- Download PDF Manual

-

(2) Disconnect fuel shutdown relay and crank the engine for several seconds, Refer to Fuel System for relay location and WARNING.

(3) Check fluid level and add if necessary. (4) Connect fuel shutdown relay and start the

(5) Turn the steering wheel slowly from lock to

engine.

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis- sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the power steering fluid is contaminated, flush the power steering system before replacing the booster.

(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal.

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster.

Fig.49HYDRO-BOOSTUNIT

1 - INLET HOSE 2 - HYDRO-BOOST UNIT 3 - MASTER CYLINDER UNIT 4 - RETURN HOSE 5 - OUTLET HOSE

INSTALLATION

(1) Install the hydraulic booster and tighten the

mounting nuts to 28 N·m (21 ft. lbs.).

(2) Install the booster push rod, washer and clip

(1) With engine off depress the brake pedal 5

onto the brake pedal.

times to discharge the accumulator.

(2) Remove brake lines from master cylinder. (3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder. (6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 49).

(3) Install the master cylinder on the mounting studs. and tighten the mounting nuts to 23 N·m (17

ft. lbs.).(4) Install the brake lines to the master cylinder

and tighten to 19-200 N·m (170-200 in. lbs.).

(5) Install the hydraulic booster line bracket onto

the master cylinder mounting studs.

(6) Install the master cylinder mounting nuts and

tighten to 23 N·m (17 ft. lbs.).

BRAKES - BASE

5 - 28

HYDRO-BOOST BRAKE BOOSTER (Continued)DR

(7) Install the hydraulic booster pressure lines to

the bracket and booster.

(8) Tighten the pressure lines to 41 N·m (30 ft.

lbs.).

NOTE: Inspect o-rings on the pressure line fittings to insure they are in good condition before installa- tion. Replace o-rings if necessary.

(9) Install the return hose to the booster. (Refer (10) Bleed base brake system,

BRAKES/HYDRAULIC/MECHANICAL DARD PROCEDURE).

to 5 - STAN-

(11) Fill

the power steering pump with fluid, (Refer to 19 - STEERING/PUMP - STANDARD PRO- CEDURE).

Fig.50REARROTOR

1 - ROTOR 2 - CALIPER ADAPTER 3 - CALIPER

CAUTION: MOPAR (MS-9602) ATF+4 is to be used in the power steering system. No other power steering or automatic transmission fluid is to be used in the system. Damage may result to the power steering pump and system if any other fluid is used, and do not overfill.

(12) Bleed the hydraulic booster (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/POWER BRAKE BOOSTER - STANDARD PROCEDURE).

ROTORS

REMOVAL

REMOVAL - REAR

(1) Raise and support the vehicle (2) Remove the tire and wheel assembly. (3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPERS - REMOVAL).

the

caliper

(4) Remove

(Fig. 50).(Refer to 5 - BRAKES/HYDRAULIC/MECHANI- CAL/DISC REMOVAL)

ADAPTER

CALIPER

BRAKE

adapter

bolts

(5) Remove the retianing clips and rotor assembly

(Fig. 50).

REMOVAL - FRONT

(1) Raise and support the vehicle. (2) Remove the wheel and tire assembly. (3) Remove the caliper from the steering knuckle, (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/ DISC BRAKE CALIPERS - REMOVAL) and remove caliper adapter assembly (Fig. 51).

NOTE: Do not allow brake hose to support caliper adapter assembly.

Fig.51CaliperAdapterAssembly

1 - KNUCKLE 2 - CALIPER 3 - ROTOR

(4) Remove the rotor from the hub/bearing wheel

studs (Fig. 52) or (Fig. 53).

INSTALLATION

INSTALLATION - REAR

(1) Install the rotor to the axleshaft (Fig. 50).

DR ROTORS (Continued)

BRAKES - BASE

5 - 29

INSTALLATION - FRONT

(1) On models with all-wheel antilock system (ABS), check condition of tone wheel on hub/bearing. If teeth on wheel are damaged, hub/bearing assembly will have to be replaced (tone wheel is not serviced separately).

(2) Install the rotor onto the hub/bearing wheel

studs.

(3) Install the caliper adapter assembly,(Refer to 5

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPERS - INSTALLATION) and tighten adapter bolts to:(4) Install the wheel and tire assembly, (Refer to 22 - TIRES/WHEELS/WHEELS - STANDARD PRO- CEDURE) and lower the vehicle.

(5) Apply the brakes several times to seat brake pads. Be sure to obtain firm pedal before moving vehicle.

SUPPORT PLATE REMOVAL

(1) Remove wheel and tire assembly. (2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER- ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 54).

Fig.52FRONTROTOR

1 - ROTOR 2 - HUB/BEARING

Fig.538LUGROTORASSEMBLY

1 - SPRING 2 - SHOCK 3 - UPPER AND LOWER SUSPENSION ARMS 4 - DISC BRAKE CALIPER 5 - DISC BRAKE CALIPER ADAPTER 6 - ROTOR

(2) Install the caliper adapter (Fig. 50) (Refer to 5

BRAKES/HYDRAULIC/MECHANICAL/DISCBRAKE CALIPER ADAPTER - INSTALLATION).

(3) Install the caliper adapter bolts (Fig. 50) and

tighten the mounting bolts to 135 N·m (100 ft.lbs).

(4) Install the disc brake caliper,

(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPERS - INSTALLATION).

(5) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE- DURE).(6) Lower the vehicle.

INSTALLATION

(1) Install support plate on axle flange (Fig. 55).

Tighten attaching bolts to 115 N·m (85 ft. lbs.).

(2) Install parking brake cable in the brake lever. (3) Install the park brake shoes (Refer to 5 - BRAKES/PARKING BRAKE/SHOES - INSTALLA- TION). (Fig. 55).

(4) Install axle shaft, (Refer to 3 - DIFFEREN- TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE SHAFTS - INSTALLATION).

(5) Adjust brake shoes to drum with brake gauge (Refer to 5 - BRAKES/PARKING BRAKE/SHOES - ADJUSTMENTS).

BRAKES - BASE

5 - 30

SUPPORT PLATE (Continued)DR

PARKING BRAKE DESCRIPTION

The parking brakes are operated by a system of cables and levers attached to a primary and second- ary shoe positioned within the drum section of the rotor.

The drum-in-hat design utilizes an independent set

of shoes to park the vehicle (Fig. 56).

Fig.54SUPPORTPLATE

1 - SUPPORT PLATE 2 - MOUNTING STUDS

(6) Install the rotor (Refer to 5 - BRAKES/HY- INSTALLA-

DRAULIC/MECHANICAL/ROTORS - TION).

(7) Install

the caliper adapter

(Refer

to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPER ADAPTER - INSTALLATION).

(8) Install the caliper (Refer to 5 - BRAKES/HY- DRAULIC/MECHANICAL/DISC BRAKE CALIPERS - INSTALLATION).

