- 2004 Dodge Sprinter Owners Manuals

- Dodge Sprinter Owners Manuals

- 2007 Dodge Sprinter Owners Manuals

- Dodge Sprinter Owners Manuals

- 2006 Dodge Sprinter Owners Manuals

- Dodge Sprinter Owners Manuals

- 2008 Dodge Sprinter Owners Manuals

- Dodge Sprinter Owners Manuals

- 2005 Dodge Sprinter Owners Manuals

- Dodge Sprinter Owners Manuals

- Download PDF Manual

-

moistened).

If the engine is already at its regular operating temperature: Add coolant until the coolant level is about 0.6 inch (1.5 cm) above the base area which is visible through the filler opening.

(cid:127) Replace and tighten the pressure cap on coolant

reservoir.

If a large quantity of coolant has been lost, or if smaller amounts are lost at regular intervals, have the engine cooling system examined by an authorized Sprinter Dealer. For coolant composition and water quality, contact your Sprinter Dealer.

WINTER OPERATION Have your vehicle winterized by an authorized Sprinter Dealer before the onset of winter. (cid:127) Have the engine oil changed, if the engine oil filled

is not approved for winter use.

(cid:127) Coolant: antifreeze/anti-corrosion concentration in

the coolant checked.

(cid:127) Windshield washer system and headlamp cleaning system (optional): add windshield washer fluid "winter wash" to the water, depending on ambient temperatures.

(cid:127) Battery:

the battery will

capacity as temperatures drop. Only a well-charged battery will ensure reliable engine starting even at low outside temperatures.

lose

(cid:127) Tires: fit M+S radial tires with a minimum tread depth of approximately 1/6 in (4 mm) on all wheels for the winter season.

MAINTAINING YOUR VEHICLE 265

BATTERIES

WARNING!

Failure to follow these instructions can result in severe personal injuries and death. Never lean over batteries while connecting, you might get injured, if the battery explodes. Battery fluid contains sulfuric acid. Do not allow this fluid to come in contact with eyes, skin or clothing. In case it does, immediately flush affected area with water and seek medical help if necessary. A battery will also produce hydrogen gas, which is flammable and explosive. Keep flames or sparks away from battery, avoid improper connection of jumper cables, smoking etc.

Use only impact-resistant batteries with a central gas release cover to prevent corrosion damage and to prevent occupants from caustic burns in the event of an accident.

The standard battery compartment.

is

located

in the engine

266 MAINTAINING YOUR VEHICLE

The auxiliary battery is located underneath the front passenger seat (optional equipment). The battery will not achieve its maximum service life unless it is kept adequately charged at all times. If the vehicle is used primarily for short distances, or left parked for lengthy periods, have the battery charge checked more frequently. Disconnecting the Battery

CAUTION!

Do not loosen or remove the battery terminal clamps while the engine is running or the key is in the ignition lock as this could damage electrical or electronic equipment beyond repair. All electrical consumers must be switched off. Do not place any metal objects on the battery. Doing so may cause a short-circuit. Loosen and remove the negative terminal clamp first, then the positive terminal. Afterwards disconnect vent tube from the fitting.

Reconnecting the Battery

Vent tube (1) Fitting (2) All electrical consumers must be switched off. First connect and tighten the positive terminal clamp, then the negative terminal. Make sure that the terminal clamps are not switched. NOTE: If batteries have to be replaced, only use batteries with a central vent cap as this will prevent corrosion damage. Connect the battery vent tube (1) to the fitting (2).

Charging the Battery Disconnect the battery before charging it with a battery charger. Comply with the operating instructions for the battery charger. To ensure that the battery is disposed of in an environmentally responsible manner, it should only be replaced by an authorized Sprinter Dealer. Batteries contain material environment with improper disposal. Large 12 volt storage batteries contain lead. Recycling of batteries is the preferred method of disposal. Many states require sellers of batteries to accept old batteries for recycling.

that can harm

the

MAINTAINING YOUR VEHICLE 267

WARNING!

(cid:127) Use only refrigerants and compressor lubricants approved by the manufacturer for your air conditioning system. Some unapproved refrigerants are flammable and can explode, injuring you. Other unapproved refrigerants or lubricants can cause the system to fail, requiring costly repairs. Refer to Section 3 of the Warranty Information Book for additional warranty information.

(cid:127) The air conditioning system contains refrigerant under high pressure. To avoid risk of personal injury or damage to the system, adding refrigerant or any repair requiring lines to be disconnected should be done by an experienced repairman.

268 MAINTAINING YOUR VEHICLE

Refrigerant Recovery and Recycling R-134a Air Conditioning Refrigerant hydrofluorocarbon (HFC) that is endorsed by the Environmental Protection Agency and is an ozone- saving product. However, the manufacturer recommends service be performed by dealers or other service facilities using recovery and recycling equipment.

that air conditioning

is

REPLACING WIPER BLADES

1. Fold over the wiper arm (2) and place the wiper

blade crosswise.

2. Press the retaining spring (1) and push the wiper

blade out of the end of the wiper arm (2).

3. Remove the wiper blade.

MAINTAINING YOUR VEHICLE 269

Appearance Care and Corrosion Protection

WARNING!

Many cleaning products can be hazardous. Some are poisonous, others are flammable. Always keep cleaning products sealed and out of the reach of children. Always follow the instructions on the particular container. Always open your ve- hicle’s doors or windows when cleaning the in- side. Never use fluids or solvents that are not designed for cleaning your vehicle. Do not use fuel as a cleaning agent. Fuel is flammable and constitutes a health hazard.

In operation, your vehicle is subjected to varying external influences which, if gone unchecked, can attack the paintwork as well as the underbody and cause lasting damage. Such damage is caused not only by extreme and varying climatic conditions, but also by air pollution, road salt, tar, gravel and stone chipping. Grease and oil, fuel, coolant, brake fluid, bird droppings, insects,

4.

Insert the end of the wiper arm (2) into the larger cutout (3) of the wiper blade.

5. Push the wiper blade into the end of the wiper

arm (2) until the retaining spring (1) engages.

270 MAINTAINING YOUR VEHICLE

tree resins etc. should be removed immediately to avoid paint damage. Frequent washing reduces and/ or eliminates the aggressiveness and potency of the above adverse influences. More frequent washings are necessary to deal with unfavorable conditions; for example operation near the ocean, in industrial areas (smoke, exhaust emissions), or during the winter months. You should check your vehicle from time to time for stone chipping or other damage. Any damage should be repaired as soon as possible to prevent the start of corrosion. In doing so, do not neglect the underside of the vehicle. A prerequisite for a thorough check is a washing of the underbody inspection. Damaged areas need to be undercoated again. Your vehicle has been treated at the factory with a wax- base rustproofing in the body cavities which will last for the lifetime of the vehicle. Post-production treatment is neither necessary nor recommended by DaimlerChrysler Corporation.

followed by a

thorough

Because of the possibility of incompatibility between materials used in the production process and others applied later.

WARNING!

Never use openings in the bodywork as steps. You could otherwise damage the vehicle and it could lead to an accident.

CAUTION!

