- Download PDF Manual

-

30’ 6” 204”

209” 28’ 3” 35’ 7” 226”

218” 30’ 8” 37’ 1” 242”

250” 33’ 6” 37’ 2” 274”

30½” x 64½” 30½” x 64½” 30½” x 64½” 30½” x 64½” 30½” x 64½” 29½” x 81” 29½” x 81”

29½” x 81”

29½” x 81”

29½” x 81”

40½” 42”

40½” 42”

40½” 42”

40½” 42”

40½” 42”

42” x 73¾”

42” x 73¾”

42” x 73¾”

42” x 73¾”

42” x 73¾”

112” 96” 111” 89½” 92” 18”

112” 96” 111” 89½” 92” 18”

112” 96” 111” 89½” 92” 18”

114” 96” 111” 89½” 92” 18”

114” 96” 111” 89½” 92” 18”

64

Krystal Enterprises

General Vehicle Dimensional Specifi cations-Body & Chassis by Model (cont)

Features Models

Seat Cushion Length Floor Height from Ground at Rear 1st Step from Ground Riser Height Step Height Movable Wall Depths(approx)- E-450

Movable Wall Depths(approx)- F-550

UVL Wheelchair Lift Door OpeningKK22

18” 31” 11¾” 6¾” 10¾” 36-40” N/A N/AKK24

18” 31” 11¾” 6¾” 10¾” 30-32” N/A N/AKK28

18” 31” 11¾” 6¾” 10¾” 28-36” N/A N/AKK30

18” 33” 12½” 9½” 12½” N/A 29-63”42”

KK33

18” 33” 12½” 9½” 12½” N/A 30-54”42”

Krystal Enterprises

6565

General Body Materials and Construction Measurements

Size of Steel Tubing used in Body Sidewall & Roof Structure Center line Spacing of Tubing used in Body Sidewall & Roof Structure Gauge of Steel Tubing used in Body Sidewall & Roof Structure Aluminum Sidewall Material One Piece Aluminum Roofi ng Material Size of Steel Tubing used in Main Floor Structure Center line Spacing of Tubing used in Floor Structure Gauge of Steel Tubing used in Floor Structure Thickness of Double Backed Insulated Fiberglass Batting Insulation Window Size

1” x 1”

32” 16

.063

.040

2” x 4” 32” max.12

2”32 x 40”

66

Krystal Enterprises

Air Conditioning Charging Chart

MODEL BY BTU’S E40 Bus 1999 with ACC A/C 68,000 BTU 86,000 BTU 40,000 BTU w/ FACTORY TIE IN F550 Bus 2000 with ACC skirt condenser 68,000 BTU 86,000 BTU 40,000 BTU w/ FACTORY TIE IN F550 ALL with ACC front condenser 68,00 BTU 40,000 BTU w/ FACTORY TIE IN E450 2000 with Carrier A/C 68,000 BTU 40,000 BTU w/ FACTORY TIE IN Roof Top Carrier A/C E450 w/ACC 2004-2005 Models 68,000 BTU 40,000 BTU w/ FACTORY TIE IN

VENTING

FREON CHARGE

4 vents 6 vents w/factory tie in

4 vents 6 vents w/factory tie in

5.50 lbs.** 6.0 lbs.** 11.0 lbs.**

5.50 lbs.** 6.00 lbs.** 11.50 lbs**

4 vents w/factory tie in

4.25 lbs.** 11.50 lbs.**

add on unit w/factory tie in Ducted

5.00 lbs.** 5.50 lbs.** 7.0 lbs.** per compressor

4 vents 2 vents

5.25 lbs**. 10.0 lbs.**

**NOTE: These fi gures may vary depending on atmospheric conditions

Krystal Enterprises

6767

Vehicle Manufacturers Identifi cation Label

E-450

14050

4600

LT225/75RX16E16X6.0

9450

LT225/RX16E16X6.0

80

80

6349

2086552

4286

DUAL

552

F-55019000

6000225/70R19.5 F 95

19.5X6.0

13500

225/70R19.5 F19.5X6.0

95

8618

2721655

6123

DUAL

655

LABEL EXPLANATION

K # - This is your permanent Krystal Vehicle Identifi cation number. VIN # - This is your DMV Vehicle Identifi cation Number. GVWR -This is the gross rated weight capacity of your vehicle GAWR Front -This is the rated weight capacity of the front axle GAWR Rear -This is the rated weight capacity of the rear axle Date Incomplete Vehicle Manufactured - This is the date the chassis was produced by FORD Date Of Manufacture by Krystal - This is the date the vehicle was completed by KRYSTAL. Paint Code - This is the master number for the paint specifi cation and color used on your vehicle. Tires, Rims - This indicates the required tire and rim sizes, and air capacities for your spe- cifi c vehicle.

