- Download PDF Manual

-

stain effectively from the paintwork, but are harmful to the luster of the painted surface, since they also remove paint/clearcoat. Further, they are detrimental to glossy surfaces such as the grille, garnish, moldings, etc. † Do not use gasoline, kerosene, benzene or paint thinners to remove road tar or other contamina- tion to the painted surface. † Do not apply wax on the areas having black mat coating as it can cause uneven discoloration, patches, blurs, etc. If stained with wax, immedi- ately wipe off with a soft cloth and warm water. † Be careful when waxing the area around the sunroof opening, not to apply any wax on the weatherstrip (black rubber). If stained with wax, the weatherstrip cannot main- tain a weatherproof seal with the sunroof.

254 VEHICLE CARE

Polishing your vehicle If painted surfaces have been severely damaged and lost their original luster and color tone, polish the surface lightly with a fine polishing compound. Avoid limiting your polishing to the damaged surface only; polish a somewhat wider area, moving the polishing cloth in one direction. After polishing, flush the compound from the surface and apply a coat of wax to regain a beautiful luster. Damaged paint Small cracks and scratches in the paint coat should be touched up as soon as possible with touch-up paint to prevent corrosion. Check body areas facing the road or the tires carefully for damage to the paint coat caused by flying stones, etc. The paint code number for your vehicle can be found on the vehicle information code plate in the engine compart- ment.

Cleaning plastic parts Use a sponge or chamois. If vehicle wax adheres on the plastic bumper or mold- ings, the surface may appear white in color. In this case, wipe it off using lukewarm water and a soft cloth or chamois.

CAUTION!

they may damage the plastic part surface.

† Do not use a scrub brush or other hard tools as † Do not use wax containing compound (polishing compound) which may damage the plastic part surface. † Do not bring plastic parts into contact with brake fluids, engine oils, greases, thinner for painting, and sulfuric acid (battery electrolyte) which may stain, crack or discolor the plastic parts. If they touch the plastic part, wipe them with a soft cloth, or chamois and an aqueous solution of neutral detergent. Then, immediately rinse the affected parts with water.

Chrome parts To prevent spots and corrosion of chrome parts, wash with water, dry thoroughly, and apply a nonabrasive automotive wax. If the chrome is severely damaged or pitted use a commercially available chrome polish. Aluminum wheels (if so equipped) A protective coating is provided over aluminum wheels. Clean aluminum wheels with a cleaner designed for use on aluminum and apply an appropriate protection agent.

CAUTION! † Do not use abrasive cleaners. † Brushes may damage the aluminum wheel sur- † Do not apply hot water directly from a steam † Wheels exposed to sea water or road chemicals

face. Be sure to use a sponge, chamois, etc.

cleaner to the wheel surface.

should be cleaned as soon as possible.

VEHICLE CARE 255

Window glass The window glass can be cleaned using only a sponge and water. Glass cleaner can be used to remove wax, oil, grease, dead insects, etc. After washing the glass, wipe dry with a clean, dry, soft cloth. Wiper blades Use a soft cloth and glass cleaner to remove grease, dead insects, etc., from the wiper blades. Replace the wiper blades when they no longer clean the windshield properly. Cleaning the sunroof (if so equipped) Clean the inside of the sunroof with a soft cloth. Hard deposits should be wiped away with a cloth dipped in warm, neutral detergent solution. Wipe away the solu- tion with a sponge dipped in fresh water. NOTE: The surface treatment on the inside of the glass may be removed if a hard cloth or organic solvent is used. Engine compartment Never spray or splash water on the electrical components in the engine compartment, as this may adversely affect the electrical circuits.

EMERGENCIES

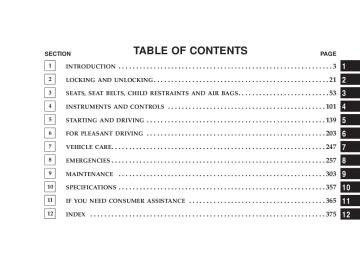

CONTENTS m If the vehicle breaks down . . . . . . . . . . . . . . . . 259

N If the engine quits . . . . . . . . . . . . . . . . . . . . . 259

m Operation under adverse driving conditions. . . 259N If your vehicle becomes stuck in sand, mud or

snow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

N On a wet road . . . . . . . . . . . . . . . . . . . . . . . . 260

N On snowy or icy roads . . . . . . . . . . . . . . . . . . 261

m Spare tire, jack and tool set storage . . . . . . . . . 262

N Handling spare tire . . . . . . . . . . . . . . . . . . . . 262

N Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

m Compact spare tire . . . . . . . . . . . . . . . . . . . . . 263

m Wheel covers (if so equipped) . . . . . . . . . . . . . 264m Jacking and tire changing . . . . . . . . . . . . . . . . 266

N Jacking up the vehicle . . . . . . . . . . . . . . . . . . 266

m Engine overheating . . . . . . . . . . . . . . . . . . . . . 274

m Jump-starting the engine . . . . . . . . . . . . . . . . . 275

N If your vehicle has anti-lock brakes . . . . . . . . . 280

m Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

m Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

N Fuse block. . . . . . . . . . . . . . . . . . . . . . . . . . . 282

m Fusible links . . . . . . . . . . . . . . . . . . . . . . . . . . 283

N Fuse load capacities . . . . . . . . . . . . . . . . . . . . 283

m Replacement of light bulbs. . . . . . . . . . . . . . . . 288

N Bulb capacity. . . . . . . . . . . . . . . . . . . . . . . . . 288258 EMERGENCIES

N Headlights (Type 1) . . . . . . . . . . . . . . . . . . . . 290

N Headlights (Type 2) . . . . . . . . . . . . . . . . . . . . 291

N Adjustment of headlight aim. . . . . . . . . . . . . . 293

N Front turn signal and parking lights. . . . . . . . . 293

N Front side marker lights . . . . . . . . . . . . . . . . . 294N Front fog light . . . . . . . . . . . . . . . . . . . . . . . . 294

N Rear combination lights . . . . . . . . . . . . . . . . . 296

N High-mounted stop light . . . . . . . . . . . . . . . . 298

N License plate light . . . . . . . . . . . . . . . . . . . . . 298

N Dome light . . . . . . . . . . . . . . . . . . . . . . . . . . 299IF THE VEHICLE BREAKS DOWN If the vehicle breaks down on the road, move to the shoulder and activate the hazard warning flashers. If there is no shoulder, or the shoulder is not safe, drive in the right lane, slowly, with the hazard flashers activated, until you reach a safe place to stop. Keep the flashers activated. If the engine quits If the engine stops, power will be lost to the steering and brakes, making steering and braking difficult. 1. The brake booster becomes inoperative and the brake pedal will be harder to push than usual. 2. Since power steering system is not operative, the steering wheel will be stiff when turning. Turn the wheel with more effort than usual.

EMERGENCIES 259

OPERATION UNDER ADVERSE DRIVING CONDITIONS

If your vehicle becomes stuck in sand, mud or snow If the vehicle becomes stuck in snow, sand, or mud, it can often be moved by a rocking motion. Turn your steering wheel right and left to clear the area around the wheels. Move the gearshift lever or selector lever rhythmically between 1st and REVERSE position (with manual trans- axle), ‘‘L’’ (Low) and ‘‘R’’ (REVERSE) position (with automatic transaxle), Autostick and ‘‘R’’ (REVERSE) po- sition (with automatic transaxle), while applying slight pressure to the accelerator pedal. Avoid racing the engine or spinning the wheels. Pro- longed efforts to free a stuck vehicle may result in overheating and transaxle failure. Allow the engine to idle for a few minutes to let the transaxle cool between rocking attempts. If the vehicle remains stuck after several rocking at- tempts, seek other assistance.

