- Download PDF Manual

-

CAUTION!

Damage to the catalytic converter can result if your vehicle is not kept in proper operating condition. In the event of engine malfunction, particularly involv- ing engine misfire or other apparent loss of perfor- mance, have your vehicle serviced promptly. Contin- ued operation of your vehicle with a severe malfunction could cause the converter to overheat, resulting in possible damage to the converter and the vehicle.

NOTE: systems can result against you.

Intentional tampering with emissions control in civil penalties being assessed

WARNING!

A hot exhaust system can start a fire if you park over materials that can burn. Such materials might be grass or leaves coming into contact with your ex- haust system. Do not park or operate your vehicle in areas where your exhaust system can contact any- thing that can burn.

In unusual situations involving grossly malfunctioning engine operation, a scorching odor may indicate severe and abnormal catalyst overheating. If this occurs, the vehicle should be stopped, the engine shut off and the vehicle allowed to cool. Thereafter, service, including a tune-up to manufacturer’s specifications, should be ob- tained immediately.

MAINTAINING YOUR VEHICLE 299

To minimize the possibility of catalyst damage: • Do not shut off the engine or interrupt the ignition when the transmission is in gear and the vehicle is in motion. • Do not try to start engine by pushing or towing the • Do not idle the engine with any spark plug wires disconnected or removed, such as when diagnostic testing, or for prolonged periods during very rough idling or malfunctioning operating conditions.

vehicle.

300 MAINTAINING YOUR VEHICLE

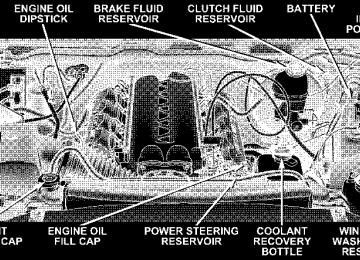

Crankcase Emission Control System Proper operation of this system depends on freedom from plugging due to deposits. As vehicle mileage builds up, the Crankcase Ventilation Valve orifice may accumu- late deposits. If a valve is not working properly, replace it with a new orifice. DO NOT ATTEMPT TO CLEAN THE OLD ORIFICE! Check the ventilation hose for indication of damage or plugging deposits. Replace if necessary. Maintenance Free Battery The top of the maintenance free battery is permanently sealed. You will never have to add water, nor is periodic maintenance required.

WARNING!

Battery fluid is a corrosive acid solution and can burn or even blind you. Don’t allow battery fluid to contact your eyes, skin or clothing. Don’t lean over a battery when attaching clamps. If acid splashes in eyes or on skin, flush the area immediately with large amounts of water. Battery gas is flammable and explosive. Keep flame or sparks away from the battery. Don’t use a booster battery or any other booster source with an output greater than 12 volts. Don’t allow cable clamps to touch each other. Battery posts, terminals and related accessories con- tain lead and lead compounds. Wash hands after handling.

CAUTION!

It is essential when replacing the cables on the battery that the positive cable is attached to the positive post and the negative cable is attached to the negative post. Battery posts are marked (+) positive and negative (-) and identified on the battery case. Also, if a “fast charger” is used while battery is in vehicle, disconnect both vehicle battery cables be- fore connecting the charger to battery. Do not use a “fast charger” to provide starting voltage.

Air Conditioner For best possible performance, your air conditioner should be checked and serviced by an Authorized Dealer at the start of each warm season. This service should include cleaning of the condenser fins and a system performance check. Drive belt tension should also be checked at this time.

MAINTAINING YOUR VEHICLE 301

WARNING!

injuring

you. Other

• Use only refrigerants approved by the manufac- turer for your air conditioning system. Some un- approved refrigerants are flammable and can ex- plode, unapproved refrigerants can cause the system to fail, requiring costly repairs. • Never add air conditioning refrigerant to correct a non-cooling problem unless pressure gauges are connected to the system by a certified technician. Lack of cooling could be due to a restriction and adding refrigerant may cause a dangerous pres- sure rise and you could be injured.

302 MAINTAINING YOUR VEHICLE

Refrigerant Recovery And Recycling The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the upper atmosphere. The manufacturer recommends that air conditioning service be done by facilities using refrigerant recycling and recovery equipment that meets SAE standard J1991. Power Steering — Fluid Check Checking the power steering fluid level at a defined service interval is not required. The fluid should only be checked if a leak is suspected, abnormal noises are apparent, and/or the system is not functioning as antici- pated. Coordinate inspection efforts through a certified DaimlerChrysler Dealership.⬙

WARNING!

Fluid level should be checked on a level surface and with the engine off to prevent injury from moving parts and to insure accurate fluid level reading. Do not overfill. Use only manufacturers recommended power steering fluid.

If necessary, add fluid to restore to the proper indicated level. With a clean cloth, wipe any spilled fluid from all surfaces. Refer to Fluids, Lubricants, and Genuine Parts for correct fluid type. Front Suspension Ball Joints The ball joints and seals should be inspected whenever the vehicle is serviced for other reasons.

if the seals on the ball

The ball joints originally supplied with the vehicle are permanently lubricated at the factory and do not require service. However, joints are the joints should be replaced. Serviceable damaged, replacement ball joints are available. Front suspension ball joints should be replaced only by a qualified service technician using tools specially de- signed for this purpose. Damage to the joints and/or suspension components may result if improper replace- ment procedures are used. If seals are damaged the ball joints should be replaced to prevent leakage or contamination of the grease. Steering Linkage — Inspection Whenever the vehicle is hoisted, all steering linkage joints should be inspected for evidence of damage. If seals are damaged, parts should be replaced to prevent leakage or contamination of the grease. Lubricate the steering linkage regularly according to the “Maintenance Schedule” in this manual.