68

Krystal Enterprises

Ridewell Air Suspension Chart

Note: All ½” bolt/nut assemblies join- ing the Ridewell hangers to the FORD frame must be torqued to 120 ft. lbs. (dry) or 90 ft. lbs (lubricated)

If any bolts are found to be loose or damaged, replace with ½”-20 SAE GRADE 8 hardware.

This sticker is located on your chassis suspension.

RIDEWELL SUSPENSION TORQUE CHART

BOLT SIZE

LUBRICATED THREADS

1 ½” 1 ¼” 1 ⅛” 1” 1” ⅞” ¾” ¾” ⅝” *¾” *½”

HANGER 1,100 FT -LB (1490 N-m) HANGER 750 FT -LB (1020 N-m) 500 FT -LB (680 N-m) GRADE 5 360 FT -LB (490 N-m) GRADE 8 460 FT -LB (625 N-m) 350 FT -LB (475 N-m) GRADE 5 160 FT -LB (220 N-m) GRADE 8 190 FT -LB (260 N-m) 100 FT -LB (135 N-m) 50 FT -LB (70 N-m) 25 FT -LB (35 N-m)

*AIR SPRING CONNECTION ONLY

After suspension has been in operation for approxi- mately 6,000 miles (10,000 KLMS), all fasteners must be re-tightened to specifi ed torque. Repeat every 15,000 miles (25,000 KLMS)

DO NOT OVER TORQUE!

Krystal Enterprises

6969

PREVENTATIVE MAINTENANCE SCHEDULE

The following Maintenance Schedule is provided as a convenient reference for the specifi ed systems and components, which require periodic service.

These schedules are not intended to be a complete list of all possible services to be performed on a regular basis, nor is it suggested that more frequent services not be considered.

Because of the different types of operations coaches are subjected to, the severity of service must be considered when establishing maintenance intervals. Therefore, any such intervals given in the following schedule must be adjusted according to the particular type of operation in which your particular vehicle will be used. The intervals given are Krystal Enterprises, Inc. recommendations and should be considered as maximum intervals. It should be noted that maintenance inspection and service operations of shorter intervals are always preferable to longer intervals.

70

Krystal Enterprises

PREVENTIVE MAINTENANCE SCHEDULE

THE FOLLOWING PAGES SPECIFY THE MINIMUM REQUIREMENTS THAT ARE NECESSARY TO PROPERLY MAINTAIN YOUR VEHICLES SYSTEMS AND COMPONENTS

CHECK EVERY DAY: ► all items on Pre-Trip inspection (see page 8) ► side passenger door emergency release valve operation ► side passenger entry door, operation, locking, damage, and adjustment ► emergency roof hatch ► emergency egress window latches ► function of all interior and exterior lights ► check all seat belts for proper operation ► tire pressure, E-450 80 psi, F-550 95 psi ► fl uid leaks from, transmission, engine, power steering, engine coolant, gear oil, fuel

CHECK EVERY MONTH: ► windshield washer fl uid level ► and drain fuel fi lter/water separator ► door linkage and pivot arm lubrication ► and lube rear Kwikee step, (if equipped) ► and clean air intake fi lter for A/C system ► tires for wear, and tread depth

Krystal Enterprises

7171

PREVENTIVE MAINTENANCE SCHEDULE

AT 5,000 MILES/600 HOURS DO THE FOLLOWING: ► change engine oil and replace fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► inspect torque specifi cations on Ridewell Suspension System ► lube door seals with silicon spray, check for proper sealing ► lube Vapor door rotary drive mechanism ► check the torque of all door hardware on Vapor door systems

AT 10,000 MILES/1200 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► clean battery terminals ► check the torque of all door hardware on Vapor door systems

