- 1999 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2011 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2012 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2007 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2004 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2001 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2005 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 1996 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2008 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2003 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2009 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 1998 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2000 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2006 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2010 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 2002 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- 1997 Nissan Pathfinder Owners Manuals

- Nissan Pathfinder Owners Manuals

- Download PDF Manual

-

I The radiator is equipped with a pres- sure cap. Use only a genuine cap as a replacement.

ENGINE COOLING SYSTEM

The engine cooling system is filled at the factory with a high-quality, year-round, anti- freeze coolant solution. The anti-freeze solu- tion contains rust and corrosion inhibitors, therefore additional cooling system additives are not necessary.

When adding or replacing the coolant, be sure to use Genuine Nissan Anti- Freeze Coolant or equivalent with the proper mixture ratio of 50% anti-freeze and 50% demineralized water/distilled water. The use of other types of coolant solutions may damage your engine cooling system.

Outside temperature down to

°C

−35

°F

−30

Anti- freeze

Deminer- alized water or distilled water

50%

50%

8-4 Do-it-yourself

SDI0378

CHECKING ENGINE COOLANT LEVEL Check the coolant level in the reservoir tank when the engine is cold. If the coolant level is below the MIN level, add coolant to the MAX level. If the reservoir tank is empty, check the coolant level in the radiator when the engine is cold. If there is insufficient coolant in the radiator, fill the radiator with coolant up to the filler opening and also add it to the reservoir tank up to the MAX level. If the engine cooling system frequently

Z 01.1.22/R50-D/V5 X

requires coolant, have it checked by your NISSAN dealer.

SDI0485

SDI0486

CHANGING ENGINE COOLANT I Major cooling system repairs should be performed by your NISSAN dealer. The service procedures can be found in the appropriate NISSAN Service Manual.

I Improper servicing can result in reduced heater performance and engine overheat- ing.

I To avoid the danger of being scalded, never change the coolant when the engine is hot.

I Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pressure fluid escaping from the radiator.

Do-it-yourself 8-5

Z 01.1.22/R50-D/V5 X

SDI0409

SDI0410

SDI0419

1. Perform the following procedure to open

the heater water cock. I Turn the ignition key from OFF to ON. I Move the heater or air conditioner tem- perature control dial to the maximum hot position then turn the ignition key to OFF.

2. Open the radiator drain plug and radiator

cap. Open the drain plugs on the engine block.

8-6 Do-it-yourself

3. Open the air release plug to drain the

coolant.

4. Flush the cooling system by running fresh

water through the radiator.

5. Close the radiator drain plug and engine

block drain plugs securely.

6. See the “Technical information” section for

cooling system capacity. Fill the radiator slowly with the proper mix- ture of coolant and water. Fill the reservoir tank slowly up to the MAX level. Then install the radiator cap and close the air release plug.

7. Start

the engine and warm it up until

it reaches normal operating temperature. Then race the engine 2 or 3 times under no load. Watch the coolant temperature gauge for signs of overheating.

8. Stop the engine. After it completely cools down, refill the radiator up to the filler opening. Fill the reservoir tank up the MAX level.

9. Check the radiator drain plug and engine block drain plugs for any sign of leakage.

Z 01.1.22/R50-D/V5 X

ENGINE OIL

Oil level should be checked regularly. Operating with insufficient amount of oil can damage the engine, and such dam- age is not covered by warranty.

SDI0420

SDI0487

CHECKING ENGINE OIL LEVEL 1. Park the vehicle on a level surface and

apply the parking brake.

2. Run the engine until

temperature.

it reaches operating

3. Turn off the engine. Wait more than 10

minutes for the oil to drain back into the oil pan.4. Remove the dipstick and wipe it clean.

Reinsert it all the way.

5. Remove the dipstick again and check the oil level. It should be between the H and L marks. If the oil level is below the L mark, remove the oil filler cap and pour recom- mended oil through the opening. Do not overfill.

6. Recheck oil level with dipstick. It is normal to add some oil between oil changes or during the break-in period, de- pending on the severity of operating con- ditions.

Do-it-yourself 8-7

Z 01.1.22/R50-D/V5 X

section for changing engine oil filter.

Be careful not to burn yourself, as the engine oil is hot.

Waste oil must be disposed of properly. Check your local regulations.

6. Clean and re-install the drain plug and new washer. Securely tighten the drain plug with a wrench. Do not use excessive force. Drain plug tightening torque:

22 to 29 ft-lb (29 to 39 N(cid:215) m)

7. Refill engine with recommended oil through the oil filler opening, then install the oil filler cap securely.

8. Start the engine.

Check for leakage around the drain plug. Correct as required.

9. Turn the engine off and wait several min- utes. Check the oil level with the dipstick. Add engine oil if necessary.

I Prolonged and repeated contact with used engine oil may cause skin can- cer.

I Try to avoid direct skin contact with used oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

I Keep used engine oil out of reach of

children.

and

“Capacities

See recommended fuel/lubricants” in the “10. Technical and consumer information” section for drain and refill capacity.

The drain and refill capacity depends on the oil temperature and drain time. Use these specifications for reference only. Always use the dipstick to determine when the proper amount of oil is in the engine.

Z 01.1.22/R50-D/V5 X

SDI0416

CHANGING ENGINE OIL 1. Park the vehicle on a level surface and

apply the parking brake.

2. Warm up the engine until it reaches oper-

ating temperature, and then turn it off.

3. Place a large drain pan under the drain

plug.

4. Remove the oil filler cap. 5. Remove the drain plug with a wrench and

completely drain the oil. If the oil filter is to be changed, remove and replace it at this time. See later in this

8-8 Do-it-yourself

Be careful not to burn yourself, as the engine oil may be hot.