(9) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE- DURE).Fig.55SUPPORTPLATEWITHBRAKESMOUNTED 1 - SUPPORT PLATE 2 - MOUNTING NUTS

Fig.56SUPPORTPLATEWITHBRAKESMOUNTED 1 - SUPPORT PLATE 2 - MOUNTING NUTS

OPERATION

To apply the parking brake the pedal is depressed. This creates tension in the cable which pulls forward on the park brake lever. The lever pushes the park brake shoes outward and into contact with the drum section of the rotor. The contact of shoe to rotor parks the vehicle.

A torsion locking mechanism is used to hold the pedal in an applied position. Parking brake release is accomplished by the hand release.

A parking brake switch is mounted on the parking brake lever and is actuated by movement of the lever. The switch, which is in circuit with the red warning light in the dash, will illuminate the warn- ing light whenever the parking brake is applied.

Parking brake adjustment is controlled by a cable tensioner mechanism. The cable tensioner, once adjusted at the factory, should not need further adjustment under normal circumstances. Adjustment may be required if a new tensioner, or cables are installed, or disconnected.

DR

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE CABLE

BRAKES - BASE

5 - 31

(1) Raise and support vehicle. (2) Lockout the parking brake cable (Fig. 58). (3) Loosen adjusting nut to create slack in front

(4) Remove the front cable from the cable connec-

cable.

tor.

(5) Compress

cable

end fitting at underbody

bracket and remove the cable from the bracket.

(6) Lower vehicle. (7) Push ball end of cable out of pedal clevis with

small screwdriver.

(8) Compress cable end fitting at the pedal bracket

and remove the cable (Fig. 57).

Fig.58LOCKOUTPARKINGCABLE

1 - LOCKING PLIERS 2 - PARKING BRAKE CABLE

(5) Compress tabs on cable end fitting on the rear park brake cable to the frame mount bracket. Then pull the cable through the bracket.

(6) Disengage the park brake cable from behind

the rotor assembly. (Fig. 59).

Fig.57ParkingBrakePedal

Fig.59DISENGAGEMENTOFCABLE

1 - PARK BRAKE PEDAL 2 - FRONT CABLE

1 - LEVER 2 - CABLE END

(9) Remove the left cowl trim and sill plate. (10) Pull up the carpet and remove the cable from

the body clip.

(7) Compress cable tabs on each cable end fitting

at the brake cable support plate.

(8) Remove the cables from the brake cable sup-

(11) Pull up on the cable and remove the cable

port plates.

with the body grommet.

REMOVAL - REAR PARK BRAKE CABLE

(1) Raise and support the vehicle. (2) Lockout the parking brake cable (Fig. 58). (3) Loosen cable adjuster nut. (4) Remove the rear park brake cable from the

intermediate park brake cable.

REMOVAL - RIGHT REAR CABLE (1) Raise and support the vehicle. (2) Lockout the parking brake cable (Fig. 58). (3) Loosen the brake cable at the equalizer and

adjuster nut.

(4) Remove the right cable from the front cable. (5) Remove the right cable from the equalizer.

5 - 32

BRAKES - BASE CABLES (Continued)DR

(6) Remove the cable from the frame bracket. (7) Remove the cable from the axle bracket. (8) Remove the cable bracket

from the shock

(9) Remove the brake cable from the brake lever.

bracket.

(Fig. 60)

Fig.60CABLEMOUNT

1 - SUPPORT PLAT 2 - CABLE MOUNT 3 - PARK BRAKE LEVER 4 - CABLE

REMOVAL - LEFT REAR CABLE (1) Raise and support the vehicle. (2) Lockout the parking brake cable (Fig. 58). (3) Loosen the brake cable at the equalizer and

adjuster nut.

bracket.

(Fig. 61)

(4) Remove the left brake cable from the equalizer. (5) Remove the brake cable from the frame

(6) Remove the brake cable from the brake lever.

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE CABLE

(1) From inside the vehicle, insert the cable end

fitting into the hole in the pedal assembly.

(2) Seat the cable retainer in the pedal assembly. (3) Engage the cable ball end in clevis on the pedal

assembly.

(4) Route the cable through the floorpan and

install the body grommet.

(5) Place the carpet down and install the left cowl

62)

trim and sill plate.

(6) Raise and support the vehicle. (7) Route the cable through the underbody bracket

and seat the cable end fitting in the bracket.

Fig.61REARDISCBRAKE

1 - DISC BRAKE CALIPER 2 - DISC BRAKE ROTOR 3 - DUST SHIELD 4 - REAR PARKING BRAKE CABLE 5 - DISC BRAKE CALIPER MOUNTING BOLTS

(8) Connect the cable to the cable connector. (9) Perform the park brake adjustment procedure, (Refer to 5 - BRAKES/PARKING BRAKE/CABLE TENSIONER - ADJUSTMENTS).

(10) Lower the vehicle.

INSTALLATION - REAR PARK BRAKE CABLE

(1) Push each cable end through the brake cable support plate hole until the cable end fitting tabs lock into place.

NOTE: Pull on the cable to ensure it is locked into place.

(2) Push the cable through the frame bracket. (3) Lock the left cable end fitting tabs into the

frame bracket hole.

(4) Install the rear cables into the tensioner rod

behind the rear of the brake assembly.

(5) Install the cable to the intermediate cable con-

nector.

(6) Release and remove the lock out device. (7) Perform the park brake adjustment procedure, (Refer to 5 - BRAKES/PARKING BRAKE/CABLE TENSIONER - ADJUSTMENTS).

(8) Remove the supports and lower the vehicle.

INSTALLATION - RIGHT REAR CABLE

(1) Install the brake cable to the brake lever. (Fig.

(2) Install the cable bracket to the shock bracket. (3) Install the cable to the axle bracket. (4) Install the cable to the frame bracket. (5) Install the right cable to the equalizer.

DR CABLES (Continued)

(6) Install the right cable to the front cable. (7) Adjust the brake cable at the equalizer and

using the adjuster nut.

BRAKES - BASE

5 - 33

Fig.63LOCKOUTPARKINGCABLE

1 - LOCKING PLIERS 2 - PARKING BRAKE CABLE

Fig.62PARKINGBRAKECABLE

1 - SUPPORT PLAT 2 - CABLE 3 - LEVER

INSTALLATION - LEFT REAR CABLE

(1) Install the brake cable to the brake lever (Fig.

(2) Install the brake cable to the frame bracket. (3) Install the left brake cable to the equalizer. (4) Adjust the brake cable at the equalizer and

61).

adjuster nut.

SHOES REMOVAL

(1) Raise and support the vehicle. (2) Remove the tire and wheel assembly. (3) Remove the disc brake caliper,(Refer to 5 -

(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPERS - REMOVAL).

(4) Remove the disc brake rotor,

BRAKES/HYDRAULIC/MECHANICAL/ROTORS REMOVAL).

(5) Lockout the parking brake cable (Fig. 63). (6) Disengage the park brake cable from behind the rotor assembly to allow easier disassembly of the park brake shoes (Fig. 64).