MAINTAINING YOUR VEHICLE 303

Body Lubrication Locks and all body pivot points, including such items as seat tracks, doors, tailgate and hood hinges, should be lubricated periodically to assure quiet, easy operation and to protect against rust and wear. Prior to the appli- cation of any lubricant, the parts concerned should be wiped clean to remove dust and grit; after lubricating excess oil and grease should be removed. Particular attention should also be given to hood latching compo- nents to insure proper function. When performing other underhood services, the hood latch, release mechanism and safety catch should be cleaned and lubricated. The external lock cylinders should be lubricated twice a year, preferably in the fall and spring. Apply a small amount of a high quality lubricant such as Mopar威 Lock Cylinder Lubricant directly into the lock cylinder.

304 MAINTAINING YOUR VEHICLE

Windshield Wiper Blades The rubber edges of the wiper blades and the windshield should be cleaned periodically with a sponge or soft cloth and a mild nonabrasive cleaner. This will remove accu- mulations of salt or road film. Operation of the wipers on dry glass for long periods may cause deterioration of the wiper blades. Always use washer fluid when using the wipers to remove salt or dirt from a dry windshield. Avoid using the wiper blades to remove frost or ice from the windshield. Keep the blade rubber out of contact with petroleum products such as engine oil, gasoline, etc. Windshield Washers The fluid reservoir is located under the hood and should be checked for fluid level at regular intervals. Fill the reservoir with windshield washer solvent only (not ra- diator antifreeze).

To prevent freeze-up of your windshield washer system in cold weather, select a solution or mixture that meets or exceeds the temperature range of your climate. This rating information can be found on most washer fluid containers.

WARNING!

Commercially available windshield washer solvents are flammable. They could ignite and burn you. Care must be exercised when filling or working around the washer solution.

After the engine has warmed, operate the defroster for a few minutes to reduce the possibility of smearing or freezing the fluid on the cold windshield. Mopar All Weather Windshield Washer Solution, used with water as directed on the container, aids cleaning action, reduces the freezing point to avoid line clogging, and is not harmful to paint or trim.

Exhaust System The best protection against carbon monoxide entry into the vehicle body is a properly maintained engine exhaust system. Whenever a change is noticed in the sound of the exhaust system, when exhaust fumes can be detected inside the vehicle, or when the underside or rear of the vehicle is damaged, have a competent mechanic inspect the com- plete exhaust system and adjacent body areas for broken, damaged, deteriorated, or mispositioned parts. Open seams or loose connections could permit exhaust fumes to seep into the passenger compartment. In addition, inspect the exhaust system each time the vehicle is raised for lubrication or oil change. Replace as required.

MAINTAINING YOUR VEHICLE 305

WARNING!

Exhaust gases can injure or kill. They contain carbon monoxide (CO) which is colorless and odorless. Breathing it can make you unconscious and can eventually poison you. To avoid breathing CO, fol- low the preceding safety tips.

Exhaust System Rubber Isolator and Loop-Type Hanger — If Equipped Inspect surfaces whenever the vehicle is hoisted for rubber to metal separation or deep cracks. SLIGHT CRACKING DUE TO WEATHERING DOES NOT AD- VERSELY AFFECT PERFORMANCE. If, however, exces- sively deep localized cracks are present, or any part of the exhaust system abnormally contacts the underbody hard- ware, the isolator and/or hanger should be replaced.

306 MAINTAINING YOUR VEHICLE

Cooling System

Cooling System Maintenance At the intervals shown in the Maintenance Schedules Section of the manual, the system should be drained, flushed and filled. Inspection Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where applicable). If coolant is dirty or rusty in appearance, the system should be drained, flushed and refilled with fresh coolant as specified. Inspect the entire cooling system for leaks. Check the face of the radiator for any accumulation of bugs, leaves, or other foreign matter. If dirty, clean the radiator core with a garden hose. With the engine OFF, gently spray water from the back of the radiator core. Check the coolant reserve tank tube for condition and tightness or connections at the reserve tank and radiator.Check the coolant pressure cap and coolant reserve system for proper vacuum sealing. With the engine at normal operating temperature, note the level of the coolant in the coolant reserve tank. Without removing the pressure cap (with the engine off), drain a small amount of coolant from the radiator draincock. If the coolant level in the reserve tank drops, the system is sealing properly. Coolant Level The coolant reserve system provides a quick visual method of determining that the coolant level is adequate. With the engine idling, and warmed to the normal operating temperature, the level of the coolant on the overflow bottle should be between the fluid level marks. Check the coolant level whenever the hood is raised. The radiator normally remains completely full, so there is no longer a need to remove the coolant pressure cap except for checking coolant freeze point or replacement with new antifreeze coolant.

WARNING!

Never add coolant to the radiator when the engine is overheated. Do not loosen or remove pressure cap to cool an overheated engine! The coolant is under pressure and severe scalding could result.

Drain, Flush And Refill At intervals shown on the Maintenance Schedules, the system should be drained, flushed and refilled. Refer to your dealer or consult a service manual for proper procedures. Adding Coolant When adding coolant, or refilling the system, a minimum solution of 50% recommended HOAT ethylene glycol engine coolant (antifreeze) and distilled water should be used. Use higher concentrations (not to exceed 70%) if temperatures below ⫺34°F (⫺37°C) are anticipated.

MAINTAINING YOUR VEHICLE 307

Use only high purity water such as distilled or deionized water when mixing the water/engine coolant solution. The use of lower quality water will reduce the amount of corrosion protection in the engine cooling system. It is the owner’s responsibility to maintain the NOTE: proper level of protection against freezing according to the temperatures occurring in the area where the vehicle is operated. NOTE: Mixing coolant types will decrease the life of the engine coolant and will require more frequent coolant changes. When additional coolant is needed to maintain the proper level, add the recommended concentration of antifreeze and water to the overflow bottle. Do not overfill.