4. Wipe the engine oil filter mounting surface

with a clean rag. Be sure to remove any old rubber gasket remaining on the mounting surface of the engine.

5. Coat the rubber gasket on the new filter

with engine oil.

6. Screw in the oil filter until a slight resistance

is felt, then tighten an additional 2/3 turn.

7. Start

the engine and check for leakage

around the oil filter. Correct as required.

8. Turn the engine off and wait several min- utes. Check the oil level. Add engine oil if necessary.

SDI0417

CHANGING ENGINE OIL FILTER 1. Park the vehicle on a level surface and

apply the parking brake.

2. Turn the engine off. 3. Loosen the oil filter with an oil filter wrench. (A special cap-type wrench will assist with oil filter removal on models with the V6

engine. This tool can be purchased from your NISSAN dealer.) Then remove the oil filter by turning it by hand.AUTOMATIC TRANSMISSION FLUID

SDI0488

I When engine is running, keep hands, jewelry, and clothing away from any moving parts such as fan and drive belt.

I Automatic transmission fluid is poi- sonous and should be stored care- fully in marked containers out of the reach of children.

Do-it-yourself 8-9

Z 01.1.22/R50-D/V5 X

5. Re-insert the dipstick into the charging pipe

as far as it will go.

6. Remove the dipstick and note the reading. If the level is on the low side of either range, add fluid to the charging pipe.

(Canada).

DexronTM

Automatic

I Do not overfill. I USE ONLY Nissan Matic D (Continen- tal U.S. and Alaska) or Genuine Transmission Nissan Fluid III/ MerconTM or equivalent may also be used. Outside the continental United States and Alaska contact a NISSAN dealer for more information regarding suitable fluids, including recom- mended brand(s) of DexronTM III/ MerconTM or DexronTM IIE/MerconTM Automatic Transmission Fluid.

TEMPERATURE CONDITIONS FOR CHECKING The fluid level should be checked using the HOT range (L & H marks) on the dipstick at fluid temperatures between 122 and 176°F (50

and 80°C) after the vehicle has been driven approximately 5 minutes in urban areas after the engine is warmed up. The level can be checked at fluid temperatures between 86 and 122°F (30 and 50°C) using the COLD range on the dipstick for reference, after the engine is warmed up but before driving. However, the fluid level must be rechecked using the HOT range. 1. Park the vehicle on a level surface and setthe parking brake.

2. Start the engine and then move the selector lever through each gear range, ending in P. 3. Check the fluid level with the engine idling. If the vehicle has been driven for a long time at high speeds, or in city traffic in hot weather, or if it is being used to pull a trailer, the fluid level cannot be read accu- rately. You should wait until the fluid has cooled down (about 30 minutes).

4. Remove the dipstick and wipe it clean with

lint-free paper.

8-10 Do-it-yourself

Z 01.1.22/R50-D/V5 X

SDI0386A

POWER STEERING FLUID

BRAKE AND CLUTCH FLUID

and clutch systems. The use of im- proper fluids can damage the brake sys- tem and affect the vehicle’s stopping ability.

Do not spill the fluid on any painted surfaces. This will damage the paint. If fluid is spilled, wash with water.

DI0187M

SDI0847

Check the fluid level.

The fluid level should be checked using the HOT range on the dipstick at fluid tempera- tures of 122 to 176°F (50 to 80°C) or using the COLD range on the dipstick at fluid tempera- tures of 32 to 86°F (0 to 30°C).

I Do not overfill. I Recommended fluid is Genuine

Nissan PSF II or equivalent.

BRAKE FLUID Check the fluid level in the reservoir. If the fluid level line or the brake warning light comes on, add DOT 3 fluid up to the MAX. line.

is below the MIN.

If fluid is added frequently, the system should be thoroughly checked by your NISSAN dealer.

Use only new fluid. Old, inferior or con- taminated fluid may damage the brake

Do-it-yourself 8-11

Z 01.1.22/R50-D/V5 X

WINDOW WASHER FLUID

and clutch systems. The use of im- proper fluids can damage the brake sys- tem and affect the vehicle’s stopping ability.

Do not spill the fluid on any painted surfaces. This will damage the paint. If fluid is spilled, wash with water.

SDI0844

CLUTCH FLUID Check the fluid level in the reservoir. If the fluid level line or the brake warning light comes on, add DOT 3 fluid up to the MAX. line.

is below the MIN.

If fluid is added frequently, the system should be thoroughly checked by your NISSAN dealer.

Use only new fluid. Old, inferior or con- taminated fluid may damage the brake

8-12 Do-it-yourself

SDI0423A

WINDOW WASHER FLUID RESERVOIR For US To check the fluid level, use your finger to plug the center hole of the cap/tube assembly (as shown above), then remove it from the tank. If there is no fluid in the tube, add fluid. Add a washer solvent to the water for better cleaning. In the winter season, add a windshield washer anti-freeze. Follow the manufacturer’s instruc- tions for the mixture ratio.

Z 01.1.22/R50-D/V5 X

Anti-freeze is poisonous and should be stored carefully marked containers out of the reach of children.

BATTERY

I Keep the battery surface clean and dry. Any corrosion should be washed off with a solution of baking soda and water.

I Make certain the terminal connections are

clean and securely tightened.

I If the vehicle is not to be used for 30 days or longer, disconnect the (—) negative battery terminal cable to prevent discharge.