(7) Remove the axleshaft (Fig. 65) (Refer to 3 - DIFFERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/ AXLE SHAFTS - REMOVAL).

(8) Disassemble the rear park brake shoes (Fig.

56).

Fig.64DISENGAGEMENTOFCABLE

1 - LEVER 2 - CABLE END

CLEANING - REAR DRUM IN HAT BRAKE

Clean the individual brake components, including the support plate exterior, with a water dampened cloth or with brake cleaner. Do not use any other cleaning agents. Remove light rust and scale from the brake shoe contact pads on the support plate with fine sandpaper.

INSPECTION - REAR DRUM IN HAT BRAKE

As a general rule, riveted brake shoes should be replaced when worn to within 0.78 mm (1/32 in.) of the rivet heads. Bonded lining should be replaced when worn to a thickness of 1.6 mm (1/16 in.).

Examine the lining contact pattern to determine if the shoes are bent or the drum is tapered. The lining should exhibit contact across its entire width. Shoes exhibiting contact only on one side should be

BRAKES - BASE

5 - 34

SHOES (Continued)DR

Fig.65AXLESHAFT

1 - AXLE SHAFT 2 - SUPPORT PLATE 3 - CALIPER 4 - PARK BRAKE SHOE ASSEMBLY

replaced and the drum checked for runout or taper (Fig. 66).

Inspect the adjuster screw assembly. Replace the assembly if the star wheel or threads are damaged, or the components are severely rusted or corroded (Fig. 66).

Discard the brake springs and retainer components if worn, distorted or collapsed. Also replace the springs if a brake drag condition had occurred. Over- heating will distort and weaken the springs.

Inspect the brake shoe contact pads on the support plate, replace the support plate if any of the pads are worn or rusted through. Also replace the plate if it is bent or distorted (Fig. 66).

INSTALLATION

NOTE: On a new vehicle or after parking brake lin- ing replacement, it is recommended that the park- ing brake system be conditioned prior to use. This is done by making one stop from 25 mph on dry pavement or concrete using light to moderate force on the parking brake foot pedal.

(1) Reassemble the rear park brake shoes (Fig.

56).

(2) Install the axleshaft (Fig. 65) (Refer to 3 - DIF- FERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/ AXLE SHAFTS - INSTALLATION).

(3) Install the park brake cable to the lever behind

the support plate.

(4) Unlock the park brake cable. (5) Install

the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS INSTALLATION).

Fig.66PARKBRAKESHOES

(6) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKE CALIPERS - INSTALLATION).

(7) Adjust the rear brake shoes (Refer to 5 - BRAKES/PARKING BRAKE/SHOES - ADJUST- MENTS).

(8) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE- DURE).(9) Lower the vehicle.

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES

the park brake pedal

CAUTION: Before adjusting the park brake shoes be sure that is in the fully released position. If park brake pedal is not in the fully released position, the park brake shoes can not be accurately adjusted.

(1) Raise vehicle. (2) Remove tire and wheel. (3) Remove disc brake caliper from caliper adapter (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/ DISC BRAKE CALIPERS - REMOVAL).

(4) Remove rotor from the axleshaft (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS REMOVAL).

BRAKES - BASE

5 - 35

DR SHOES (Continued)

NOTE: When measuring the brake drum diameter, the diameter should be measured in the center of the area in which the park brake shoes contact the surface of the brake drum.

(5) Using Brake Shoe Gauge, Special Tool C-3919, or equivalent, accurately measure the inside diam- eter of the park brake drum portion of the rotor (Fig. 67).

Fig.69SettingGaugeToParkBrakeShoe

Measurement

1 - RULER 2 - SPECIAL TOOL C-3919

Fig.67MeasuringParkBrakeDrumDiameter

(6) Using a ruler that reads in 64th of an inch, accurately read the measurement of the inside diam- eter of the park brake drum from the special tool (Fig. 68).

Fig.68ReadingParkBrakeDrumDiameter

1 - SPECIAL TOOL C-3919

2 - RULER(7) Reduce the inside diameter measurement of the brake drum that was taken using Special Tool C-3919 by 1/64 of an inch. Reset Gauge, Brake Shoe, Special Tool C-3919 or the equivalent used, so that the outside measurement jaws are set to the reduced measurement (Fig. 69).

(8) Place Gauge, Brake Shoe, Special Tool C-3919, or equivalent over the park brake shoes. The special tool must be located diagonally across at the top of one shoe and bottom of opposite shoe (widest point) of the park brake shoes.

(9) Using the star wheel adjuster, adjust the park brake shoes until the lining on the park brake shoes just touches the jaws on the special tool.

(10) Repeat step 8 above and measure shoes in

both directions.

(11) Install brake rotor on the axleshaft (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTORS - INSTALLATION).(12) Rotate rotor to verify that the park brake shoes are not dragging on the brake drum. If park brake shoes are dragging, remove rotor and back off star wheel adjuster one notch and recheck for brake shoe drag against drum. Continue with the previous step until brake shoes are not dragging on brake drum.

(13) Install disc brake caliper on caliper adapter (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/ DISC BRAKE CALIPERS - INSTALLATION).

(14) Install wheel and tire. (15) Tighten the wheel mounting nuts in the proper sequence until all nuts are torqued to half the specified torque. Then repeat the tightening sequence to the full specified torque of 129 N·m (95 ft. lbs.).

(16) Lower vehicle. (17) Apply and release the park brake pedal one time. This will seat and correctly adjust the park brake cables.

CAUTION: Before moving vehicle, pump brake pedal several times to ensure the vehicle has a firm enough pedal to stop the vehicle.

BRAKES - BASE

5 - 36

SHOES (Continued)NOTE: On a new vehicle or after parking brake lin- ing replacement, it is recommended that the park- ing brake system be conditioned prior to use. This is done by making one stop from 25 mph on dry pavement or concrete using light to moderate force on the parking brake foot pedal.

(18) Road test the vehicle to ensure proper func-

tion of the vehicle’s brake system.

ADJUSTMENT - WITH ADJUSTING TOOL

Adjustment can be made with a standard brake gauge or with adjusting tool. Adjustment is per- formed with the complete brake assembly installed on the backing plate.

(1) Be sure parking brake lever is fully released. (2) Raise vehicle so rear wheels can be rotated

freely.

support plates.

(3) Remove plug from each access hole in brake

(4) Loosen parking brake cable adjustment nut

until there is slack in front cable.

(5) Insert adjusting tool

access hole and engage tool screw star wheel (Fig. 70).

through support plate in teeth of adjusting

Fig.70BrakeAdjustment

1 - STAR WHEEL 2 - LEVER 3 - BRAKE SHOE WEB 4 - SCREWDRIVER 5 - ADJUSTING TOOL 6 - ADJUSTER SPRING

(6) Rotate adjuster screw star wheel (move tool handle upward) until slight drag can be felt when wheel is rotated.