Do not use abrasive or strong cleaning materials such as steel wool or scouring powder, which will scratch metal and painted surfaces.

Scratches, corrosive deposits, corrosion or damage due to negligent or incorrect care cannot always be removed or repaired with car-care products. In such cases it is best to seek aid by your authorized Sprinter Dealer. The following topics deal with the cleaning and care of your vehicle and give important "how-to" information as well as references to car-care products.

Power Washer When using a power washer for cleaning the vehicle always observe manufacturers’ operating instructions.

Automatic Car Wash If the vehicle is very dirty, prewash it before you drive into the car wash.

MAINTAINING YOUR VEHICLE 271

CAUTION!

Never use a round nozzle to power wash tires. The intense jet of water can result in damage to the tire. Always replace a damaged tire. Always keep the jet of water moving across the surface. To avoid damaging the vehicle, do not aim the water jet directly at electrical components, end of electrical lines, electrical connectors, intake or ventilation openings, brake hoses, door joints, seals, other rubber parts.

WARNING!

Smears impair visibility, which is impaired fur- ther by unfavourable conditions (e.g. fog, dark- ness, driving snow). If a wax preservative is sprayed on after washing the vehicle, wipe off the wax from the windshield and the wiper blade rubbers. This will prevent smears forming on the windshield.

Fold in the exterior mirrors before washing the vehicle in an automatic car wash and make sure that the windshield wiper switch is in position 0. The exterior mirrors and windshield wipers could otherwise be damaged. Make sure that mirrors are fully folded out after leaving the automatic car wash.

272 MAINTAINING YOUR VEHICLE

to

tar

remover

remove. A

Tar Stains Quickly remove tar stains before they dry and become more difficult is recommended. Paintwork, Painted Body Components Paint care should be applied when water drops on the paint surface do not "bead up", normally every 3 to 5 months, depending on climate and washing detergent used. Paint cleaner should be applied if paint surface shows signs of dirt embedding (i.e. loss of gloss). Do not apply any of these products or wax if your vehicle is parked in the sun or if the hood is still hot. Use the appropriate paint stick for quick and provisional repairs of minor paint damage (i.e., chips from stones, vehicle doors etc.). Engine Cleaning Prior to cleaning the engine compartment, make sure to protect electrical components and connectors from the intrusion of water and cleaning agents.

Corrosion protection, such as anticorrosion wax should be applied to the engine compartment after every engine cleaning. Before applying, all control linkage bushings and joints should be lubricated. The poly-V-belt and all pulleys should be protected from any wax. Vehicle Washing Do not use hot water or wash your vehicle in direct sunlight. Use only a mild car wash detergent. Thoroughly spray the vehicle with a diffused jet of water. Direct only a very weak spray towards the ventilation intake. Use plenty of water and rinse the sponge and chamois frequently. Rinse with clear water and thoroughly wipe dry with a chamois. Do not allow cleaning agents to dry on the finish. Due to the width of the vehicle, prior to running the vehicle through an automatic car wash, fold back the outside mirrors from getting damaged. In the winter, thoroughly remove all traces of road salt as soon as possible.

to prevent

them

When washing the underbody, do not forget to clean the inner sides of the wheels.

WARNING!

Dirty or iced-up steps and entrances create a risk of slipping or falling. Keep steps, entrances and footwear free from dirt (e.g. mud, clay, snow and ice).

Ornamental Moldings For regular cleaning and care of very dirty chrome- plated parts, use a chrome cleaner. Headlamps, Taillamps, Identification Lamps, Turn Signal Lenses Use a mild car wash detergent with plenty of water. To prevent scratches, never apply strong force and use only a soft, non-scratchy cloth when cleaning the lenses. Do not attempt to wipe dirty lenses with a dry cloth or sponge.

MAINTAINING YOUR VEHICLE 273

N54.65-2046-20

Reversing Aid Sensors Use a mild car wash detergent with plenty of water. To prevent scratches, never apply strong force and use only a soft, non-scratchy cloth when cleaning the sensors. Do not attempt to wipe dirty sensors with dry, coarse or hard cloths and do not scrub. You will otherwise scratch or damage the sensors. If you clean the sensors using a high-pressure cleaner, only direct it at the sensors for a short period and maintain a minimum distance of 4 in (10 cm) from the sensors.

274 MAINTAINING YOUR VEHICLE

Window Cleaning Use a window cleaning solution on all glass surfaces. An automotive glass cleaner is recommended.

There are 2 steps in the front bumper. This makes it easier to clean the windshield.

WARNING!

For safety reasons, remove key from ignition lock before cleaning the windshield, otherwise the wiper motor can suddenly turn on and cause in- jury. Dirty or iced-up steps create a risk of slipping or falling. Do not use the step in the front bumper when it is icy or dirty.

Wiper Blade Clean the wiper blade rubber with a clean cloth and detergent solution.

WARNING!

For safety reasons, remove key from ignition lock before cleaning the wiper blade, otherwise the wiper motor can suddenly turn on and cause se- vere personal injuries and death.

Light Alloy Wheels A wheel care product should be used for regular cleaning of the light alloy wheels. If possible, clean wheels once a week, using a soft bristle brush and a strong spray of water. Follow instructions on container. NOTE: Use only acid-free cleaning materials. The acid could lead to corrosion. Instrument Cluster Use a gentle dishwashing detergent or mild detergent for delicate fabrics as a washing solution. Wipe with a cloth moistened in lukewarm solution. Do not use scouring agents. Steering Wheel and Gear Selector Lever Wipe with a damp cloth and dry thoroughly or clean with a leather care product.

MAINTAINING YOUR VEHICLE 275

Cup Holder Use a gentle dishwashing detergent or mild detergent for delicate fabrics as a washing solution. Wipe with a cloth moistened in lukewarm solution. Do not use scouring agents. Seat Belts The webbing must not be treated with chemical cleaning agents. Use only clear, lukewarm water and soap. Do not dry the webbing at temperatures above 176 ° F (+80 ° C) or in direct sunlight.

WARNING!

Do not bleach or dye seat belts as this may severe- ly weaken them. Due to this treatment they may not be able to provide adequate protection. For ex- ample, in a crash the belts can be torn.

Headliner and Shelf Below Rear Window Clean with soft bristle brush, or use a dry-shampoo cleaner in case of excessive dirt.

276 MAINTAINING YOUR VEHICLE

Upholstery Using aftermarket seat covers or wearing clothing that have the tendency to give off coloring (e.g. when wet etc.) may cause the upholstery to become permanently discolored. By lining the seats with a proper intermediate cover, contact discoloration will be prevented. Leather Upholstery Wipe leather upholstery with a damp cloth and dry thoroughly or clean with a leather care product. Exercise particular care when cleaning perforated leather as its underside should not become wet. Cloth Upholstery Clean with soft bristle brush, or use a dry-shampoo cleaner in case of excessive dirt. Tex Upholstery Pour an interior care product onto soft lint-free cloth and apply with light pressure. Hard Plastic Trim Items Pour an interior care product onto soft lint-free cloth and apply with light pressure.

