- 2016 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2009 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2006 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2008 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2013 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2003 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2011 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2014 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

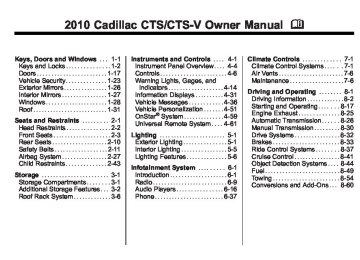

- 2010 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2015 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2005 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2004 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2012 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- 2007 Cadillac CTS Owners Manuals

- Cadillac CTS Owners Manuals

- Download PDF Manual

-

dealer/retailer when the oil is changed. See Recommended Fluids and Lubricants on page 10‑7 for the proper fluid to use.

Hydraulic Clutch It is not necessary to regularly check clutch fluid unless you suspect there is a leak in the system. Adding fluid will not correct a leak. A fluid loss in this system could indicate a problem. Have the system inspected and repaired. When to Check and What to Use

The hydraulic clutch fluid reservoir cap has this symbol on it. See Engine Compartment Overview on page 9‑6 for reservoir location.

Refer to the Maintenance Schedule for the proper fluid to use. See Recommended Fluids and Lubricants on page 10‑7 . The fluid requires changing every two years. See Scheduled Maintenance on page 10‑3 . How to Check and Add Fluid Visually check the clutch fluid reservoir to make sure the fluid level is at the MIN (minimum) line on the side of the reservoir. The hydraulic clutch fluid system should be closed and sealed. Do not remove the cap to check the fluid level or to top-off the fluid level. Remove the cap only when necessary to add the proper fluid until the level reaches the MIN line.

How to Inspect the Engine Air Cleaner/Filter To inspect the air cleaner/filter, remove the filter from the vehicle and lightly shake the filter to release loose dust and dirt. If the filter remains caked with dirt, a new filter is required. To inspect or replace the engine air cleaner/filter: 1. Turn the ignition off.

Engine Air Cleaner/Filter The engine air cleaner/filter is in the engine compartment on the driver side of the vehicle, near the front. See Engine Compartment Overview on page 9‑6 for more information on location. When to Inspect the Engine Air Cleaner/Filter Inspect the air cleaner/filter at the Maintenance II intervals and replace it at the first oil change after each 80 000 km (50,000 mile) interval. See Scheduled Maintenance on page 10‑3 for more information. If you are driving in dusty/dirty conditions, inspect the filter at each engine oil change.

Vehicle Care

9-15

3. Disconnect the electrical

connector from the air box.

4. Loosen the screw on the clamp

holding the air outlet duct in place. Do not remove the clamp. Move the duct aside.

5. Remove the hose from the air cleaner housing mounting arm. Move the hose aside.

2. Remove the side cover by

pulling up on the front of the cover.

9-16

Vehicle Care

6. Remove the three air cleaner

housing cover screws.

7. Move the air cleaner housing cover and remove the cover from the air cleaner housing.

8. Remove the air cleaner filter from the air cleaner housing.

How to Reinstall Engine Air Cleaner/Filter 1.

Install the air cleaner into the air cleaner housing. The outer air cleaner filter seal must be fitted properly in the air cleaner housing.

2. Align the air cleaner housing cover tabs to the air cleaner housing. Install the air cleaner housing cover.

3.

4.

5.

6.

Install the air cleaner housing cover screws. Install the hose to the air cleaner housing mounting arm. The hose must be routed correctly. Install the air cleaner outlet duct to the air cleaner housing.

7. Tighten the air cleaner outlet

duct screw clamp.

8. Attach the electrical connector to

the air box.

9. Reinstall the side cover.

Vehicle Care

9-17

{ WARNING

Operating the engine with the air cleaner/filter off can cause you or others to be burned. The air cleaner not only cleans the air; it helps to stop flames if the engine backfires. Use caution when working on the engine and do not drive with the air cleaner/filter off.

Notice: If the air cleaner/filter is off, dirt can easily get into the engine, which could damage it. Always have the air cleaner/filter in place when you are driving.

9-18

Vehicle Care

Cooling System The cooling system allows the engine to maintain the correct working temperature. When you decide it is safe to lift the hood, here is what you will see:

A. Electric Engine Cooling Fan(s)

(Out of View)

B. Coolant Surge Tank and

Pressure Cap

{ WARNING

An electric engine cooling fan under the hood can start up even when the engine is not running and can cause injury. Keep hands, clothing, and tools away from any underhood electric fan.

{ WARNING

Heater and radiator hoses, and other engine parts, can be very hot. Do not touch them. If you do, you can be burned. Do not run the engine if there is a leak. If you run the engine, it could lose all coolant. That could cause an engine fire, and you could be burned. Get any leak fixed before you drive the vehicle.

Notice: Using coolant other than DEX-COOL® can cause premature engine, heater core, or radiator corrosion. In addition, the engine coolant could require changing sooner, at 50 000 km (30,000 miles) or 24 months, whichever occurs first. Any repairs would not be covered by the vehicle warranty. Always use DEX-COOL® (silicate-free) coolant in the vehicle.

Engine Coolant The cooling system in the vehicle for all engines and the intercooler is filled with DEX-COOL®. This coolant is designed to remain in the vehicle for five years or 240 000 km (150,000 miles), whichever occurs first. The following explains the cooling system and how to check and add coolant when it is low. If there is a problem with engine overheating, see Engine Overheating on page 9‑23 .