(7) Push and hold adjuster lever away from star

wheel with thin screwdriver.

(8) Back off adjuster screw star wheel until brake

drag is eliminated.

DR

(9) Repeat adjustment at opposite wheel. Be sure

adjustment is equal at both wheels.

(10) Install support plate access hole plugs. (11) Adjust parking brake cable and lower vehicle. (12) Depress park brake pedal and make sure park

brakes hold the vehicle staionary. (13) Release park brake pedal.

PEDAL REMOVAL

(1) Release the parking brake. (2) Raise the vehicle. (3) Loosen the cable tensioner nut at the equalizer

to create slack in the front cable.

(4) Lower the vehicle. (5) Remove the knee bolster, (Refer to 23 - BODY/ COLUMN

PANEL/STEERING

INSTRUMENT OPENING COVER - REMOVAL).

(6) Disconnect

the brake lamp wire from the

switch on the pedal assembly.

(7) Roll the carpet back,

loosen the front cable

grommet from the floorpan and the cable retainer.

(8) Disengage the release rod (Fig. 71) from the

arm on the pedal assembly.

(9) Remove the bolts/nuts from the pedal assembly

and remove the assembly.

Fig.71PARKINGBRAKEPEDAL

1 - RELEASE ROD 2 - PEDAL ASSEMBLY

INSTALLATION

(1) Position the replacement pedal assembly on the

dash and cowl.

ft. lbs.) (Fig. 72).

assembly.

(2) Install the bolts/nuts and tighten to 28 N·m (21

(3) Install the park brake release rod. (4) Connect the front cable to the arm on the pedal

DR PEDAL (Continued)

BRAKES - BASE

5 - 37

(5) Tighten the front cable grommet to the floor-

pan and the cable retainer, roll the carpet back.

(6) Connect the wires to the brake lamp switch. (7) Install the knee bolster, (Refer to 23 - BODY/ COLUMN

PANEL/STEERING INSTRUMENT OPENING COVER - INSTALLATION).

(8) Raise the vehicle. (9) Adjust the parking brake cable tensioner (Refer to 5 - BRAKES/PARKING BRAKE/CABLE TEN- SIONER - ADJUSTMENTS).

(6) Check the rear brake shoe adjustment with standard brake gauge (Refer to 5 - BRAKES/PARK- ING BRAKE/SHOES - ADJUSTMENTS).

(7) Install the rotors (Refer to 5 - BRAKES/HY- INSTALLA- the rotors rotate freely

DRAULIC/MECHANICAL/ROTORS - TION) and verify that without drag.

(8) Install the wheel/tire assemblies, (Refer to 22 - TIRES/WHEELS/WHEELS - STANDARD PROCE- DURE).

(9) Lower the vehicle enough for access to the park brake foot pedal. Then fully apply the park brakes.

NOTE: Leave park brakes applied until adjustment is complete.

(10) Raise the vehicle again. (11) Mark the tensioner rod 6.35 mm (1/4 in.) from

edge of the tensioner (Fig. 73).

(12) Tighten the adjusting nut on the tensioner rod

until the mark is no longer visible.

CAUTION: Do not loosen, or tighten the tensioner adjusting nut for any reason after completing adjustment.

(13) Lower the vehicle until the rear wheels are

15-20 cm (6-8 in.) off the shop floor.

(14) Release the park brake foot pedal and verify that rear wheels rotate freely without drag. Then lower the vehicle.

Fig.73AdjustmentMark

1 - TENSIONER CABLE BRACKET 2 - TENSIONER 3 - CABLE CONNECTOR 4 - 6.35mm (1/4 IN.) 5 - ADJUSTER NUT

Fig.72PARKINGBRAKEASSEMBLY

1 - PEDAL ASSEMBLY 2 - MOUNTING NUT

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT

NOTE: Tensioner adjustment is only necessary when the tensioner, or a cable has been replaced or disconnected for service. When adjustment is nec- essary, perform adjustment only as described in the following procedure. This is necessary to avoid faulty park brake operation.

(1) Raise the vehicle. (2) Back off the cable tensioner adjusting nut to

create slack in the cables.

(3) Remove the rear wheel/tire assemblies. Then remove the brake rotors (Refer to 5 - BRAKES/HY- DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(4) Verify the brakes are in good condition and

operating properly.

(5) Verify the park brake cables operate freely and

are not binding, or seized.

5 - 38

BRAKES - BASE

RELEASE HANDLE REMOVAL

DR

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the driver side outboard end of the instrument panel to access and unsnap the plas- tic retainer clip that secures the park brake release linkage rod to the park brake mechanism on the left cowl side inner panel.

(3) Disengage the park brake release linkage rod

end from the park brake mechanism.

(4) Lift the park brake release handle to access and unsnap the plastic retainer clip that secures the park brake release linkage rod to the lever on the back of the park brake release handle.

(5) Lower the park brake release handle and reach under the driver side outboard end of the instrument panel to disengage the park brake release linkage rod end from the lever on the back of the park brake release handle.

(6) Lift the park brake release handle to access the

handle mounting bracket.

(7) Using a trim stick or another suitable wide flat-bladed tool, gently pry each of the park brake release handle mounting bracket latch tabs away from the retaining notches in the instrument panel receptacle (Fig. 74).

(8) With both of the park brake release handle mounting bracket latches released, slide the handle and bracket assembly down and out of the instru- ment panel receptacle.

INSTALLATION

instrument panel.

(1) Position the park brake release handle to the

(2) Slide the handle and bracket assembly up into the instrument panel receptacle until both of the park brake release handle mounting bracket latches are engaged with the notches in the instrument panel receptacle.

(3) Lower the park brake release handle and reach under the driver side outboard end of the instrument panel to engage the park brake release linkage rod

Fig.74ParkBrakeReleaseHandleRemove/Install 1 - CLIP 2 - ROD 3 - MOUNTING BRACKET 4 - TRIM STICK 5 - LATCH TABS 6 - PARK BRAKE RELEASE HANDLE

end with the lever on the back of the park brake release handle.

(4) Lift the park brake release handle to access and snap the plastic retainer clip that secures the park brake release linkage rod to the lever on the back of the park brake release handle over the link- age rod.

(5) Reach under the driver side outboard end of the instrument panel to access and engage the park brake release linkage rod end to the park brake mechanism.

(6) Snap the plastic retainer clip that secures the park brake release linkage rod to the park brake mechanism on the left cowl side inner panel over the linkage rod.

(7) Reconnect the battery negative cable.

DR

BRAKES - ABS

5 - 39

BRAKES - ABS

TABLE OF CONTENTS

page

page

BRAKES - ABS

HYDRAULIC/MECHANICAL

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 39

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

STANDARD PROCEDURE - ABS BRAKEBLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING . . . . . . . . . . . . . . . 43

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING . . . . . . . . . . . . . . . 43

SPECIFICATIONS

TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . 40

FRONT WHEEL SPEED SENSOR

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 41

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 42REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 43TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR . . . . . . . . . . . . . . . . . . . . . . 43

BRAKES - ABS DESCRIPTION

The antilock brake system (ABS) is an electroni- cally operated, three channel brake control system. The vehicle has Electronic Variable Brake Propor- tioning (EVBP) designed into the system which elim- inates the combination/proportioning valve.