308 MAINTAINING YOUR VEHICLE

NOTE: Failure to follow the antifreeze concentration and replacement recommendations, or failure to use antifreeze formulated to prevent corrosion of all cooling system metals, may result in radiator plugging, overheat- ing, or cooling system leaks such as in core hole plugs.

WARNING!

Never add coolant to the radiator when the engine is overheated. Do not loosen or remove pressure cap to cool an overheated engine. The coolant is under pressure and severe scalding could result.

Recommended Engine Coolant Refer to Fluids, Lubricants and Genuine Parts for correct fluid type.

CAUTION!

• Mixing of coolants other than specified engine coolant, may result in engine damage, and de- crease corrosion protection. If a non-HOAT cool- ant is introduced into the cooling system in an emergency, it should be replaced with the speci- fied coolant as soon as possible. • Do not use plain water alone or alcohol base engine coolant (antifreeze) products. Do not use additional rust inhibitors or antirust products, as they may not be compatible with the radiator engine coolant and may plug the radiator. • This vehicle has not been designed for use with Propylene Glycol based coolants. Use of Propy- lene Glycol based coolants is not recommended.

Disposal Of Used Engine Coolant Used ethylene glycol based engine coolant is a regulated substance requiring proper disposal. Check with your local authorities to determine the disposal rules for your community. Do not store ethylene glycol-based engine coolant in open containers or allow it to remain in puddles on the ground. Prevent ingestion by animals and children. If ingested by a child, contact a physician immediately. Clean up any ground spills immediately. Coolant Pressure Cap The coolant pressure cap must be fully tightened to prevent the loss of coolant and to insure that the coolant will return to the radiator from the coolant reserve tank. The pressure cap should be inspected and cleaned if there is any accumulation of foreign material on the sealing surfaces.

MAINTAINING YOUR VEHICLE 309

WARNING!

The warning words “DO NOT OPEN HOT” on the radiator pressure cap are a safety precaution. Heat causes pressure to build up in the cooling system. To prevent scalding or injury, do not remove the pres- sure cap.

Hoses And Vacuum/Vapor Harnesses Inspect surfaces of hoses and nylon tubing for evidence of heat and mechanical damage. Hard or soft spots, brittle rubber, cracking, tears, cuts, abrasions, and exces- sive swelling indicate deterioration of the rubber. Pay particular attention to those hoses nearest to high heat sources such as the exhaust manifold. Inspect hose routing to be sure hoses do not come in contact with any heat source or moving component which may cause heat damage or mechanical wear.

310 MAINTAINING YOUR VEHICLE

Insure nylon tubing in these areas has not melted or collapsed. Inspect all hose connections such as clamps and cou- plings to make sure they are secure and no leaks are present. Components should be replaced immediately if there is any evidence of wear or damage that could cause failure. Brake System

Power Disc Brakes (front and rear) Disc brakes do not require adjustment; however, several hard stops during the break-in period are recommended to seat the linings and wear off any foreign material. Brake Master Cylinder The fluid level of the master cylinder should be checked when performing under the hood service, or immedi- ately if the brake system warning lamp indicates system failure.

The brake master cylinder has a translucent plastic reservoir. On the outboard side of the reservoir, there is a “MAX” dot and an “MIN” dot. The fluid level must be kept within these two dots. Do not add fluid above the MAX mark, because leakage may occur at the cap. With disc brakes the fluid level can be expected to fall as the brake linings wear. However, an unexpected drop in fluid level may be caused by a leak and a system check should be conducted. Refer to Fluids, Lubricants and Genuine Parts for the correct Fluid type.

WARNING!

Use of a brake fluid that may have a lower initial boiling point, or is unidentified as to specification, may result in sudden brake failure during hard prolonged braking. You could have an accident.

WARNING!

Overfilling the brake fluid reservoir can result in spilling brake fluid on hot engine parts and the brake fluid catching fire.

Use only brake fluid that has been in a tightly closed container to avoid contamination from foreign matter or moisture.

CAUTION!

Do not allow a petroleum-base fluid to contaminate the brake fluid. Seal damage may result.

MAINTAINING YOUR VEHICLE 311

Brake Hoses Inspection should be performed whenever the brake system is serviced or at intervals specified. Inspect hy- draulic brake hoses for surface cracking, scuffing or worn spots. If there is any evidence of cracking, scuffing, or worn spots, the hose should be replaced immediately! Eventual deterioration of the hose can take place with possible burst failure. Clutch Hydraulic System

The clutch hydraulic system is a sealed maintenance-free system. In the event of leakage or other malfunction, the system must be replaced. Clutch Linkage If the clutch pedal linkage begins to squeak or grunt, the clutch pedal pivot bushings should be lubricated. Refer to Fluids, Lubricants and Genuine Parts for the correct lubricant type.

312 MAINTAINING YOUR VEHICLE

Propeller Shaft Universal Joints Cross Type (No fittings) — Relubrication of this type of universal joint is not required. The seals should be inspected for external leaks or damage. If external leaks or damage is evident, the universal joint should be replaced. Rear Axle Fluid Level Refer to Fluids, Lubricants and Genuine Parts for the correct Fluid type. For normal service, periodic fluid level checks are not required. When the vehicle is serviced for other reasons the exterior surfaces of the axle assembly should be inspected. If gear oil leakage is suspected inspect the fluid level. This inspection should be made with the vehicle in a level position. The fluid level should be 3/4” ± 1/4” below the plug on DANA M60 HD/248 mm rear axles.

Drain and Refill Vehicles operated in normal service do not have regularly scheduled oil changes. If fluid has become contaminated with water or to provide the correct viscosity grade, drain and refill. Lubricant Selection Refer to Fluids, Lubricants and Genuine Parts for correct fluid type. NOTE: The presence of water in the gear lubricant will result in corrosion and possible failure of differential components. Operation of the vehicle in water, as may be encountered in some off-highway types of service, will require draining and refilling the axle to avoid damage.