I Do not expose the battery to flames or electrical sparks. Hydrogen gas generated by battery action is explo- sive. Do not allow battery fluid to contact your skin, eyes, fabrics, or painted surfaces. After touching a battery or battery cap, do not touch or rub your eyes. Thoroughly wash your hands. If the acid contacts your eyes, skin or clothing, immediately flush with water for at least 15 minutes and seek medical attention.

I When working on or near a battery, always wear suitable eye protection and remove all jewelry.

I Keep the battery out of the reach of Do-it-yourself 8-13

Z 01.1.22/R50-D/V5 X

SDI0389

For CANADA Add fluid when the low washer fluid warning light comes on. Add a washer solvent to the water for better cleaning. In the winter season, add a windshield washer anti-freeze. Follow the manufacturer’s instructions for the mixture ratio.

Do not substitute engine anti-freeze coolant for window washer solution. This may result in damage to the paint.

DRIVE BELTS

children.

JUMP STARTING If jump starting is necessary, see “Jump start- ing” in the “6. In case of emergency” section. If the engine does not start by jump starting, the battery may have to be replaced. Contact your NISSAN dealer.

DI0137M

SDI0424

Check the fluid level in each cell. It should be between the MAX. and MIN. lines. If it is necessary to add fluid, add only distilled water to bring the level to the indicator in each filler opening. Do not overfill. 1. Remove the cell plugs using a suitable tool. 2. Add distilled water up to the MAX. level. 3. Tighten cell plugs.

Be sure the ignition key is OFF. The engine could rotate unexpectedly.

1. Visually inspect each belt for signs of un- usual wear, cuts, fraying or looseness. If the belt is in poor condition or loose, have it replaced or adjusted by your NISSAN dealer.

2. Have the belts checked regularly for condi- tion and tension in accordance with the maintenance schedule in this manual.

Z 01.1.22/R50-D/V5 X

8-14 Do-it-yourself

SPARK PLUGS

engaged securely.

REPLACING SPARK PLUGS 1. Disconnect spark plug cables. Keep track

of the original cable location.

When disconnecting, always hold the boots — not the cables. Mark all cables to identify their original location.

SDI0723

Be sure the engine and ignition switch are off and that the parking brake is

2. Remove spark plugs with a spark plug

wrench. (Type A or B)

SDI0392

Be sure to use the correct wrench to remove the plugs. An incorrect wrench can cause damage.

Do-it-yourself 8-15

Z 01.1.22/R50-D/V5 X

AIR CLEANER

SDI0390

DI0065

SDI0393

3. Check each new spark plug gap with a

feeler gauge. Correct it as required.

4. Install spark plugs. When installing a plug, turn it in two or three turns by hand and then tighten with a spark plug wrench. Be careful not to over- tighten it.

The filter element should not be cleaned and reused as it is given a special treatment. We recommended it be replaced according to the maintenance intervals. See “Periodic mainte- nance” in the “9. Maintenance” section for maintenance intervals. When replacing the filter, wipe the inside of the air cleaner housing and the cover with a damp cloth.

Tightening torque:

14 to 22 ft-lb (20 to 29 N(cid:215) m)

5. Reconnect the spark plug cables to their

original positions.

I Operating the engine with the air cleaner off can cause you or others to be burned. The air cleaner not only

8-16 Do-it-yourself

SDI0391

Z 01.1.22/R50-D/V5 X

WINDSHIELD WIPER BLADES

cleans the air, it stops flame if the engine backfires. If it is not there, and the engine backfires, you could be burned. Do not drive with it off, and be careful working on the engine with the air cleaner off.

I Never pour fuel into the throttle body or attempt to start the engine with the air cleaner removed. Doing so could result in serious injury.

DI0155MA

the blades and using the wiper, replace the blades. REPLACEMENT 1. Pull the wiper arm. 2. Push the lock pin, then remove the wiper

blade.

3. Insert the new wiper blade to the wiper arm

until a click sounds.

CLEANING If your windshield is not clear after using the windshield washer of if a wiper blade chatters when running, wax or other material may be on the blade or windshield.

the windshield with a Clean the outside of washer solution or a mild detergent. Your windshield is clean if beads do not form when rinsing with clear water.

Clean the blade by wiping it with a cloth soaked in a washer solution or a mild deter- gent. Then rinse the blade with clear water. If your windshield is still not clear after cleaning

Do-it-yourself 8-17

Z 01.1.22/R50-D/V5 X

After wiper blade replacement, return the wiper arm to its original position.

Otherwise it may be damaged when the engine hood is opened.

Make sure the wiper blade contacts the glass. Otherwise, the arm may be dam- aged from wind pressure.

PARKING BRAKE AND BRAKE PEDAL

DI1010-C

CHECKING PARKING BRAKE Pull the parking brake lever up. If the number of clicks is out of the range as listed above, see your NISSAN dealer.

8-18 Do-it-yourself

SDI0425

If you wax the surface of the hood, be careful not to let wax get into the washer nozzle. This may cause clogging or im- proper windshield washer operation. If wax gets into the nozzle, remove it with a needle or small pin.

Z 01.1.22/R50-D/V5 X

Self-adjusting brakes Your vehicle is equipped with self-adjusting brakes.

The front disc-type brakes self-adjust every time the brake pedal is applied. The rear drum-type brakes self-adjust every time the parking brake is applied. If the brake pedal goes down farther than normal, it may be due to a lack of adjustment of the rear drum brakes. Apply the parking brake several times.

DI0453

CHECKING BRAKE PEDAL With the engine running, check distance A between the upper surface of the pedal and the dash lower panel. Distance A

M/T models

2-1/2 in (65 mm) or more

A/T models

2-3/4 in (70 mm) or more

If it is out of the range shown above, see your NISSAN dealer.