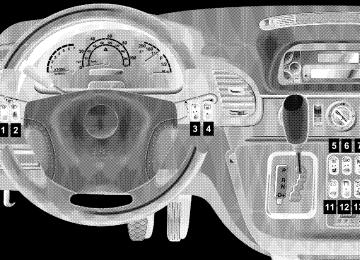

Plastic and Rubber Parts Do not use oil or wax on these parts. Do not use any caustic or alcohol-based or solvent- based substances to clean plastic surfaces. Avoid the use of stain removers, iodine tincture, nail varnish and nail varnish remover, acetone, methylated spirits, chlorine or ammonium-based cleaning agents, cleaning agents containing abrasive substances. ELECTRICAL FUSES Damaged fuses are recognizable from their burnt-out filament. Prior to exchanging a fuse, turn the key in the ignition- column lock to the 0 position and switch off the consumer involved. NOTE: Fuses must not be bridged. Replace fuses with specified rated current. Only replace fuses when the cause of the malfunction has been rectified. NOTE: Fuses and relays (standard equipment) are on the underside of the ignition column, refer to "Fuses and Relays Standard Equipment".

Fuses, relays and diodes (optional equipment) are below the driver’s seat, refer to "Optional Fuse and Relay Equipment".

CAUTION!

When replacing a blown fuse, it is important to use only a fuse having the correct amperage rating. The use of a fuse with a rating other than indicated may result in a dangerous electrical system overload. If a properly rated fuse continues to blow, it indicates a problem in the circuit that must be corrected.

MAINTAINING YOUR VEHICLE 277

Standard Fuse and Relay Equipment

Locked (1) Unlocked (2) Detent spring – engage when the cover is fitted (3)

278 MAINTAINING YOUR VEHICLE

Position of fuses and relays

Fuses (4) Relays (5)

Fuse Assignment, Standard Equipment

MAINTAINING YOUR VEHICLE 279

280 MAINTAINING YOUR VEHICLE

No. Rated 1. 2. 3.

10A 10A 10A

4. 5. 6. 7.

8.

9.

10A 10A 20A 15A

20A

15A

Circuit Parking lamp right, taillamp right High beam head lamp,right High beam head lamp, left, high beam indicator lamp Backup lamp Brake lamp Windshield wiper motor Horn, heated rear window, air recirculation switch, optional equipment relay (terminal 15) Interior lighting, cigarette lighter, radio (terminal 30) Clock, hazard warning lamps, parking lamps

10.

10A

11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21.

10A 10A 10A 15A 10A 25A 15A 15A 15A 15A 30A

Instrument lighting, license plate lamp daytime driving lamps Side lamp, left; taillamp, left Low beam headlamp, right Low beam headlamp, left Fog lamp Radio (terminal 15) Engine control unit Engine control unit Ignition (terminal 15) Not in use Heater controls (terminal 30) Heater blower (terminal 30)

MAINTAINING YOUR VEHICLE 281

Relay Assignment, Standard Equipment Windshield wiper motor (W) (1) Diesel engine control unit (M) (2) Turn signals (B) (3)

Fuse and Relay Optional Equipment The cover is located below the driver’s seat. Remove cover: 1. Press both detent springs down and remove cover.

Install cover:

2. Position cover at bottom and engage both detent

springs.

282 MAINTAINING YOUR VEHICLE

Fuse, Relay, and Diode Assignments – Optional Equipment

NOTE: The arrangement of the fuses (1) depends on the optional equipment installed on the vehicle. The assignments are shown on the inside of the cover of the fuse box. Diodes: No.

Circuit

1. 2. 3. 4.

Not in use Not in use Not in use Not in use

MAINTAINING YOUR VEHICLE 283

Fuses: No. Rated

Circuit

5. 6.

7.

8.

10A 7.5A

25A

40A

40A

9. 10. Relays: No.

Immobilizer Anti-lock brake system (ABS) Electronic Stability program (ESP®)* Anti-lock brake system (ABS) Electronic Stability program (ESP®)* Not in use Electronic Stability program (ESP®)* Anti-lock brake system (ABS) Not in use

Circuit

Not in use 11. Starter relay 12. Not in use 13. * 2500 Type Vehicles only

284 MAINTAINING YOUR VEHICLE

BULB REPLACEMENT

WARNING!

Bulbs and bulb holders can become very hot. Al- low the lamp to cool down before changing the bulb. Keep bulbs out of reach of children. Do not use bulbs which have been dropped or which show signs of scratches on the glass. They could explode. Changing an H7 bulb: The bulb is pressurized. Always wear eye and hand protection.

Switch the lights off to prevent short circuits. Only touch new bulbs with a clean, lint-free cloth. Do not touch bulbs with wet or greasy fingers. Only fit 12 volt bulbs of the same type as before and with the correct wattage rating.

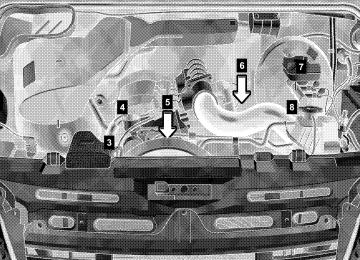

Front Lamp Unit

from

changed

Bulbs are compartment. Move the retainer bar to the side and remove the housing cover.

engine

inside

the

MAINTAINING YOUR VEHICLE 285

Turn Signal Lamps and Side-Marker Lamps

Turn signal lamp and sidemarker lamp, 3457 NA – 12V 28/7.5W, yellow glass (1) Low beam headlamp, H7 – 12V 55W (2) Fog lamp, H1 – 12V 55W (3) Side and parking lamps, W5W – 12V 5W (4) High beam headlamps, H1 – 12V 55 (5)

1. Turn

bulb

holder,

together with

counterclockwise and remove.

bulb,

2. Remove the bulb from the bulb holder. 3. 4.

Insert a new bulb in the bulb holder. Insert the bulb holder together with the bulb and turn clockwise to the stop.

286 MAINTAINING YOUR VEHICLE

Low Beam Headlamps

3. Remove the bulb. 4.

Insert the new bulb so that the retaining lugs are fed into the recesses in the reflector section of the bulb holder.

5. Clip in the retaining springs. 6. Press on the cable connector. 7. Secure the housing cap.

1. Unplug the cable connector from the bulb. 2. Unclip in the retaining springs. Press the retaining the headlamps and down

towards

springs (direction of arrow).

Fog Lamp (Optional)

1. Remove the cable connector from the bulb holder. 2. Press both retaining springs in the direction of the headlamps and then outward (in the direction of the arrow).

MAINTAINING YOUR VEHICLE 287

3. Remove the bulb. 4. Put in the new bulb so that the retaining lugs on the bulb holder are inserted into the recesses in the bulb holder reflector section. 5. Secure both retaining springs. 6. Press on the cable connector. 7. Secure the housing cap.

288 MAINTAINING YOUR VEHICLE

Side and Parking Lamps

High Beam Headlamp

1. Pull out the bulb holder with the bulb. 2. Replace the bulb. 3. 4. Secure the housing cap.

Insert the bulb holder.

1. Unplug the cable connector from the bulb. 2. Press the retaining spring towards the headlamps

and outwards (direction of arrow).