Manual Transmission

Lubricant Selection Refer to the Fluids, Lubricants and Genuine Parts section for correct fluid type.

CAUTION!

Using a transmission fluid other than the manufac- turer’s recommended fluid may cause deterioration in transmission shift quality. Refer to the Fluids, Lubricants and Genuine Parts section for correct fluid type.

Fluid Level Check The fluid in the transmission should be checked when- ever other underhood services are done. Check the fluid level by removing the fill plug located on the left side of

MAINTAINING YOUR VEHICLE 313

the transmission. The fluid level should be at the bottom of the fill hole. Add fluid, if necessary, to maintain the proper level. Frequency of Fluid Change Under normal operating conditions, the fluid installed at the factory will give satisfactory lubrication for the life of the vehicle. If the vehicle is operated under severe conditions, change the fluid as specified in Maintenance Schedule B. If contaminated with water, the fluid should be changed immediately. Automatic Transmission

Fluid Level Check The fluid level should be checked when the engine is fully warmed up and the fluid in the transmission is at normal operating temperature. Operation of the trans- mission with an improper fluid level will greatly reduce the life of the transmission and of the fluid. Check the fluid level whenever the vehicle is serviced.

314 MAINTAINING YOUR VEHICLE

Procedure For Checking Fluid Level To properly check the automatic transmission fluid level, the following procedure must be used: 1. The vehicle must be on level ground. 2. The engine should be running at curb idle speed for a minimum of 60 seconds. 3. Fully apply parking brake. 4. Place the gear selector briefly in each gear position ending with the lever in N (Neutral). 5. Remove the dipstick and determine if the fluid is hot or warm. Hot fluid is approximately 180°F (82°C) which is the normal operating temperature after the vehicle has been driven at least 15 miles. The fluid can not be comfortably held between the finger tips. Warm is when fluid is between 85° - 125°F (29° - 52°C).

6. Wipe the dipstick clean and reinsert until seated. Remove dipstick and note reading.

a. If the fluid is hot, the reading should be in the crosshatched area marked “OK”. b. If the fluid is warm, the reading should be between the two holes. If the fluid level indicates low, add sufficient fluid to bring to the proper level.

Fluid is added through the dipstick tube. NOTE: To prevent dirt and water from entering the transmission after checking or replenishing fluid, make certain that the dipstick cap is properly seated. Selection Of Lubricant Refer to Fluids, Lubricants and Genuine Parts for the correct lubricant type. It is important that the transmis- sion fluid be maintained at the prescribed level using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac- turers recommended fluid may cause deterioration in transmission shift quality and/or torque converter shudder. Using a transmission fluid other than the manufacturers recommended fluid will result in more frequent fluid and filter changes. Refer to Fluids, Lubricants and Genuine Parts for correct fluid type.

Automatic Transmission Fluid and Filter Change To obtain best performance and long life for automatic transmissions, the manufacturer recommends that you follow the maintenance schedule that applies to your type of driving (Refer to the Maintenance Schedule Section 8).

MAINTAINING YOUR VEHICLE 315

It is important that proper lubricant is used in the trans- mission. Refer to Fluids, Lubricants and Genuine Parts for the correct lubricant type. A band adjustment and filter change should be made at the time of the oil change. The fluid and filter should be changed and the bands adjusted as specified in the Maintenance Schedule (Sec- tion 8). Vehicles having severe usage should follow Maintenance Schedule “B” of the Maintenance Schedule (Section 8). If the transmission is disassembled for any NOTE: reason, the fluid and filter should be changed, and the bands adjusted. Special Additives The manufacturer recommends against the addition of any additives to the transmission. Exception to this policy is the use of special dyes to aid in detecting fluid leaks. The use of transmission sealers should be avoided, since they may adversely affect seals.

316 MAINTAINING YOUR VEHICLE

In some instances,

Front Wheel Bearings Front wheel bearings for all Dodge Ram Trucks are sealed-for-life. They do not require greasing or seal replacement. these bearings will “purge” excess grease and the bearing will look slightly wet. This is normal. Periodic inspection for excess play is recommended. Selection of Lubricating Grease The National Lubricating Grease Institute (NLGI) has developed a symbol (Certification Mark) to aid the vehicle owner in the proper selection of grease for the lubrication of wheel bearings and chassis components. This symbol (an example is shown below) is located on the grease container and identifies the application and quality of the grease.

are

There two groups identified, those for wheel bearings (Letter “G”) and those for chassis (Letter “L”) lubrication. Perfor- mance categories within these groups result in dual letter for each group. The letter des- ignations shown in the ex- ample the highest quality level available and when combined as shown can be used for both wheel bearing and chassis lubrication. Use only those greases that have the NLGI symbol on the container along with the proper quality level for your application.

designations

are

Appearance Care and Protection from Corrosion

Protection of Body and Paint from Corrosion Vehicle body care requirements vary according to geo- graphic locations and usage. Chemicals that make roads passable in snow and ice, and those that are sprayed on trees and road surfaces during other seasons, are highly corrosive to the metal in your vehicle. Outside parking, which exposes your vehicle to airborne contaminants, road surfaces on which the vehicle is operated, extreme hot or cold weather and other extreme conditions will have an adverse effect on paint, metal trim, and under- body protection. The following maintenance recommendations will enable you to obtain maximum benefit from the corrosion resistance built into your vehicle. What Causes Corrosion? Corrosion is the result of deterioration or removal of paint and protective coatings from your vehicle.