AT 15,000 MILES/1800 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires

72

Krystal Enterprises

PREVENTIVE MAINTENANCE SCHEDULE

► inspect engine air fi lter ► replace engine and frame mounted fuel fi lters ► inspect steering linkage, suspension, ball joints, driveshafts, and driveshaft guards ► inspect engine cooling system and hoses ► inspect brake system ► inspect exhaust system and heat shields ► inspect automatic transmission fl uid and external fi lter element ► check wheels for end play and noise ► inspect and lubricate 4 x 2 ball joints (E-450 only) ► inspect and lubricate steering idler arms ► replace cabin air fi lter, if equipped ► inspect half shaft boots, if equipped ► re-inspect torque settings on Ridewell Suspension System ► clean air compressor intake fi lter ► lube door seals with silicon spray, check for proper sealing ► check air system for leaks, and electrical connections ► lube Vapor door rotary drive mechanism ► check the torque of all door hardware on Vapor door systems

AT 20,000 MILES/2400 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth

Krystal Enterprises

7373

PREVENTIVE MAINTENANCE SCHEDULE

► rotate tires ► inspect engine air fi lter ► clean battery terminals ► check the torque of all door hardware on Vapor door systems

AT 25,000 MILES/3000 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► check the torque of all door hardware on Vapor door systems ► clean condenser coils

AT 30,000 MILES/3600 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► replace engine air fi lter ► replace engine and frame mounted fuel fi lters ► inspect steering linkage, suspension, ball joints, driveshafts, and driveshaft guards ► inspect engine cooling system and hoses

74

Krystal Enterprises

PREVENTIVE MAINTENANCE SCHEDULE

► inspect brake system ► inspect exhaust system and heat shields ► change automatic transmission fl uid and external fi lter element ► check wheels for end play and noise ► inspect and lubricate 4 x 2 ball joints (E-450 only) ► inspect and lubricate steering idler arms ► replace cabin air fi lter, if equipped ► inspect half shaft boots, if equipped ► clean air compressor intake fi lter ► clean battery terminals ► lube door seals with silicon spray, check for proper sealing ► re-inspect torque settings on Ridewell Suspension System ► check air system for leaks, and electrical connections ► lube Vapor door rotary drive mechanism ► check the torque of all door hardware on Vapor door systems ► inspect drive belts and replace if necessary

AT 35,000 MILES/4200 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires

Krystal Enterprises

7575

PREVENTIVE MAINTENANCE SCHEDULE

► inspect engine air fi lter ► check the torque of all door hardware on Vapor door systems

AT 40,000 MILES/4800 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► clean battery terminals ► check the torque of all door hardware on Vapor door systems

AT 45,000 MILES/5400 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► replace engine and frame mounted fuel fi lters ► inspect steering linkage, suspension, ball joints, driveshafts, and driveshaft guards ► inspect engine cooling system and hoses ► inspect brake system ► inspect exhaust system and heat shields ► check wheels for end play and noise

76

Krystal Enterprises

PREVENTIVE MAINTENANCE SCHEDULE

► inspect and lubricate 4 x 2 ball joints (E-450 only) ► inspect and lubricate steering idler arms ► replace cabin air fi lter, if equipped ► inspect half shaft boots, if equipped ► clean air compressor intake fi lter ► lube door seals with silicon spray, check for proper sealing ► re-inspect torque settings on Ridewell Suspension System ► check air system for leaks, and electrical connections ► lube Vapor door rotary drive mechanism ► check the torque of all door hardware on Vapor door systems

AT 50,000 MILES/6000 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► clean battery terminals ► check the torque of all door hardware on Vapor door systems ► clean condenser coils

AT 55,000 MILES/6600 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter

Krystal Enterprises

7777

PREVENTIVE MAINTENANCE SCHEDULE

► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► check the torque of all door hardware on Vapor door systems

AT 60,000 MILES/7200 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► replace engine and frame mounted fuel fi lters ► inspect steering linkage, suspension, ball joints, driveshafts, and driveshaft guards ► inspect engine cooling system and hoses ► inspect brake system ► inspect exhaust system and heat shields ► change automatic transmission fl uid and external fi lter element ► check wheels for end play and noise ► lubricate 4 x 4 hub needle bearings ► lubricate 4 x 2 wheel bearings ► replace wheel bearing grease seal ► inspect and lubricate 4 x 2 ball joints (E-450 only)

