drivers to steer clear of you and your vehicle. This is an emergency warning system, not to be used when the vehicle is in motion.

Hazard Warning Switch

To activate the warning flasher, push down on the button on top of the steering column until it latches. To turn the warning flasher off, push down again to unlatch the button. NOTE: With extended use, the flasher may run down your battery.

IF YOUR ENGINE OVERHEATS In any of the following situations, you can reduce the potential for overheating by taking the appropriate ac- tion. • On the highways — Slow down. • In city traffic — While stopped, put transmission in N

(Neutral), but do not increase engine idle speed.

NOTE: There are steps that you can take to slow down an impending overheat condition. If your air conditioner is on, turn it off. The air conditioning system adds heat to the engine cooling system and turning off the A/C removes this heat. You can also turn the Temperature Control to maximum heat, the Mode Control to floor, and the Fan Control to High. This allows the heater core to act as a supplement to the radiator and aids in removing heat from the engine cooling system.

WHAT TO DO IN EMERGENCIES 289

CAUTION!

Driving with a hot cooling system could damage your vehicle. If the temperature gauge reads “H”, pull over and stop the vehicle. Idle the vehicle with the air conditioner turned off until the pointer drops back into the normal range. If the pointer remains on the “H”, and you hear continuous chimes, turn the engine off immediately, and call for service.

JUMP STARTING PROCEDURE

NOTE: Check the charge indicator on the battery. If the indicator is light or yellow, replace the battery. 1. Wear eye protection and remove any metal jewelry such as watch bands or bracelets that might make an unintended electrical contact.

290 WHAT TO DO IN EMERGENCIES

2. When boost is provided by a battery in another vehicle, park that vehicle within booster cable reach but without letting the vehicles touch. Set the parking brake, place the transmission in P (Park), and turn the ignition to OFF for both vehicles. 3. Turn off the heater, radio and all unnecessary electrical loads. 4. Connect one end of a jumper cable to the positive terminal of the discharged battery. Connect the other end of the same cable to the positive terminal of the booster battery. 5. Connect the other cable, first to the negative terminal of the booster battery and then connect the other end to a non-paint metal surface on the engine of the vehicle with the discharged battery. Make sure you have a good contact on the engine.

6. Start the engine in the vehicle which has the booster battery, let the engine idle a few minutes, then start the engine in the vehicle with the discharged battery. 7. When removing the jumper cables, reverse the above sequence exactly. Be careful of the moving belts and fan. NOTE: To start the vehicle following connection of a booster battery, the Security Alarm System must first be disabled by cycling a front door key cylinder or by using the keyless entry transmitter.

WARNING!

Jump starting can be dangerous. To avoid personal injury or damage to electrical components in vehicle, observe the following warnings: • Battery fluid is a corrosive acid solution and can burn or even blind you. Don’t allow battery fluid to contact your eyes, skin, or clothing. Don’t lean over a battery when attaching clamps. If acid splashes in eyes or on skin, flush the area immediately with large amounts of water. • Do not use a booster battery or any other booster source that has a greater than 12–volt system, i.e., do not use a 24–volt power source.

WHAT TO DO IN EMERGENCIES 291

• Never attempt to jump start a discharged battery that is frozen, because it could rupture or explode during jump starting. • Be sure your vehicle is not touching the jump start • Observe all Battery Warnings in Section 7 of this

vehicle.

manual, while jump starting your vehicle.

WARNING!

Do not attempt to push or tow your vehicle to get it started. Unburned fuel could enter the catalytic converter and, once the engine has started, ignite and damage the converter and vehicle.

MAINTAINING YOUR VEHICLE

CONTENTS

䡵 6.1L Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

䡵 Onboard Diagnostic System — OBD II . . . . . . . . 297

▫ Loose Fuel Filler Cap Message . . . . . . . . . . . . 297䡵 Emissions Inspection And Maintenance

Programs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

䡵 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . 299

䡵 Dealer Service . . . . . . . . . . . . . . . . . . . . . . . . . 300

䡵 Maintenance Procedures . . . . . . . . . . . . . . . . . . 300

. . . . . . . . . . . . . . . . . . . . . . . . . . 301▫ Engine Oil

▫ Engine Oil Filter . . . . . . . . . . . . . . . . . . . . . . 304

▫ Drive Belts — Check Condition AndTensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