MAINTAINING YOUR VEHICLE 317

The most common causes are: • Road salt, dirt and moisture accumulation. • Stone and gravel impact. • Insects, tree sap and tar. • Salt in the air near seacoast localities. • Atmospheric fallout/industrial pollutants. Washing • Wash your vehicle regularly. Always wash your ve- hicle in the shade using a mild car wash soap, and rinse the panels completely with clear water. • If insects, tar or other similar deposits have accumu- • Use Mopar威 auto polish to remove road film and stains and to polish your vehicle. Take care never to scratch the paint.

lated on your vehicle, wash it as soon as possible.

318 MAINTAINING YOUR VEHICLE

• Avoid using abrasive compounds and power buffing that may diminish the gloss or thin out the paint finish.

CAUTION!

Do not use abrasive or strong cleaning materials such as steel wool or scouring powder, which will scratch metal and painted surfaces.

Special Care • If you drive on salted or dusty roads or if you drive near the ocean, hose off the undercarriage at least once a month. • It is important that the drain holes in the lower edges

of the doors, rocker panels be kept clear and open.

• If you detect any stone chips or scratches in the paint, touch them up immediately. The cost of such repairs is considered the responsibility of the owner. • If your vehicle is damaged due to an accident or similar cause which destroys the paint and protective coating have your vehicle repaired as soon as possible. The cost of such repairs is considered the responsibil- ity of the owner. • All wheels and wheel trim, especially aluminum and chrome plated wheels should be cleaned regularly with mild soap and water to prevent corrosion. To remove heavy soil, select a nonabrasive, non-acidic cleaner. Do not use scouring pads, steel wool, a bristle brush or metal polishes. Only Mopar威 cleaners are recommended. Do not use oven cleaner. Avoid auto- matic car washes that use acidic solutions or harsh brushes that may damage the wheels’ protective fin- ish.

• If you carry special cargo such as chemicals, fertilizers, de-icer salt, etc., be sure that such materials are well packaged and sealed. • If a lot of driving is done on gravel roads, consider • Use Mopar威 touch up paint on scratches as soon as possible. Your dealer has touch up paint to match the color of your vehicle.

mud or stone shields behind each wheel.

Interior Care Use Mopar威 Fabric Cleaner to clean fabric upholstery and carpeting. Use Mopar威 Vinyl Cleaner to clean vinyl upholstery and trim. Mopar威 Total Clean is specifically recommended for leather upholstery.

MAINTAINING YOUR VEHICLE 319

Your leather upholstery can be best preserved by regular cleaning with a damp soft cloth. Small particles of dirt can act as an abrasive and damage the leather upholstery and should be removed promptly with a damp cloth. Stubborn soils can be removed easily with a soft cloth and Mopar威 Total Clean. Care should be taken to avoid soaking your leather upholstery with any liquid. Please do not use polishes, oils, cleaning fluids, solvents, deter- gents, or ammonia based cleaners to clean your leather upholstery. Application of a leather conditioner is not required to maintain the original condition.

WARNING!

Do not use volatile solvents for cleaning purposes. Many are potentially flammable, and if used in closed areas they may cause respiratory harm.

320 MAINTAINING YOUR VEHICLE

Glass Surfaces All glass surfaces should be cleaned on a regular basis with any commercial household-type glass cleaner. Never use an abrasive type cleaner. Use caution when cleaning inside rear windows equipped with electric defrosters or windshields equipped with a windshield wiper de-icer. Do not use scrapers or other sharp instru- ments which may scratch the elements. When cleaning the rear view mirror, spray cleaner on the towel or rag that you are using. Do not spray cleaner directly on the mirror. Cleaning Plastic Instrument Cluster Lenses The lenses in front of the instruments in this vehicle are molded in clear plastic. When cleaning the lenses, care must be taken to avoid scratching the plastic.

1. Clean with a wet soft rag. A mild soap solution may be used, but do not use high alcohol content or abrasive cleaners. If soap is used, wipe clean with a clean damp rag. 2. Dry with a soft tissue. Seat Belt Maintenance Do not bleach, dye or clean the belts with chemical solvents or abrasive cleaners. This will weaken the fabric. Sun damage will also weaken the fabric. If the belts need cleaning, use a mild soap solution or lukewarm water. Do not remove the belts from the car to wash them. Replace the belts if they appear frayed or worn or if the buckles do not work properly.

INTEGRATED POWER MODULE

Cavity Cartridge

Fuse

Integrated Power Module

Your vehicle is equipped with a fuse and relay center located in the engine compartment near the battery. Located on the underside of the cover is a label that identifies each component.

MAINTAINING YOUR VEHICLE 321

Mini Fuse 20 Amp Yellow 20 Amp Yellow 20 Amp Yellow 20 Amp Yellow 20 Amp Yellow 10 Amp Red 15 Amp Blue 10 Amp Red

Description

Power Outlet Console

CCN Door Locks/ BTSI Spare

Spare

Power Sunroof

OCM/VIST Fan/ Wastegate Reverse Lockout Sole- noid Battery Heated Mirrors

322 MAINTAINING YOUR VEHICLE

Cavity Cartridge

Fuse 30 Amp Pink

10

11

12

13

14

15

Mini Fuse

5 Amp Orange 10 Amp Red

25 Amp Natural

15 Amp Blue 20 Amp Yellow

Description

Off Road Module Power Trx-Off Rd Pkg Sen (Gas Engine Only) IOD-CNN/Radio/ Under Hood Lamp/ WCM/SDARS/HFM Electric Brake