3. Remove the bulb. 4.

Insert the new bulb so that the retaining lugs are fed into the recesses in the reflector section of the bulb holder.

5. Clip in the retaining springs. 6. Press on the cable connector. 7. Secure the housing cap.

Taillamps Cargo/Passenger Van

MAINTAINING YOUR VEHICLE 289

Locked (1) Unlocked (2) Bulbs are changed from inside the cargo area. The rear lamp cluster bulb holder is located behind the interior paneling. Remove the paneling.

Brake lamp, taillamp, standing lamp, P21/5W – 12V 21/5W (1) Backup lamp, P21W – 12V 21W (2) Turn signal lamp, P21W – 12V 21W (3) Side-marker lamp, R5W – 12V 5W (4)

1. Unclip and remove the bulb socket. 2. To change a bulb, press the bulb into the bulb

socket, turn it counterclockwise and remove.

3. Insert the new bulb. 4. Clip the bulb socket into place.

290 MAINTAINING YOUR VEHICLE

Chassis

1. Loosen retaining screw a and remove lamp

housing.

2. To change a bulb, press the bulb into the bulb

socket, turn it counterclockwise and remove. Insert the new bulb. Install lamp housing.

3. 4.

(1) Retaining screws (2) Clearance lamp, R5W - 12V 5W (3) Turn signal lamp, P21W - 12V 21W (4) Stop lamp, P21W - 12V 21W (5) Taillamp, R5W - 12V 5W (6) Backup lamp, P21W - 12V 21W (7) License plate lamp (driver‘s side only),

R5W - 12V 5W

License Plate Lamps (Cargo/Passenger Vans Only)

Additional Brake Lamp (Cargo/Passenger Vans Only)

MAINTAINING YOUR VEHICLE 291

1. Press the bulb socket to the left, against the force of

the spring, and remove.

2. Replace the bulb, C5W – 12V 5W. 3. 4. Re-install the bulb socket.

Install the cover.

(1) Retaining screws 1. Take out the retaining screws (1) and remove the

lamp housing.

2. To change a bulb, P21W – 12V 21W

Press the bulb into the bulb socket, turn it counterclockwise and remove. Insert the new bulb. Install the lamp housing.

3. 4.

292 MAINTAINING YOUR VEHICLE

Side-Mounted Turn Signals

Side-Marker Lamps, Standing Lamps (Optional)

1. Press the lamp housing to the front, against the

force of the spring, and remove. 2. Replace the bulb, W5W - 12V 5W 3.

Install the bulb socket.

Retaining screws (1) Bulb socket (2) 1. Take out the retaining screws (1) and remove the

lamp housing.

2. Turn the bulb socket (2) counterclockwise and

remove.

3. Replace the bulb, W3W – 12V 3W. 4.

Install the bulb socket (2).

Identification Lamps (Cargo/passenger vans only)

Interior Lighting in Passenger Compartment and Load Compartment

MAINTAINING YOUR VEHICLE 293

(1) Retaining screw 1. Take out the retaining screw (1) and remove the

lamp housing.

2. To change a bulb, 12V 4CP

Press the bulb into the bulb socket, turn it counterclockwise and remove. Insert the new bulb. Install the lamp housing.

3. 4.

1. Align a screwdriver on the retaining spring, press it

in and pry the lamp housing out.

2. Replace the bulb, K – 12V 18W 3.

Install the lamp housing.

294 MAINTAINING YOUR VEHICLE

Interior Lighting with Reading Lamp

Interior Lighting with Interior Sensor Protection

1. Use a screwdriver on the catch spring to press in

and remove the bulb housing. 2. Replace the bulb, K – 12V 10W. 3.

Install the lamp housing.

1. Use a screwdriver on the catch spring, remove the

bulb housing.

2. Turn the bulb holder with the bulb in the direction

of the arrow and remove it.

3. Replace the bulb holder and bulb, K – 12V 6W 4.

Install the lamp housing.

Exit Lamps (Optional)

(1) Lamp housing (2) Cable connector (3) Bulb holder

MAINTAINING YOUR VEHICLE 295

1. Use a screwdriver on the catch spring to remove the

lamp housing (1).

2. Press the locating spring on the cable connector (2), hold it down, and remove the cable connector (2). 3. Turn the bulb holder (3) to the left and remove it. 4. Replace the bulb, W5W - 12V 5W. 5.

Install the bulb holder (3) and attach the cable connector (2).

296 MAINTAINING YOUR VEHICLE

CAPACITIES

Engine with oil filter

Engine oil

Fuel tank

Including reserve fuel

Cooling system Windshield washer

system

All vehicles

about 9.5 US qt (9.0 l)

about 26.4 US gal (100 l)

about 2.8 US gal (10.5 l)

about 2.7 US gal (10.0 l)

about 7.4 US qt (7.0 l)

Recommended Fluids and Lubricants The manufacturer recommends for your vehicle model the use of DaimlerChrysler approved fluids and lubricants, e.g. engine oil, gear oil, automatic transmission fluid, brake fluid, power steering fluid, coolant and anti-corrosion/anti-freeze fluid only.

WARNING!

Failure to use fluids and lubricants which meet the standards and specifications described in this booklet or failure to adhere to the specified re- placement intervals may result in damage to safe- ty-related systems of your vehicle, such as the brake system, which could cause an accident and/ or serious injury to you and others. Use only fluids and lubricants meeting the standards and specifications and adhere to specified replacement intervals.

MAINTAINING YOUR VEHICLE 297

CAUTION!

Failure to use fluids and lubricants which meet the standards and specifications described in this booklet or failure to adhere to the specified replacement intervals may result in a significantly shortened service life and/or damage to components of your vehicle, the repair of which will not be covered by Warranty. Use only fluids and lubricants meeting the standards and specifications and adhere to specified replacement intervals.

298 MAINTAINING YOUR VEHICLE

The following oils have been determined to meet DaimlerChrysler requirements.

MB approved Engine Oil

76 Pure Synthetic Motor Oil 76 Royal Triton QLT Agip All Guard Motor Oil Agip Eurosport Agip Synthetic PC Akron Ultra Clear C1-41

BP Vanellus C6 Global Plus Brad Penn Euro-Diesel LD Castrol Elixion1

Castrol Tection S1

Chevron Delo 400 Multigrade Diesel Special Benz M&A Dislub Premium Exxon XD-3 Extra1

FormulaShell Ultra FormulaShell Ultra AB Gonher Super Fleet MB-III Hydroclear Power-D Engine Oil IDO Premium 15W-40

Kendall GT-1 Full Synthetic Motor OilSAE

5W-40

15W-40

15W-40

5W-40

5W-40

15W-40

10W-40

15W-40

5W-30

15W-40

15W-40

15W-40

15W-40

15W-40

5W-40

5W-30

15W-40

15W-40

15W-40

5W-40MB Sheet 229.3

228.3

228.3

229.3

229.3

228.3

228.3

228.3

228.5

228.3

228.3

228.3

228.3

228.3

229.3

229.5

228.3

228.3

228.3

229.3Long Life EF Diesel Engine Oil Multi- grade Lubral Super Diesel MB-III Max Raloy Diesel MB Motorenöl 000 989 60 01 13