The system is designed to prevent wheel lockup and maintain steering control during braking. Pre- venting lockup is accomplished by modulating fluid pressure to the wheel brake units.

The hydraulic system is a three channel design. The front wheel brakes are controlled individually and the rear wheel brakes in tandem. The ABS elec- trical system is separate from other electrical circuits in the vehicle. A specially programmed controller antilock brake unit operates the system components.

ABS system major components include: † Controller Antilock Brakes (CAB) † Hydraulic Control Unit (HCU) † Wheel Speed Sensors (WSS) † ABS Warning Light

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 43

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 44RWAL VALVE

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 44

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 45OPERATION

Battery voltage is supplied to the CAB. The CAB performs a system initialization procedure at start up. A check of the ABS motor is performed at 15

miles per hour. Initialization consists of a static and dynamic self check of system electrical components. The static and dynamic checks occurs at ignition start up. During the dynamic check, the CAB briefly cycles solenoids to verify operation. An audible noise may be heard during this self check. This noise should be considered normal. The ABS motor and pump are then checked at a speed of 15 mile per hour.If an ABS component exhibits a fault during ini- tialization, the CAB illuminates the amber warning light and registers a fault code in the microprocessor memory.

The CAB monitors wheel speed sensor inputs con- tinuously while the vehicle is in motion. However, the CAB will not activate any ABS components as long as sensor inputs indicate normal braking.

During normal braking, the master cylinder, power booster and wheel brake units all function as they would in a vehicle without ABS. The HCU compo- nents are not activated.

BRAKES - ABS

5 - 40

BRAKES - ABS (Continued)The purpose of the antilock system is to prevent wheel lockup. Preventing lockup helps maintain vehi- cle braking action and steering control.

The antilock CAB activates the system whenever

sensor signals indicate periods of wheel slip.

The antilock system prevents lockup during a wheel slip condition by modulating fluid apply pres- sure to the wheel brake units.

Brake fluid apply pressure is modulated according to wheel speed, degree of slip and rate of decelera- tion. Sensors at each front wheel convert wheel speed into electrical signals. These signals are transmitted to the CAB for processing and determination of wheel slip and deceleration rate.

The ABS system has three fluid pressure control channels. The front brakes are controlled separately and the rear brakes in tandem. A speed sensor input signal indicating a wheel slip condition activates the CAB antilock program.

There are Two solenoid valves (Isolation and Dump valve) which are used in each antilock control chan- nel. The valves are all located within the HCU valve body and work in pairs to either increase, hold, or decrease apply pressure as needed in the individual control channels.

During an ABS stop the ISO valve is energized which acts to prevent further pressure build-up to

DR

the calipers. Then the Dump valve dumps off pres- sure until the wheel unlocks. This will continue until the wheels quit slipping altogether.

STANDARD PROCEDURE - ABS BRAKE BLEEDING

ABS system bleeding requires conventional bleed- ing methods plus use of the DRB scan tool. The pro- cedure involves performing a base brake bleeding, followed by use of the scan tool to cycle and bleed the HCU pump and solenoids. A second base brake bleed- ing procedure is then required to remove any air remaining in the system.

(1) Perform base brake bleeding,(Refer to 5 - BRAKES - STANDARD PROCEDURE) OR (Refer to 5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector. (3) Select ANTILOCK BRAKES, followed by MIS- CELLANEOUS, then ABS BRAKES. Follow the instructions displayed. When scan tool displays TEST COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time,(Re- fer to 5 - BRAKES - STANDARD PROCEDURE) OR (Refer to 5 - BRAKES - STANDARD PROCEDURE). (5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

SPECIFICATIONS

TORQUE CHART

DESCRIPTION ABS Assembly Mounting Bolts ABS Assembly CAB Screws ABS Assembly

Brake Line Fittings

Wheel Speed Sensors

Front Sensor Bolt

Wheel Speed Sensors

Bracket To Knuckle

Wheel Speed Sensors

Rear Sensor Stud

Controller

Mounting Screws

RWAL Module Mounting Bolts

TORQUE SPECIFICATIONS

N·m 15

3.5

19

21

6.7

22.5

15

Ft. Lbs.

In. Lbs.

11

—

—

—

—

—

—

11

—

31

170

190

60

200

53

—

DR BRAKES - ABS (Continued)

DESCRIPTION

RWAL Valve

Brake Line Fittings

Rear Wheel Speed Sensor

Mounting Bolt

BRAKES - ABS

5 - 41

N·m 19

24

Ft. Lbs.

—

—

In. Lbs.

170

200

FRONT WHEEL SPEED SENSOR DESCRIPTION

The ABS brake system uses 3 wheel speed sensors. A sensor is mounted to each front hub/bearings. The third sensor is mounted on top of the rear axle dif- ferential housing.

OPERATION

The Wheel Speed Sensor consists of a magnet sur- rounded by windings from a single strand of wire. The sensor sends a small AC signal to the CAB. This signal is generated by magnetic induction. The mag- netic induction is created when a toothed sensor ring (exciter ring or tone wheel) passes the stationary magnetic WSS.

When the ring gear is rotated, the exciter ring passes the tip of the WSS. As the exciter ring tooth approaches the tip of the WSS, the magnetic lines of force expand, causing the magnetic field to cut across the sensor’s windings. This, in turn causes current to flow through the WSS circuit (Fig. 1) in one direc- tion. When the exciter ring tooth moves away from the sensor tip, the magnetic lines of force collapse cutting the winding in the opposite direction. This causes the current to flow in the opposite direction. Every time a tooth of the exciter ring passes the tip of the WSS, an AC signal is generated. Each AC sig- nal (positive to negative signal or sinewave) is inter- preted by the CAB. It then compares the frequency of the sinewave to a time value to calculate vehicle speed. The CAB continues to monitor the frequency to determine a deceleration rate that would indicate a possible wheel-locking tendency.

sor is directly affected by:

netic field, the stronger the signal

The signal strength of any magnetic induction sen- † Magnetic field strength; the stronger the mag- † Number of windings in the sensor; more wind- † Exciter ring speed; the faster the exciter ring/ † Distance between the exciter ring teeth and WSS; the closer the WSS is to the exciter ring/tone wheel, the stronger the signal will be

tone wheel rotates, the stronger the signal will be

ings provide a stronger signal

The rear WSS is not adjustable. A clearance speci- fication has been established for manufacturing toler-

Fig.1OperationoftheWheelSpeedSensor

1 - MAGNETIC CORE 2 - CAB 3 - AIR GAP 4 - EXCITER RING 5 - COIL

If

the

clearance

ances. is not within these specifications, then either the WSS or other compo- nents may be damaged. The clearance between the WSS and the exciter ring is 0.005 – 0.050 in.