260 EMERGENCIES

WARNING!

On a wet road

When attempting to rock your vehicle out of a stuck position, be sure that the area around the vehicle is clear of people. The rocking motion may cause the vehicle to suddenly lurch forward or backward, causing injury to by-standers.

CAUTION!

† Avoid flooded roads. Water depth can be decep- tive, and you could be seriously hurt by driving into flood water. † When driving in rain, on water-covered roads, or through a vehicle wash, water could enter the brake drum linings or discs, resulting in tempo- rarily ineffective brakes. In such cases, lightly depress the brake pedal to see if the brakes operate properly. If they do not, lightly depress the pedal several times while driving in order to dry the brake pads or linings, then check them again.

CAUTION!

† When driving in rain, a layer of water may form between the tires and the road surface (hydroplan- ing). This reduces a tire’s frictional resistance on the road, resulting in loss of steering stability and braking capability. When driving on a wet road, observe the following: (a) Drive your vehicle at a safe speed. (b) Do not drive on worn tires. (c) Always maintain the specified tire inflation pressures.

On snowy or icy roads 1. When driving on a road covered by snow or ice, it is recommended that you use snow tires.

EMERGENCIES 261

CAUTION!

Tire chains are not recommended for your vehicle. The clearance between the chains and the body is small, and body damage may occur.

2. Drive slowly. Avoid any sudden starts or stops, abrupt brake application or sharp cornering. 3. Depressing the brake pedal during travel on snowy or icy roads may cause tire slippage and skidding. When a skid occurs, take your foot off the accelerator. Steer gently into the skid. Braking will differ, depending upon whether you have anti-lock brakes (ABS). If you do have ABS, brake by pressing the brake pedal firmly, and keeping it pressed. If you do not have ABS (vehicles without anti-lock braking system) pump the brake pedal with short rapid jabs, each time fully applying and fully releasing for greatest effect. 4. Allow extra distance between your vehicle and the vehicle in front of you, and avoid sudden braking.

262 EMERGENCIES

SPARE TIRE, JACK AND TOOL SET STORAGE

Handling spare tire

Jack

Tool set

Loosen

Clamp

The spare tire, jack and tool set are stowed in the trunk.

Remove the installation clamp to remove the spare tire. To install the spare tire, tighten the clamp firmly with your fingers until the spare tire has no more play.

N01A1180

N03A1870

Jack

Storage bracket

To remove

To store

N21C0010

To remove Turn the shaft end so that the jack contracts and detach it from the storage bracket. To store Turn the shaft end by hand to expand the jack until it is secured firmly in position.

EMERGENCIES 263

COMPACT SPARE TIRE The compact spare tire is designed to save space in the trunk and its lighter weight makes it easier to use if a flat tire occurs.

CAUTION!

† The tire pressure should be periodically checked and maintained at the specified pressure while the tire is stowed. † Driving with an insufficient tire pressure can lead to an accident. If you have no choice but to drive with an insufficient tire pressure, keep your speed down and adjust to the specified pressure [60 psi (420 kPa)] as soon as possible. † The compact spare should only be used temporarily and should be returned to the trunk and the original tire repaired or replaced as soon as possible. If your vehicle is equipped with aluminum type wheels, the wheel nuts for aluminum type wheels can be used temporarily on the compact spare tire wheel. † Do not exceed 50 mph (80 km/h) while the com-

pact spare tire is installed on the vehicle.

264 EMERGENCIES

CAUTION!

spare tire.

† Avoid rapid starting and braking with a compact † Avoid driving through automatic vehicle washes and over obstacles that could possibly damage the vehicle’s under-carriage. Because the tire is smaller than the original tire, vehicle ground clearance is slightly reduced. † As the compact spare tire is specifically designed for your vehicle, it should not be used on any other vehicle. † The compact spare tire should not be used on any other wheels, nor should standard tires, snow tires, wheel covers or trim rings be used with the compact spare wheel. If such use is attempted, damage to these items or other vehicle components may occur. † Do not use snow chains with your compact spare tire. Because of the smaller tire size, a snow chain will not fit properly. This could cause damage to the vehicle and could result in loss of the chains. † The compact spare tire pressure should be checked once a month while the tire is stowed.

WHEEL COVERS (IF SO EQUIPPED)

To remove

N23B0630

Wrap the tip of the bar with a cloth, insert it deeply into the notch provided in the wheel cover, and pry the cover away from the wheel. Using the same procedure on the other side, work the wheel cover away from the wheel to remove it com- pletely.

EMERGENCIES 265

NOTE: The wheel cover is made of plastic; use caution when prying it off. NOTE: Some styles of wheels will have bolt-on type wheel covers. To remove this style, remove the bolts that hold the cover to the wheel.

To install

CAUTION!

Trying to simply remove the wheel cover with your bare hands may severely injure your fingers.

N23B0910

Align the air valve with the valve opening provided on the wheel cover. Then pound around the outer edge of the wheel cover with your hand to secure it in place. NOTE: The full wheel cover has its reverse side pro- vided with a symbol mark to show the air valve location.

266 EMERGENCIES

Before installing the wheel cover to the wheel, make sure that the opening with the symbol mark is correctly aligned with the air valve.

JACKING AND TIRE CHANGING

If a tire must be changed, do so only after making sure the vehicle is stopped in a safe, flat location. Jacking up the vehicle 1. Park the vehicle on level and stable ground. 2. Switch on the hazard warning flashers, set up a warning triangle, flashing signal light, etc., at an ad- equate distance from the vehicle, and have all passengers leave the vehicle. Turn the ignition key to the “LOCK” position. 3. Set the parking brake firmly, and move the gearshift lever (manual transaxle) to the “N” (Neutral) position or move the selector lever (automatic transaxle) to the “P” (PARK) position.

N24A0100

4. Apply a chock or block (A) at the tire diagonally opposite the tire (B) to be changed. NOTE: The chock shown is not supplied with the ve- hicle. It is recommended that you keep one in the vehicle for use if required.

EMERGENCIES 267

WARNING!

† Do not set the jack at any other position on the vehicle than those specified. If the jack is set at a wrong position, the body of the vehicle could be dented or the jack might fall over and cause personal injury.

† Avoid using the jack on tilted or soft surfaces.

Otherwise, the jack might slip and cause personal injury. Always use the jack on a flat, hard surface. Before setting the jack, check to ensure that there is no sand or pebbles on the underside of the jack base.

N22A1280

5. Place the jack under one of the jacking points shown in the illustration. Use the jacking point closest to the tire being changed. C = Jacking point

268 EMERGENCIES

6. Rotate the jack by hand until the flange portion (D) fits in the groove at the top of the jack.

NOTE: Before use, turn the top of jack and set it as shown in the illustration.

N22A1450

N21C0280

EMERGENCIES 269

N22A1830

N22A0010

7. Remove the wheel nut wrench and bar from the tool bag (located inside the trunk).

8. Insert the bar (E) into the wheel nut wrench (F). Then attach the end of the bar to the jack end, as shown in the illustration. Slowly rotate the wheel nut wrench until the tire is slightly raised off the ground surface.

270 EMERGENCIES

WARNING!

† Before using the jack, chock or block the wheel that is tire diagonally opposite the jacking point. † Stop jacking up the vehicle when the tire is raised off the ground. It is dangerous to raise the vehicle any higher. † Do not get under the vehicle while using the jack. † Avoid jarring the raised vehicle or leaving it supported on the jack for extended periods. Both are very dangerous. † Do not use a jack other than the one provided † The jack should not be used for any purpose other † No one should stay in the vehicle while the jack is † Do not start or run the engine while the vehicle is

than changing a tire.

with your vehicle.

used.

on the jack.