78

Krystal Enterprises

PREVENTIVE MAINTENANCE SCHEDULE

► inspect and lubricate steering idler arms ► replace cabin air fi lter, if equipped ► inspect half shaft boots, if equipped ► clean air compressor intake fi lter ► clean battery terminals ► lube door seals with silicon spray, check for proper sealing ► re-inspect torque settings on Ridewell Suspension System ► check air system for leaks, and electrical connections ► lube Vapor door rotary drive mechanism ► check the torque of all door hardware on Vapor door systems ► inspect drive belts and replace if necessary

AT 65,000 MILES/7800 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► check the torque of all door hardware on Vapor door systems

AT 70,000 MILES/8400 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter

Krystal Enterprises

7979

PREVENTIVE MAINTENANCE SCHEDULE

► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► clean battery terminals ► check the torque of all door hardware on Vapor door systems

AT 75,000 MILES/9000 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► replace engine and frame mounted fuel fi lters ► inspect steering linkage, suspension, ball joints, driveshafts, and driveshaft guards ► inspect engine cooling system and hoses ► inspect brake system ► inspect exhaust system and heat shields ► check wheels for end play and noise ► inspect and lubricate 4 x 2 ball joints (E-450 only) ► inspect and lubricate steering idler arms ► replace cabin air fi lter, if equipped ► inspect half shaft boots, if equipped clean air compressor intake fi lter

80

Krystal Enterprises

PREVENTIVE MAINTENANCE SCHEDULE

► lube door seals with silicon spray, check for proper sealing ► re-inspect torque settings on Ridewell Suspension System ► lube Vapor door rotary drive mechanism ► check the torque of all door hardware on Vapor door systems ► clean condenser coils

AT 80,000 MILES/9600 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► clean battery terminals ► check air system for leaks, and electrical connections ► check the torque of all door hardware on Vapor door systems

AT 85,000 MILES/10200 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► check the torque of all door hardware on Vapor door systems

Krystal Enterprises

8181

PREVENTIVE MAINTENANCE SCHEDULE

AT 90,000 MILES/10800 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► replace engine and frame mounted fuel fi lters ► inspect steering linkage, suspension, ball joints, driveshafts, and driveshaft guards ► inspect engine cooling system and hoses ► inspect brake system ► inspect exhaust system and heat shields ► check wheels for end play and noise ► inspect and lubricate 4 x 2 ball joints (E-450 only) ► inspect and lubricate steering idler arms ► replace cabin air fi lter, if equipped ► inspect half shaft boots, if equipped clean air compressor intake fi lter ► clean battery terminals ► lube door seals with silicon spray, check for proper sealing ► re-inspect torque settings on Ridewell Suspension System ► check air system for leaks, and electrical connections ► lube Vapor door rotary drive mechanism ► check the torque of all door hardware on Vapor door systems

82

Krystal Enterprises

PREVENTIVE MAINTENANCE SCHEDULE

► inspect drive belts and replace if necessary

AT 95,000 MILES/11400 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► check the torque of all door hardware on Vapor door systems

AT100,000 MILES/12000 HOURS DO THE FOLLOWING: ► change engine oil and replace oil fi lter ► inspect tires for wear and inspect tread depth ► rotate tires ► inspect engine air fi lter ► clean condenser coils ► clean battery terminals ► check the torque of all door hardware on Vapor door systems

Krystal Enterprises

8383

SUPPLEMENTARY PREVENTIVE MAINTENANCE INFORMATION

In addition to the required Preventative Maintenance information included in the previous schedule, the following specifi c exceptions should be noted.

Yellow Coolant: Must be changed every 5 years or 100,000 miles (whichever comes fi rst), then after initial change, every 3 years or 50,000 miles.

Rear Axle Lubricant: Must be changed every 50,000 miles

Transfer Case Fluid: Must be replaced every 60,000 miles

Change Rear Wheel Drive Axle Fluid: On Dana axles using synthetic fl uid, fl uid must be changed every 150,000 miles

Check your FORD Owner’s Guide Supplement, for special operating condition mainte- nance requirements, that may be applicable due to your specifi c vehicle operating profi le.

84

Krystal Enterprises

User Notes - Preventive Maintenance

Additional User Notes

Additional User Notes

Krystal Enterprises

8585

Basic Troubleshooting Guide

The following section details basic troubleshooting techniques that will help you to understand and determine the best course of action regarding some commonly encountered problems.