▫ Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . 305

▫ Engine Air Cleaner Filter . . . . . . . . . . . . . . . . 305

▫ Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 305

▫ Catalytic Converter . . . . . . . . . . . . . . . . . . . . 306

▫ Maintenance-Free Battery . . . . . . . . . . . . . . . . 307

▫ Air Conditioner Maintenance . . . . . . . . . . . . . 309294 MAINTAINING YOUR VEHICLE

▫ Power Steering Fluid Check . . . . . . . . . . . . . . 310

▫ Body Lubrication . . . . . . . . . . . . . . . . . . . . . 311

▫ Windshield Wiper Blades . . . . . . . . . . . . . . . . 312

▫ Windshield Washers — Front And Rear . . . . . 312

▫ Exhaust System . . . . . . . . . . . . . . . . . . . . . . 313

▫ Cooling System . . . . . . . . . . . . . . . . . . . . . . . 314

▫ Hoses And Vacuum/Vapor Harnesses . . . . . . . 319

▫ Brake System . . . . . . . . . . . . . . . . . . . . . . . . 319

▫ Brake Fluid Level Check . . . . . . . . . . . . . . . . 321

▫ Fuel System Hoses . . . . . . . . . . . . . . . . . . . . 322

▫ Automatic Transmission . . . . . . . . . . . . . . . . 323

▫ Front And Rear Wheel Bearings . . . . . . . . . . . 324▫ Appearance Care And Protection From

䡵 Fuse Panel

Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

. . . . . . . . . . . . . . . . . . . . . . . . . . . 328

▫ Interior Fuses . . . . . . . . . . . . . . . . . . . . . . . . 328

▫ Underhood Fuses (Power Distribution Center) . 330

▫ Underhood Fuses (Integrated Power Module) . 332

䡵 Vehicle Storage . . . . . . . . . . . . . . . . . . . . . . . . 334

䡵 Replacement Bulbs . . . . . . . . . . . . . . . . . . . . . . 334

䡵 Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . 335

▫ Head Light . . . . . . . . . . . . . . . . . . . . . . . . . . 335

▫ Front Turn Signal . . . . . . . . . . . . . . . . . . . . . 337

▫ Front Fog Light . . . . . . . . . . . . . . . . . . . . . . 338

▫ Rear Tail, Stop, Turn Signal, And Back-UpLights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

▫ Center High Mounted Stop Light (CHMSL) . . . 340

䡵 Fluid Capacities . . . . . . . . . . . . . . . . . . . . . . . . 341

䡵 Fluids, Lubricants, And Genuine Parts . . . . . . . . 342MAINTAINING YOUR VEHICLE 295

▫ Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

▫ Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343296 MAINTAINING YOUR VEHICLE

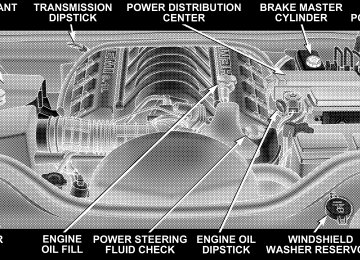

6.1L ENGINE

ONBOARD DIAGNOSTIC SYSTEM — OBD II Your vehicle is equipped with a sophisticated onboard diagnostic system called OBD II. This system monitors the performance of the emissions, engine, and automatic transmission control systems. When these systems are operating properly, your vehicle will provide excellent performance and fuel economy, as well as engine emis- sions well within current government regulations. If any of these systems require service, the OBD II system will turn on the “Malfunction Indicator Light.” It will also store diagnostic codes and other information to assist your service technician in making repairs. Al- though your vehicle will usually be drivable and not need towing, see your dealer for service as soon as possible.

MAINTAINING YOUR VEHICLE 297

CAUTION!

• Prolonged driving with the “Malfunction Indica- tor Light” on could cause further damage to the emission control system. It could also affect fuel economy and driveability. The vehicle must be serviced before any emissions tests can be per- formed. • If the “Malfunction Indicator Light” is flashing while the engine is running, severe catalytic con- verter damage and power loss will soon occur. Immediate service is required.

Loose Fuel Filler Cap Message After fuel is added, the vehicle diagnostic system can determine if the fuel filler cap is loose, improperly installed, or damaged. A loose fuel filler cap message will be displayed in the instrument cluster. Tighten the gas

298 MAINTAINING YOUR VEHICLE

cap until a ⬙clicking⬙ sound is heard. This is an indication that the gas cap is properly tightened. Press the odometer reset button to turn the message off. If the problem persists, the message will appear the next time the vehicle is started. This might indicate a damaged cap. If the problem is detected twice in a row, the system will turn on the Malfunction Indicator Light (MIL). Resolving the problem will turn the MIL light off.