Mexlub CF-4 MB-3P Mobil 1 0W-40

Mobil Delvac 1

Mobil Delvac 1300 Super1

Mobil SHC Formula MB MOPAR® Part No. 04798231AD Motul 8100 E-Tech 0W-40

Motul 8100 X-cess 5W-40

Panolin Indy SV Pennzoil European Formula Ultra Pennzoil Synthetic European Formula Premium Synthetik Motorenöl QS Superfleet Quaker State European Formula Ultra Quaker State Full Synthetic European For- mula Quaker State Super Series III1

Raloy Diesel Turbo MX15W-40

228.3

15W-40

5W-30

10W-40

15W-40

0W-40

5W-40

15W-40

5W-30

15W-40

0W-40

5W-40

5W-40

5W-30

5W-40

5W-30

15W-40

5W-30

5W-4015W-40

15W-40228.3

228.5

228.5

228.3

229.5

228.5

228.3

229.5

228.3

229.3

229.3

229.3

229.5

229.3

229.5

228.3

229.5

229.3228.3

228.3Raloy Motor Diesel Repsol Turbo UHPD Roshfrans Voltro Diesel1

Shell Helix Ultra Shell Helix Ultra Shell Rimula X CH-4

Shell Rimula X CH-4

Shell Rotella T Multigrade1

Super Diesel Oil MB-3

Supreme Duty Diesel Engine Oil Multi- grade Unoil GX-7

Ursa Premium TDX Ursa Premium TDX Valvoline SynPower MXL 1. Engine oil also meets API classification CI-4.15W-40

10W-40

15W-40

5W-30

5W-40

15W-40

20W-50

15W-40

15W-40

15W-405W-40

10W-30

15W-40

0W-30228.3

228.5

228.3

229.3

229.3

228.3

228.3

228.3

228.3

228.3229.3

228.3

228.3

229.3MAINTAINING YOUR VEHICLE 299

Other oils may meet requirements - see oil label to determine.

300 MAINTAINING YOUR VEHICLE

COMPONENT

SERVICE INTERVAL

PRODUCT NAME/PRODUCT NUMBER

MB SHEET

Air Conditioning The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the upper atmosphere. Refrigerant R-134a Automatic

361.0

236.10— once only at 80,000 mi (128,000 km)

Refrigerant R-134a Shell ATF 3403/M-115

MOPAR® Part No. 05127382AA, or equivalent Fuchs/Shell ATF 3353Transmission Fluid

236.12

Brakes Use brake fluid approved to DaimlerChrysler standard MB 331.0 and/or DaimlerChrysler material standard MS-9971, brake fluid certified to DOT 4 Plus standards, that also maintains a minimum dry boiling point (ERBP) of 500°F (260°C), a minimum wet boiling point (WERBP) of 356°F (180°C) and maximum viscosity of 1500 mm2/s, conforming to FMVSS 116 and ISO 4925. Brake Fluid

Intac B026D

2 years

331.0

Dry boiling point: 500°F (260°C) Wet boiling point: 356°F (180°C),

Engine Oil

12 months or 10,000 mi (16,000 km)

MOPAR® MS-9971 Part No. 04549625AC, or equivalent See "Approved Engine Oils"

MAINTAINING YOUR VEHICLE 301

COMPONENT

Engine Coolant, Anticorrosion/ Antifreeze Fluid

SERVICE INTERVAL 15 years or 160,000 mi (256,000 km)

PRODUCT NAME/PRODUCT NUMBER

EURO Peak Coolant/Anti-freeze, OLD WORLD INDUSTRIES Zerex G05, The Valvoline Company Zerex G48, The Valvoline Company Glysantin G05, BASF AG MOPAR® Part No. 05066386AA, or equivalent

MB SHEET 325.0

Power Steering Power Steering, no fluid service required Power Steering fluid — Rear Axle Gear Oil

120,000 mi (192,000 km)

Mobil ATF-D, Exxon Mobil Corporation, or equivalent

Shell Spirax MB 90

MOPAR® Part No. 05136033AA, or equivalent236.3

235.0

MAINTENANCE SCHEDULES

CONTENTS

(cid:81) Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

(cid:81) Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

(cid:81) Maintenance - Without ASSYSTMaintenance Computer . . . . . . . . . . . . . . . . . . . . . 305

(cid:133) Maintenance Intervals . . . . . . . . . . . . . . . . . . . . 305(cid:81) Maintenance - With ASSYST

Maintenance Computer . . . . . . . . . . . . . . . . . . . . . 306

(cid:81) Regular Check-Ups. . . . . . . . . . . . . . . . . . . . . . . . . 306(cid:81) Special Maintenance Requirements . . . . . . . . . . . 307

(cid:133) Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

(cid:133) Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

(cid:133) Dust Filter for Heating/VentilationReplacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

(cid:81) Engine Oil Change and Filter Replacement . . . . 307

(cid:133) Once a Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

(cid:81) Scope of Work for Maintenance service . . . . . . . 308

(cid:133) Oil Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

(cid:133) Additional Maintenance Work . . . . . . . . . . . . . 310

(cid:133) Additional Maintenance Work After ... Years 310M

304 MAINTENANCE SCHEDULES

INTRODUCTION This is intended as a guide to the service requirements of your vehicle. It contains all necessary instructions concerning service intervals and operations which have to be carried out. Scope and frequency of maintenance work primarily depend on the vehicle's operating conditions. In the interest of maintaining the vehicle's operating safety, the specified work should be performed regularly and in good time. Our vehicles are subject to ongoing development. Technical progress may also affect the scope of service work performed. "Daily vehicle checks" before starting a journey are the responsibility of the driver.

in accordance with

WARRANTY The Sprinter Dealer network is at your disposal for maintenance work. Each of these workshops has the equipment and tools, the specially trained, skilled and experienced personnel and receives regular technical instruction from DaimlerChrysler Corporation to ensure that your vehicle is inspected and maintained thoroughly and latest procedures. Please follow the instructions given in this Owner’s Manual and ensure that they are observed, even if you hand the vehicle over to a third party for use or care. By not observing these instructions you may void your warranty rights. If the specified oil and maintenance services are not carried out regularly or at the time intervals specified, a decision as to the validity of a warranty claim can only be made after DaimlerChrysler Corporation has investigated your claim.

the

lubricant additives

is not The use of Special recommended. The use of such additives may affect your warranty rights. With regard to legal stipulations concerning emissions control, please note that engines have to be serviced and adjusted in accordance with special instructions and using special measuring equipment. Modifications to or interference with the emissions control systems are not permissible. All Sprinter Dealer are familiar with the relevant and appliable regulations.

MAINTENANCE SCHEDULES 305

MAINTENANCE - WITHOUT ASSYST MAINTENANCE COMPUTER Maintenance Intervals

Oil service and fuel filter replacement – Refer to

Normal Operation

every 10,000 miles or 16,000 km or 12 months

Maintenance service

every 30,000 miles or 48,000 km

Additional work must be carried out at yearly intervals. As a general rule, to avoid unnecessary visits to the workshop you should try to have necessary repair work performed together with other maintenance work.