What to Use

{ WARNING Adding only plain water to the cooling system can be dangerous. Plain water, or some other liquid such as alcohol, can boil before the proper coolant mixture will. The vehicle's coolant warning system is set for the proper coolant mixture. With plain water or the wrong mixture, the engine could get too hot but you would not get the overheat warning. The engine could catch fire and you or others could be burned. Use a 50/50 mixture of clean, drinkable water and DEX-COOL® coolant.

Vehicle Care

9-19

Checking Coolant The vehicle must be on a level surface when checking the coolant level. The engine coolant reservoir is located in the engine compartment on the driver side of the vehicle. See Engine Compartment Overview on page 9‑6 . Check to see if coolant is visible in the surge tank. If the coolant inside the surge tank is boiling, do not do anything else until it cools down. If coolant is visible but the coolant level is not at or above the FULL COLD mark, add a 50/50 mixture of clean, drinkable water and DEX-COOL® coolant at the coolant surge tank, but be sure the cooling system is cool before this is done. See Engine Coolant on page 9‑18

for more information.Use a 50/50 mixture of clean, drinkable water and DEX-COOL® coolant. If using this mixture, nothing else needs to be added. This mixture: . Gives freezing protection down

to −37°C (−34°F), outside temperature.

. Gives boiling protection up to

129°C (265°F), engine temperature.

. Protects against rust and

corrosion.

. Will not damage aluminum parts. . Helps keep the proper engine

temperature.

Notice: If an improper coolant mixture is used, the engine could overheat and be badly damaged. The repair cost would not be covered by the vehicle warranty. Too much water in the mixture can freeze and crack the engine, radiator, heater core, and other parts.

9-20

Vehicle Care

If the engine is warm or hot, the coolant level should be at or above the FROID/FULL COLD line on the side of the coolant surge tank. If the engine is cold, the coolant level should be near the FROID/FULL COLD line on the side of the coolant surge tank. If it is not, there could be a leak in the cooling system. How to Add Coolant to the Surge Tank

{ WARNING

You can be burned if you spill coolant on hot engine parts. Coolant contains ethylene glycol and it will burn if the engine parts are hot enough. Do not spill coolant on a hot engine.

Notice: This vehicle has a specific coolant fill procedure. Failure to follow this procedure could cause the engine to overheat and be severely damaged.

{ WARNING

An electric engine cooling fan under the hood can start up even when the engine is not running and can cause injury. Keep hands, clothing, and tools away from any underhood electric fan.

{ WARNING

Steam and scalding liquids from a hot cooling system can blow out and burn you badly. They are under pressure, and if you turn the surge tank pressure cap — even a little — they can come out at high speed. Never turn the cap when the cooling system, including the surge tank pressure cap, is hot. Wait for the cooling system and surge tank pressure cap to cool if you ever have to turn the pressure cap.

If coolant is needed, add the proper DEX-COOL® coolant mixture at the coolant surge tank. If no coolant is visible in the surge tank, add coolant as follows: 1. Remove the coolant surge tank pressure cap when the cooling system, including the coolant surge tank pressure cap and upper radiator hose, is no longer hot. Turn the pressure cap slowly counterclockwise about one-quarter turn and then stop. If you hear a hiss, wait for that to stop. A hiss means there is still some pressure left.

Vehicle Care

9-21

By this time, the coolant level inside the coolant surge tank may be lower. If the level is lower, add more of the proper mixture to the coolant surge tank until the level reaches the FROID/FULL COLD line on the side of the coolant surge tank. 5. Then replace the pressure cap.

Be sure the pressure cap is hand-tight and fully seated.

Notice: If the pressure cap is not tightly installed, coolant loss and possible engine damage may occur. Be sure the cap is properly and tightly secured. Recheck the coolant level in the bottle next time you use your vehicle to insure the system is full when cold. See Engine Coolant on page 9‑18 .

2. Then keep turning the pressure

3. Fill the coolant surge tank with

cap slowly and remove it.

the proper mixture, to slightly above the FROID/FULL COLD line on the side of the coolant surge tank.

4. With the coolant surge tank

pressure cap off, start the engine and let it run until you can feel the upper radiator hose getting hot. The upper radiator hose is the top hose coming out of the radiator, on the passenger side of the vehicle. Watch out for the engine cooling fans.

9-22

Vehicle Care

Checking Coolant in the Intercooler System (CTS-V) The vehicle must be on a level surface when checking the coolant level. The super charged engine intercooler coolant fill neck is located in the engine compartment on the passenger side of the vehicle. See Engine Compartment Overview on page 9‑6. On the coolant fill neck, there is a cold fill region between the two horizontal lines shown. Check to see if coolant is visible in the coolant fill neck. If the coolant is not visible or below the cold fill region in the fill neck, add a 50/50 mixture of clean, drinkable water and DEX-COOL® coolant at the coolant fill bottle, but be sure the cooling system is cool before this is done.

Adding Coolant to the Intercooler System Coolant (CTS-V)

2. Then keep turning the pressure

cap slowly and remove it.