EMISSIONS INSPECTION AND MAINTENANCE PROGRAMS In some localities, it may be a legal requirement to pass an inspection of your vehicle’s emissions control system. Failure to pass could prevent vehicle registration.

For states which have an I/M (Inspection and Maintenance) requirement, this check verifies the following: the MIL (Malfunction Indicator Lamp)

is functioning and is not on when the engine is running, and that the OBD (On Board Diagnostic) system is ready for testing. Normally, the OBD system will be ready. The OBD system may not be ready if your vehicle was recently serviced, if you recently had a dead battery, or a battery replacement. If the OBD system should be determined not ready for the I/M test, your vehicle may fail the test. Your vehicle has a simple ignition key actuated test which you can use prior to going to the test station. To check if your vehicle’s OBD system is ready, you must do the following: 1. Insert your ignition key into the ignition switch. 2. Turn the ignition to the ON position, but do not crank or start the engine. 3. If you crank or start the engine, you will have to start this test over.

4. As soon as you turn your key to the ON position, you will see your MIL symbol come on as part of a normal bulb check. 5. Approximately 15 seconds later, one of two things will happen:

a. The MIL will flash for about 10 seconds and then return to being fully illuminated until you turn off the ignition key or start the engine. This means that your vehicle’s OBD system is not ready and you should not proceed to the I/M station. b. The MIL will not flash at all and will remain fully illuminated until you turn off the ignition key or start the engine. This means that your vehicle’s OBD system is ready and you can proceed to the I/M station.

If your OBD system is not ready, you should see your authorized dealer or repair facility. If your vehicle was recently serviced or had a battery failure or replacement,

MAINTAINING YOUR VEHICLE 299

you may need to do nothing more than drive your vehicle as you normally would in order for your OBD system to update. A recheck with the above test routine may then indicate that the system is now ready. Regardless of whether your vehicle’s OBD system is ready or not ready, if the MIL symbol is illuminated during normal vehicle operation, you should have your vehicle serviced before going to the I/M station. The I/M station can fail your vehicle because the MIL symbol is on with the engine running.

REPLACEMENT PARTS Use of genuine Mopar威 parts for normal/scheduled maintenance and repairs is highly recommended to in- sure the designed performance. Damage or failures caused by the use of non-Mopar威 parts for maintenance and repairs will not be covered by the manufacturer’s warranty.

300 MAINTAINING YOUR VEHICLE

DEALER SERVICE Your dealer has the qualified service personnel, special tools and equipment to perform all service operations in an expert manner. Service Manuals are available which include detailed service information for your vehicle. Refer to these manuals before attempting any procedure yourself. NOTE: systems can result against you.

Intentional tampering with emissions control in civil penalties being assessed

WARNING!

You can be badly injured working on or around a motor vehicle. Do only that service work for which you have the knowledge and the proper equipment. If you have any doubt about your ability to perform a service job, take your vehicle to a competent mechanic.

MAINTENANCE PROCEDURES The pages that follow contain the required maintenance services determined by the engineers who designed your vehicle. Besides the maintenance items for which there are fixed maintenance intervals, there are other items that should operate satisfactorily without periodic maintenance. However, if a malfunction of these items does occur, it

could adversely affect the engine or vehicle performance. These items should be inspected if a malfunction is observed or suspected. Engine Oil

Checking Oil Level To assure proper engine lubrication, the engine oil must be maintained at the correct level. Check the oil level at regular intervals, such as every fuel stop. The best time to check the engine oil level is about 5

minutes after a fully warmed engine is shut off or before starting the engine after it has sat overnight. Checking the oil while the vehicle is on level ground will improve the accuracy of the oil level readings. Maintain the oil level in the “SAFE” range. Adding one quart of oil when the reading is at the bottom of the “SAFE” range will result in an oil level at the top of the “SAFE” range on these engines.MAINTAINING YOUR VEHICLE 301

NOTE: Fill engine oil one quart at a time.

Engine Oil Dipstick

302 MAINTAINING YOUR VEHICLE

CAUTION!

Overfilling or underfilling will cause oil aeration or loss of oil pressure. This could damage your engine.

CAUTION!

Operating the engine with the oil levels below the safe zone, or operating with oil levels that exceed the top of the safe zone may cause engine damage.

Change Engine Oil Road conditions and your kind of driving affects the interval at which your oil should be changed. Check the following list to see if any apply to you. • Day or night temperatures are below 32°F (0°C).

speeds during hot weather, above 90°F (32°C).