The assembly plant performs a “Rolls Test” on every vehicle that leaves the assembly plant. One of the test performed is a test of the WSS. To properly test the sensor, the assembly plant connects test equipment to the Data Link Connector (DLC). This connector is located to the right of the steering col- umn and attached to the lower portion of the instru- ment panel (Fig. 2). The rolls test terminal is spliced to the WSS circuit. The vehicle is then driven on a set of rollers and the WSS output is monitored for proper operation.

REMOVAL

(1) Remove the front rotor (Refer to 5 - BRAKES/ HYDRAULIC/MECHANICAL/ROTORS - REMOV- AL).

(2) Remove the wheel speed sensor mounting bolt

from the hub. (Fig. 3)

BRAKES - ABS

5 - 42

FRONT WHEEL SPEED SENSOR (Continued)DR

REAR WHEEL SPEED SENSOR DIAGNOSIS AND TESTING - REAR WHEEL ANTILOCK

Diagnosis of base brake conditions which are mechanical in nature should be performed first. This includes brake noise, lack of power assist, parking brake, or vehicle vibration during normal braking.

The RWAL brake system performs several self- tests every time the ignition switch is turned on and the vehicle is driven. The CAB monitors the system inputs and outputs circuits to verify the system is operating properly. If the CAB senses a malfunction in the system it will set a DTC into memory and trig- ger the warning lamp.

is used to NOTE: The MDS or DRB III scan tool diagnose the RWAL system. For test procedures refer to the Chassis Diagnostic Manual.

REMOVAL

(1) Raise the vehicle on a hoist. (2) Remove the brake line mounting nut and

remove the brake line from the sensor stud.

(3) Remove the mounting stud from the sensor and

shield (Fig. 4).

Fig.4REARWHEELSPEEDSENSOR

1 - WHEEL SPEED SENSOR 2 - MOUNTING BOLT 3 - AXLE HOUSING

(4) Remove the sensor and shield from the differ-

(5) Disconnect the sensor wire harness and remove

ential housing.

the sensor.

Fig.2DataLinkConnector-Typical

1 - 16–WAY DATA LINK CONNECTOR

(3) Remove the wheel speed sensor from the hub. (4) Remove the wiring from the clips and discon-

nect the electrical connector.

Fig.3WHEELSPEEDSENSOR

1 - WHEEL SPEED SENSOR MOUNTING BOLT 2 - WHEEL SPEED SENSOR 3 - HUB/BEARING

INSTALLATION

(1) Install the wiring to the clips and Reconnect

the electrical connector.

(2) Install the wheel speed sensor to the hub. (3) Install the wheel speed sensor mounting bolt to

the hub. Tighten the bolt to 21 N·m (190 in. lbs.).

(4) Install the front rotor and brake caliper assem- bly (Refer to 5 - BRAKES/HYDRAULIC/MECHANI- CAL/ROTORS - INSTALLATION).

DR REAR WHEEL SPEED SENSOR (Continued) INSTALLATION

(1) Connect the harness to the sensor. Be sure the seal is securely in place between the sensor and the wiring connector.

(2) Install the O-ring on the sensor (if removed). (3) Insert the sensor in the differential housing. (4) Install the sensor shield. (5) Install the sensor mounting stud and tighten to

(6) Install the brake line on the sensor stud and

24 N·m (200 in. lbs.).

install the nut.

(7) Lower the vehicle.

TONE WHEEL DIAGNOSIS AND TESTING - REAR WHEEL SPEED SENSOR

Diagnosis of base brake conditions which are mechanical in nature should be performed first. This includes brake noise, lack of power assist, parking brake, or vehicle vibration during normal braking.

The Antilock brake system performs several self- tests every time the ignition switch is turned on and the vehicle is driven. The CAB monitors the system inputs and outputs circuits to verify the system is operating properly. If the CAB senses a malfunction in the system it will set a DTC into memory and trig- ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to diagnose the Antilock Brake system. For test proce- dures refer to the Chassis Diagnostic Manual.

HYDRAULIC/MECHANICAL DESCRIPTION - ELECTRONIC VARIABLE BRAKE PROPORTIONING

Vehicles equipped with ABS use electronic variable brake proportioning (EVBP) to balance front-to-rear braking. The EVBP is used in place of a rear propor- tioning valve. The EVBP system uses the ABS sys- tem to control the slip of the rear wheels in partial braking range. The braking force of the rear wheels is controlled electronically by using the inlet and out- let valves located in the integrated control unit (ICU).

OPERATION - ELECTRONIC VARIABLE BRAKE PROPORTIONING

EVBP is able to decrease, hold and increase rear brake pressure without activating full ABS control. Upon entry into EVBP the inlet valve for the rear brake circuit is switched on so that the fluid supply

BRAKES - ABS

5 - 43

from the master cylinder is shut off. In order to decrease the rear brake pressure, the outlet valve for the rear brake circuit is pulsed. This allows fluid to enter the low pressure accumulator (LPA) in the hydraulic control unit (HCU) resulting in a drop in fluid pressure to the rear brakes. In order to increase the rear brake pressure, the outlet valve is switched off and the inlet valve is pulsed. This increases the pressure to the rear brakes.

The EVBP will remain functional during many ABS fault modes. If both the red BRAKE and amber ABS warning indicators are illuminated, the EVBP may not be functioning.

HCU (HYDRAULIC CONTROL UNIT) DESCRIPTION

The HCU consists of a valve body, pump motor, low pressure accumulators, inlet valves, outlet valves and noise attenuators.

OPERATION

Accumulators in the valve body store extra fluid released to the system for ABS mode operation. The pump provides the fluid volume needed and is oper- ated by a DC type motor. The motor is controlled by the CAB.

The

valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control to the front and rear brakes. One channel controls the rear wheel brakes in tandem. The two remaining channels control the front wheel brakes individually. During antilock braking, the solenoid valves are

opened and closed as needed.

During normal braking, the HCU solenoid valves and pump are not activated. The master cylinder and power booster operate the same as a vehicle without an ABS brake system.

NOTE: The three modes mentioned below do occur but not necessarily in the order listed everytime.

During antilock braking, solenoid valve pressure modulation occurs in three stages, pressure increase, pressure hold, and pressure decrease. The valves are all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed sensor signals indicate high wheel slip at one or more wheels. At this point, the CAB closes the inlet

BRAKES - ABS

5 - 44

HCU (HYDRAULIC CONTROL UNIT) (Continued)DR

then opens the outlet valve, which also opens the return circuit to the accumulators. Fluid pressure is allowed to bleed off (decrease) as needed to prevent wheel lock.

Once the period of high wheel slip has ended, the CAB closes the outlet valve and begins a pressure increase or hold cycle as needed.

PRESSURE HOLD

Both solenoid valves are closed in the pressure hold cycle but only the inlet valve is energized. Fluid apply pressure in the control channel is maintained at a constant rate. The CAB maintains the hold cycle until sensor inputs indicate a pressure change is nec- essary.