PROBLEM

VIBRATION: Noises or Vibration at high speeds only, or in a certain range of speeds:

POSSIBLE SOLUTIONS

A certain range of speeds indicates a damaged or otherwise out-of- balance drive line, Contact the Service Dept. Only SELECT drive line shops that are qualifi ed to properly balance the multiple drive line ex- tensions used in your bus. The Krystal Service Dept. can recommend one near you.

REAR A/C BLOWER INOPERATIVE Check to make sure the FORD front A/C unit is on. If the rear A/C is

MOVING CARGO PARTITION TO ADD ADDITIONAL SEATING Caution: Do Not Exceed Weight Distribution/Payload Limitations EXTERIOR LIGHTING

SLIDER WINDOWS HARD TO OPEN AND CLOSED

still not working, call the Krystal Service Dept. Remove seats in front of the Partition Wall and loosen all four bolts securing the wall. Then go behind the wall and remove the channel nut on the fl oor, this will allow the wall to be move back and then additional seating can be installed. Note: torque Seat Bolts to 35 ft. lbs. E-450: One or all exterior clearance lights inoperative, please refer to the FORD wiring schematic in the Krystal Electrical Schematic Manual F-550: Exterior running lights work off of the Krystal relay board. If any of the windows start to stick during opening or closing, simply spray both side tracks with silicone spray and work the windows a few times to lubricate the tracks. This should be done approximately every three months.

86

Krystal Enterprises

Basic Troubleshooting Guide

PROBLEM

POSSIBLE SOLUTIONS

PAGING SYSTEM INOPERATIVE

NO TELEVISION RECEPTION

REAR VCP & TV INOPERATIVE

EXTERIOR SEALANTS CRACKING OR LIFTING

Check the 5 amp fuse on the circuit board above the driver. Wiring schematics and instructions for the paging system are located in this manual on page 23. If the TV has power, but you cannot pickup any stations, make sure VCP mode button on the P.A. System is engaged and the VCP power button is engaged. Check to make sure all connections on the back of both units are tight. Check the fuse located at the front face of the TV, and on the backside of the VCP. If the exterior seams of the bus ever crack or start lifting, simply clean the area with rubbing alcohol or mineral spirits completely. After this has been done you can remove the old silicone by using a sharp knife or razor cutter. Clean the area again with the above cleaners and apply a thin bead of white exterior silicone and smooth the bead with your fi nger for a smooth appearance.

REAR ELECTRIC STEP INOPERATIVE Check to make sure the step switch is turned on. This switch is located

inside the cargo area on the right hand sidewall. If this will not power up the step, call the Krystal Service Dept. The rear step should be lubricated every 30 days to ensure proper operation of the step.

REAR STEREO/CD INOPERATIVE Check to make sure all connections are tight. Also remove the stereo

and check the fuse located on the backside of the stereo.

Krystal Enterprises

8787

Basic Troubleshooting Guide

PROBLEM

CANNOT REMOVE WATER FROM LAVATORY

POSSIBLE SOLUTIONS

Make sure fresh water tank has water in it and the water pump switch is in the on position. NOTE: Always be sure to turn the water pump switch off when not in use. Failure to do so could cause a steady drain on the auxiliary battery or could cause damage to the water pump. The fresh water fi ll is located under the bus at the rear of the vehicle.

PASSENGER LIGHTS INOPERATIVE Check to make sure the switch on the overhead control panel is turned

BACK-UP ALARM INOPERATIVE

on. NOTE: There is a 5 minute light timer for the interior lights which will automatically turn them off when the door is open. The interior light switch needs to be turned on for at least 10 seconds to reset the timer. Check to make sure reverse lights are coming on, if not, check the fuse located in the FORD fuse panels.