Power-Battery RWAL/ABS Module Feed Park Lamps Left

Trailer Park Lamps

Cavity Cartridge

Fuse

40 Amp Green 30 Amp Pink

16

17

18

19

20

21

22

23

Mini Fuse 15 Amp Blue 15 Amp Blue

10 Amp Red 10 Amp Red 2 Amp Gray 10 Amp Red

Description

Park Lamps Right

Spare

ABS Pump

Trailer Tow

ORC2

ORC Preset Carrier

IGN Switch Feed

ECM/WCM/HVC

30 Amp Pink

Cavity Cartridge

Fuse 20 Amp Blue

40 Amp Green

24

25

26

27

28

29

30

31

Mini Fuse

10 Amp Red 20 Amp Yellow

10 Amp Red

10 Amp Red 15 Amp Blue 10 Amp Red

Description

Subwoofer Amplifier

Power Mirror

Brake Switch/ CHMSL/Stop Lamp Power Seats

Power Run/Start- NCC/WCM/ABS/ RWAL Switches/EC Mirror/ Smart Bar Spare

PCM/Transfer Case Brake

Cavity Cartridge

Fuse

32

33

34

35

36

37

38

MAINTAINING YOUR VEHICLE 323

Mini Fuse 10 Amp Red

10 Amp Red 10 Amp Red 15 Amp Blue 25 Amp Natural 15 Amp Blue 20 Amp Yellow

Description

HVAC/Ajustable Pedals/Heated Seats Switch LED/Exhaust Brake Power-IGN Run Misc

Spare

CNN Illumination

Audio_Amplifier

Spare

Power Outlet IP

39

40

41

42

324 MAINTAINING YOUR VEHICLE

Cavity Cartridge

Fuse

Mini Fuse 10 Amp Red 20 Amp Yellow 25 Amp Natural

Description

Sunroof/Seatbelt Ten- sioner Cigar Lighter

Spare

30 Amp Pink

Diesel PCM (Diesel Only)

1. Disconnect the battery negative (-) cable before remov- ing the cover. 2. Use specified fuses only. 3. Always properly reinstall the cover.

VEHICLE STORAGE If you are storing your vehicle for more than 21 days, we recommend that you take the following steps to mini- mize the drain on your vehicle’s battery: • Disconnect the Ignition-Off Draw fuse (I.O.D.) fuse located in the Fuse and Relay Center, located in the engine compartment. The I.O.D. cavity includes a snap-in retainer that allows the fuse to be discon- nected, without removing it from the fuse block. • As an alternative to the above steps you may, discon-

nect the negative cables from both batteries.

REPLACEMENT LIGHT BULBS

LIGHT BULBS — Inside Bulb No. Overhead Console Lights . . . . . . . . . . . . . . . TS 212-2

Dome Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7679

All of the inside bulbs are brass or glass wedge base. Aluminum base bulbs are not approved.LIGHT BULBS — Outside Bulb No. Back-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3057

Center High Mounted Stop Lamp . . . . . . . . . . . . . 912

Fog Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 9006LL Headlamp (Halogen) . . . . . . . . . . . . . . . . . . . . . H13

Side Marker Bulb . . . . . . . . . . . . . . . . . . . . . . . W5W Park & Turn Signal . . . . . . . . . . . . . . . . . . . 3157NAK Rear License Plate Lamp . . . . . . . . . . . . . . . . . . . 168MAINTAINING YOUR VEHICLE 325

Rear Cargo Light. . . . . . . . . . . . . . . . . . . . . . . . . 912

Tail & Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3057

Cab Clearance Lights . . . . . . . . . . . . . . . . . . . . . . 168

Dual Rear Wheel Sidemarker Light . . . . . . . . . . . . 168

Dual Rear Wheel Tailgate ID Lights (3) . . . . . . . . . 168BULB REPLACEMENT

Headlight (Halogen)/Front Park and Turn Lights

CAUTION!

This is a halogen bulb. Avoid touching the glass with your fingers. Reduced bulb life will result.

326 MAINTAINING YOUR VEHICLE

1. Open the hood 2. Remove the two (2) bolts from the front of the head- light housing.

3. Remove the plug from the inner fender well and remove

through the

access hole.

the nut

Front Headlight Housing Bolts

Inner Fender Plug

MAINTAINING YOUR VEHICLE 327

NOTE: For easier removal, pull the headlight assembly straight forward, applying the greatest amount of force to the outer edge of the headlight assembly.

Rear Headlight Housing Nut Access

4. Pull the housing out from the fender to allow room to disconnect the electrical connectors.

Headlight Removal

328 MAINTAINING YOUR VEHICLE

Bulb Removal

5. Unlock and pull connector straight from the base of the headlight halogen bulb.

6. Twist connector on turn signal/park light bulb 1⁄4 turn and remove connector and bulb from housing. 7. Remove housing from vehicle with headlight halogen bulb in housing. 8. Twist the headlight halogen bulb 1⁄4 turn and remove headlight bulb from the housing. 9. Replace headlight or turn signal bulb. Do not touch the headlight halogen bulb. 10. Reverse procedure for installation of bulbs and hous- ing.

Tail, Stop, Turn and Backup Lights

1. Remove the two (2) screws that pass through the bed sheetmetal.

2. Pull the housing straight out from the body, with a quick motion, to separate the housing from the body. If not pulled straight, locators may be damaged.

MAINTAINING YOUR VEHICLE 329

330 MAINTAINING YOUR VEHICLE

3. Push the red lock slide in on the connector and remove the housing from the vehicle. 4. Remove the four (4) screws from the bulb strip in the housing.

5. Pull the appropriate bulb straight from the bulb strip.

• Top Bulb: Park/Turn/Hazard • Center Bulb: Stop/Park/Sidemarker • Bottom Bulb: Backup Lights 6. Reverse procedure for installation of bulbs and housing.

7. While holding the taillight firmly in place, fasten the top screw first. Center High-Mounted Stoplight With Cargo Light

1. Remove the two (2) screws holding the housing/lens to the body as shown.

MAINTAINING YOUR VEHICLE 331

2. Separate the connector holding the housing and wir- ing harness to the body.

3. Turn desired bulb socket 1⁄4 turn and remove socket and bulb from housing.

332 MAINTAINING YOUR VEHICLE

4. Pull desired bulb straight from the socket.

Cab Top Clearance Lights — If Equipped

1. Remove the two screws from the top of the light.

• Outside Bulbs: Cargo Lamps • Inside Bulb: Center High Mount Stop Lamp 5. Reverse procedure for installation of bulbs and hous- ing.