NOTE: Place the spare wheel under the vehicle body near the jack; this helps to minimize danger should the jack slip out of position.

N24A1500

EMERGENCIES 271

Tapered nut

Flange nut

N24A0210

N24A1410

9. Remove the wheel nuts with the wheel nut wrench, then take the wheel off.

CAUTION!

Handle the wheel cover carefully when replacing the flat to avoid the wheel surface becoming scratched and causing premature corrosion.

tire,

NOTE: Clear out any mud, etc. on the hub surface, hub bolts or in the installation holes in the wheel. 10. Install the spare wheel with the nut’s tapered end facing inward, then tighten by hand until the wheel is no longer loose.

272 EMERGENCIES

CAUTION!

Never apply oil to either wheel bolts or nuts as it can cause them to overtighten.

NOTE: Flange nuts can be temporarily used on the steel wheel, but return to the original wheel and tire as soon as possible. If all four wheels are changed to steel wheels, use tapered nuts.

11. Lower the vehicle slowly and then tighten the nuts in the sequence shown in the illustration until each nut has been tightened to the specified torque.

N24A0220

88 to 108 N•m (65 to 80 ft lb)

EMERGENCIES 273

CAUTION!

Never use extra force with your foot on the wheel nut wrench or a pipe extension as you can over- tighten the nut.

12. Lower and remove the jack, and store the jack, flat tire and chock. Have the damaged tire repaired as soon as possible.

13. Check tire inflation pressure. Tire inflation pressure specifications are shown on a placard located on the driver’s side ‘‘B’’-Pillar.

N24A1420

274 EMERGENCIES

CAUTION!

† The emergency tire is to be used only temporarily when the standard tire is damaged. Repair the damaged tire as soon as possible. Replace the emergency tire with the standard tire. † After changing the tire and driving the vehicle approximately 621 miles (1000 km), retighten the wheel nuts to make sure that they are not loose. † If the steering wheel vibrates after changing the tire, have the tire checked for balance at an autho- rized dealer. † Avoid mixing one type of tire with another type or using tires of a size other than the specified size. Premature mechanical wear and reduced handling may result.

ENGINE OVERHEATING If the engine coolant temperature gauge indicator enters the “H” (hot) position, the engine may be overheated. In any of the following situations, you can reduce the potential for overheating by taking the appropriate ac- tion. † On the highways — Slow down. † In city traffic — While stopped, put transaxle in

neutral, but do not increase engine idle speed.

NOTE: There are steps that you can take to slow down an impending overheat condition. If your air conditioner is on, turn it off. The air conditioning system adds heat to the engine cooling system and turning off the A/C removes this heat. You can also turn the Temperature control to maximum heat, the Mode control to floor, and the fan control to High. This allows the heater core to act as a supplement to the radiator and aids in removing heat from the engine cooling system.

CAUTION!

Driving with a hot cooling system could damage your vehicle. If temperature gauge reads “H”, pull over and stop the vehicle. Idle the vehicle with the air conditioner turned off until the pointer drops back into the normal range. If the pointer remains on the “H”, turn the engine off immediately, and call for service.

WARNING!

A hot engine cooling system is dangerous. You or others could be badly burned by steam or boiling coolant. You may want to call a service center if your vehicle overheats. If you decide to look under the hood yourself, see Maintenance Section of this manual. Follow the warnings under the Cooling System Pressure Cap paragraph.

EMERGENCIES 275

WARNING!

† When working near the radiator cooling fan, dis- connect the fan motor lead or turn the ignition key to the OFF position. The fan is temperature con- trolled and can start at any time the ignition key is in the ON position. † You or others can be badly burned by hot coolant or steam from your radiator. If you see or hear steam coming from under the hood, don’t open the hood until the radiator has had time to cool. Never try to open a cooling system pressure cap when the radiator is hot.

JUMP-STARTING THE ENGINE If the engine cannot be started because the battery is weak or dead, the battery from another vehicle can be used with booster cables to start the engine.

276 EMERGENCIES

WARNING!

connection. You wouldn’t be able to start your vehicle, and the bad ground could damage the electrical systems.

When using jumper cables to start a vehicle, follow procedures exactly and exercise extreme caution.

CAUTION!

Do not try to start your vehicle by pushing or towing. Vehicles equipped with an automatic transaxle can- not be started this way. Pushing or towing a vehicle equipped with a manual transaxle may overheat and damage the catalytic converter. Also, there is a greater risk of an accident when a vehicle is being pushed or towed.

1. Remove any metal jewelry such as watch bands or bracelets that might make an inadvertent electrical con- tact. 2. Position the vehicles close enough together so the booster cables can reach, but be sure the vehicles aren’t touching each other. If they are, it could cause a ground

CAUTION!

Check the other vehicle. It must have a 12-volt battery. If the other system isn’t 12-volts, both sys- tems can be damaged.

3. You could be injured if the vehicles move. Set the parking brake firmly on each vehicle. Put an automatic transaxle in “P” (PARK) or a manual transaxle in “N” (Neutral). Turn the ignition key to the “LOCK” position.

WARNING!

Turn the ignition key to the “LOCK” position on both vehicles. Use care to make sure that the cables or your clothes are never caught by the fan or drive belt. Personal injury could result.

NOTE: Turn off all lights, heater and other electrical loads. This will avoid sparks and help save both batter- ies. 4. Make sure battery electrolyte is at the proper level. (See “Battery” on page 317.)

WARNING!

If electrolyte fluid is not visible, or appears to be frozen, do not attempt jump starting. The battery might rupture or explode if the tempera- ture is below the freezing point or if it is not filled to the proper level.

EMERGENCIES 277

N29A0790

278 EMERGENCIES

6. Connect one end of the other jumper cable to the negative (-) terminal of the booster battery (B), and the other end to the engine block of the vehicle with the discharged battery (A) at the point farthest from the battery.

N29A1070

5. Connect one end of one booster cable to the positive (+) terminal of the discharged battery (A), and the other end to the positive (+) terminal of the booster battery (B). NOTE: Remove the terminal cover before connecting the booster cable to the positive terminal of the battery. Use the proper cables suitable for the battery size. Otherwise heat damage to the cables could result. Check the booster cables for damage and corrosion before use.

WARNING!

! › ! fi ! fl

† Be sure to observe the connecting sequence of ‹ † Make sure that the connection fl

is made to the engine properly. If the connection is directly made to the negative side of the battery, the flammable gases generated from the battery might catch fire and explode. † When connecting the booster cable, do not con- nect the positive (+) cable to the negative (-) terminal. Otherwise sparks might cause explosion of the battery. † Use care not to have the booster cable caught in the cooling fan or other rotating parts in the engine compartment.

7. Start the engine in the vehicle which has the booster battery, let the engine idle a few minutes, then start the engine in the vehicle with the discharged battery. 8. After the engine is started, disconnect the cables in the reverse order.

EMERGENCIES 279

WARNING!

† Charging the battery installed in the vehicle might cause the battery to catch fire and explode. Or, damage to the vehicle could result. If it has to be charged in that condition for unavoidable reasons, disconnect the vehicle side negative lead. † Keep sparks, cigarettes and flames away from the battery because the battery may produce an explosion. † Use adequate ventilation when charging or using † Remove all the caps before charging the battery. † Electrolyte (battery acid) is corrosive diluted sulfuric acid. If electrolyte comes in contact with your hands, eyes, clothes, or the painted surface of your vehicle, thoroughly flush with water. If electrolyte gets in your eyes, flush them thoroughly with water imme- diately, and get prompt medical attention.

the battery in an enclosed space.