M

306 MAINTENANCE SCHEDULES

MAINTENANCE - WITH ASSYST MAINTENANCE COMPUTER ASSYST provides you with information on the best possible timing for maintenance work. When the next maintenance service is due, this will be indicated in the multi-function display with the symbol 9 Oil service and fuel filter replacement 9 Maintenance service - displayed in km/miles

or days.

If the display shows the number of days, the symbol È will also appear in the multi-function display. You should have the maintenance performed within the stated period/distance. The service indicator will be reset by your Sprinter Dealer after an oil service and/or maintenance service has been performed.

REGULAR CHECK-UPS To maintain the safe operation of your vehicle, it is recommended that you perform the following tasks on a regular basis (i.e., weekly or whenever the vehicle is refueled). Check: (cid:127) Engine oil level (cid:127) Brake system, clutch mechanism – fluid level (cid:127) Battery – acid level (cid:127) Windshield washer system and headlamp cleaning

system – fluid level

(cid:127) Mechanical assemblies (e. g. ,engine, transmission,

etc.) – check for leaks

(cid:127) Condition of tires and tire pressures (cid:127) All exterior lights

SPECIAL MAINTENANCE REQUIREMENTS If bodies built by manufacturers other than DaimlerChrysler Corporation are fitted to the vehicle, the maintenance requirements and lubrication intervals specified by the body manufacturer must be adhered to, in addition to all standard maintenance requirements. Brake Fluid Only use brake fluids approved by the manufacturer (DOT 4 plus). Information about brake fluids is available from your Sprinter Dealer. Coolant Have the corrosion inhibitor/antifreeze concentration in the coolant checked before the onset of winter (once a year in countries with high prevailing temperatures). Have the coolant renewed every fifteen years or 100,000 miles. Dust Filter for Heating/Ventilation Replacement The dust filter and the tailgate interior filter are renewed during service. However, if operating conditions are dusty, these filters should be renewed more frequently.

routine maintenance

MAINTENANCE SCHEDULES 307

ENGINE OIL CHANGE AND FILTER REPLACEMENT In a minimum, change the engine oil and oil filter once a year - even if the vehicle mileage per year is extremly low. For standard oil service schedules, please see the chapter oil service and maintenance service. Once a Year Select the viscosity of the engine oil (SAE classes) according to the outside air temperature. Only use engine oil approved by DaimlerChrysler Corporation system guidelines. Information is available from your Sprinter Dealer. If the fuel used has a sulphur content exceeding 0.05 % by weight, the service intervals should be split in half. If the sulphur content of the fuel used is between 0.3% and 0.8% by weight, the service intervals should be split in half (i.e. every 5,000 miles instead of every 10,000 miles).

the ASSYST

following

if

M

308 MAINTENANCE SCHEDULES

SCOPE OF WORK FOR MAINTENANCE SERVICE Oil Service Oil change Engine: Oil change and filter replacement Check fluid levels of the following system, refill as necessary. If fluid is lost, trace and eliminate cause – as a separate order. Power-assisted steering Lubrication work: Trailer tow hitch (original equipment) Maintenance ASSYST maintenance computer reset

Function check Signalling system, warning and indicator lamps Headlamps, exterior lighting Windscreen wipers, windscreen washer system Check for leaks and damage. Check for abrasion points and ensure that lines are correctly routed! All assemblies: Engine, transmission, transfer case, front axle, rear axle, steering, power steering pump All lines and hoses, sensor cables Rubber boots on front axle drive shafts, rubber boots on front axle suspension ball joints, shock absorbers

Check fluid levels for the following systems, correct as necessary. Should there be a loss of fluid which cannot be explained by regular use, trace and eliminate the cause. Engine cooling system Check corrosion inhibitor/antifreeze, refill as necessary.

Hydraulic brake system Battery Windscreen washer system Engine Fuel filter renewal Air cleaner with maintenance indicator: Check degree of contamination. Air cleaner filter element renewed as necessary.

MAINTENANCE SCHEDULES 309

Chassis and body Trailer coupling: Check operation, play and retaining fixtures Secondary rubber springs: Visual check Tire pressures: Correct as necessary, including spare tyre Check thickness of brake pads Brake test Check condition of brake disks. Brake disks renewal as necessary – as a separate order Check condition of steering mechanism Heating/ventilation dust filter renewal

310 MAINTENANCE SCHEDULES

Additional Maintenance Work Automatic transmission once only at 80,000 miles/ 128000km Oil and filter change During every second maintenance service Air cleaner without maintenance indicator: Air cleaner filter element renewal Check poly-V-belt for wear and signs of damage During every fourth maintenance service Change rear axle fluid

Additional Maintenance Work After ... Years Every 2 years Change brake fluid Every 3 years Air cleaner filter element renewal (note installation date) Every 15 years or 100,000 miles Coolant renewal Note coolant composition

IF YOU NEED CONSUMER ASSISTANCE

CONTENTS

(cid:81) Suggestions For Obtaining Service

For Your Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

(cid:133) Prepare for the Appointment . . . . . . . . . . . . . . 312

(cid:133) Prepare a List . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

(cid:133) Be Reasonable with Request . . . . . . . . . . . . . . . 312(cid:81) If You Need Assistance . . . . . . . . . . . . . . . . . . . . . 312

(cid:81) Warranty Information . . . . . . . . . . . . . . . . . . . . . . 315

(cid:81) Mopar® Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

(cid:81) Reporting safety Defects . . . . . . . . . . . . . . . . . . . . 315312 IF YOU NEED CONSUMER ASSISTANCE

SUGGESTIONS FOR OBTAINING SERVICE FOR YOUR VEHICLE Prepare for the Appointment If you’re having warranty work done, be sure to have the right papers with you. Take your warranty folder. All work to be performed may not be covered by the warranty, discuss additional charges with the service manager. Keep a maintenance log of your vehicle’s service history. This can often provide a clue to the current problem Prepare a List Make a written list of your vehicle’s problems or the specific work you want done. If you’ve had an accident, or work done that is not on your maintenance log, let the service advisor know. Be Reasonable with Request If you list a number of items, and you must have your vehicle by the end of the day, discuss the situation with the service advisor and list the items in order of priority. At many dealers you may obtain a rental vehicle at a minimal daily charge. If you need a rental, it is advisable to make these arrangements when you call for an appointment.

IF YOU NEED ASSISTANCE The manufacturer and its dealers are vitally interested in your satisfaction. We want you to be happy with our products and services.

Your selling dealer is best equipped and most anxious to provide prompt resolution for any warranty issue or related matter that you may experience. The manufacturer’s dealer have the facilities, factory- trained technicians, special tools, and the latest information to assure your vehicle is fixed correctly and in a timely manner. The manufacturer has empowered its dealers to make warranty and repair decisions that ensure you are not inconvenienced. There are no need for you to wait for a decision from the manufacturer. If a special circumstance occurs that requires information from the manufacturer, we have asked the dealer’s service management to make the contact on your behalf.