2. Rotate the socket 1⁄4 turn and pull it from the light assembly.

3. Pull the bulb straight from it’s socket and replace.

MAINTAINING YOUR VEHICLE 333

334 MAINTAINING YOUR VEHICLE

Tailgate ID Lights (Dual Rear Wheels)

1. Remove the two screws and housing and access the bulb sockets from the rear.

2. Turn socket 1⁄4 turn counterclockwise to access the bulb.

Side Marker Lights (Dual Rear Wheels)

MAINTAINING YOUR VEHICLE 335

3. Pull bulb straight out from socket. 4. Reverse procedure for installation of bulbs and hous- ing.

1. Push rearward on the side marker light assembly. 2. Pull the entire assembly from the fender. 3. Turn socket 1⁄4 turn counterclockwise and remove from assembly to access the bulb. 4. Pull bulb straight out from socket.

336 MAINTAINING YOUR VEHICLE

5. Reverse procedure for installation of bulbs and hous- ing. Fog Lights

1. Reach under the vehicle, unlock and twist connector counterclockwise 1⁄4 turn and remove connector and bulb from housing.

2. Pull bulb straight from the connector.

3. Reverse procedure for installation of bulbs and hous- ing.

FLUID CAPACITIES

Fuel

SRT-10 - Standard Cab Models

SRT-10 - Quad Cab Models

Engine Oil (with filter)

8.3L (SAE 0W-40 MS-10725)

Cooling System

8.3L

MAINTAINING YOUR VEHICLE 337

U.S.

26 gal. 34 gal.

10 qts.

20 qts.

Metric

98L 129L

9.5 L

19L

338 MAINTAINING YOUR VEHICLE

FLUIDS, LUBRICANTS AND GENUINE PARTS Engine Component Engine Coolant

Engine Oil

Engine Oil Filter Spark Plugs

Fuel Selection

Fluids, Lubricants and Genuine Parts Mopar威 Antifreeze/Coolant 5 Year/102,000 Mile Formula HOAT (Hybrid Or- ganic Additive Technology) P/N 05066386AA or equivalent. We only recommend synthetic engine oils, such as Mobil 1威, that are API Certified and meet the requirements of Material Standard MS-10725. Mopar威 Engine Oil Filter, P/N 5281090 or equivalent. Refer to the Vehicle Emission Control Information label in the engine com- partment. 91 Octane, (R+M)/2 Method

Chassis Component Manual Transmission Fluid

Automatic Transmission Fluid Clutch Linkage Limited-Slip Rear Axle

Brake Master Cylinder

Power Steering Reservoir

MAINTAINING YOUR VEHICLE 339

Fluids, Lubricants and Genuine Parts. Mopar Synthetic Manual Transmission Lubricant 75W/85W (Castrol Syn- torq LT 75W/85W) Mopar威 ATF+4, Automatic Transmission Fluid. Multipurpose Grease, NLGI Grade 2 E.P. Mopar威 SAE 90W. Limited-Slip Rear Axles require the addition of 147 ml (5 oz.) Mopar威 limited slip additive. Mopar威 DOT 3 and SAE J1703 should be used. If DOT 3 brake fluid is not available, then DOT 4 or DOT 4+ is acceptable. Use only recommended brake fluids. Mopar威 ATF+4, Automatic Transmission Fluid

MAINTENANCE SCHEDULES

CONTENTS

䡵 Emission Control System Maintenance . . . . . . . . 342

䡵 Maintenance Schedules . . . . . . . . . . . . . . . . . . . 342▫ Schedule “B” . . . . . . . . . . . . . . . . . . . . . . . . 345

▫ Schedule “A” . . . . . . . . . . . . . . . . . . . . . . . . 355M

342 MAINTENANCE SCHEDULES

EMISSION CONTROL SYSTEM MAINTENANCE The “Scheduled” maintenance services, listed in bold type in this section (Section 8) must be done at the times or mileages specified to assure the continued proper functioning of the emission control system. These, and all other maintenance services included in this manual, should be done to provide best vehicle performance and reliability. More frequent maintenance may be needed for vehicles in severe operating conditions such as dusty areas and very short trip driving. Inspection and service also should be done any time a malfunction is suspected. NOTE: Maintenance, replacement, or repair of the emis- sion control devices and systems on your vehicle may be performed by any automotive repair establishment or individual using any automotive part which has been certified pursuant to U.S. EPA or, in the State of Califor- nia, California Air Resources Board regulations.

MAINTENANCE SCHEDULES There are two maintenance schedules that show the required service for your vehicle. First is Schedule “B”. It is for vehicles that are operated under the conditions that are listed below and at the beginning of the schedule. • Day or night temperatures are below 32° F (0° C). • Stop and go driving. • Extensive engine idling. • Driving in dusty conditions. • Short trips of less than 10 miles (16 km). • More than 50% of your driving is at sustained high • Drag Race Operation. • Heavy Loading.

speeds during hot weather, above 90° F C (32°).

• Taxi, police, or delivery service (commercial service). • Off-road or desert operation. • If equipped for and operating with E-85 (ethanol)

fuel.

If ANY of these apply to you then change your NOTE: engine oil every 3,000 miles (5 000 km) or 3 months, whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. If ANY of these apply to you then flush and NOTE: replace your engine coolant every 102,000 miles (170 000

km) or 60 months, whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. NOTE: Most vehicles are operated under the conditions listed for Schedule ⬙B⬙.MAINTENANCE SCHEDULES 343

Second is Schedule “A”. It is for vehicles that are not operated under any of the conditions listed under Sched- ule ⬙B⬙. Use the schedule that best describes your driving condi- tions. Where time and mileage are listed, follow the interval that occurs first. NOTE: Under no circumstances should oil change in- tervals exceed 6000 miles (10 000 km) or 6 months whichever comes first.