280 EMERGENCIES

WARNING!

† Always wear protective clothing and goggles † Keep the battery out of the reach of children.

when working near the battery.

If your vehicle has anti-lock brakes If the vehicle is driven without sufficient battery charge, after the engine has been started by using booster cables, the engine may misfire. This can cause the anti-lock braking system warning light to blink on and off. This is a result of insufficient battery voltage; it is not a malfunc- tion of the brake system. If this happens, fully charge the battery before driving.

TOWING When towing your vehicle, all state and local regulations for towing must be followed. Incorrect towing equipment could damage your vehicle. When towing is required, contact a professional towing service and make sure that flat bed type, dolly type or wheel lift type towing equipment is used. Do not attempt to be towed by another vehicle with a rope using the tie-down hooks.

CAUTION!

purposes.

† Tie-down hooks should never be used for towing † This vehicle can NOT be towed by a tow truck using sling lift type equipment. This is to prevent the bumper from deformation. If this vehicle is towed, use wheel lift, dolly type or flat bed equipment. † Use the flat bed type, dolly type or dolly type equipment if a vehicle has the following condi- tions: • Any of the transaxle, axles, steering system or • Automatic transaxle fluid level is low.

power train is damaged.

Sling lift type

Flat bed type

Dolly type

Wheel lift type

Front wheel lift

Rear wheel lift

EMERGENCIES 281

CAUTION!

† Towing should only be done by a professional tow service particularly if it will involve towing on winding roads, hills or heavy traffic. If you have any doubts, use a professional tow service.

Towing—front wheel lift Place the gearshift lever (manual transaxle) to Neutral or the selector lever (automatic transaxle) in the “N” (NEU- TRAL) position. Release the parking brake. Towing—rear wheel lift Turn the ignition key to the “ACC” position and secure the steering wheel in a straight-ahead position with a rope or similar device. Never place the ignition key in the “LOCK” position. This will result in damage to the steering lock mechanism. If you have to tow an automatic transaxle model with the rear wheels raised (with the front wheels on the ground): Observe the following restricted towing speeds and distances. • Speed: 30 mph (50 km/h) • Distance: 18 miles (30 km)

N25A0202

282 EMERGENCIES

CAUTION!

Never tow an automatic transaxle model with the rear wheels raised (with the front wheels on the ground) when the automatic transaxle fluid level is low. This may cause serious and expensive damage to the transaxle.

FUSES Passenger compartment

Fuse block To prevent damage to the electrical system due to short- circuiting or overloading, each individual circuit is pro- vided with a fuse. There are fuse blocks in the passenger compartment and in the engine compartment. The fuse block in the passenger compartment is located on the driver’s side at the position shown in the illustration.

N09A1230

In the engine compartment, the fuse block is located as shown in the illustration.

N09A1880

FUSIBLE LINKS Fusible links will melt to prevent a fire in the event that a large current flows through a system protected by a fusible link. In case of a melted fusible link, see your authorized dealer for inspection and replacement.

Fuse load capacities

EMERGENCIES 283

N29C0322

The fuse cover lists the names of the electrical systems and the fuse capacities. Spare fuses are contained in the

284 EMERGENCIES

—

Capacity

SOCKET Accessory socket

Audio — Sunroof

cover of the instrument panel (driver’s side). Always use a fuse of the same capacity for replacement. Passenger compartment fuse location Fuse location table No. Symbol Electrical system 10

11

12

13

14Rear window defogger Heater — —

Door lock Rear window wiper — Relay Electric remote-controlled outside mirror — Cigarette lighter

— — SOCKET Accessory socket

20A — 20A 15A 30A 30A — — 15A 15A 15A 15A 7.5A 7.5A

—

15

16— 15A

R/C MIR

—

No. Symbol Electrical system 17

18

19

20

21

22

23

24Engine Control Windshield wiper Door mirror heater Relay Cruise control Back up light Gauge Engine control

CRUISE

25

—

Spare fuse

Capacity

7.5A 20A 7.5A 7.5A 7.5A 7.5A 7.5A 10A 30A 20A 15A 10A

I Some fuses may not be installed on your vehicles, depending on the vehicle model or specifications. I The table above shows the main equipment corre- sponding to each fuse.

Spare fuse location Spare fuses are contained in the cover of the instru- ment panel (driver’s side). Always use a fuse of the same capacity for replacement.

EMERGENCIES 285

Engine compartment Fuse location table

Engine compartment fuse location

N29B2642

286 EMERGENCIES

No. 10

11

12

13

14

15

16

17

18

19

20

21Symbol

Electrical system Fuse (+B) Radiator fan motor Anti-lock braking system Ignition switch Electric window controls Fog lights

—

—

Horn Engine control Air conditioning Stop lights — Alternator Hazard warning flasher Automatic transaxle Headlights high beam (right) Headlights high beam (left) Headlights low beam (right) Headlights low beam (left) Position lights (right) Position lights (left)

Capacity 60A 50A 60A 40A 30A 15A — 15A 20A 10A 15A — 7.5A 10A 20A 10A 10A 10A 10A 7.5A 7.5A

No. 22

23

24

25Symbol

Electrical system Dome lights Audio Fuel pump Defroster

Capacity 10A 10A 15A 40A

† Some fuses may not be installed on your vehicle. Fuse application depends on the vehicle model, specifica- tions, or options.

7.5A 10A 15A 20A 30A 40A 50A 60A

BROWN

RED

LIGHT BLUE

YELLOW GREEN GREEN

RED

YELLOW

Fuse replacement

EMERGENCIES 287

OK

Blown fuse

N29C0020

1. Before replacing a fuse, always turn off the electrical item concerned and turn the ignition key to the “LOCK” position. 2. Remove the fuse cover. 3. Referring to the fuse location diagrams and corre- sponding tables, check the fuse that relates to the prob- lem.

N29C0200

4. There is a fuse puller in the cover of the instrument panel (driver’s side). Remove the fuse puller, clamp it on the fuse you wish to remove, and pull the fuse straight out from the fuse block. If the fuse is not blown, some- thing else must be causing the problem; contact an authorized dealer to have the problem checked.

288 EMERGENCIES

5. Insert a new fuse of the same capacity securely into the fuse block location.

N29C0010

CAUTION!

† Never use a fuse with a capacity larger than that specified or any substitute, such as wire, foil, etc. Doing so will cause the circuit wiring to heat up and could cause a fire. † If the newly inserted fuse blows again after a short time, have the electrical system checked by an authorized dealer to find and correct the cause.

REPLACEMENT OF LIGHT BULBS Before replacing a bulb, be sure the light is off. Do not touch the glass part of the new bulb with your bare fingers; the skin oil left on the glass will evaporate when the bulb gets hot and the vapor will condense on the reflector and dim the surface. Bulb capacity A bulb should only be replaced with a new bulb of the same rating and type. The designation can be found on the base of the bulb.

EMERGENCIES 289

N10B2800

N10B2810

Outside

Description

1 - Headlight (Type 1)

2 - Headlight (Type 2)

3 - Front side marker light 4 - Front turn signal and

parking light

5 - Front fog light

Wattage or

Candela Power

ANSI Trade No.

or Bulb type

60W

51W

1.5cp 2.2cp

37.5W

9005 X/S (HB3A) 9006 X/S (HB4A) 194NA NAk

896

Description

6 - High-mounted stop

light

7 - Stop and tail light 8 - Back up light 9 - Rear turn signal light 10 - Rear side marker light 11 - License plate light

Wattage or

Candela Power

ANSI Trade No.

or Bulb type

18W (W16W)

32/3cp 18W 32cp 3cp 3cp

—

1157

9211156NA

168

168290 EMERGENCIES

Inside

Description

Dome Light Rear personal light Trunk light Reading light

Wattage or

Candela Power

10W 8W 5W 4W

Headlights (Type 1)

1. Turn the light socket counterclockwise and pull it out and remove the light bulb.

N10C1910

2. Pull the clip (A) and remove the light bulb from the socket.

Headlights (Type 2)

1. Loosen the bolt (A), move the horn (B) (left side only).

EMERGENCIES 291

N10C1920

N10C1760

292 EMERGENCIES

2. Turn the light socket counterclockwise and pull it out and remove the light bulb.

3. Pull the clip (A) and remove the light bulb from the socket.

N10C1930

N10C1940

CAUTION!