88

Krystal Enterprises

Troubleshooting Notes

PROBLEM

POSSIBLE SOLUTIONS

Krystal Enterprises

8989

E-450 Circuit Board Assembly

Circuit Board located in compartment above driver

See fuse & relay legend on next page

90

Krystal Enterprises

E-450 Circuit Board - Electrical Diagrams

Low Side Switching Controller

High Side Switching Controller

Module 1

30A 25A 20A 30A

Module 2

Module 3

Relay Fuses

Power Solenoid

20A 15A Module 4

Relay Fuses

Relay Module Legend (all amperage are maximum) Module 1 (from left to right) 1. Door Switch 10A 2. Spare 15A 3. Spare 10A 4. Interior Lights 15A 5. Interior Lights 15A Module 2 (from left to right) 1. Heat Valve 10A 2. Rear A/C Low 15A 3. A/C Compressor 10A 4. Spare 15A 5. Spare 15A Module 3 (from left to right) 1. Front A/C High 30A 2. Front A/C Low 25A 3. Front Condenser 20A 4. Rear A/C High 30A Module 4 (from left to right) 1. Rear Condenser 20A 2. Front A/C Mode 15A

Battery & Ignition Fuse Legend

Krystal Enterprises

9191

E-450 Shuttle Bus- Wiring Diagram

92

Krystal Enterprises Krystal Enterprises

Ref Drwg 300-042

E-450 Shuttle Bus - Drivers Side Wiring Diagram

Rear Door Ajar (warning light)

Charge Solenoid (pass through leed)

See Detail “D” (harness confi guration In rear of bus)

Left Turn Light (route along fl oor on driver side)

Condenser Fans

3rd Brake Light (located on left rear) (used only upon customer request)

A/C Tie In (pass through harness to factory plug)

Reference Table 1. Running Light 2. Running Light 3. Running Light 4. Side Marker Light 5. Running Light 6. Left Rear Cabin Speaker 7. Microswitch

8. Rear A/C 9. Luggage Compart- ment Light 10. Step Switch 11. Right Rear Cabin Speaker 12. Running Light 13. Running Light Ref Drwg 300-042

Krystal Enterprises

9393

E-450 Shuttle Bus - Rear Wiring Diagram

DETAIL “D” Rear Harness Confi guration

Right Tail Lights

Power Step

License Plate Light

Running Light

Left Tail Light

Back-up Alarm

Ground Wires

Trailer Plug Connection (attach harness to factory plug routed along chassis)

Ref Drwg 300-042

94

Krystal Enterprises

THIS PAGE IS INTENTIONALLY BLANK

Krystal Enterprises

9595

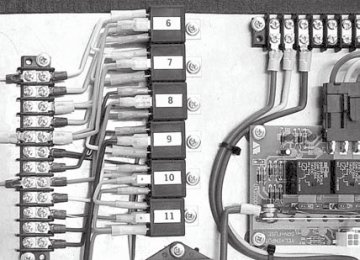

F-550 Circuit Board Assembly Ver. 1

10

11

IRD

IRD

IRD

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

F-550 circuit board located above driver F-550 circuit board located above driver

Krystal Enterprises

96

F-550 Circuit Board Ver 1 - Electrical Diagram

Relays

Circuit Breakers

Front A/C Board

Krystal Enterprises

9797

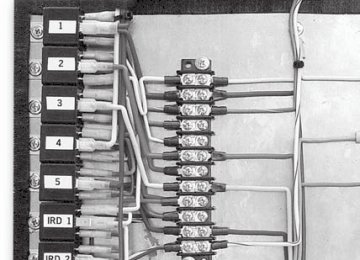

F-550 Circuit Board Assembly Ver. 2

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

F-550 circuit board located above driver

Krystal Enterprises

98

F-550 Circuit Board Ver 2 - Electrical Diagram

Relays

Circuit Breakers

Front A/C Board

Rear A/C Board

Krystal Enterprises

9999

E-450 & F-550 Modular Circuit Board Assembly Ver. 3

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

100

Krystal Enterprises

E-450 & F-550 Modular Circuit Board Assembly Ver. 3 Legend

Low Side Modular Switching Unit

Interior Lights - 15 amp fuse-max Interior Lights - 15 amp fuse-max

2 Door - 10 amp fuse-max 3 Heat Valve - 15 amp fuse-max 4 Spare - 10 amp fuse-max 7 Heater Fan Relay-HIGH 8 Heater Fan Relay-LOW 9 High Idle Relay 10 Door Interlock Relay 11 Rear Condenser Relay 12 Reading Lights- 15 amp fuse-max 13 Reading Lights- 15 amp fuse-max 14 Clearance Lights- 10 amp fuse-max 15 Clearance Lights- 10 amp fuse-max 16 Spare- 15 amp fuse-max 17 High Side Modular Switching Unit