See your NISSAN dealer and have it checked if the brake pedal height does not return to normal.

Brake pad wear indicators The disc brake pads on your vehicle have audible wear indicators. When a brake pad requires replacement, it will make a high pitched scraping or screeching sound when the vehicle is in motion whether or not the brake pedal is depressed. Have the brakes checked as soon as possible if the wear indi- cator sound is heard. Under some driving or climate conditions, oc-

casional brake squeak, squeal or other noise may be heard. Occasional brake noise during light to moderate stops is normal and does not affect the function or performance of the brake system.

The rear drum brakes (if so equipped) do not have audible wear indicators. Should you ever hear an unusually loud noise from the rear drum brakes, have them inspected as soon as possible by your NISSAN dealer. Proper brake inspection intervals should be followed. For additional information, see “Periodic maintenance” in the “9. Mainte- nance” section for maintenance intervals. BRAKE BOOSTER Check the brake booster function with the following steps: 1. With the engine off, press and release the times. When brake brake pedal several travel) re- pedal movement (distance of mains the same from one pedal application to the next, continue on to the next step.

2. While depressing the brake pedal, start the engine. The pedal height should drop a little.

3. With the brake pedal depressed, stop the engine. Keeping the pedal depressed for Do-it-yourself 8-19

Z 01.1.22/R50-D/V5 X

CLUTCH PEDAL

FUSES

about 30 seconds, the pedal height should not change.

4. Run the engine for one minute without depressing the brake pedal, then turn it off. Depress the brake pedal several times. The pedal travel distance will decrease gradu- ally with each depression as the vacuum is released from the booster.

If the brakes do not operate properly, have the brake checked by your NISSAN dealer.

DI0070-B

SDI0395

CHECKING CLUTCH PEDAL Press the pedal by hand and be sure the free travel is within the above limit. If free travel is out of the range shown above, see your NISSAN dealer.

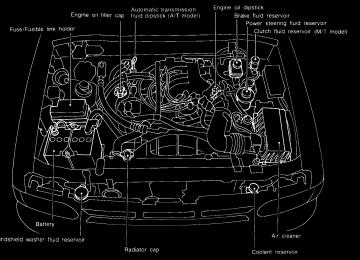

ENGINE COMPARTMENT

Never use a fuse of higher amperage rating than that specified on the fuse box cover. This could damage the elec- trical system or cause a fire.

If any electrical equipment does not operate, check for an open fuse.

1. Be sure the ignition key and the headlight

switch are OFF.

Z 01.1.22/R50-D/V5 X

8-20 Do-it-yourself

2. Open the engine hood. 3. Remove the fuse box cover. 4. Remove the fuse with the fuse puller. 5. If the fuse is open, replace it with a new

fuse.

6. If a new fuse opens again, have the elec- trical system checked and repaired by your NISSAN dealer.

Fusible links If any electrical equipment does not operate and fuses are in good condition, check the fusible links. If any of these fusible links are melted, replace only with genuine NISSAN parts.

PASSENGER COMPARTMENT

Never use a fuse of higher amperage rating than that specified on the fuse box cover. This could damage the elec- trical system or cause a fire.

If any electrical equipment does not operate, check for an open fuse.

1. Be sure the ignition key and the headlight

switch are OFF.

SDI0447

2. Pull to open the fuse box cover/coin tray. 3. Pull the fuse box cover/coin tray horizon-

tally to remove it.

4. Remove the fuse with the fuse puller. 5. If the fuse is open, replace it with a new

fuse.

6. If a new fuse opens again, have the elec- trical system checked and repaired by your NISSAN dealer.

Do-it-yourself 8-21

Z 01.1.22/R50-D/V5 X

LIGHTS

8-22 Do-it-yourself

SDI0907

Z 01.1.22/R50-D/V5 X

HEADLIGHTS The headlight is a semi-sealed beam type which uses a replaceable headlight (halogen) bulb. A bulb can be replaced inside the engine compartment without removing the headlight assembly.

6. Install the new bulb in the reverse order of

removal.

Aiming is not necessary after replacing the bulb. When aiming adjustment is neces- sary, contact your NISSAN dealer.

High pressure halogen gas is sealed inside the halogen bulb. The bulb may break if the glass envelope is scratched or the bulb is dropped.

Hold the plastic base when handling the bulb. Never touch the glass envelope.

Replacing the headlight bulb 1. Disconnect the battery negative cable.

2. Disconnect

the electrical connector from

the rear end of the bulb.

3. Pull off the rubber cap.

4. Push and turn the retaining pin to loosen it.

5. Remove the headlight bulb. Do not shake

or rotate the bulb when removing it.

SDI0908

DO NOT TOUCH THE BULB. I Be sure the lip of the rubber cap

contacts the headlight body.

I Use the same number and wattage as

originally installed:

Wattage 60/55

Bulb No. HB2I Do not leave the bulb out of the head- light reflector for a long period of time as dust, moisture, and smoke may enter the headlight body and affect the performance of the headlight.

Do-it-yourself 8-23

Z 01.1.22/R50-D/V5 X

Item

Wattage (W)

Side combination light

Front fog light (H3 type)

Rear combination light

Turn signal

Stop/Tail

Back-up

High mounted stop light

License plate light

Interior light

Vanity mirror light

Personal light

*1: For 5W light *2: Option Bulb identification

MDI0006

21/5

55

27

21/5

18

5 or 10

7.5

10

1.4

Bulb No.

7443

1156

7443

921

168

168*1

89*2—

—

—

Replacement procedures All other lights are either type A, B, C or D. When replacing a bulb, first remove the lens and/or cover.