† Never hold the halogen light bulb with a bare hand, dirty glove, etc. The oil from your hand could cause the bulb to break the next time the headlights are operated. If the glass surface is dirty, it should be cleaned with alcohol and installed after drying thor- oughly.

EMERGENCIES 293

Adjustment of headlight aim The alignment of the headlights should be checked by an authorized dealer. Front turn signal and parking lights

N10F0760

Turn the light socket counterclockwise and pull it out and remove the light bulb.

N10C1840

294 EMERGENCIES

Front side marker lights

Front fog lights 1. Turn the front turn signal light socket counterclock- wise.

Turn the light socket counterclockwise and pull it out and remove the light bulb.

N10D0170

N10F0760

2. Turn the light socket counterclockwise and pull it out.

3. Pull both clips away from the center as shown and remove the bulb from the socket by pulling out.

EMERGENCIES 295

N10X1650

N10C1700

296 EMERGENCIES

CAUTION!

† Never hold the halogen light bulb with a bare hand, dirty glove, etc. The oil from your hand could cause the bulb to break the next time the fog lights are operated. If the glass surface is dirty, it should be cleaned with alcohol and installed after drying thor- oughly.

Rear combination lights 1. Turn the trim cover clip (A) counterclockwise and remove the trim cover clip. Partially remove the trim cover in the trunk.

N20I0170

N10C1840

2. Remove the light case mounting nuts. Disconnect the connector.

Remove the bulb from the socket by turning it counter- clockwise while pressing it inward.

EMERGENCIES 297

3. Slide the light unit outward to remove it. Remove each bulb socket assembly by turning it counterclockwise.

N20I0160

A - Stop and tail light B - Rear turn signal light C - Back up light D - Rear side marker light

N20I0100

298 EMERGENCIES

High-mounted stop light

License plate light

Remove the socket assembly and bulb together by turn- ing it counterclockwise. Remove the bulb from the socket by pulling out.

Remove the lens mounting screws, remove the socket assembly and the bulb together by turning it counter- clockwise. And remove the bulb by pulling out.

N10V0700

N10J0310

Trunk light

EMERGENCIES 299

Dome light 1. Insert a flat blade screwdriver into the notch of the light assembly and pry gently downward to remove it. Type 1

Clips

Pull both clips away from the center as shown and remove the light unit. Then remove the bulb by pulling out.

N10O0230

N10M0380

NOTE: Wrap a cloth around the tip of the screwdriver to avoid scratching the light assembly.

300 EMERGENCIES

2. Remove the light bulb from the light holder.

Reading lights

N10M0410

N11I0040

Insert a straight blade screwdriver into the notch of the light assembly and pry gently to remove the lens. Remove the light bulb from the light holder. NOTE: Wrap a cloth around the tip of the straight blade screwdriver in order to avoid scratching the lens.

Rear personal light

EMERGENCIES 301

N10Q0090

Insert the tip of a flat blade screwdriver at the edge of the lens, pry gently to remove the lens, and then remove the bulb from the light holder. NOTE: Wrap a cloth around the tip of the screwdriver in order to avoid scratching the lens.

MAINTENANCE

CONTENTS m View of engine compartment . . . . . . . . . . . . . . 305

m Service precautions . . . . . . . . . . . . . . . . . . . . . 306

m Emission-control system maintenance . . . . . . . 307

m Emissions Testing . . . . . . . . . . . . . . . . . . . . . . 308

m Onboard Diagnostic System (OBD II) . . . . . . . . 308

m Replacement Parts . . . . . . . . . . . . . . . . . . . . . . 309N Fuel system (tank, filler tube, connections,

and fuel tank filler cap) . . . . . . . . . . . . . . . . . 309

N Fuel hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

N Air cleaner filter . . . . . . . . . . . . . . . . . . . . . . 310

N Evaporative emission control system(except evaporative emission canister) . . . . . . . 310

N Spark plugs. . . . . . . . . . . . . . . . . . . . . . . . . . 311

N Ignition cables . . . . . . . . . . . . . . . . . . . . . . . . 311N Distributor cap and rotor . . . . . . . . . . . . . . . . 311

m General maintenance . . . . . . . . . . . . . . . . . . . . 312

N Engine oil and oil filter. . . . . . . . . . . . . . . . . . 312

m Engine coolant. . . . . . . . . . . . . . . . . . . . . . . . . 316

N To check the coolant level . . . . . . . . . . . . . . . . 316

N To add coolant. . . . . . . . . . . . . . . . . . . . . . . . 316

m Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

m Clutch fluid (manual transaxle) . . . . . . . . . . . . 318

N To check the clutch fluid. . . . . . . . . . . . . . . . . 318

N To replace the fluid . . . . . . . . . . . . . . . . . . . . 318

m Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

N During cold weather . . . . . . . . . . . . . . . . . . . 319304 MAINTENANCE

N Disconnection and connection . . . . . . . . . . . . . 319

m Automatic transaxle. . . . . . . . . . . . . . . . . . . . . 321

N To check the fluid level. . . . . . . . . . . . . . . . . . 322

N Procedure for checking the fluid level . . . . . . . 322

m Manual transaxle. . . . . . . . . . . . . . . . . . . . . . . 323

m Disc brake pads, rear drum brake liningsand rear wheel cylinders . . . . . . . . . . . . . . . . . 323

m Brake hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

m Ball joint, steering linkage seal and driveshaft boots . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

m Supplemental Restraint System (SRS) . . . . . . . . 323

m Door hinges, rear hatch hinges, hood lockrelease mechanism and safety catch . . . . . . . . . 324

m Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . 324

m Windshield wiper blades . . . . . . . . . . . . . . . . . 325

N Windshield washers . . . . . . . . . . . . . . . . . . . . 325

m Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . 326m Drive belt (for generator, water pump, power

steering pump) . . . . . . . . . . . . . . . . . . . . . . . . 327

m Timing belt . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

m Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

N Tire inflation pressures . . . . . . . . . . . . . . . . . . 328

N Radial ply tires . . . . . . . . . . . . . . . . . . . . . . . 330

N Tire pressure for sustained high-speed driving . . . 330

N Oversize tires . . . . . . . . . . . . . . . . . . . . . . . . 330

N Tire maintenance . . . . . . . . . . . . . . . . . . . . . . 331

N Cargo loads. . . . . . . . . . . . . . . . . . . . . . . . . . 331

N Tread wear indicators . . . . . . . . . . . . . . . . . . . 331

N Tire rotation . . . . . . . . . . . . . . . . . . . . . . . . . 332

N Tire chains. . . . . . . . . . . . . . . . . . . . . . . . . . . 333

N Snow tires . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

m Regular Maintenance Schedule. . . . . . . . . . . . . 334

m Severe Maintenance Schedule. . . . . . . . . . . . . . 343VIEW OF ENGINE COMPARTMENT 2.4 liter engine

MAINTENANCE 305

7. Brake fluid reservoir 8. Windshield washer reservoir 9. Drive belt 10. Radiator cap 11. Automatic transaxle fluid level dipstick 12. Air cleaner filter

3.0 liter engine

Q02A2510

1. Power steering fluid reservoir 2. Engine coolant reservoir 3. Engine oil filler cap 4. Engine oil level dipstick 5. Battery 6. Clutch fluid reservoir (manual transaxle only)

Q02A2520

306 MAINTENANCE

NOTE: The Scheduled Maintenance Charts are located in the rear of this maintenance section. Always refer to the schedules for proper service intervals.