CAUTION!

Failure to perform the required maintenance items may result in damage to the vehicle.

M

344 MAINTENANCE SCHEDULES

At Each Stop for Fuel • Check the engine oil level about 5 minutes after a fully warmed engine is shut off. Checking the oil level while the vehicle is on level ground will improve the accu- racy of the oil level reading. Add oil only when the level is at or below the ADD or MIN mark. • Check the windshield washer solvent and add if

required.

damage.

Once a Month • Check tire pressure and look for unusual wear or • Inspect the battery and clean and tighten the terminals • Check the fluid levels of coolant reservoir, brake master cylinder, and transmission and add as needed.

as required.

• Check all lights and all other electrical items for correct

operation.

At Each Oil Change • Change the engine oil filter. • Inspect the exhaust system. • Inspect the brake hoses. • Inspect the CV joints (if equipped) and front suspen- • Check the automatic transmission fluid level. • Check the manual transmission fluid level. • Check the coolant level, hoses, and clamps.

sion components.

Schedule “B” Follow schedule “B” if you usually operate your vehicle under one or more of the following conditions. • Day or night temperatures are below 32° F (0° C). • Stop and go driving. • Extensive engine idling. • Driving in dusty conditions. • Short trips of less than 10 miles (16 km). • More than 50% of your driving is at sustained high • Drag Race Operation. • Heavy Loading. • Taxi, police, or delivery service (commercial service).

speeds during hot weather, above 90° F C (32°).

• Off-road or desert operation. • If equipped for and operating with E-85 (ethanol)

SCHEDULE “B” 345

fuel.

If ANY of these apply to you then change your NOTE: engine oil every 3,000 miles (5 000 km) or 3 months, whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. If ANY of these apply to you then flush and NOTE: replace your engine coolant every 102,000 miles (170 000

km) or 60 months, whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. If none of these apply to you, then change your engine oil at every interval shown on schedule ⬙A⬙ of the ⬙Mainte- nance Schedules⬙ section of this manual.346 SCHEDULE “B”

Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Drain and refill automatic transmission fluid. Re- place filter and adjust bands.* Rotate tires. Check spare tire for proper pressure and correct stowage. Change rear axle fluid. Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary.

9,000

(15 000)3,000

(5 000)6,000

(10 000)12,000

(20 000)15,000

(25 000)SCHEDULE “B” 347

Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Drain and refill automatic transmission fluid. Re- place filter and adjust bands.* Drain and refill manual transmission fluid. Rotate tires. Check spare tire for proper pressure and correct stowage. Change rear axle fluid. Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary. Replace spark plugs. Inspect and replace, if necessary, the PCV valve.**

27,000

(45 000)18,000

(30 000)21,000

(35 000)24,000

(40 000)30,000

(50 000)X**

M

348 SCHEDULE “B”

Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Drain and refill automatic transmission fluid. Re- place filter and adjust bands.* Drain and refill manual transmission fluid. Rotate tires. Check spare tire for proper pressure and correct stowage. Change rear axle fluid. Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary.

33,000

(55 000)39,000

(65 000)36,000

(60 000)42,000

(70 000)45,000

(75 000)48,000

(80 000)Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Drain and refill automatic transmission fluid. Re- place filter and adjust bands.* Rotate tires. Check spare tire for proper pressure and correct stowage. Change rear axle fluid. Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary. Replace spark plugs. Replace ignition cables. Inspect and replace, if necessary, the PCV valve.** Flush and replace engine coolant at 60 months, if not relaced at 102,000 miles (170 000 km)

SCHEDULE “B” 349

51,000

(85 000)57,000

(95 000)54,000

(90 000)60,000

(100 000)X**

M

350 SCHEDULE “B”

Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Drain and refill automatic transmission fluid. Re- place filter and adjust bands.* Drain and refill manual transmission fluid. Rotate tires. Check spare tire for proper pressure and correct stowage. Inspect engine air cleaner filter. Change rear axle fluid. Inspect brake linings. Inspect auto tension drive belt and replace if re- quired.

63,000

(105 000)66,000

(110 000)69,000

(115 000)72,000

(120 000)75,000

(125 000)Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Drain and refill automatic transmission fluid. Re- place filter and adjust bands.* Drain and refill manual transmission fluid. Rotate tires. Check spare tire for proper pressure and correct stowage. Change rear axle fluid. Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary. Replace spark plugs. Inspect PCV valve, replace as necessary.** Inspect auto tension drive belt and replace if re- quired.

78,000

(130 000)81,000

(135 000)84,000

(140 000)87,000

(145 000)90,000

(150 000)SCHEDULE “B” 351

X**

352 SCHEDULE “B”

Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Rotate tires. Check spare tire for proper pressure and correct stowage. Flush and replace engine coolant, if not replaced at 60

months. Inspect brake linings.93,000

(155 000)96,000

(160 000)99,000

(165 000)102,000

(170 000)Miles (Kilometers) Change engine oil and engine oil filter at in- terval shown or 3 months, whichever comes first. Drain and refill automatic transmission fluid. Replace filter and adjust bands.* Drain and refill automatic transmission fluid. Replace filter and adjust bands. Drain and refill manual transmission fluid. Rotate tires. Check spare tire for proper pressure and cor- rect stowage. Change rear axle fluid. Inspect brake linings. Inspect engine air cleaner filter, replace if necessary. Replace spark plugs.

105,000

(175 000)108,000

(180 000)111,000

(185 000)114,000

(190 000)117,000

(195 000)120,000

(200 000)SCHEDULE “B” 353

M

354 SCHEDULE “B”

105,000

(175 000)