18 Power Solenoid 19 Step- 25 amp fuse-max, 12 ga Red #260

20 Luggage Light- 10 amp fuse-max, 16 ga Red #320

21 To High Side Module- 3 amp fuse-max, 16 ga Red 22 To Panel LED- 3 amp fuse-max, 18 ga Red/Wht 23 Battery Fuse Block Module 24 Rear Step IGN-15 amp fuse-max, 16 ga Purple #280

25 Air Comp. IGN-15 amp fuse-max, 16 ga Purple #280

26 Heater Fan-HIGH, 15 amp fuse-max, 14 ga Red/Blk 27 Heater Fan-LOW, 10 amp fuse-max, 14 ga Yell/Red 28 Heater Relay Coil, 3 amp fuse-max, 18 ga Red 29 Ignition Fuse Block Module 30 High Idle- 7.5 amp fuse-max, 14 ga Org/Blk 31 Television- 10 amp fuse-max, 14 ga Org/Yell 32 Switch Panel IGN- 15 amp fuse-max, 16 ga Purple #280

33 Air Compressor Circuit Breaker 34 Five (5) Minute Light TimerSee detailed diagrams of items 1 & 17

( Low/High Side Switching Modules) on pages 102-103

Krystal Enterprises

101101

E-450 & F-550 LOW SIDE RELAY SWITCHING MODULE Ver. 3

SPARE FUSES

5 RELAY MODULE

Low Side Switching

INTELLITEC FUSE BLOCK

6 Pin Connector

5 Pin Connector

102

Krystal Enterprises

PIN

6 P I N C O N N E C T O R

Door Switch- 18 Ga Wht (to 5 min timer 18 ga Wht/Blk)

To Door- 16 Ga Blu/Wht #420C

Heat Valve Trigger- 18 Ga Grn/Blk

Heat Valve- 14 Ga Grn #400

Coil #3- Not Used

Output #3- Not Used

PIN

5 P I N C O N N E C T O R

To Interior Light Switch- 18 Ga Yel (to 5 min. timer+side- 18 Ga Yel/Blk with Diode)

Interior Lights- 14 Ga Yel- #350#B

To Interior Light Switch- 18 Ga Yel

Interior LIghts- 14 Ga Yel- - #350#A

Coil Common- 16 Ga Red- Battery- To Pin #1 On Fuse Block

To Battery- 8 Ga Red

E-450 & F-550 HIGH SIDE RELAY SWITCHING MODULE Ver. 3

SPARE FUSES

5 RELAY MODULE

High Side Switching

INTELLITEC FUSE BLOCK

6 Pin Connector

5 Pin Connector

PIN

6 P I N C O N N E C T O R

From Reading Light- 18 Ga Wht/Pupl

To Reading Lights #D- 16 Ga Org #700

Jumper from Pin#1- 18 Ga Wht/Pupl

To Reading Lights #E- 14 Ga Org #700

Clearance Lights #F- 16 Ga Brn/Wht #230

Clearance Lights #G- 14 ga Brn #230

PIN

5 P I N C O N N E C T O R

Clearance Lights-Jumper-16 Ga Brn/Wht #230

Clearance Lights #H- 14 Ga Brn #230

Not Used

Not Used

Coil Common- 16 Ga Wht

To Battery- 8 Ga Red

Krystal Enterprises

103103

E-450 & F-550 Front & Rear A/C Module

As used on 2004 & later models

ITEM NO

DESCRIPTION

COMMENT

7.5 amp Compressor Fuse

30 amp Condensor Fuse

35 amp High Side Fuse

20 amp Low Side Fuse

Compressor Relay

Condenser Relay

High Side Relay

Low Side Relay

These modules are used to control all A/C functions for the front and rear A/C units. Each A/C unit requires one (1) module each. These modules are mounted in the header above the driver, behind the driver’s control panel.

104

Krystal Enterprises

Front/Rear A/C Module Wiring Diagram

REF: RELAYS

REF: FUSES

Detail of A/C Module wiring as shown in photos on pg. 104

Krystal Enterprises

105105

E-450 & F-550 RELAY BUSS VER D

HEATER FAN HIGH

HEATER FAN LOW

HIGH IDLE

SPARE

REAR CONDENSER

85

30

87a 87a 87

86

85

30

87a 87a 87

86

85

8530

87a 87a 87

86

85

30

87a 87

86

85

8530

87a 87a 87

86

106