SERVICE PRECAUTIONS Adequate care of your vehicle at regular intervals serves to preserve the value and appearance as long as possible. Some maintenance items can be performed by the owner, while others should be done only by an authorized dealer. This section describes only those items which can be performed by the owner. In the event a malfunction or other problem is discovered, have it corrected by an authorized dealer. This section contains information on inspection mainte- nance procedures that you can do yourself, if you so desire. Follow the instructions and precautions for each of the various procedures.

WARNING!

† When checking or servicing the inside of the engine compartment, be sure the engine is stopped and has had a chance to cool down. † If it is necessary to do work in the engine com- partment with the engine running, be especially careful that your clothing, hair, etc. does not become caught by the fan, drive belts, or other moving parts.

WARNING!

† The fan may turn on automatically even if the engine is not running; turn the ignition key to the “LOCK” position and remove the key to ensure safety while you work in the engine compartment. † Do not smoke, or allow open flames around fuel † Be extremely cautious when working around the battery. It contains poisonous and corrosive sulfu- ric acid. † Do not get under your vehicle with just the car’s

or the battery. The fumes are flammable.

jack supporting it. Always use properly rated automotive jack stands. † Improper handling of components and materials used in the vehicle can endanger your personal safety. Consult an authorized dealer if you have questions.

MAINTENANCE 307

EMISSION-CONTROL SYSTEM MAINTENANCE Your vehicle is equipped with an emission-control sys- tem which satisfies all requirements of the U.S. Environ- mental Protection Agency. The emission-control system consists of: (1) a positive crankcase ventilation system (2) an evaporative emission-control system (3) an exhaust emission- control system. The 9Scheduled9 maintenance services listed must be performed at the times or mileages specified to assure the continued proper functioning of the emission-control system. These, and all other “General” maintenance services included in this manual, should be performed to provide the best vehicle performance and reliability. More frequent maintenance may be needed for vehicles driven under severe operating conditions such as dusty areas and frequent start and stop driving. In order to assure the proper function of the emission- control system, it is recommended that you have your vehicle inspected and maintained by an authorized dealer in accordance with the schedule in this manual. Inspection and service should also be performed any time a malfunction is suspected.

308 MAINTENANCE

EMISSIONS TESTING In some localities, it may be or will become a legal requirement to ensure that all emissions components and systems are functioning properly as a part of the test procedure. The test center accomplishes this by checking the On Board Diagnostic System system (OBD) with an electronic scan tool. If your vehicle has recently been serviced, the OBD system may have been reset to a 9not ready9 condition because the OBD system has not had sufficient time since the servicing to reconfirm that emissions components are operating properly. In most cases, a reasonable mix and amount of normal city and highway driving and at least one overnight-off period will be required to prepare your vehicle for this check; however your DaimlerChrysler Motors Corporation dealer has the equipment and procedures required to make certain that the OBD system of your vehicle is ready for the required testing.

ONBOARD DIAGNOSTIC SYSTEM (OBD II) To meet new government regulations and promote cleaner air, your vehicle is equipped with a sophisticated onboard diagnostic system called OBD II. This system

monitors the performance of the emissions, engine, and automatic transaxle control systems. When these systems are operating properly, your vehicle will provide excel- lent performance and fuel economy, as well as engine emissions well within current government regulations. If any of these systems require service, the OBD II system will turn on the Malfunction Indicator Light. It will also store diagnostic codes and other information to assist your service technician in making repairs. Al- though your vehicle will usually be driveable and not need towing, see your dealer for service as soon as possible.

CAUTION!

Prolonged driving with the light on could cause further damage to the emission control system. It could also affect fuel economy and driveability. The vehicle must be serviced before any state emissions tests can be performed.

If the light is flashing, severe catalytic converter damage and power loss will soon occur. Immediate service is required. If the gas cap is not tightened properly, the light may come on. Be sure the gas cap is tightened every time you add fuel. Tighten the cap until you hear it “click.”

REPLACEMENT PARTS Use of genuine Mopar parts for normal/scheduled main- tenance and repairs is highly recommended to insure the designed performance. Damage or failures caused by the use of non-Mopar parts for maintenance and repairs will not be covered by the DaimlerChrysler Motors Corpora- tion warranty. Fuel system (tank, filler tube, connections, and fuel tank filler cap) Check periodically for damage or leakage in the fuel lines and connections, and check for damage and looseness of the fuel tank filler tube cap. Particular attention should be paid to examining those fuel lines nearest to high heat sources such as the exhaust manifold.

MAINTENANCE 309

WARNING!

If you see a fuel leak or if you smell fuel, do not operate the vehicle. Any spark (including from the ignition ), flame or smoking material could cause an explosion or fire. Call an authorized dealer for assistance.

Fuel hoses Inspect the surfaces of hoses for evidence of heat and mechanical damage, hard and brittle rubber, cracking, tears, cuts and abrasions. Particular attention should be paid to examining those hose surfaces nearest to high heat sources such as the exhaust manifold. Inspect all hose connections, such as clamps and couplings, to make sure they are secure and that no leaks exist. If there is any evidence of deterioration or damage, hoses should be replaced immediately.

310 MAINTENANCE

Air cleaner filter

M23A0130

The air cleaner filter will become dirty and loaded with dust during use, and the filtering effect will be substan- tially reduced. Replace it with a new filter in accordance with the schedule in this manual. 1. Unclamp the air cleaner cover. 2. Take out the air cleaner filter.

After replacing the air cleaner filter, reinstall the cover in its original position.

CAUTION!

Take care not to damage the engine air flow sensor when removing the air cleaner cover.

Evaporative emission control system (except evaporative emission canister) If the fuel-vapor vent line is clogged or damaged, the fuel-vapor mixture will escape, polluting the atmosphere. Have the system checked at an authorized dealer at the mileage specified on the scheduled maintenance chart.

Spark plugs

Iridium tipped type

P15A0340

Spark plugs must fire properly to assure proper engine performance and emission-control. Do not reuse spark plugs by cleaning or regapping. Spark plugs should be replaced at the mileage specified on the scheduled maintenance chart. Your vehicle may be equipped with standard type spark plugs or iridium tipped ones. Iridium tipped spark plugs are identified by blue marks on the ceramic. They do not

MAINTENANCE 311

require replacement as frequently as the conventional type spark plug and are designed to last much longer. NOTE: Use the recommended or equivalent spark plugs listed under “Engine specifications” on page 361. Use of non-recommended plugs will cause engine dam- age, loss of performance or radio noise. Ignition cables The ignition cables should be kept clean, properly con- nected, and fully seated. Terminals should be fully seated and should not be removed from the distributor or coil towers unless they are damaged or cable testing indicates high resistance or broken insulation. Cracked, damaged, or faulty cables must be replaced. Distributor cap and rotor Check the distributor cap and rotor to maintain proper function and good emission control.

Engine oil and oil filter 2.4 liter engine

Good

312 MAINTENANCE

GENERAL MAINTENANCE The following pages contain the maintenance service recommended by DaimlerChrysler. In addition to the general maintenance items for which fixed maintenance intervals have been specified, there are other items which are expected to operate satisfactorily without periodic maintenance. However, if a malfunction of these items does occur, it could adversely affect the engine or vehicle performance. These items should be inspected if a malfunction is observed or suspected. See your authorized dealer for assistance, if you have any questions.