This is why you should always talk to your dealer’s service manager first. Most matters can be resolved with this process.

(cid:127) If for some reason you are still not satisfied, talk to the general manager or owner of the dealership. They want to know if you need assistance.

(cid:127) If your dealership is unable to resolve the concern, you may contact the Manufacturer’s Customer Center.

Any communication to the Manufacturer’s Customer Center should include the following information:

(cid:127) Owner’s name and address

(cid:127) Owner’s telephone number (home and office)

(cid:127) Dealership name

(cid:127) Vehicle identification number

(cid:127) Vehicle delivery date and mileage

DaimlerChrysler Motors Corporation Customer Center P.O. Box 21-8004

Auburn Hills, MI 48321-8004

Phone: (800) 992-1997

IF YOU NEED CONSUMER ASSISTANCE 313

DaimlerChrysler Canada, Inc. Customer Center P.O. Box 1621

Windsor, Ontario N9A 4H6

Phone: (800) 465-2001

In Mexico contact: Av. Prolongacion Paseo de la Reforma, 1240

Sante Fe C.P. 05109

Mexico, D.F. In Mexico (915) 729-1248 or 729-1240

Outside Mexico (525) 729-1248 or 729-1240

Customer Assistance For The Hearing Impaired Or Speech Impaired (TDD/TTY) To assist customers who have hearing difficulties, the manufacturer TDD (Telecommunication Devices for the Deaf) equipment at its Customer Center. Any hearing or speech impaired customer who has access to a TDD or a conventional teletypewriter (TTY) in the United States can communicate with the manufacturer by dialing 1- 800-380-CHRY.installed

special

has

314 IF YOU NEED CONSUMER ASSISTANCE

Service Contract

You may have purchased a service contract for your vehicle to help protect you from the high cost of unexpected repairs after your manufacturer’s new vehicle limited warranty expires. The manufacturer stands behind only the manufacturer’s Service Contracts. If you purchased a manufacturer’s Service Contract, you will receive Plan Provisions and an Owner Identification Card in the mail within three weeks of your vehicle delivery date. If you have any questions about your service contract, call the manufacturer’s Service Contract National Customer Hotline at 1-800-521-9922.

We appreciate that you have made a major investment when you purchased your new vehicle. Your dealer has also made a major investment in facilities, tools, and training to assure that you are absolutely delighted with your ownership experience. You’ll be pleased with their sincere efforts to resolve any warranty issues or related concerns.

The manufacturer will not stand behind any service contract that is not the manufacturer’s Service Contract. It is not responsible for any service contract other than the manufacturer’s Service Contract. If you purchased a is not a manufacturer’s Service Contract, and you require service after your manufacturer’s new vehicle limited warranty expires, please refer to your contract documents and contact the person listed in those documents.

service contract

that

IF YOU NEED CONSUMER ASSISTANCE 315

To contact NHTSA, you may either call the Auto Safety Hotline toll free at 1–888-327-4236 (TTY: 1-800-424- 9153) or go to http://www.NHTSA.gov or write to: NHTSA, U.S. Department of Transportation, Washington, D.C. 20590. You can also obtain other information about motor vehicle safety from the Hotline. In Canada: If you believe that your vehicle has a safety defect, you should contact the Customer Service Department immediately. Canadian customers who wish to report a safety defect to the Canadian government should write to: Transport Canada, Motor Vehicle Defect Investigations and Recalls, 2780 Sheffield Road, Ottawa, Ontario, K1B 3V9.

WARRANTY INFORMATION See your manufacturer’s Warranty Information Booklet for information on your warranty coverage and transfer of warranty.

MOPAR® PARTS Mopar® fluids, lubricants, parts, and accessories are available from your dealer. They will help you keep your vehicle operating at its best.

REPORTING SAFETY DEFECTS In the 50 United States and Washington D.C.: If you believe that your vehicle has a defect which could cause a crash or cause injury or death, you should immediately inform the National Highway Traffic Safety Administration to notifying the manufacturer.

in addition

(NHTSA)

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your dealer, and the manufacturer.

INDEX

A Special Note Concerning Vehicle Alteration. . . . 230

Acceleration Skid Control . . . . . . . . . . . . . . . . . . . . . 167

Deactivating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Indicator Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Warning Lamp . . . . . . . . . . . . . . . . . . . . . . . . 146, 169

Acceleration Skid Control (ASR). . . . . . . . . . . . 169, 170

Air Conditioner for the Rear Passenger Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Air Recirculation. . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Air Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129Air Conditioning

Climate Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Rear Passenger Compartment . . . . . . . . . . . . . . . 126

Air Conditioning, Regulated . . . . . . . . . . . . . . . . . . . 124

Air Filter Restriction Indicator. . . . . . . . . . . . . . . . . . 258Air Recirculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Air VentsCenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Upper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Airbag and Belt Tensioners . . . . . . . . . . . . . . . . . . . . . 49

Airbag Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Alarm Pushbutton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alignment and Balance. . . . . . . . . . . . . . . . . . . . . . . . 206

Anti-Lock Brake System (ABS) Indicator Lamp . . . 164

Appearance and Care . . . . . . . . . . . . . . . . . . . . . . . . . 269

Armrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Ashtray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8210

318 INDEX

ASSYST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

ASSYST Maintenance Computer . . . . . . . . . . . . . . . 112

Automatic Lock Feature . . . . . . . . . . . . . . . . . . . . . . . . 19

Automatic Transmission . . . . . . . . . . . . . . . . . . . . . . 148

Accelerator Position . . . . . . . . . . . . . . . . . . . . . . . . 149

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Gear Selector Lever Position . . . . . . . . . . . . . . . . . 150

Maneuvering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Selector Lever Manually Unlocking. . . . . . . . . . . 153

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Auxiliary Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Auxiliary Heat Exchanger . . . . . . . . . . . . . . . . . . . . . 139

Auxiliary HeaterSettings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Timer Auxiliary Heater (Water and Air Heater) 134

Tips for Coping with Problems . . . . . . . . . . . . . . 140Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . 267

Disconnecting the Battery . . . . . . . . . . . . . . . . . . . 266

Reconnecting the Battery . . . . . . . . . . . . . . . . . . . . 266

Replacing Batteries in Remote Keyless Entry. . . . 22Battery Charge Indicator Lamp . . . . . . . . . . . . . . . . . 106

Belt TensionersLocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Belt Tensioners and Airbag . . . . . . . . . . . . . . . . . . . . . 49

Bleeding the Diesel Fuel System . . . . . . . . . . . . . . . . 216

Body Builder Guideline . . . . . . . . . . . . . . . . . . . . . . . 229

Brake Assist System (BAS) . . . . . . . . . . . . . . . . . . . . . 172

Brake fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Brake Fluid Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . 261

Brake Indicator Lamp . . . . . . . . . . . . . . . . . . . . . . . . . 160

Brake Pad Wear Indicator. . . . . . . . . . . . . . . . . . . . . . 159

Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Fluid Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Brake System, Anti-Lock . . . . . . . . . . . . . . . . . . . . . . 165

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Brake Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Service Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158Bulbs