• Stop and go driving. • Extensive engine idling. • Driving in dusty conditions. • Short trips of less than 10 miles (16 km). • More than 50% of your driving is at sustained high • Trailer towing. If ANY of these apply to you then change your NOTE: engine oil every 3,000 miles (5 000 km) or 3 months, whichever comes first. Refer to “Maintenance Schedule B” in Section 8 of this manual. If none of these apply to you, then change your engine oil at every interval shown on “Maintenance Schedule ⬙A.⬙ Refer to Section 8 of this manual.

NOTE: Under no circumstances should oil change in- tervals exceed 6,000 miles (10 000 km) or 6 months whichever comes first. Engine Oil Selection For best performance and maximum protection under all types of operating conditions, the manufacturer only recommends full synthetic engine oils that are API rated as SM/CF and meet the requirements of DaimlerChrysler Material Standard MS-10725. Use Mopar or an equivalent oil meeting the specification MS-10725. The manufacturer recommends the use of a full synthetic engine oil, such as Mobil 1威 SAE 0W-40 or equivalent. Engine Oil Viscosity Chart The proper SAE viscosity grade of engine oil should be selected based on the following recommendation and be within the operating temperature shown in the engine oil viscosity chart.

MAINTAINING YOUR VEHICLE 303

Materials Added to Engine Oil The manufacturer strongly recommends against the ad- dition of any additives (other than leak detection dyes) to the engine oil. Engine oil is an engineered product and it’s performance may be impaired by supplemental ad- ditives.

304 MAINTAINING YOUR VEHICLE

Disposing of Used Engine Oil And Oil Filters Care should be taken in disposing of used engine oil and oil filters from your vehicle. Used oil and oil filters, indiscriminately discarded, can present a problem to the environment. Contact your dealer, service station, or governmental agency for advice on how and where used oil and oil filters can be safely discarded in your area. Engine Oil Filter The engine oil filter should be replaced at every engine oil change. Engine Oil Filter Selection The manufacturer’s engines have a full-flow type oil filter. Use a filter of this type for replacement. The quality of replacement filters varies considerably. Only high quality filters should be used to assure most efficient service. Mopar Engine Oil Filters are a high quality oil filter and are recommended.

Drive Belts — Check Condition and Tensioner Belt tension is controlled by means of an automatic tensioner. No belt tension adjustments are required. However, belt and belt tensioner condition should be inspected at the specified intervals, and replaced if re- quired. See your authorized dealer for service. At the mileage indicated on the appropriate “Mainte- nance Schedule,” all belts and tensioner should be checked for condition. Improper belt tension can cause belt slippage and failure. Belts should be inspected for evidence of cuts, cracks, glazing, or frayed cords and replaced if there is indication of damage which could result in belt failure. Low gen- erator belt tension can cause battery failure. Also check belt routing to make sure there is no interfer- ence between the belts and other engine components.

Spark Plugs Spark plugs must fire properly to assure engine perfor- mance and emission control. New plugs should be in- stalled at the specified mileage. The entire set should be replaced if there is any malfunction due to a faulty spark plug. Malfunctioning spark plugs can damage the cata- lytic converter. For proper type of replacement spark plugs, refer to the “Vehicle Emission Control Informa- tion” label in the engine compartment. Engine Air Cleaner Filter Under normal driving conditions, replace the air filter at the intervals shown on “Maintenance Schedule A.” If, however, you drive the vehicle frequently under dusty or severe conditions, the filter element should be inspected periodically and replaced if necessary at the intervals shown on “Maintenance Schedule B.”

MAINTAINING YOUR VEHICLE 305

WARNING!

The air cleaner can provide a measure of protection in the case of engine backfire. Do not remove the air cleaner unless such removal is necessary for repair or maintenance. Make sure that no one is near the engine compartment before starting the vehicle with the air cleaner removed. Failure to do so can result in serious personal injury.

Fuel Filter A plugged fuel filter can cause stalling, limit the speed at which a vehicle can be driven or cause hard starting. Should an excessive amount of dirt accumulate in the fuel tank, filter replacement may be necessary. See your local dealer for service.

306 MAINTAINING YOUR VEHICLE

Catalytic Converter The catalytic converter requires the use of unleaded fuel only. Leaded gasoline will destroy the effectiveness of the catalyst as an emission control device. Under normal operating conditions, the catalytic con- verter will not require maintenance. However, it is im- portant to keep the engine properly tuned to assure proper catalyst operation and prevent possible catalyst damage.