M03A0700

3.0 liter engine Good

M03A0710

To check and refill engine oil It is normal for an engine to consume some oil. You may find it necessary to add oil between the recommended oil change intervals. Before starting the engine, check the engine oil level. Replenish if necessary. To check the oil level, remove the dipstick, wipe it off, and gently insert it fully into the crankcase. Slowly remove it again. The oil level must not exceed the range of “Good” on the dipstick.

MAINTENANCE 313

NOTE: The engine must be “OFF” when performing oil level checks. If the level does not reach the range of “Good”, which indicates minimum necessary quantity of oil, remove the oil filler cap on the engine valve cover, and refill to within the “Good” range.

CAUTION!

Overfilling the crankcase will cause oil aeration and loss of oil pressure, which could damage the engine.

WARNING!

† Used engine oil is contaminated, and can cause skin problems: Avoid contact with the skin and wash thoroughly after working with used oil.

† Keep used oil out of reach of children.

314 MAINTENANCE

To replace the oil filter The oil filter should be replaced at the time or mileage specified on the scheduled maintenance chart. You should be sure that any replacement filter used on this vehicle is a high quality filter. The manufacturer’s specifications for Genuine DaimlerChrysler oil filters require that the filter be capable of withstanding a pressure of 256 psi (1.8MPa). A Genuine DaimlerChrysler oil filter is recommended as a replacement filter. Follow the installation instructions printed on the filter.

Engine oil identification mark ILSAC certification mark (“Starburst” symbol)

Use only engine oils displaying the ILSAC certification symbol on the front of the container.

M03A0150

API service symbol

Recommended engine oil viscosity

MAINTENANCE 315

M03A1320

If you are unable to find oils with the ILSAC certification mark (“Starburst” symbol), an API classification SL, SL/CF oil with above label may be used. This mark appears on the top of the oil containers and has three distinct areas for identifying various aspects of the oil. 1. The top portion will indicate the quality of the oil. 2. The center portion will show the SAE grade of the oil viscosity.

M03B0010

Use engine oil with proper thickness for the outdoor temperature where you will be driving. SAE 5W-30 engine oil is best for the outdoor temperature range shown in the above chart. You are strongly encouraged to use SAE 5W-30 engine oils to aid in low temperature starting and for improved fuel economy.

316 MAINTENANCE

ENGINE COOLANT

To check the coolant level The coolant reserve system provides a quick visual method for determining the coolant level. When the engine is cold, the level of the coolant in the reserve tank should be between the FULL and LOW marks. The radiator normally remains completely full so there is no need to remove the radiator cap except for checking the coolant freeze point or replacing the antifreeze coolant. To add coolant Use DaimlerChrysler Genuine Coolant or an equivalent. Genuine Coolant provides excellent protection against corrosion and rust formation of all metals, including aluminum, and prevents clogs in the radiator, heater, cylinder head, engine block, etc. If frequent coolant additions are required, or if the level in the reserve tank does not drop when the engine cools, the system should be pressure-tested for leaks. Take your vehicle to an authorized dealer for inspection of the cooling system.

CAUTION!

† Do not use alcohol or methanol anti-freeze or any engine coolants mixed with alcohol or methanol anti-freeze. The use of an improper anti-freeze can cause corrosion of aluminum components. † When additional coolant is needed to maintain the proper level, a minimum of 50% concentration of ethylene-glycol antifreeze in water should be added to the reserve tank. Do not overfill. A higher concentration (not to exceed 60%) should be used if a lower freezing point is required. The concentration level can be checked using instru- ments available at automotive supply stores, or can be done by your authorized dealer or service station. Use only high quality ethylene-glycol antifreeze coolant formulated to prevent corrosion of all cooling system metals. † Do not top off with water only. Water by itself reduces the rust-protective and anti-freeze quali- ties of the coolant and has a lower boiling point. It can also cause damage to the cooling system if it should freeze. Do not use tap water, as it may cause corrosion and rust formation.

Radiator cap The radiator cap must be fully tightened to prevent loss of coolant and engine damage.

WARNING!

Make sure that the engine is thoroughly cooled down before removing the radiator cap, otherwise hot steam or boiling coolant may gush from the filler port and scald you.

Points to remember 1. Do not overfill the reserve tank. 2. A special radiator cap is used to ensure sealing and to allow the coolant to return from the reserve tank to the radiator when the engine cools. If cap replacement is necessary, use the proper cap. 3. Check the coolant freeze point in the radiator using proper instruments, when it is safe to do so. If antifreeze is added, the contents of the reserve tank must be protected against freezing. 4. Keep the front of the radiator clean. If your vehicle is equipped with air conditioning, keep the front of the condenser clean.

MAINTENANCE 317

If the temperature of the engine coolant does not rise 5. normally after engine warm-up, take the vehicle to an authorized dealer to have the thermostat checked, and replaced if necessary.

BRAKE FLUID Recommended brake fluid conforming to DOT 3 or DOT 4

should be used. The reservoir cap must be fully tightened to avoid contamination from foreign matter or moisture.CAUTION!

damage to painted surfaces.

† Do not allow petroleum-based fluid to contact, mix with, or otherwise contaminate the brake fluid. Seal damage will result. † Take care in handling brake fluid as it may cause † Use only the specified brake fluid. Also, the additives in different brands may result in a chemical reaction when mixed together, so avoid mixing different brands if possible. † Keep the reservoir tank cap closed to prevent the brake fluid from evaporating or absorbing moisture.

318 MAINTENANCE

CLUTCH FLUID (MANUAL TRANSAXLE)

Good

M10A0040

To check the clutch fluid The clutch fluid in the clutch master cylinder should be checked when performing other underhood services. In addition, the system should be checked for leakage at the same time. Check to make certain that the clutch fluid level is always between the MAX and MIN level mark- ings on the fluid reservoir and refill the fluid, if necessary. A rapid fluid loss indicates a leak in the clutch system which should be inspected by an authorized dealer and repaired immediately.

To replace the fluid Recommended brake fluid conforming to DOT 3 or DOT 4

should be used. The reservoir cap must be fully tightened to avoid contami- nation from foreign matter or moisture.CAUTION!

† Do not allow petroleum-based fluid to contact, mix with, or otherwise contaminate the clutch fluid. Seal damage will result. † Take care in handling clutch fluid as it may cause † Use only the specified clutch fluid.

damage to painted surfaces.

Also, the additives in different brands may result in a chemical reaction when mixed together, so avoid mixing different brands if possible. † Keep the reservoir tank cap closed to prevent the clutch fluid from deteriorating due to moisture or air exposure.

BATTERY

Test indicator

M07B0080

The condition of the battery is very important for quick starting and proper functioning of the vehicle’s electrical system. Check the battery at regular intervals. To determine the battery charge, check the battery test indicator on top of the battery. If the test indicator is a blue/green color when viewed from above, the battery is OK. A black colored indicator

MAINTENANCE 319

means the battery is low on charge and may require charging. Have it checked at an authorized dealer. During cold weather The capacity of the battery is reduced at low tempera- tures. This is the result of its chemical and physical properties and this is why a very cold battery, particu- larly one that is not fully charged, will only deliver a fraction of the starter current that is normally available. It is recommended that you have the battery checked by an authorized dealer before the start of cold weather and, if necessary, have it charged or replaced. This not only ensures reliable starting, but prolongs battery life. Disconnection and connection To disconnect the battery cable, stop the engine, discon- nect the negative terminal first, then the positive termi- nal. To reconnect the battery, first connect the positive terminal and then the negative terminal, before starting the vehicle.