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Front Lamp Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 284Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Care of Vehicle

Engine Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Headlamps, Taillamps, Turn Signal Lenses . . . . 273

Vehicle Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . 272Care of vehicle

Paintwork, painted body components . . . . . . . . 272

Power washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Tar stains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Catalytic Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Central Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Locking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Central Locking Switch. . . . . . . . . . . . . . . . . . . . . . . . . 17

Locking and Unlocking . . . . . . . . . . . . . . . . . . . . . . 19

Locking Status Display . . . . . . . . . . . . . . . . . . . . . . 18

To Program the Automatic Lock Feature . . . . . . . 19Changing a Bulb

Additional Brake Lamp . . . . . . . . . . . . . . . . . . . . . 291

Exit Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Front Lamp Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Interior Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Interior Lighting with Interior Sensor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294INDEX 319

License Plate Lamp . . . . . . . . . . . . . . . . . . . . . . . . . 291

Reading Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Side-Marker Lamp . . . . . . . . . . . . . . . . . . . . . . . . . 292

Side-Mounted Turn Signal . . . . . . . . . . . . . . . . . . 292

Taillamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Changing the Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Checking Coolant Level . . . . . . . . . . . . . . . . . . . . . . . 263

Checking Weights of Vehicle and Trailer. . . . . . . . . 224

Cigar Lighter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

CleaningCup Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Hard Plastic Trim Items . . . . . . . . . . . . . . . . . . . . . 276

Instrument Cluster . . . . . . . . . . . . . . . . . . . . . . . . . 275

Light Alloy Wheels . . . . . . . . . . . . . . . . . . . . . . . . . 275

Plastic and Rubber Parts . . . . . . . . . . . . . . . . . . . . 276

Seat Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Steering Wheel and Gear Selector Lever . . . . . . . 275

Upholstery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Wiper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Cleaning Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18210

320 INDEX

Climate Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Comfortseat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Comfortseat (Optional). . . . . . . . . . . . . . . . . . . . . . . . . 61

Compartments in Front Doors. . . . . . . . . . . . . . . . . . . 87

Constant RPMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Consumer AssistanceBe Reasonable with Request . . . . . . . . . . . . . . . . . 312

If You Need Assistance . . . . . . . . . . . . . . . . . . . . . 312

Prepare a List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Prepare for the Appointment . . . . . . . . . . . . . . . . 312

Coolant Level Indicator Lamp. . . . . . . . . . . . . . . . . . 108

Coolant Temperature Gauge . . . . . . . . . . . . . . . . . . . 103

Coolant, Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Cooling System, Engine . . . . . . . . . . . . . . . . . . . . . . . 261

Corrosion Protection . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Cup Holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

De-Fogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Dehumidification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

De-Icing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Diesel Fuels for Use at Very Low Temperatures . . 211Direction of Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Displaying Engine Oil Level . . . . . . . . . . . . . . . . . . . 115

DoorsFront Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rear Cargo Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Sliding Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Draining Fuel Filter with Water Separator . . . . . . . 214

Driver’s Airbag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Driving Safety Systems . . . . . . . . . . . . . . . . . . . . . . . . 163

Electric Sun Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Electrical Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Fuse and Relay Optional Equipment . . . . . . . . . . 281

Fuse, Relay, and Diode Assignments - Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Relay Assignment, Standard Equipment . . . . . . 281

Standard Fuse and Relay Equipment. . . . . . . . . . 277

Electrical Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Electronic Brake Force Distribution . . . . . . . . . . . . . 167

Electronic Brake Force Distribution Lamp. . . . . . . . 160

Electronic Stability Program . . . . . . . . . . . . . . . . . . . 169

Emission Label, Vehicle/Engine . . . . . . . . . . . . . . . . . . 8Emission Related Component . . . . . . . . . . . . . . . . . . 256

Emissions Control System . . . . . . . . . . . . . . . . . . . . . 228

Engine Break-in Recommendations . . . . . . . . . . . . . . 52

Engine Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Engine Control Unit Indicator Lamp . . . . . . . . . . . . 109

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Engine Cooling System. . . . . . . . . . . . . . . . . . . . . . . . 261

Engine Oil Consumption . . . . . . . . . . . . . . . . . . . . . . . 53

Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Indicator in Instrument Cluster . . . . . . . . . . . . . . 117

Engine Oil Level - Display in Instrument Cluster . 114

Engine Oil Level Indicator Lamp . . . . . . . . . . . . . . . 107

Engine Oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Engine oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Engine Speed, Maximum . . . . . . . . . . . . . . . . . . . . . . 145

Engine, Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Exhaust Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Exhaust Gas, Inhalation of . . . . . . . . . . . . . . . . . . 54, 228

Fax Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Fire Extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Fog Lamp Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68INDEX 321

Folding Seat at Partition . . . . . . . . . . . . . . . . . . . . . . . . 63

Fording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Front Seat Passenger Airbag . . . . . . . . . . . . . . . . . . . . 48

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Fuel Filter with Water Separator . . . . . . . . . . . . . . . . 210

Fuel Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Fuels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Bleeding the Diesel Fuel System. . . . . . . . . . . . . . 216

Diesel Fuels for Use at Very Low Temperatures 211

Draining Fuel Filter with Water Separator . . . . . 214

Fuel Filter with Water Separator . . . . . . . . . . . . . 210

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . 213

Refueling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Fuse and Relay Optional Equipment . . . . . . . . . . . . 281

Fuse, Relay, and Diode Assignments - Optional Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Fuses, Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Gear Selector Lever Position . . . . . . . . . . . . . . . . . . . 150

Glove Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Lockable Glove Compartment . . . . . . . . . . . . . . . . 8710

322 INDEX

Hazard Warning Flasher Switch . . . . . . . . . . . . . . . . 232

Head Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Headlamp Cleaning System . . . . . . . . . . . . . . . . . . . . 77

Headlamp Range Control. . . . . . . . . . . . . . . . . . . . . . . 68

Headlamps, taillamps, turn signal lenses . . . . . . . . 273

Heated Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . 123

Heater, Seat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118, 120

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Hydroplaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

IgnitionLock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Starter Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Immobilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Important Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 179

Indicator Lamp Symbols . . . . . . . . . . . . . . . . . . . . . . 110

Inhalation of Exhaust Gas . . . . . . . . . . . . . . . . . . . . . . 54

Installing a Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Instrument and Display Lighting . . . . . . . . . . . . . . . . 99

Instrument ClusterBattery Charge Indicator Lamp . . . . . . . . . . . . . . 106

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Coolant Level Indicator Lamp . . . . . . . . . . . . . . . 108

Coolant Temperature Gauge. . . . . . . . . . . . . . . . . 103

Engine Control Unit Indicator Lamp . . . . . . . . . . 109

Engine Oil Level Indicator Lamp . . . . . . . . . . . . . 107

Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Trip Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Water in Fuel Indicator Lamp. . . . . . . . . . . . . . . . 106

Instrument Cluster and Indicator Lamps. . . . . . . . . . 93

Instruments and Controls. . . . . . . . . . . . . . . . . . . . . . . 91

Interior Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Cargo Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Driver and Rear-Seat Passenger/Cargo Area. . . . 69