8-24 Do-it-yourself

Z 01.1.22/R50-D/V5 X

SDI0910

SDI0911

SDI0912

Do-it-yourself 8-25Z 01.1.22/R50-D/V5 X

TIRES AND WHEELS

SDI0333

DI0047

If you have a flat tire, see “Flat tire” in the “6. In case of emergency” section. TIRE PRESSURE Maximum inflation pressure Do not exceed the maximum inflation pres- sures shown on the side wall of the tire. Tire inflation pressure Periodically check the tire pressure (including spare). Incorrect tire pressure may adversely affect tire life and vehicle handling. Tire pres- sure should be checked when tires are COLD. Tires are considered COLD after the vehicle

Z 01.1.22/R50-D/V5 X

8-26 Do-it-yourself

SDI0980

has been parked for three or more hours, or driven less than 1 mile (1.6 km). COLD tire pressures are shown on the tire placard affixed to the inside of the glove box lid.

with high speed capability tires. Driv- ing faster than 85 MPH (140 km/h) may result in tire failure, loss of con- trol and possible injury.

I Improperly inflated tires can fail sud-

denly and cause an accident.

I The vehicle capacity weight is indi- cated on the tire placard. Do not load your vehicle beyond this capacity. Overloading your vehicle may result in reduced tire life, unsafe operating conditions due to premature tire fail- ure, or unfavorable handling charac- teristics and could also lead to a serious accident. Loading beyond the specified capacity may also result in failure of other vehicle components. I Before taking a long trip, or whenever you have loaded your vehicle heavily, use a tire pressure gauge to ensure that the tire pressure is at the speci- fied level.

I Do not drive your vehicle over 85

MPH (140 km/h) unless it is equippedTYPES OF TIRES

When changing or replacing tires, be sure all four tires are of the same type (for example, summer, all season or snow) and construction. Your NISSAN dealer may be able to help you with information about tire type, size, speed rating and availability. Replacement tires may have a lower speed rating than the factory equipped tires, and may not match the potential maximum vehicle speed. Never exceed the maximum speed rating of the tire.

All season tires NISSAN specifies all season tires on some models to provide good performance for use all year around, including snowy and icy road conditions. All season tires are identified by

ALL SEASON and/or M&S on the tire sidewall. Snow tires have better snow traction than all season tires and may be more appropriate in some areas. Summer tires NISSAN specifies summer tires on some mod- els to provide superior performance on dry roads. Summer tire performance in snow and ice will be substantially reduced. Summer tires do not have the tire traction rating M&S on the tire sidewall. If you operate your vehicle in snowy or icy conditions, NISSAN recommends the use of SNOW or ALL SEASON tires on all four wheels. Snow tires If snow tires are needed, it is necessary to select tires equivalent in size and load rating to the original equipment tires. If you do not, it can adversely affect the safety and handling of your vehicle. Generally, snow tires will have lower speed ratings than factory equipped tires and may not match the potential maximum vehicle speed. Never exceed the maximum speed rating of the tire. If you install snow tires on four wheel drive Do-it-yourself 8-27

Z 01.1.22/R50-D/V5 X

models, they must also be the same size, brand, construction and tread pattern on all four wheels.

If you operate your vehicle in snowy or icy conditions, NISSAN recommends the use of SNOW or ALL SEASON tire on all four wheels. For additional traction on icy roads, studded tires may be used. However, some provinces and states prohibit their use. Check local, state and provincial laws before installing studded tires. Skid and traction capabilities of studded snow tires, on wet or dry surfaces, may be poorer than that of non-studded snow tires. TIRE CHAINS Use of tire chains is prohibited according to location. Check the local laws before installing tire chains. When installing tire chains, make sure they are of proper size for the tires on your vehicle and are installed according to the chain manufacturer’s suggestions. Use only SAE class S chains. Other types may dam- age your vehicle. Use chain tensioners when recommended by the tire chain manufacturer to ensure a tight fit. Loose end links of the tire chain must be secured or removed to prevent the possibility of whipping action damage to the fenders or underbody. If possible, avoid fully loading your vehicle when using tire chains. In addition, drive at a reduced speed. 8-28 Do-it-yourself

Otherwise, your vehicle may be damaged and/or vehicle handling and performance may be adversely affected. Do not use tire chains on dry roads. Tire chains must be installed only on the rear wheels and not on the front wheels.

Do not drive with tire chains on paved roads which are clear of snow. Driving with chains in such conditions can cause damage to the various mechanisms of the vehicle due to some overstress. When driving on clear paved roads, be sure to change to 2WD.

SDI0724

CHANGING TIRES AND WHEELS Tire rotation NISSAN recommends that tires be rotated every 7,500 miles (12,000 km) for 2WD ve- hicles and 3,750 miles (6,000 km) for 4WD vehicles. However, the timing for tire rotation may vary according to your driving habits and road surface conditions. See “Flat tire” in the “6. In case of emergency” section for tire replacing procedures.

Z 01.1.22/R50-D/V5 X

Wheel nut tightening torque:

87 to 108 ft-lb (118 to 147 N(cid:215) m)

I After rotating the tires, adjust the tire

pressure.

I Retighten the wheel nuts after the aluminum wheel has been run for the first 600 miles (1,000 km). (also in cases of a flat tire, etc.)

replaced.

Replacing tires and wheels When replacing a tire, use the same size, speed rating and load carrying capacity as originally equipped. See “Specifications” in the “10. Technical and consumer information” sec- tion for tires and wheels.

I The use of tires other than those recommended or the mixed use of tires of different brands, construction (bias, bias-belted or radial), or tread patterns can adversely affect the ride, braking, handling, ground clearance, body-to-tire clearance, snow chain clearance, speedometer calibration, headlight aim and bumper height. Some of these effects may lead to accidents and could result in serious personal injury.