320 MAINTENANCE

WARNING!

cause it to overheat and be damaged.

† Never disconnect the battery while the engine is running; doing so could damage the vehicle’s electrical components. † Never short-circuit the battery; doing so could † Keep sparks, cigarettes and flames away from the battery because the battery may produce an explo- sion. † Electrolyte (battery acid) is corrosive diluted sul- furic acid. If electrolyte comes in contact with, your hands, eyes, clothes, or the coated surface of your vehicle, thoroughly flush the area with wa- ter. If electrolyte gets in your eyes, flush them with water immediately and get prompt medical attention.

WARNING!

battery in an enclosed space.

nect the battery cables from the vehicle.

† Ventilate the area when charging or using the † Always wear protective clothing and goggles when working with the battery, or have a skilled technician do it. † If the battery is to be quick-charged, first discon- † In order to prevent a short circuit, be sure to disconnect the negative(-) terminal first, and re- connect it last. † If the electrolyte level is very low, have the battery † Battery posts, terminals and related accessories contain lead and lead compounds. Wash hands after handling.

checked at an authorized dealer.

NOTE 1. Check each battery terminal for corrosion. If necessary, neutralize corrosion by washing with a solution of bak- ing soda and water. Apply grease to posts and clamps after cleaning or tightening. 2. Before cleaning the battery, tighten all filler port caps to prevent foreign matter from entering the battery. 3. Check to see if the battery is securely installed and cannot be moved. Also check each terminal for tightness. 4. When the vehicle is to be left unused for a long period of time, remove the battery and store it in a place where the battery fluid will not freeze. The battery should be stored only in a fully charged condition.

MAINTENANCE 321

AUTOMATIC TRANSAXLE

Good

M05A0530

The automatic transaxle should be maintained and ser- viced by an authorized dealer to obtain the best perfor- mance and maximize life. It is important that the trans- axle fluid be maintained at the level prescribed.

322 MAINTENANCE

To check the fluid level The fluid level should be checked when the engine temperature gauge indicates a normal warmed up con- dition and the fluid in the transaxle is heated to its normal operating temperature. Operation with an im- proper fluid level will greatly reduce the life of the transaxle and the fluid. Procedure for checking the fluid level 1. With the parking brake engaged and the engine idling, select each gear momentarily, ending with the selector lever in the “N” (NEUTRAL) position. 2. The fluid level should be at the HOT mark, but never above the HOT mark when the engine is at its normal warmed up condition. Add or drain as necessary to bring the fluid to this prescribed level. 3. Make certain that the dipstick cap is reseated properly to prevent dirt and water from entering the transaxle.

WARNING!

Transaxle fluid is extremely flammable and poison- ous. Do not spill fluid when adding or draining.

To add or change the fluid

Drain plug

Use only recommended Mopar ATF+4 automatic trans- mission fluid to ensure optimum transaxle performance.

M05A0460

Special additives DaimlerChrysler does not recommend the addition of any fluid additives to the transaxle.

MANUAL TRANSAXLE Add oil to maintain the proper level. Refill or change oil according to the scheduled maintenance table.

Lubricant Viscosity range

Gear Oil Classification GL-4

SAE75W-90 or 75W-85WDISC BRAKE PADS, REAR DRUM BRAKE LININGS AND REAR WHEEL CYLINDERS Proper brakes are essential to safe operation of your vehicle. Check brake pads and rear brake linings for wear, and check rear wheel cylinders for leakage. For proper braking performance, replace brake pads with original equipment type pads.

BRAKE HOSES Brake hoses and tubing should be checked for: 1. Severe surface cracking, scuffing or worn spots. If the casing of the hose is exposed by cracks or abrasions in the

MAINTENANCE 323

rubber hose cover, the hose should be replaced. Deterio- ration of the hose could cause brake failure. 2. Faulty installation may cause twisting, or wheel, tire or chassis interference.

BALL JOINT, STEERING LINKAGE SEAL AND DRIVE SHAFT BOOTS Check the following parts for damage and grease leak- age: 1. Ball joint boots of the front suspension and steering linkage 2. Bellows on both ends of the drive shaft

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) The entire SRS system must be inspected by an autho- rized dealer 10 years after the vehicle manufacture date shown on the certification label. [See “SRS servicing” on page 98.]

324 MAINTENANCE

DOOR HINGES, REAR HATCH HINGES, HOOD LOCK RELEASE MECHANISM AND SAFETY CATCH The door hinges, trunk hinges, hood lock release mecha- nism and hood safety catch should be inspected, cleaned, and lubricated as required to maintain ease of operation and to provide protection against rust and wear. Apply engine oil to door hinges, hood hinges, and trunk hinges. Apply Multipurpose Grease NLGI Grade 2 sparingly to all sliding contact areas of the hood latch and release lever. Work lubricant into the hood lock mechanism until all frictional surfaces are covered. Also, apply a film of the same lubricant to the pivot contact areas of the safety catch.

EXHAUST SYSTEM

WARNING!

Carbon monoxide gas found in the vehicle’s exhaust is poisonous. Inhalation of exhaust fumes can cause unconsciousness or death.

The best protection against carbon monoxide entry into the vehicle interior is a properly maintained engine exhaust system. Whenever a change is noticed in the sound of the exhaust system; when exhaust fumes can be detected inside the vehicle; or when the underside or rear of the vehicle is damaged, have a competent technician inspect the com- plete exhaust system and adjacent body areas for broken, damaged, deteriorated, or mispositioned parts. In addition inspect the exhaust system each time the vehicle is raised for lubrication or oil change. Replace as required. Open seams or loose connections could permit danger- ous exhaust fumes to seep into the trunk and passenger compartments. Do this service when performing underbody service. Check for any of the following conditions: 1. Check for holes or exhaust gas leakage caused by corrosion or damage. 2. Check the joints and connections for looseness or exhaust gas leakage. 3. Check the rubber hangers and brackets for damage.

Windshield washers

MAINTENANCE 325

WINDSHIELD WIPER BLADES Check the wiper blades occasionally. Periodic cleaning of the wiper blades is suggested to remove the accumula- tion of salt and road film. The wiper blade arms and glass areas should be cleaned with a sponge or cloth and a mild detergent or non-abrasive cleaner. If the blades continue to streak or smear, they should be replaced. NOTE: Do not operate wipers for long periods on dry glass; this accelerates deterioration of the rubber and could scratch the glass.

M31A0730

The windshield washer reservoir is in the engine com- partment. Check the fluid level at regular intervals and replenish the fluid if necessary. NOTE: When freezing weather is anticipated flush out the water in the reservoir by operating the pump. Fill the reservoir with windshield antifreeze (not radiator anti- freeze) and operate the system for a few seconds to flush out any residual water.

326 MAINTENANCE

PARKING BRAKE

For vehicles with rear disc brakes: You should feel the parking brake take hold between 3 to 5 clicks. Also check to see if the lever is properly engaged with the ratchet, when pulled.

I27A0100

Check the parking brake lever travel occasionally. To check, pull the lever slowly and count the number of clicks of the ratchet. For vehicles with rear drum brakes: You should feel the parking brake take hold between 5 to 7 clicks.

DRIVE BELT (FOR GENERATOR, WATER PUMP, POWER STEERING PUMP) 2.4 liter engine

Power steering pump pulley

Water pump pulley

Inspect the drive belt for evidence of cuts and cracks, and replace it if damaged. When replacing the belt with a new belt, make sure that there is no interference between the belt and other engine components. Then, check the tension of the belt at the designated point. The deflection must be within specification.

MAINTENANCE 327

Crank shaft pulley

A/C