PRESSURE INCREASE

The inlet valve is open and the outlet valve is closed during the pressure increase cycle. The pres- sure increase cycle is used to reapply thew brakes. This cycle controls re-application of fluid apply pres- sure.

REMOVAL

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Disconnect the battery cables from the battery. (3) Remove the battery. (4) Disconnect the two electrical harness connec-

tors (Fig. 5).

(Fig. 5).

(5) Remove the five brake lines from the HCU

(6) Remove HCU/CAB mounting bolts and remove

the HCU/CAB (Fig. 5).

INSTALLATION

NOTE: If the CAB is being replaced with a new CAB is must be reprogrammed with the use of a DRB III.

(1) Install HCU/CAB on the mounts and Tighten

the bolts to 15N·m (11 ft. lbs.) (Fig. 5).

(2) Install the five brake lines to the HCU and

tighten to 19 N·m (170 in. lbs.) (Fig. 5).

(3) Install the two electrical harness connectors to the HCU/CAB and push down on the release to secure the connectors.

(4) Install the battery. (5) Install the battery cables to the battery. (6) Remove the prop rod on the brake pedal. (7) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

RWAL VALVE DESCRIPTION

Rear Wheel Antilock (RWAL) brake system is stan- dard equipment on 1500 series vehicles. The RWAL brake system is designed to prevent rear wheel lock-up on virtually all types of road surfaces. RWAL braking is desirable because a vehicle which is stopped without locking the rear wheels will retain directional stability. This allows the driver to retain greater control of the vehicle during braking.

The valve is located on the drivers side inner fender under the hood. The valve modulates hydrau- lic pressure to the rear brakes.

The RWAL components include: † RWAL Valve † Controller Antilock brake (CAB) † Rear Wheel Speed Sensor (WSS)

OPERATION

When the brakes are applied, hydraulic fluid is routed from the master cylinder’s secondary circuit to the RWAL valve. From there hydraulic fluid is routed to the rear brakes. The Controller Antilock Brake (CAB) contains an Electronic Variable Brake Propor- tioning (EVBP) control algorithm, which proportions the applied braking force to the rear wheels during braking. The EVBP function of the RWAL system takes the place of a conventional hydraulic propor- tioning valve. The CAB monitors the rear wheel speed through the rear wheel speed sensor and cal- culates an estimated vehicle deceleration. When an established deceleration threshold is exceeded, an isolation valve is closed to hold the applied brake pressure to the rear brakes constant. Upon further increases in the estimated vehicle deceleration, the isolation valve is selectively opened to increase rear

Fig.5HYDRAULICCONTROLUNIT

1 - HYDRAULIC CONTROL UNIT 2 - MOUNTING BOLTS

DR RWAL VALVE (Continued)

brake pressure in proportion to the front brake pres- sure. If impending rear wheel lock-up is sensed, the CAB signals the RWAL valve to modulate hydraulic brake pressure to the rear wheels to prevent lock-up. NORMAL BRAKING Since the RWAL valve also performs the EVBP or proportioning function, vehicle deceleration under normal braking may be sufficient to trigger the EVBP function of the RWAL system without full RWAL activity as would normally occur during an impending rear wheel lock-up. As previ- ously mentioned, the isolation valve is selectively closed and opened to increase rear brake pressure in proportion to the front brake pressure under EVBP control. Slight brake pedal pulsations may be noticed as the isolation valve is opened.

REMOVAL

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Disconnect the battery cables from the battery. (3) Remove the battery. (4) Disconnect

the electrical harness connector

(Fig. 6).

(Fig. 6).

(5) Remove the brake lines from the rwal valve

(6) Remove rwal valve mounting nuts and remove

the rwal valve (Fig. 6).

INSTALLATION

(1) Install rwal valve and Tighten the nuts to 15

N·m (11 ft. lbs.) (Fig. 6).

BRAKES - ABS

5 - 45

Fig.6RWALVALVE

1 - RWAL VALVE 2 - MOUNTING NUTS

(2) Install the brake lines to the rwal valve and

tighten to 19 N·m (170 in. lbs.) (Fig. 6).

(3) Install the electrical harness connector to the

rwal valve and secure the connector.

(4) Install the battery. (5) Install the battery cables to the battery. (6) Remove the prop rod on the brake pedal. (7) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

DR

CLUTCH

CLUTCH

TABLE OF CONTENTS

page

FLYWHEEL

CLUTCH

6 - 1

page

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . 1

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

WARNING DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 6DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . 11

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 12

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 12CLUTCH DISC

PILOT BEARING

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . 6REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 12CLUTCH HOUSING

LINKAGE

DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . 8

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 10CLUTCH RELEASE BEARING

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 11REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 13CLUTCH PEDAL POSITION SWITCH

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 14

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . 14CLUTCH DESCRIPTION

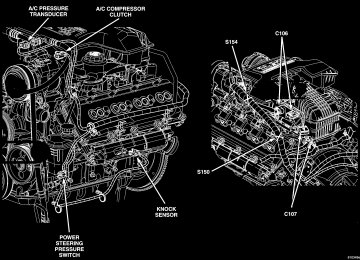

The clutch mechanism consists of a flywheel, a sin- gle, dry-type disc, and a diaphragm style clutch cover (Fig. 1). A hydraulic linkage is used to operate the clutch release bearing and fork. The flywheel is bolted to the rear flange of the crankshaft. The clutch pressure plate is bolted to the flywheel with the clutch disc located between these two compo- nents. The clutch system provides the mechanical, but still easily detachable, link between the engine and the transmission. The system is designed to ensure that the full torque output of the engine is transfered to the transmission while isolating the transmission from the engine firing pulses to mini- mize concerns such as gear rattle.

OPERATION

Leverage, clamping force and friction are what make the clutch work. The disc serves as the friction element and a diaphragm spring and pressure plate provide the clamping force. The clutch pedal, hydrau- lic linkage, release lever and bearing provide the leverage.

The clutch master cylinder push rod is connected to the clutch pedal. When the clutch pedal is depressed, the slave cylinder is operated by the clutch master cylinder mounted on the dash panel. The release fork is actuated by the hydraulic slave cylinder mounted on the transmission housing. The

Fig.1ENGINEPOWERFLOW

release bearing is operated by a release fork pivoting on a ball stud mounted in the transmission housing. The release bearing then depresses the pressure plate spring fingers, releasing pressure on the clutch disc and allowing the engine crankshaft to spin inde- pendently of the transmission input shaft (Fig. 2).

CLUTCH

6 - 2

CLUTCH (Continued)DR

(EPA), FOR THE HANDLING AND DISPOSAL OF PRODUCTS CONTAINING ASBESTOS.