3. Add the proper DEX-COOL®

coolant mixture to the fill neck until the coolant is within the cold fill region. With the intercooler system pressure cap off, start the engine and let it run for a couple of minutes. Then turn the engine off. By this time, the coolant level inside the fill neck may be lower. If the level drops where coolant is no longer within the cold fill region of the fill neck with the engine off, add more of the DEX-COOL® coolant mixture to the fill neck until the level is again visible in the cold fill region.

4. Then replace the pressure cap.

Be sure the pressure cap is hand-tight and fully seated.

1. Remove the intercooler system

pressure cap when the intercooler system hoses are no longer hot. Turn the pressure cap slowly counterclockwise about one-quarter of a turn. If you hear a hiss, wait for that to stop. This allows any pressure still left to be vented.

Notice: If the pressure cap is not tightly installed, coolant loss and possible engine damage may occur. Be sure the cap is properly and tightly secured. If the coolant is not at the proper level when the system cools down again, see your dealer/retailer.

Engine Overheating The vehicle has several indicators to warn of engine overheating. There are two engine hot messages that may be displayed in the Driver Information Center (DIC). See Driver Information Center (DIC) on page 4‑31 for more information. You may decide not to lift the hood when this warning appears, but instead get service help right away. See Roadside Service on page 12‑6 .

If you do decide to lift the hood , make sure the vehicle is parked on a level surface. Then check to see if the engine cooling fans are running. If the engine is overheating, the fan(s) should be running. If they are not, do not continue to run the engine and have the vehicle serviced. Notice: Engine damage from running the engine without coolant is not covered by the warranty. Notice: If the engine catches fire because of being driven with no coolant, your vehicle can be badly damaged. The costly repairs would not be covered by the vehicle warranty.

Vehicle Care

9-23

If Steam Is Coming From The Engine Compartment { WARNING

Steam from an overheated engine can burn you badly, even if you just open the hood. Stay away from the engine if you see or hear steam coming from it. Just turn it off and get everyone away from the vehicle until it cools down. Wait until there is no sign of steam or coolant before you open the hood. If you keep driving when your engine is overheated, the liquids in it can catch fire. You or others could be badly burned. Stop your engine if it overheats, and get out of the vehicle until the engine is cool.

If the temperature overheat gage is no longer in the overheat zone or an overheat warning no longer displays, the vehicle can be driven. Continue to drive the vehicle slow for about 10 minutes. Keep a safe vehicle distance from the car in front of you. If the warning does not come back on, continue to drive normally. If the warning continues, pull over, stop, and park the vehicle right away. If there is no sign of steam, idle the engine for three minutes while parked. If the warning is still displayed, turn off the engine until it cools down. Also, see “Overheated Engine Protection Operating Mode” next in this section.

Overheated Engine Protection Operating Mode This operating mode allows your vehicle to be driven to a safe place in an emergency. Should a hot engine condition exist, an overheat protection mode which alternates firing groups of cylinders helps prevent engine damage. In this mode, there is a loss in power and engine performance. Driving extended miles (km) and/or towing a trailer in the overheat protection mode should be avoided.

9-24

Vehicle Care

If No Steam Is Coming From The Engine Compartment If an engine overheat warning is displayed but no steam can be seen or heard, the problem may not be too serious. Sometimes the engine can get a little too hot when the vehicle: . Climbs a long hill on a hot day. . Stops after high-speed driving. Idles for long periods in traffic. Tows a trailer.

If the overheat warning is displayed with no sign of steam: 1. Turn the air conditioning off. 2. Turn the heater on to the highest

3.

temperature and to the highest fan speed. Open the windows as necessary. In heavy traffic, let the engine idle in N (Neutral) while stopped. If it is safe to do so, pull off the road, shift to P (Park) or N (Neutral) and let the engine idle.

Power Steering Fluid

See Engine Compartment Overview on page 9‑6 for the location of the power steering fluid reservoir. When to Check Power Steering Fluid It is not necessary to regularly check power steering fluid unless you suspect there is a leak in the system or you hear an unusual noise. A fluid loss in this system could indicate a problem. Have the system inspected and repaired.

How to Check Power Steering Fluid To check the power steering fluid: 1. Turn the key off and let the

engine compartment cool down. 2. Wipe the cap and the top of the

reservoir clean.

3. Unscrew the cap and wipe the

dipstick with a clean rag.

4. Replace the cap and completely

tighten it.

5. Remove the cap again and look at the fluid level on the dipstick.

The level should be between the HOT and COLD marks. If necessary, add only enough fluid to bring the level up to the mark.

Vehicle Care

9-25

What to Use To determine what kind of fluid to use, see Recommended Fluids and Lubricants on page 10‑7 . Always use the proper fluid.

Washer Fluid

What to Use When adding windshield washer fluid to the vehicle, be sure to read the manufacturer's instructions before use. If you will be operating your vehicle in an area where the temperature may fall below freezing, use a fluid that has sufficient protection against freezing.

9-26

Vehicle Care

Adding Washer Fluid The Washer Fluid Low Add Fluid message will appear on the Driver Information Center (DIC) when the fluid level is low. See Driver Information Center (DIC) on page 4‑31 for more information.

Open the cap with the washer symbol on it. Add washer fluid until the tank is full. See Engine Compartment Overview on page 9‑6 for reservoir location.