I If the wheels are changed for any reason, always replace with wheels which have the same offset dimen- sion. Wheels of a different offset

Do-it-yourself 8-29

Tire wear and damage

MDI0004

I Tires should be periodically in- spected for wear, cracking, bulging or objects caught in the tread. If ex- cessive wear, cracks, bulging or deep cuts are found, the tire should be replaced.

I The original tires have a built-in tread wear indicator. When the wear indica- tor is visible, the tire should be

Z 01.1.22/R50-D/V5 X

I Do not use abrasive cleaners when wash-

ing the wheels.

I Inspect wheel rims regularly for dents or corrosion. This may cause loss of pressure or damage the tire bead.

I We recommend that the road wheels be waxed to protect against road salt in areas where it is used during winter.

could cause early tire wear, possibly degraded vehicle handling character- istics and/or interference with the brake discs/drums. Such interference can lead to decreased braking effi- ciency and/or early brake pad/shoe wear.

I Do not install a deformed wheel or tire even if it has been repaired. Such wheels or tires could have structural damage and could fail without warn- ing.

I The use of retread tire is not rec-

ommended.

Four wheel drive models

Always use tires of the same size, brand, construction (bias, bias-belted or ra- dial), and tread pattern on all four wheels. A spare tire of the same size, brand, construction and tread pattern must also be used. Failure to do so may result in a circumference difference be- tween tires on the front and rear axles

8-30 Do-it-yourself

which will cause excessive tire wear and may damage the transmission, transfer case and differential gears.

If excessive tire wear is found, it is recom- mended that all four tires be replaced with tires of the same size, brand, construction and tread pattern. The tire pressure and wheel alignment should also be checked and cor- rected as necessary. Contact your NISSAN dealer. Wheel balance Unbalanced wheels may affect vehicle han- dling and tire life. Even with regular use, wheels can get out of balance. Therefore, they should be balanced as required.

Wheel balance service should be performed with the wheels off the vehicle. Spin balancing the rear wheels on the vehicle could lead to transmission damage. Care of wheels I Wash the wheels when washing the vehicle

to maintain their appearance.

I Clean the inner side of the wheels when the wheel is changed or the underside of the vehicle is washed.

Z 01.1.22/R50-D/V5 X

DI0117

CLUTCH HOUSING DRAIN

Whenever you drive in deep water or mud, check water entry in the clutch housing by removing the blind plug at the bottom of the transmission case. After checking, be sure to reinstall the plug.

Do-it-yourself 8-31

Z 01.1.22/R50-D/V5 X

MEMO

8-32 Do-it-yourself

Z 01.1.22/R50-D/V5 X

9 Maintenance

Maintenance precautions .......................................... 9-2

General maintenance................................................ 9-2

Exterior maintenance ................................................ 9-2

Interior maintenance ................................................. 9-3Periodic maintenance schedules .............................. 9-5

Schedule 1 ................................................................ 9-5

Schedule 2 ................................................................ 9-5Z 01.1.22/R50-D/V5 X

MAINTENANCE PRECAUTIONS

Your new NISSAN has been designed to have minimum maintenance requirements with longer service intervals to save you both time and money. However, some day-to-day and regular maintenance is essential to maintain your NISSAN’s good mechanical condition, as well as its emission and engine performance.

It is the owner’s responsibility to make sure that the specified maintenance, as well as general maintenance, is performed.

As the vehicle owner, you are the only one who can ensure that your vehicle receives the proper maintenance care. You are a vital link in the maintenance chain. General maintenance:

General maintenance includes those items which should be checked during normal day- to-day operation of the vehicle. They are es- sential if your vehicle is to continue to operate properly. It is your responsibility to perform these procedures regularly as prescribed. These checks or inspections can be done by yourself, a qualified technician or, if you prefer, your NISSAN dealer. Periodic maintenance: The maintenance items listed in this part are required to be serviced at regular intervals. 9-2 Maintenance

However, under severe driving conditions, ad- ditional or more frequent maintenance will be required. Where to go for service: If maintenance service is required or your vehicle appears to malfunction, have the sys- tems checked and tuned by an authorized NISSAN dealer. NISSAN technicians are well-trained special- ists and are kept up to date with the latest service information through technical bulletins, service tips, and in-dealership training pro- grams. They are completely qualified to work on NISSAN’s vehicles before they work on your vehicle, they have worked on it. You can be confident that your NISSAN deal- er’s service department performs the best job to meet the maintenance requirements on your vehicle — in a reliable and economic way.

than after

rather

GENERAL MAINTENANCE

During the normal day-to-day operation of the vehicle, general maintenance should be per- formed regularly as prescribed in this section. If you detect any unusual sounds, vibrations or smell, be sure to check for the cause or have your NISSAN dealer do it promptly. In addition, you should notify your NISSAN dealer if you think that repairs are required. When performing any checks or maintenance work, see “Maintenance precautions” in the “8. Do-it-yourself” section. EXTERIOR MAINTENANCE Additional information on the following items with * is found in the “8. Do-it- yourself” section. Outside the vehicle The maintenance items listed here should be performed from time to time, unless otherwise specified. Tires*: Check the pressure with a gauge periodically when at a service station, including the spare, and adjust to the specified pressure if neces- sary. Check carefully for damage, cuts or excessive wear.