CAUTION!

Damage to the catalytic converter can result if your vehicle is not kept in proper operating condition. In the event of engine malfunction, particularly involv- ing engine misfire or other apparent loss of perfor- mance, have your vehicle serviced promptly. Contin- ued operation of your vehicle with a severe malfunction could cause the converter to overheat, resulting in possible damage to the converter and the vehicle.

NOTE: systems can result against you.

Intentional tampering with emissions control in civil penalties being assessed

WARNING!

A hot exhaust system can start a fire if you park over materials that can burn. Such materials might be grass or leaves coming into contact with your ex- haust system. Do not park or operate your vehicle in areas where your exhaust system can contact any- thing that can burn.

In unusual situations involving grossly malfunctioning engine operation, a scorching odor may indicate severe and abnormal catalyst overheating. If this occurs, the vehicle should be stopped, the engine shut off and the vehicle allowed to cool. Thereafter, service, including a tune-up to manufacturer’s specifications, should be ob- tained immediately.

MAINTAINING YOUR VEHICLE 307

To minimize the possibility of catalyst damage: • Do not shut off the engine or interrupt the ignition when the transmission is in gear and the vehicle is in motion. • Do not try to start engine by pushing or towing the • Do not idle the engine with any spark plug wires disconnected or removed, such as when diagnostic testing, or for prolonged periods during very rough idling or malfunctioning operating conditions.

vehicle.

Maintenance-Free Battery Your vehicle is equipped with a maintenance-free battery. You will never have to add water, nor is periodic main- tenance required.

308 MAINTAINING YOUR VEHICLE

WARNING!

Battery posts, terminals, and related accessories con- tain lead and lead compounds. Always wash hands after handling the battery.

To determine the battery charge, check the battery test indicator (if equipped) on top of the battery. Refer to the illustration.

CAUTION!

It is essential when replacing the cables on the battery that the positive cable is attached to the positive post and the negative cable is attached to the negative post. Battery posts are marked (+) positive and negative (-) and identified on the battery case. Also, if a “fast charger” is used while battery is in the vehicle, disconnect both vehicle battery cables be- fore connecting the charger to battery. Do not use a “fast charger” to provide starting voltage.

Air Conditioner Maintenance For best possible performance, your air conditioner should be checked and serviced by an Authorized Dealer at the start of each warm season. This service should include cleaning of the condenser fins and a performance test. Drive belt tension should also be checked at this time.

MAINTAINING YOUR VEHICLE 309

WARNING!

• Use only refrigerants and compressor lubricants approved by the manufacturer for your air condi- tioning system. Some unapproved refrigerants are flammable and can explode, injuring you. Other unapproved refrigerants or lubricants can cause the system to fail, requiring costly repairs. Refer to the Warranty Information Book for further warranty information. • The air conditioning system contains refrigerant under high pressure. To avoid risk of personal injury or damage to the system, adding refrigerant or any repair requiring lines to be disconnected should be done by an experienced repairman.

310 MAINTAINING YOUR VEHICLE

Refrigerant Recovery and Recycling R-134a Air Conditioning Refrigerant is a hydrofluorocar- bon (HFC) that is endorsed by the Environmental Pro- tection Agency and is an ozone-saving product. How- ever, the manufacturer recommends that air conditioning service be performed by dealers or other service facilities using recovery and recycling equipment. NOTE: Use only manufacturer approved A/C System Sealers, Stop Leak Products, Seal Conditioners, Compres- sor Oil, or Refrigerants. Power Steering Fluid Check The power steering system requires the use of Mopar威 (P/N Hydraulic 05142893AA), which meets DaimlerChrysler Material Standard MS-10838.

System Power

equivalent,

Steering

Fluid

or

CAUTION!

Do not use Automatic Transmission Fluid (ATF) or other types of power steering fluids when servicing the power steering system of this vehicle. Damage to the power steering system can result from the use of the wrong power steering fluid.

Checking the power steering fluid level at a defined service interval is not required. The fluid should only be checked if a leak is suspected, abnormal noises are apparent, and/or the system is not functioning as antici- pated. Coordinate inspection efforts through a certified “DaimlerChrysler Dealership.”

WARNING!

Fluid level should be checked on a level surface with the engine off to prevent injury from moving parts, and to insure accurate fluid level reading. Do not overfill. Use only the manufacturer’s recommended fluid.