Notice:

. When using concentrated

washer fluid, follow the manufacturer's instructions for adding water.

. Do not mix water with

ready-to-use washer fluid. Water can cause the solution to freeze and damage the washer fluid tank and other parts of the washer system. Also, water does not clean as well as washer fluid.

. Fill the washer fluid tank

only three-quarters full when it is very cold. This allows for fluid expansion if freezing occurs, which could damage the tank if it is completely full.

. Do not use engine coolant

(antifreeze) in the windshield washer. It can damage the vehicle's windshield washer system and paint.

Brakes This vehicle has disc brakes. Disc brake pads have built-in wear indicators that make a high-pitched warning sound when the brake pads are worn and new pads are needed. The sound can come and go or be heard all the time the vehicle is moving, except when applying the brake pedal firmly.

{ WARNING

The brake wear warning sound means that soon the brakes will not work well. That could lead to an accident. When the brake wear warning sound is heard, have the vehicle serviced.

Notice: Continuing to drive with worn-out brake pads could result in costly brake repair.

Some driving conditions or climates can cause a brake squeal when the brakes are first applied or lightly applied. This does not mean something is wrong with the brakes. Properly torqued wheel nuts are necessary to help prevent brake pulsation. When tires are rotated, inspect brake pads for wear and evenly tighten wheel nuts in the proper sequence to torque specifications in Capacities and Specifications on page 11‑2. Brake linings should always be replaced as complete axle sets. Brake Pedal Travel See your dealer/retailer if the brake pedal does not return to normal height, or if there is a rapid increase in pedal travel. This could be a sign that brake service might be required.

Brake Adjustment Every time the brakes are applied, with or without the vehicle moving, the brakes adjust for wear. Replacing Brake System Parts The braking system on a vehicle is complex. Its many parts have to be of top quality and work well together if the vehicle is to have really good braking. The vehicle was designed and tested with top-quality brake parts. When parts of the braking system are replaced, be sure to get new, approved replacement parts. If this is not done, the brakes might not work properly. For example, installing disc brake pads that are wrong for the vehicle, can change the balance between the front and rear brakes — for the worse. The braking performance expected can change in many other ways if the wrong replacement brake parts are installed.

Vehicle Care

9-27

Brake Fluid

The brake master cylinder reservoir is filled with DOT 3 brake fluid as indicated on the reservoir cap. See Engine Compartment Overview on page 9‑6 for the location of the reservoir. There are only two reasons why the brake fluid level in the reservoir might go down:

The brake fluid level goes down because of normal brake lining wear. When new linings are installed, the fluid level goes back up.

9-28

Vehicle Care

. A fluid leak in the brake

hydraulic system can also cause a low fluid level. Have the brake hydraulic system fixed, since a leak means that sooner or later the brakes will not work well.

Do not top off the brake fluid. Adding fluid does not correct a leak. If fluid is added when the linings are worn, there will be too much fluid when new brake linings are installed. Add or remove brake fluid, as necessary, only when work is done on the brake hydraulic system.

{ WARNING

If too much brake fluid is added, it can spill on the engine and burn, if the engine is hot enough. You or others could be burned, and the vehicle could be damaged. Add brake fluid only when work is done on the brake hydraulic system.

When the brake fluid falls to a low level, the brake warning light comes on. See Brake System Warning Light on page 4‑26.

What to Add Use only new DOT 3 brake fluid from a sealed container. See Recommended Fluids and Lubricants on page 10‑7. Always clean the brake fluid reservoir cap and the area around the cap before removing it. This helps keep dirt from entering the reservoir.

{ WARNING

With the wrong kind of fluid in the brake hydraulic system, the brakes might not work well. This could cause a crash. Always use the proper brake fluid.

Notice:

. Using the wrong fluid

can badly damage brake hydraulic system parts. For example, just a few drops of mineral-based oil, such as engine oil, in the brake hydraulic system can damage brake hydraulic system parts so badly that they will have to be replaced. Do not let someone put in the wrong kind of fluid. If brake fluid is spilled on the vehicle's painted surfaces, the paint finish can be damaged. Be careful not to spill brake fluid on the vehicle. If you do, wash it off immediately.

Battery The battery is in the trunk, behind the trim panel, on the passenger side of the vehicle. Refer to the replacement number shown on the original battery label when a new battery is needed.

{ DANGER

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

After a power loss, such as disconnecting the battery or removing the maxi fuses in the power distribution fuse block, the following steps must be performed to calibrate the electronic throttle control. If this is not done, the engine will not run properly. 1. Turn the ignition to ON/RUN.

Do not start the engine.

2. Leave the ignition in ON/RUN for at least three minutes so that the electronic throttle control will cycle and re-learn its home position.

3. Turn the ignition to LOCK/OFF. 4. Start and run the engine for at

least 30 seconds.

Vehicle Care

9-29

Vehicle Storage

{ WARNING

Batteries have acid that can burn you and gas that can explode. You can be badly hurt if you are not careful. See Jump Starting on page 9‑103 for tips on working around a battery without getting hurt.

Infrequent Usage: Remove the black, negative (−) cable from the battery to keep the battery from running down. Extended Storage: Remove the black, negative (−) cable from the battery or use a battery trickle charger.