Z 01.1.22/R50-D/V5 X

Wheel nuts*:

When checking the tires, make sure no nuts are missing, and check for any loose nuts. Tighten if necessary. Tire rotation*: Tires should be rotated every 7,500 miles (12,000 km) for 2WD vehicles and 3,750 miles (6,000 km) for 4WD vehicles. However, the timing for tire rotation may vary according to your driving habits and road surface condi- tions. Wheel alignment and balance: If the vehicle should pull to either side while driving on a straight and level road, or if you detect uneven or abnormal tire wear, there may be a need for wheel alignment. If the steering wheel or seat vibrates at normal highway speeds, wheel balancing may be needed. Windshield wiper blades*: Check for cracks or wear if they do not wipe properly. Doors and engine hood: Check that all doors and the engine hood, operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, rollers

and links if necessary. Make sure that the secondary latch keeps the hood from opening when the primary latch is released. When driving in areas using road salt or other corrosive materials, check lubrication fre- quently. Inside the vehicle Lights*: Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights are all operating properly and installed securely. Also check headlight aim. INTERIOR MAINTENANCE The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle, etc. Warning lights and chimes: Make sure that all warning lights and chimes are operating properly. Windshield wiper and washer*: Check that the wipers and washer operate properly and that the wipers do not streak.

Windshield defroster:

Check that the air comes out of the defroster outlets properly and in sufficient quantity when operating the heater or air conditioner. Steering wheel:

Check for changes in the steering conditions, such as excessive freeplay, hard steering or strange noises. Seats:

Check seat position controls such as seat adjusters, seatback recliner, etc. to ensure they operate smoothly and that all latches lock securely in every position. Check that the head restraints move up and down smoothly and that the locks (if so equipped) hold securely in all latched positions. Seat belts:

Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and retrac- tors) operate properly and smoothly, and are installed securely. Check the belt webbing for cuts, fraying, wear or damage. Accelerator pedal:

Check the pedal for smooth operation and make sure the pedal does not catch or require

Maintenance 9-3

Z 01.1.22/R50-D/V5 X

uneven effort. Keep the floor mats away from the pedal. Clutch pedal*: Make sure the pedal operates smoothly and check that it has the proper free travel. Brakes: Check that the brakes do not pull the vehicle to one side when applied. Brake pedal and booster*: Check the pedal for smooth operation and make sure it has the proper distance under it when depressed fully. Check the brake booster function. Be certain to keep floormats away from the pedal. Parking brake*: Check that the lever has the proper travel and confirm that your vehicle is held securely on a fairly steep hill with only the parking brake applied. Automatic transmission P position mechanism: On a fairly steep hill check that your vehicle is held securely with the selector lever in the P position without applying any brakes.

9-4 Maintenance

Under the hood and vehicle The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel. Windshield washer fluid*: Check that there is adequate fluid in the tank. Engine oil level*: Check the level after parking the vehicle on a level spot and turning off the engine. (Be sure to wait a few minutes to allow the oil to drain back into the sump.) Brake and clutch fluid levels*: Make sure that the brake and clutch fluid level is between the MAX and MIN lines on the reservoir. Power steering fluid level* and lines: Check the level when the fluid is cold and the engine is turned off. Check the lines for proper attachment, leaks, cracks, etc. Automatic transmission fluid level*: Check the level after putting the selector lever in P (Park) with the engine idling.

Engine coolant level*:

Check the coolant level when the engine is cold. Radiator and hoses:

Check the front of the radiator and clean off any dirt, insects, leaves, etc., that may have accumulated. Make sure the hoses have no cracks, deformation, rot or loose connections. Engine drive belts*:

Make sure that no belt is frayed, worn, cracked or oily. Battery*:

Check the fluid level in each cell. It should be between the MAX and MIN lines. Exhaust system: Make sure there are no loose supports, cracks or holes. If the sound of the exhaust seems unusual or there is a smell of exhaust fumes, immediately locate the trouble and correct it. See “Precautions when starting and driving” in the “5. Starting and driving” section for exhaust gas (carbon monoxide). Underbody: The underbody is frequently exposed to corro- sive substances such as those used on icy

Z 01.1.22/R50-D/V5 X

ing for long distances, such as police, taxi or door-to-door delivery use.

I Driving in dusty conditions. I Driving on rough, muddy, or salt spread

roads.

I Towing a trailer, using a camper or a

car-top carrier. SCHEDULE 2

Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown in Sched- ule 1 apply to your driving habits.roads or to control dust. It is very important to remove these substances, otherwise rust will lines and form on the floor pan, frame, fuel around the exhaust system. At the end of winter, the underbody should be thoroughly flushed with plain water, being careful to clean those areas where mud and dirt may accumu- late. For additional information, see “Cleaning exterior” in the “7. Appearance and care” sec- tion. Fluid leaks: Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has been parked for a while. Water dripping from the air conditioner after use is normal. If you should notice any leaks or if gasoline fumes are evident, check for the cause and have it cor- rected immediately.

PERIODIC MAINTENANCE SCHEDULES To ensure smooth, trouble-free, safe and eco- nomical driving, NISSAN provides two differ- ent maintenance schedules that may be used, depending upon the conditions in which you usually drive. These schedules contain both distance and time intervals, up to 60,000 miles (96,000 km)/48 months. For most people, the odometer reading will indicate when service is needed. However, if you drive very little, your vehicle should be serviced at the regular time intervals shown in the schedule. After 60,000 miles (96,000 km) or 48

months, continue periodic maintenance at the same mileage/time intervals. SCHEDULE 1

Follow Periodic Maintenance Schedule 1 if your driving habits frequently include one or more of the following driving conditions: I Repeated short trips of less than 5 miles(8 km).

I Repeated short trips of less than 10

miles (16 km) with outside temperatures remaining below freezing.I Operating in hot weather in stop-and-go

rush hour traffic.