DIAGNOSIS AND TESTING

A road test and component inspection is recom- mended to determine a clutch problem. During a road test, drive the vehicle at normal speeds. Shift the transmission through all gear ranges and observe clutch action. If the clutch chatters, grabs, slips or does not release properly, remove and inspect the clutch components. If the problem is noise or hard shifting, further diagnosis may be needed as the transmission or another driveline component may be at fault.

CLUTCH CONTAMINATION

Fig.2CLUTCHOPERATION

1 - FLYWHEEL 2 - PRESSURE PLATE FINGERS 3 - PIVOT POINT 4 - RELEASE BEARING PUSHED IN 5 - CLUTCH DISC ENGAGED 6 - CLUTCH DISC ENGAGED 7 - RELEASE BEARING

WARNING

WARNING:: EXERCISE CARE WHEN SERVICING CLUTCH COMPONENTS. FACTORY INSTALLED CLUTCH DISCS DO NOT CONTAIN ASBESTOS FIBERS. DUST AND DIRT ON CLUTCH PARTS MAY CONTAIN ASBESTOS FIBERS FROM AFTERMAR- KET COMPONENTS. BREATHING EXCESSIVE CON- CENTRATIONS OF THESE FIBERS CAN CAUSE SERIOUS BODILY HARM. WEAR A RESPIRATOR DURING SERVICE AND NEVER CLEAN CLUTCH COMPONENTS WITH COMPRESSED AIR OR WITH A DRY BRUSH. EITHER CLEAN THE COMPONENTS WITH A WATER DAMPENED RAGS OR USE A VAC- UUM CLEANER SPECIFICALLY DESIGNED FOR REMOVING ASBESTOS FIBERS AND DUST. DO NOT CREATE DUST BY SANDING A CLUTCH DISC. REPLACE THE DISC IF THE FRICTION MATERIAL IS DAMAGED OR CONTAMINATED. DISPOSE OF ALL DUST AND DIRT CONTAINING ASBESTOS FIBERS IN SEALED BAGS OR CONTAINERS. THIS WILL HELP MINIMIZE EXPOSURE TO YOURSELF AND TO OTHERS. FOLLOW ALL RECOMMENDED SAFETY PRACTICES PRESCRIBED BY THE OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION (OSHA) AND THE ENVIRONMENTAL SAFETY AGENCY

Fluid contamination is a frequent cause of clutch malfunctions. Oil, water or clutch fluid on the clutch disc and pressure plate surfaces will cause chatter, slip and grab. Inspect components for oil, hydraulic fluid or water/road splash contamination.

Oil contamination indicates a leak at either the rear main seal or transmission input shaft. Clutch fluid leaks are usually from damaged slave cylinder push rod seals. Heat buildup caused by slippage between the pressure plate, disc and flywheel can bake the oil residue onto the components. The glaze- like residue ranges in color from amber to black.

Road splash contamination is dirt/water entering the clutch housing due to loose bolts, housing cracks. Driving through deep water puddles can force water/ road splash into the housing through such openings.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems can be caused by worn or damage clutch components. A visual inspection of the release components will usu- ally reveal the problem part.

Release problems can result in hard shifting and noise. Look for leaks at the clutch cylinders and interconnecting line and loose slave cylinder bolts. Also worn/loose release fork, pivot stud, clutch disc, pressure plate or release bearing.

Engagement problems can result in slip, chatter/ shudder and noisy operation. The causes may be clutch disc contamination, wear, distortion or fly- wheel damage. Visually inspect to determine the actual cause of the problem.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment with the crankshaft and transmission input shaft. Misalignment caused by excessive runout or warpage of any clutch component will cause grab, chatter and improper clutch release.

DR CLUTCH (Continued) CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial (face) runout of a new disc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.) from the outer edge of the disc facing. Obtain another disc if runout is excessive.Check condition of the clutch before installation. A warped cover or diaphragm spring will cause grab and incomplete release or engagement. Be careful when handling the cover and disc. Impact can distort the cover, diaphragm spring, release fingers and the hub of the clutch disc.

Use an alignment tool when positioning the disc on the flywheel. The tool prevents accidental misalign- ment which could result in cover distortion and disc damage.

A frequent cause of clutch cover distortion (and consequent misalignment) is improper bolt tighten- ing.

FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of the flywheel face with a dial indicator.Common causes of runout are: † heat warpage † improper machining † incorrect bolt tightening † improper seating on crankshaft flange shoulder

CLUTCH

6 - 3

† foreign material on crankshaft flange Flywheel machining is not recommended. The fly- wheel clutch surface is machined to a unique contour and machining will negate this feature. Minor fly- wheel scoring can be cleaned up by hand with 180

grit emery or with turning equipment. Remove only enough material to reduce scoring (approximately 0.001 - 0.003 in.). Heavy stock removal is not rec- ommended. Replace the flywheel if scoring is severe and deeper than 0.076 mm (0.003 in.). Excessive stock removal can result in flywheel cracking or warpage after installation; it can also weaken the fly- wheel and interfere with proper clutch release.Clean the crankshaft flange before mounting the flywheel. Dirt and grease on the flange surface may cock the flywheel causing excessive runout. Use new bolts when remounting a flywheel and secure the bolts with Mopar Lock And Seal or equivalent. Tighten flywheel bolts to specified torque only. Over- tightening can distort the flywheel hub causing runout.

DIAGNOSIS CHART

The diagnosis charts Diagnosis Chart describe common clutch problems, causes and correction. Fault conditions are listed at the top of each chart. Conditions, causes and corrective action are outlined in the indicated columns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

DIAGNOSIS CHART

CONDITION

POSSIBLE CAUSES

CORRECTION

Disc facing worn out

1. Normal wear.

2. Driver frequently rides (slips) the clutch. Results in rapid overheating and wear. 3. Insufficient clutch cover diaphragm spring tension.

1. Replace cover and disc.

2. Replace cover and disc.

3. Replace cover and disc.

Clutch disc facing contaminated with oil, grease, or clutch fluid.

1. Leak at rear main engine seal or transmission input shaft seal.

1. Replace appropriate seal.

2. Excessive amount of grease applied to the input shaft splines. 3. Road splash, water entering housing. 4. Slave cylinder leaking.

2. Remove grease and apply the correct amount of grease. 3. Replace clutch disc. Clean clutch cover and reuse if in good condition. 4. Replace hydraulic clutch linkage.

1. Release bearing sticking or binding and does not return to the normal running position.

1. Verify failure. Replace the release bearing and transmission front bearing retainer as necessary.

Clutch is running partially disengaged.

CLUTCH

6 - 4

CLUTCH (Continued)DR

CONDITION

POSSIBLE CAUSES

CORRECTION

Flywheel below minimum thickness specification.

1. Improper flywheel machining. Flywheel has excessive taper or excessive material removal.

1. Replace flywheel.

Clutch disc, cover and/or diaphragm spring warped or distorted.

1. Rough handling. Impact bent cover, spring, or disc.

1. Replace disc or cover as necessary.

2. Improper bolt tightening procedure.

2. Tighten clutch cover using proper procedure.