9-30

Vehicle Care

All-Wheel Drive If your vehicle is equipped with all-wheel-drive, this is an additional system that needs lubrication. Transfer Case

When to Check Lubricant It is not necessary to regularly check the transfer case fluid unless you suspect there is a leak or you hear an unusual noise. A fluid loss could indicate a problem. Have it inspected and repaired.

How to Check Lubricant

A. Drain Plug B. Fill Plug To get an accurate reading, the vehicle should be on a level surface. If the level is below the bottom of the filler plug hole, located on the transfer case, you'll need to add

some lubricant. Add enough lubricant to raise the level to the bottom of the filler plug hole. Use care not to overtighten the plug.

What to Use Refer to the Maintenance Schedule to determine what kind of lubricant to use. See Recommended Fluids and Lubricants on page 10‑7.

Rear Axle

When to Check Lubricant It is not necessary to regularly check rear axle fluid unless you suspect there is a leak or you hear an unusual noise. A fluid loss could indicate a problem. Have it inspected and repaired.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a level surface. If the level is below the bottom of the filler plug hole, located on the rear axle, you'll need to add some lubricant. Add enough lubricant to raise the level to the bottom of the filler plug hole.

What to Use Refer to the Maintenance Schedule to determine what kind of lubricant to use. See Recommended Fluids and Lubricants on page 10‑7.

Starter Switch Check

{ WARNING When you are doing this inspection, the vehicle could move suddenly. If the vehicle moves, you or others could be injured.

1. Before starting this check, be

sure there is enough room around the vehicle.

2. Firmly apply both the parking brake and the regular brake. See Parking Brake (Manual) on page 8‑34 or Parking Brake (Electric) on page 8‑35.

Vehicle Care

9-31

Do not use the accelerator pedal, and be ready to turn off the engine immediately if it starts.

3. For automatic transmission

vehicles, try to start the engine in each gear. The vehicle should start only in P (Park) or N (Neutral). If the vehicle starts in any other position, contact your dealer/retailer for service. For manual transmission vehicles, put the shift lever in Neutral, push the clutch pedal down halfway, and try to start the engine. The vehicle should start only when the clutch pedal is pushed down all the way to the floor. If the vehicle starts when the clutch pedal is not pushed all the way down, contact your dealer/retailer for service.

9-32

Vehicle Care

Automatic Transmission Shift Lock Control System Check

{ WARNING When you are doing this inspection, the vehicle could move suddenly. If the vehicle moves, you or others could be injured.

1. Before starting this check, be

sure there is enough room around the vehicle. It should be parked on a level surface.

2. Firmly apply the parking brake. See Parking Brake (Manual) on page 8‑34 or Parking Brake (Electric) on page 8‑35. Be ready to apply the regular brake immediately if the vehicle begins to move.

3. With the engine off, turn the

ignition to ON/RUN, but do not start the engine. Without applying the regular brake, try to move the shift lever out of P (Park) with normal effort. If the shift lever moves out of P (Park), contact your dealer/retailer for service.

Ignition Transmission Lock Check While parked, and with the parking brake set, try to turn the ignition to LOCK/OFF in each shift lever position.

The ignition should turn to LOCK/OFF only when the shift lever is in P (Park).

. With the key access ignition

system, the ignition key should come out only in LOCK/OFF.

See Ignition Positions (Key Access) on page 8‑18 or Ignition Positions (Keyless Access) on page 8‑19.

Contact your dealer/retailer if service is required.

Park Brake and P (Park) Mechanism Check { WARNING

When you are doing this check, the vehicle could begin to move. You or others could be injured and property could be damaged. Make sure there is room in front of the vehicle in case it begins to roll. Be ready to apply the regular brake at once should the vehicle begin to move.

Park on a fairly steep hill, with the vehicle facing downhill. Keeping your foot on the regular brake, set the parking brake.

To check the parking brake's holding ability: With the engine running and the transmission in N (Neutral), slowly remove foot pressure from the regular brake pedal. Do this until the vehicle is held by the parking brake only. To check the P (Park) mechanism's holding ability: With the engine running, shift to P (Park). Then release the parking brake followed by the regular brake.

Contact your dealer/retailer if service is required.

Wiper Blade Replacement Windshield wiper blades should be inspected for wear or cracking. See Scheduled Maintenance on page 10‑3 . It is a good idea to clean or replace the wiper blade assembly on a regular basis or when worn. For proper windshield wiper blade length and type, see Maintenance Replacement Parts on page 10‑9. To replace the wiper blade assembly: 1. Turn the ignition to ON/RUN with

the engine off.

2. Turn on the windshield wipers and turn them off again when the wipers are in the out-wipe position. The driver side blade will be straight up and down on the windshield.

3. Pull the windshield wiper assembly away from the windshield.

Vehicle Care

9-33

4. Lift up the wiper blade

assembly cap.

5. Pull the wiper blade assembly down far enough to release it from the J-hooked end of the wiper arm. Slide the assembly away from the arm. Allowing the wiper blade arm to touch the windshield when no wiper blade is installed could damage the windshield. Any damage that occurs would not be covered by your warranty. Do not allow the wiper blade arm to touch the windshield.

9-34

Vehicle Care

6. Replace the blade with a

new one.

7. Reinstall the wiper blade

assembly by sliding it over the wiper arm to engage the J-hooked end. Pull up on the assembly to lock it into place. 8. Repeat the steps for the other

wiper.

. Be placed so it is perpendicular

to the wall.

. Not have any snow, ice, or mud

on it.

. Be fully assembled and all other

work stopped while headlamp aiming is being performed. . Normally loaded with a full

tank of fuel and one person or 75 kg (160 lbs) sitting on the driver seat.

. Have all tires properly inflated. If your vehicle has a spare tire, ensure the spare tire is in its original location in the vehicle. Headlamp aiming is done with the vehicle's low-beam headlamps. The high-beam headlamps will be correctly aimed if the low-beam headlamps are aimed properly.

Headlamp Aiming The vehicle has a visual optical headlamp aiming system. The aim has been preset at the factory and should need no further adjustment. However, if the vehicle is damaged in a crash, the headlamp aim may be affected and adjustment may be necessary. If oncoming vehicles flash their high beams at you, this may also mean the vertical aim needs to be adjusted. It is recommended that the vehicle is taken to your dealer/retailer for service if the headlamps need to be re-aimed. It is possible however, to re-aim the headlamps as described. The vehicle should: . Be placed so the headlamps are 7.6 m (25 ft) from a light colored wall.

. Have all four tires on a level

surface which is level all the way to the wall.

To adjust the vertical aim: 1. Open the hood. See Hood on

page 9‑5 for more information.

Vehicle Care

9-35

Halogen Headlamps

High Intensity Discharge

Headlamps

2. Locate the aim dot on the lens of

the low-beam headlamp.

3. Record the distance from the ground to the aim dot on the low-beam headlamp.

4. At a wall, measure from the

ground upward (A) to the recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B)

the width of the vehicle at the wall where it was marked in Step 4.

9-36

Vehicle Care

Notice: Do not cover a headlamp to improve beam cut-off when aiming. Covering a headlamp may cause excessive heat build-up which may cause damage to the headlamp. 6. Turn on the low-beam

headlamps and place a piece of cardboard or equivalent in front of the headlamp not being aimed. This should allow only the beam of light from the headlamp being aimed to be seen on the flat surface.

The top edge of the cut-off should be positioned at the bottom edge of the horizontal tape line.

Driver Side Shown

7. Locate the vertical headlamp

aiming screws, which are under the hood near each headlamp assembly. They are covered by a rubber caps. The adjustment screw can be turned with a 6 mm hex driver. 8. Turn the vertical aiming screw

until the headlamp beam is aimed to the horizontal tape line. Turn it clockwise or counterclockwise to raise or lower the angle of the beam.

9. Make sure that the light from the

headlamp is positioned at the bottom edge of the horizontal tape line. The lamp on the left (A) shows the correct headlamp aim. The lamp on the right (B) shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for

the opposite headlamp.

Bulb Replacement For the proper type of replacement bulbs, see Replacement Bulbs on page 9‑39 . For any bulb changing procedure not listed in this section, contact your dealer/retailer.

Halogen Bulbs

{ WARNING

Halogen bulbs have pressurized gas inside and can burst if you drop or scratch the bulb. You or others could be injured. Be sure to read and follow the instructions on the bulb package.

Vehicle Care

9-37

High Intensity Discharge (HID) Lighting

Fog Lamps

{ WARNING

The low beam high intensity discharge lighting system operates at a very high voltage. If you try to service any of the system components, you could be seriously injured. Have your dealer/retailer or a qualified technician service them.

The up-level vehicle has HID headlamps. The park lamp function is also a function of the HID headlamp. After an HID headlamp bulb has been replaced, the beam might be a slightly different shade than it was originally. This is normal.

To replace fog lamp bulb: 1. Pull out the push-pins located on

the underside of the protection shield to remove the shield.

2. Reach up behind the front

bumper area from under the vehicle to access the lamp housing.

3. Remove the electrical connector

from the bulb by lifting the two plastic clips.

9-38

Vehicle Care

4. Remove the bulb socket from

the lamp housing by turning the bulb socket one-quarter turn counterclockwise.

5. Pull the old bulb from the lamp

housing keeping the bulb straight as you pull it out. Install a new bulb.

6. 7. Reinstall the electrical connector

by pushing in the two plastic clips.

8. Push the bulb socket into the

lamp housing and turn the socket one-quarter turn clockwise.

License Plate Lamp (Sedan) To replace one of these bulbs:

3. Turn the socket

counterclockwise and remove it.

4. Pull the bulb straight out to

remove it.

5. Push the new bulb straight into

the socket.

6. Reverse Steps 1 through 3 to

reinstall the license plate lamp assembly.

1. Push tab to remove the license

plate lamp.

2. Turn the license plate lamp

assembly down to remove it.

Vehicle Care

9-39

6. Push the replacement bulb

straight into the bulb socket and turn the bulb socket clockwise to install into lamp assembly.

7. Turn the lamp assembly into the liftgate engaging the clip side first.

8. Push on the lamp side opposite the clip until the lamp assembly snaps into place.

Replacement Bulbs

Exterior Lamp

Fog Lamp (Up Level Only) License Plate Lamp

Bulb

Number

H11LL

W5WLL

For replacement bulbs not listed here, contact your dealer/retailer.

A. Bulb Socket B. Bulb C. Lamp Assembly

4. Turn the bulb socket (A)

counterclockwise to remove from lamp assembly (C).

5. Pull the bulb (B) straight out of

the bulb socket.

License Plate Lamp (Wagon) To replace one of these bulbs: 1. Open the liftgate. See Liftgate

(Wagon) on page 1‑19 for more information.

Passenger side shown,

driver side similar

2. Push the left end of the lamp

assembly towards the right.

3. Turn the lamp assembly down to

remove from liftgate.

9-40

Vehicle Care

Electrical System

Electrical System Overload The vehicle has fuses and circuit breakers to protect against an electrical system overload. When the current electrical load is too heavy, the circuit breaker opens and closes, protecting the circuit until the current load returns to normal or the problem is fixed. This greatly reduces the chance of circuit overload and fire caused by electrical problems.

Fuses and circuit breakers protect the following in the vehicle: . Headlamp Wiring . Windshield Wiper Motor . Power Windows and other

Power Accessories

Headlamp Wiring An electrical overload may cause the lamps to go on and off, or in some cases to remain off. Have the headlamp wiring checked right away if the lamps go on and off or remain off.

Windshield Wipers If the wiper motor overheats due to heavy snow or ice, the windshield wipers will stop until the motor cools and will then restart. Although the circuit is protected from electrical overload, overload due to heavy snow or ice, may cause wiper linkage damage. Always clear ice and heavy snow from the windshield before using the windshield wipers. If the overload is caused by an electrical problem and not snow or ice, be sure to get it fixed.

Fuses and Circuit Breakers The wiring circuits in the vehicle are protected from short circuits by a combination of fuses and circuit breakers. This greatly reduces the chance of damage caused by electrical problems. To check a fuse, look at the silver-colored band inside the fuse. If the band is broken or melted, replace the fuse. Be sure to replace a bad fuse with a new one of the identical size and rating.

Fuses of the same amperage can be temporarily borrowed from another fuse location, if a fuse goes out. Replace the fuse as soon as you can. To identify and check fuses, circuit breakers, and relays, see Engine Compartment Fuse Block (CTS) on page 9‑41 or Engine Compartment Fuse Block (CTS-V) on page 9‑45

or Engine Compartment Fuse Block (CTS Wagon) on page 9‑48 and Rear Compartment Fuse Block (CTS) on page 9‑51 or Rear Compartment Fuse Block (CTS-V) on page 9‑53 or Rear Compartment Fuse Block (CTS Wagon) on page 9‑55.Vehicle Care

9-41

Engine Compartment Fuse Block (CTS) The underhood fuse block is located on the passenger side of the engine compartment.

Lift the fuse block cover to access the fuses. Notice: Spilling liquid on any electrical components on the vehicle may damage it. Always keep the covers on any electrical component.

9-42

Vehicle Care

Mini-Fuses

Usage

Mini-Fuses

Usage

A/C CLTCH

ABS

AFS

Air Conditioning Clutch Antilock Braking System (ABS) Adaptive Forward Lighting System

AIRBAG

IGN AQS/ ISRVM/ REAR

CAMERA

AWD

Airbag Switch

Air Quality Sensor/ Inside Rear View Mirror/Rear View Camera All-Wheel Drive

Mini-Fuses

BCM 1

BCM 2

BCM 3

BCM 4

BCM 5

BCM 6, BCM 7

DISPLYDRL/LT LO BEAM

DRL RT

Usage Body Control Module 1

Body Control Module 2

Body Control Module 3

Body Control Module 4

Body Control Module 5

Body Control Module 6 and 7

Display Daytime Running Lamps/Left Low-Beam Headlamp Right Daytime Running Lamp (DRL)Vehicle Care

9-43

Mini-Fuses

Usage

Mini-Fuses

Usage

Mini-Fuses

Usage

DRL/WSW

ECM

ECM/

TCM IGN

EMIS 1

EMIS 2

EVEN COILSDaytime Running Lamps/Windshield Washer Pump Engine Control Module (ECM) ECM, Transmission Control Module (TCM), Instrument Panel Cluster (IPC), PASS-Key III+ Module Emission 1

Emission 2Even Coils

FRT FOG Front Fog Lamps

HDLP WASH HORN

Not Used

Horn

LO BEAM DRL LEFT

LT

HI BEAM

LT

LO BEAM

LTR

Low-Beam Daytime Running Lamps (Left) Left High-Beam Headlamp Left Low-Beam Headlamp Cigarette Lighter

MISC IGN Ignition NAV MTR Navigation Motor ODD COILS Odd Coils PED PRO Not Used

PWR

MODING

RT

HI BEAM

RT

LO BEAM

RT

LO BEAM

PassKey Module, Body Control Module Right High-Beam Headlamp Right Low-Beam Headlamp Right Low-Beam Headlamp

SPARE SPARE

STR/WHL/

CNTRL

TCM BATT

TOSS/BRK VAC RLY

WPR SPARE

J-Case Fuses

Spare Spare Steering Wheel Illumination Transmission Control Module Battery Transmission Output Speed Sensor/Brake Vacuum Relay Windshield Wiper Spare

Usage

ABS MTR ABS Motor

BLWR BRK

VAC PUMP

EPB

Blower Brake Vacuum Pump Not Used

9-44

Vehicle Care

J-Case Fuses FAN 1

FAN 2

REAR DEFOG STRTR SPAREUsage

Cooling Fan 1

Cooling Fan 2Rear Defogger

Starter Spare

WSW/HTR Not Used

Relays

A/C

CMPRSR

DRL

(W/O HID) LO BEAM

(HID)

Usage

Air Conditioning Compressor Clutch Daytime Running Lamps (without High Intensity Discharge), Low-Beam Headlamps (High Intensity Discharge)

Relays

FAN S/P

FAN 1

FAN 2Usage

Cooling Fan Series/Parallel Cooling Fan 1

Cooling Fan 2FOG LAMP Fog Lamps

HDLP WASH

HI BEAM

HORN IGN 1

LO BEAM (W/O HID)

LT DRL (HID)

Not Used

High-Beam Headlamp Horn Ignition 1

Low-Beam (without High Intensity Discharge), Left Daytime Running Lamp (High Intensity Discharge)Relays

Usage

PWR/TRN Powertrain

REAR DEFOG

RT

DRL (HID)

SPARE STRTR WPR

WPR HI

WSW

Rear Defogger

Right Daytime Running Lamp (High Intensity Discharge) Spare Starter Windshield Wiper Windshield Wiper High Speed Windshield Washer Pump

Engine Compartment Fuse Block (CTS-V) The underhood fuse block is located on the passenger side of the engine compartment.

Vehicle Care

9-45

Mini-Fuses

Usage

Mini-Fuses

Usage

Lift the fuse block cover to access the fuses. Notice: Spilling liquid on any electrical components on the vehicle may damage it. Always keep the covers on any electrical component.

A/C CLTCH

ABS

AFS

Air Conditioning Clutch Antilock Braking System (ABS) Adaptive Forward Lighting System

AIRBAG

IGN AQS/ ISRVM/ REAR

CAMERA

BCM 1

Airbag Switch

Air Quality Sensor/ Inside Rear View Mirror/Rear View Camera Body Control Module 1

9-46

Vehicle Care

Mini-Fuses

BCM 2

BCM 3

BCM 4

BCM 5

BCM 6, BCM 7

DISPLYDRL LT

DRL RT

DRL/WSW

ECM

Usage Body Control Module 2

Body Control Module 3

Body Control Module 4

Body Control Module 5

Body Control Module 6 and 7

Display Left Daytime Running Lamps Right Daytime Running Lamp (DRL) Daytime Running Lamps/Windshield Washer Pump Engine Control Module (ECM)Mini-Fuses

Usage

ECM, Transmission Control Module (TCM), Instrument Panel Cluster (IPC), PASS-Key III+ Module Emission 1

Emission 2Even Coils

ECM/

TCM IGN

EMIS 1

EMIS 2

EVEN COILSFRT FOG Front Fog Lamps

HDLP WASH HORN INTCLR

LT

HI BEAM

LT

LO BEAM

LTR

Headlamp Washer

Horn Intercooler Pump Left High-Beam Headlamp Left Low-Beam Headlamp Cigarette Lighter

Usage

Mini-Fuses MISC IGN Ignition NAV MTR Navigation Motor ODD COILS Odd Coils PED PRO Not Used

PWR

MODING

RT

HI BEAM

RT

LO BEAM

SPARE

STR/WHL/

CNTRL S/ROOF

TCM BATT

WPR

PassKey Module, Body Control Module Right High-Beam Headlamp Right Low-Beam Headlamp Spare Steering Wheel Illumination Sunroof Transmission Control Module Battery Windshield Wiper

J-Case Fuses

Usage

ABS MTR ABS Motor

BLWR EPB FAN 1

FAN 2MRTD

REAR DEFOG STRTR SPARE

Blower Electric Park Brake Cooling Fan 1

Cooling Fan 2

MR Ride/ Suspension ControlRear Defogger

Starter Spare

WSW/HTR Not Used

Relays

A/C

CMPRSR

FAN S/P

Usage

Air Conditioning Compressor Clutch Cooling Fan Series/Parallel

Vehicle Care

9-47

Relays FAN 1

FAN 2Usage Cooling Fan 1

Cooling Fan 2FOG LAMP Fog Lamps

Relays SPARE STRTR WPR

HDLP WASH

HI BEAM

HORN IGN 1

INTCLRLT DRL

Headlamp Washer

WPR HI

WSW

High-Beam Headlamp Horn Ignition 1

Intercooler Pump Left Daytime Running LampsUsage

Spare Starter Windshield Wiper Windshield Wiper High Speed Daytime Running Lamps/Windshield Washer Pump

LO BEAM Low Beam PWR/TRN Powertrain

REAR DEFOG

RT DRL

Rear Defogger

Right Daytime Running Lamp

9-48

Vehicle Care

Engine Compartment Fuse Block (CTS Wagon) The underhood fuse block is located on the passenger side of the engine compartment.

Mini-Fuses

Usage

Mini-Fuses

Usage

Lift the fuse block cover to access the fuses. Notice: Spilling liquid on any electrical components on the vehicle may damage it. Always keep the covers on any electrical component.

A/C CLTCH

ABS

AFS

Air Conditioning Clutch Antilock Braking System (ABS) Adaptive Forward Lighting System

AIRBAG

IGN AQS/ ISRVM/ REAR

CAMERA

Airbag Switch