I Extensive idling and/or low speed driv-

Maintenance 9-5

Z 01.1.22/R50-D/V5 X

only)

Maintenance for offroad driving Whenever you drive offroad through sand, mud or water as deep as the wheel hub, more frequent maintenance may be required of the following items: G Brake pads and discs G Brake lining and drums G Brake lines and hoses G Wheel bearing grease G Differential, transmission and transfer oil G Steering linkage G Propeller shafts and front drive shafts G Air cleaner filter G Clutch housing (See “Clutch housing drain” in the “8. Do-it-yourself” section for check- ing water entry.)

These items should be checked frequently to assure safe and proper operation of your ve- hicle.

9-6 Maintenance

Z 01.1.22/R50-D/V5 X

Schedule 1

Abbreviations: R = ReplaceMAINTENANCE OPERATION

I = Inspect. Correct or replace if necessary.

]: At the mileage intervals only

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Emission control system maintenance Drive belts Air cleaner filter EVAP vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter (Use Part No. 15208 31U00 or equivalent.) Spark plugs (PLATINUM-TIPPED type) Timing belt

15 18.75 22.5 26.25

(42) (24) 12

21(30) 15

(36) 18

Miles · 1,000

(km · 1,000) Months3.75

(6)7.5 11.25

(12) (18)See NOTE (1)

See NOTE (2)* See NOTE (3)

30 33.75 37.5 41.25

(66) (48) 24

33(54) 27

(60) 30

45 48.75 52.5 56.25

(90) (72) 36

45(78) 39

(84) 42

I* [R] I* I*

60

(96) 48I* [R] I* I*

R*

[R]

Replace every 105,000 miles (168,000 km)

NOTE:

(1) If operating mainly in dusty conditions, more frequent maintenance may be required. (2) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or

extremely high, the filters might become clogged. In such an event, replace them immediately.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months. H Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

Maintenance 9-7

Z 01.1.22/R50-D/V5 X

Schedule 1

Abbreviations: R = ReplaceMAINTENANCE OPERATION

I = Inspect. Correct or replace if necessary. L = Lubricate

]: At the mileage intervals only

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Miles · 1,000

(km · 1,000) Months3.75

(6)See NOTE (1)

Chassis and body maintenance Brake lines & cables Brake pads, rotors, drums & linings Automatic transmission & transfer fluid, manual transmission & differential gear oil (exc. LSD) Limited-slip differential (LSD) gear oil Steering gear, linkage & transfer gear, axle & suspension parts Drive shaft boots ( Propeller shaft Front wheel bearing grease (4x2) Front wheel bearing grease ( Exhaust system Supplemental air bag system and supple- mental side air bag systems (if so equipped) Automatic Speed Control Device (ASCD) vacuum hoses

See NOTE (2)

See NOTE (1)

See NOTE (3)

See NOTE (4)

7.5 11.25

(12) (18)15 18.75 22.5 26.25

(42) (24) 12

21(30) 15

(36) 18

30 33.75 37.5 41.25

(66) (48) 24

33(54) 27

(60) 30

45 48.75 52.5 56.25

(90) (72) 36

45(78) 39

(84) 42

60

(96) 48NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000 miles (48,000 km)

or 24 months except for LSD. Change LSD gear oil every 15,000 miles (24,000 km) or 12 months.

(2) The propeller shaft should be re-greased after being immersed in water. (3) If operating frequently in water, replace grease every 3,750 miles (6,000 km) or 3 months. (4) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the F.M.V.S.S. certification label.

9-8 Maintenance

Z 01.1.22/R50-D/V5 X

Schedule 2

Abbreviations: R = ReplaceMAINTENANCE OPERATION

I = Inspect. Correct or replace if necessary.

]: At the mileage intervals only

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Miles · 1,000

(km · 1,000) Months7.5

(12)15

(24) 1222.5

(36) 18Emission control system maintenance Drive belts Air cleaner filter EVAP vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter (Use Part No. 15208 31U00 or equivalent.) Spark plugs (PLATINUM-TIPPED type) Timing belt

See NOTE (1)* See NOTE (2)

30

(48) 24I* [R] I* I*

37.5

(60) 3045

(72) 3652.5

(84) 4260

(96) 48I* [R] I* I*

R* [R]

Replace every 105,000 miles (168,000 km)

NOTE:

(1) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or

extremely high, the filters might become clogged. In such an event, replace them immediately.

(2) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months. H Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

Maintenance 9-9

Z 01.1.22/R50-D/V5 X

Schedule 2

Abbreviations: R = ReplaceMAINTENANCE OPERATION

Perform at number of miles, kilometers or months, whichever comes first.

I = Inspect. Correct or replace if necessary. L = Lubricate

]: At the mileage intervals only

Miles · 1,000

(km · 1,000) Months7.5

(12)15

(24) 1222.5

(36) 1830

(48) 2437.5

(60) 3045

(72) 3652.5

(84) 4260

(96) 48MAINTENANCE INTERVAL

Chassis and body maintenance Brake lines & cables Brake pads, rotors, discs, drums & linings Automatic transmission & transfer fluid, manual transmission & dif- ferential gear oil (exc. LSD) Limited-slip differential (LSD) gear oil Steering gear, linkage & transfer gear, axle & suspension parts Drive shaft boots (

Propeller shaft Front wheel bearing grease (4x2) Front wheel bearing grease ( Exhaust system Supplemental air bag system and supplemental side air bag systems (if so equipped) Automatic Speed Control Device (ASCD) vacuum hoses

See NOTE (1)

See NOTE (2)

NOTE: