- Download PDF Manual

-

The 1.4-ltr. 16V 55kW Engine with roller-type cam follower

Design and Function

DY STU

SELF

Whether it(cid:213)s a matter of better fuel economy, higher engine output or lower exhaust emissions - the demands on engines are constantly increasing. This presents our engineers with new tasks, with the result that the Volkswagen engine range is constantly growing.

Example: weight saving

During development, the weight of the new 1.4-ltr. 16V 55kW engine was reduced by about 10 kg by modifying its design.

This self-study programme explains the technical innovations in our engine range using the 1.4-ltr. 16V 55kW engine as an example.

These differences arise out of the various techni- cal demands on the engines and are described in this Self-Study Programme.

196_168

Apart from minor differences in the engine mechanics, the 1.6-lr. 16V 88kW engine for the Polo GTI will have these new features, too.

The Self-Study Programme is not a Workshop Manual.

Precise instructions for testing, adjustment and repair can be found in the appropriate Workshop Manual.

New

Importan

At a glance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Valve actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

toothed belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sealing flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Con rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19Engine management . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Static high-voltage distribution . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Hall sender G40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Self-diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Special-purpose tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Introduction

One of a (cid:210)new generation(cid:211)

The 1.4-ltr. 16V 55kW engine is the first of a new generation of engines featuring roller-type cam followers. It is fundamentally different from the 1.4-ltr. 16V 74kW engine with bucket tappets.

The main differences are:

the die cast aluminium crankcase the cylinder head, where only the existing valve clearance and angle have been adopted.

New and advanced developments include:

196_068

The overall effects of these design modificati- ons are:

significant reduction in fuel consumption,

- performance on a par with

predecessor models, - weight savings and

compliance with the more stringent exhaust gas limit values now in effect in Germany.

the plastic intake manifold

the cylinder head and camshaft housing

valves are activated by roller-type cam followers

the crankcase is made of die cast aluminium

the duocentric oil pump

the exhaust manifold

the Magneti Marelli 4AV engine management system

Specifications

1.4-ltr. 16V 55kW engine

The 1.4-ltr. engine develops 128Nm of torque at 3200rpm. Maximum output is 55kW at 5000rpm.

1.6-ltr. 16V 88kW engine

By comparison, the 1.6-ltr. engine develops 148Nm of torque at 3400rpm and a maximum output of 88kW at 6200rpm.

Torque [Nm]

Output [kW]

196_070

Engine speed [rpm]

Output [kW]

Torque [Nm]

196_088

Engine speed [rpm]

1.4-ltr. engine

1.6-ltr. engine

AHW AKQ exhaust emission level D3

AJV exhasut emission level D3

1390

76.5 / 75.6

10.5:1

1598

76.5 / 86.9

10.6:1

Magneti Marelli 4AV

Magneti Marelli 4AV

Engine code

Displacement [cm

Bore/stroke [mm]

Compression ratio

Mixture preparation Engine management system

Fuel [RON]

95 / 91

98 / 95

Exhaust gas post-treatment

Lambda control, main catalytic converter for MVEG-A II for the AHW engine additional micro catalytic con- verter for exhaust emission level D3 for the AKQ engine

Lambda control, primary and main catalytic converters for exhaust emission level D3

The knock control lets you run the 1.4- ltr. and 1.6-ltr. engines on RON 91 and RON 95 fuel respec- tively. This may result in a slight loss of power and torque.

Engine Mechanics

The plastic intake manifold

consists of three component parts which are wel- ded together. The material is made of high- grade polyamide which is resistant to tempera- tures of up to 140¡C for short periods of time.

The use of plastics has made it possible to keep the weight of the intake manifold down to three kilograms. As a result, the intake manifold is rou- ghly 36% lighter than a comparable intake mani- fold made of aluminium. The plastic intake manifold also has a very smooth surface, and this improves the induced air flow.

The following components are mounted in the plastic intake manifold:

the injectors, the fuel distributor, the throttle valve control unit and the intake manifold pressure sender and the intake air temperature sender.

The air filter housing is secured to the pla- stic intake manifold by two screws. The max. permissible tightening torque is 3.5Nm.

induced air

Upper shell

Middle section

Upper/lower parts of intake manifold

The plastic intake manifold of the 1.4-ltr. engine

196_071

An aluminium intake manifold is used for the 1.6-ltr. 16V 88kW engine. It has been adapted to the engine(cid:213)s requirements.

Valve gear

is accommodated in the cylinder head and camshaft housing.

The camshaft housing is by and large identical to the cylinder head cover which was previously used as standard. What(cid:213)s new is that the camshafts are

now inserted into the housing. The bearing covers and camshaft housing limit the axial clea- rance of the camshafts. The camshafts run in three bearings.

The valve assembly comprising valves, roller- type cam followers and hydraulic support ele- ments is located in the cylinder head.

Exhaust camshaft

Camshaft housing Hydraulic support element

Intake camshaft

Cylinder head

Roller-type cam follower

196_018

Bearing cover

Inserted camshaft

Camshaft housing

196_075

Cylinder head

The gasket between the camshaft housing and the cylinder head is in the form of a fluid seal. Do not apply the sealant too thickly, since this may cause excess sealant to enter the oil drillings and damage the engine.

Engine Mechanics

Valve activation

With this engine generation, the valves are activ- ated via a roller-type cam follower with a hydraulic support element.

Advantages:

less friction fewer moving masses.

Conclusion:

Less engine power is required to drive the cam- shafts.

Camshaft

Cam roll

Roller-type cam follower

Valve

196_010

Hydraulic support element

Low-friction roller bearing

Design

The roller-type cam follower comprises a sheet- metal moulding acting as a lever and a cam roll with a roller bearing. The cam follower is clipped onto the support ele- ment and seated on the valve.

The hydraulic support element has the same function as the hydraulic bucket tappet. It serves as a hydraulic valve lifter and support for the roller-type cam follower.

The lubrication system

Lubricant flows between the hydraulic support element and the roller-type cam follower as well as between the cams and the cam roll along an oil duct integrated in the support element. Oil is injected into the cam roll through a drilling in the roller-type cam follower.

Oil

Cam roll

Lubricant duct

196_009

Function

The support element serves as a pivot for the rol- ler-type cam follower. The cam contacts the cam roll and presses the lever down. The lever in turn activates the valve.

A high valve lift is achieved with a relatively small cam due to the fact that the leverage bet- ween the cam roll and support element is smaller than between the valve and support element.

It is not possible to inspect the hydraulic support elements.

196_011

Engine Mechanics

The hydraulic support element

serves as a support for the roller-type cam follower and hydraulic valve lifter.

Design

The support element is connected to the oil circuit. It comprises the following elements:

- a piston, - a cylinder and - a piston spring.

A small ball, in combination with a pressure spring integrated in the lower oil chamber, makes up the one-way valve.

Hydraulic valve lifter

If valve backlash occurs, the piston spring forces the piston out of the cylinder until the cam roll makes contact with the cam. When the piston is pressed out of the cylinder, the oil pressure in the lower oil chamber drops. The one-way-valve opens and surplus oil flows into the oil chamber. The one-way-valve closes when the pressure between the lower and upper oil chambers has been equalised.

Valve lift

When the cam contacts the cam roll, the pres- sure inside the lower oil chamber rises because the oil here cannot be compressed. The piston cannot be forced any further into the cylinder. Thus, the support element acts as a rigid support for the roller-type cam follower. The inlet or exhaust valve opens.

10

Piston with drilling

Cylinder

Upper oil chamber

Lower oil chamber

196_014

Oil inlet

Piston spring

One-way valve

Valve clearance

196_016

196_017

Connecting drive

Tension pulley Connecting drive

Deflection pulley

196_021

Belt-driven crankshaft gear

The toothed belt drive

The toothed belt drive is divided into a main drive and a connecting drive on account of the small overall width of the of the cylinder head.

Main drive

Main drive

The coolant pump and the intake camshaft are driven by the crankshaft by means of a toothed belt integrated in the main drive. An automatic tension pulley and two deflection pulleys reduce toothed belt fluctuation.

Deflection pulley

Belt pulley Coolant pump

Tension pulley Main drive

The connecting drive

is located outside the cylinder head.

The exhaust camshaft is driven by the intake camshaft by means of a second toothed belt integrated in the connecting drive.

Again, an automatic tension pulley reduces too- thed belt fluctuation.

You can find exact instructions for adjustment the camshaft timing in the Workshop Manual.

196_024

11

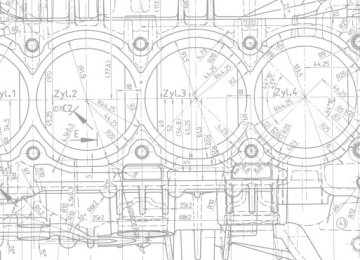

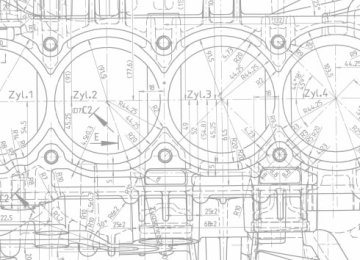

Engine Mechanics

The crankcase

used in the 1.4-ltr. 16V 55kW engine is made of die cast aluminium.

The liners are made of gray cast iron. They are press-fitted in the crankcase and machinable.

Land with press-fitted cast iron liners

Coolant duct

Section of the aluminium crankcase of the 1.4-ltr. engine

For corrosion reasons, only coolant additive G12 is approved for use.

196_086

12

The crankshaft

is manufactured from gray cast iron and has only four balancing weights. Despite this weight saving, the crankshaft has the same running cha- racteristics as a crankshaft with eight balancing weights.

The 1.6-ltr. 16V 88kW engine has a crankshaft with eight balancing weights.

Bearing seats

Balancing weight

Balancing weight

Bearing cover

196_087

Crankshaft

Balancing weight

You must not remove or loosen the crankshaft in the 1.4-ltr. engine.

Even when you loosen the bearing cover screws, the inner structure of the aluminium bearing seat relaxes, resulting in deformation of the crankshaft. If you undo the bearing cover screws, you must replace the crankcase complete with the crankshaft.

13

Engine Mechanics

The sealing flange

The crankcase is sealed with a sealing flange on the clutch side. The sender wheel for the engine speed sender G28 is integrated in the sealing flange.

In future, sealing flanges of two manufacturers will be used for this engine generation. The designs of these sealing flanges (e.g. engine speed sender housing) differ to such an extent that they cannot be replaced with another make of sealing flange.

Engine speed sender G28

Sealing flange with spring-ring gasket

In this case, the joint between the sealing flange and the sender wheel is sealed with a spring-ring gasket. The sender wheel is also sealed off from the crankshaft by an elastomer gasket. The sen- der wheel is precisely pressed onto the cranks- haft.

Crankshaft

Elastomer gasket

Sender wheel

Gasket

Sealing takes place at the sender wheel.

14

196_100

196_099

Sealing flange Sender wheel

Section of crankshaft

sender wheel

Sealing flange

Sealing flange with PTFE sealing ring

PTFE stands for polytetrafluorethylene. It is better known as Teflon - a special type of heat- and wear-resistant plastic.

The PTFE sealing ring sealing is located directly between the sealing flange and crankshaft. No additional elastomer gasket is needed. With this type of sealing flange, too, the sender wheel is pressed onto the crankshaft in a precise posi- tion.

Crankshaft

PTFE sealing ring

Sealing takes place on the crankshaft.

Engine speed sender G28

PTFE gasket

196_097

Sealing flange

Sender wheel

Section of crankshaft

Sender wheel

Sealing flange

196_098

For detailed instructions for installing the various sealing flanges, please refer to the Workshop Manual.

15

Engine Mechanics

The duocentric oil pump

is designed as a crankshaft oil pump. This means that the inner race is seated directly on the crankpin at the front end of the cranks- haft. The special shape of the crankshaft at the crank- pin has made it possible to reduce the outer dia- meter of the oil pump to only 62mm.

The term (cid:210)duocentric(cid:211) describes the geometric shape of the gearing of the inner and outer races.

In addition to a reduced level of friction and a weight saving of approximately 1kg, engine noise emission has also been improved by driving the crankshaft directly.

The oil pump housing rounds off the engine block at the front end.

Crankpin with polygonal profile

196_081

Housing

Outer race

196_020

Inner race

16

Cover plate

Function

The inner race is seated on the crankpin and drives the outer race. The space between the gears on the intake side is enlarged when the inner and outer races rotate, due to their diffe- rent axes of rotation.

Oil is is drawn in through a snorkel-type intake and conveyed to the delivery side.

The space between the gears becomes smaller on the delivery side. The oil is forced into the oil circuit. A pressure limiting valve prevents the maximum permissible oil pressure being exceeded, e.g. at high engine speeds.

Oil is drawn in

196_004

Oil is forced into the oil circuit

Pressure limiting valve

196_007

17

Engine Mechanics

The con rods

are machined using two different methods depending on their source: 1. Cutting, 2. Cracking.

Cutting

Cracking

In the cutting process, the con rod is initially rough-machined and then cut into a piston rod and piston rod cover. These two parts are bolted together for finish-machining purposes.

In the cracking process, the con rod is initially pre-machined as a complete part. At the end of this process, the con rod is separated by a tool into a piston rod and piston rod cover with great force.

The advantage:

The resulting fracture face is unique. This means that only the same two parts match up with one another. The con rod costs less to produce.

- Good positive connection.

196_072

196_082

196_073

196_074

As a rule, con rods must be replaced as a set. Don(cid:213)t forget to mark which con rod belongs to which cylinder.

18

Exhaust system

The main goals for the development of the exhaust system were to save space and weight and, above all, to meet tougher exhaust emission standards.

The exhaust manifold comprises four single pipes which converge on a flange. This results in a weight saving of approximately 4.5kg in comparison with conventional exhaust systems. In addition, the exhaust manifold, cata- lytic converter and lambda probe reach opera- ting temperature more quickly and exhaust gas treatment is initiated sooner.

In the case of 1.4-ltr. engine with the engine code AKQ, a micro catalytic converter with a metal substrate is welded into the headpipe of the exhaust system. This metal substrate is coated with a catalyst. The lambda probe is situated upstream of the micro catalytic converter.

196_077

Micro catalytic converter

Heat shield

Lambda probe

196_076

19

Test your knowledge

1. The valve gear of the 1.4-ltr. 16V 55kW engine

a) is housed in the cylinder head and camshaft housing,

b) has camshafts which run in three bearings and whose axial clearance is limited by the bearing

cover and camshaft housing,

c) has a cylinder head containing the valve gear complete with a cylinder head cover.

2. For valve activation via the roller-type cam follower

a) the valves and levers are securely interconnected,

b) any valve backlash which arises is adjusted automatically,

c) there is less friction and moving mass than in the case of bucket tappets,

d) a large cam must provide sufficient valve lift.

3. The crankshaft

a) must be removed and relubricated for inspection,

b) must not be loosened and can only be replaced complete with the crankcase.

4. Please annotate the following drawing.

d)

a)

b)

c)

20

e)

f)

196_018

Engine Management

Magneti Marelli 4AV Engine Control Unit

The Magneti Marelli 4AV engine management system is used for the new engine generation. It is housed in the plenum chamber.

The engine control unit has the following stan- dard functions:

In contrast to engine control unit version 1AV, version 4AV has:

- Cylinder-sequential injection

with quick start function, Intelligent idling speed control, Intelligent lambda control, Intelligent tank ventilation, Intelligent exhaust gas recirculation, Intelligent knock control, - Self-diagnostic capability.

- a static high-voltage distribution, - a Hall sender at the intake camshaft and

- an engine speed sender at the

crankshaft instead of the previous system of engine speed recognition via the distributor.

196_101

Rngine control unit, 80-pin connector

196_092

21

Control unit for 4AV J448

Engine Management

System overview

Intake manifold pressure sender G71

with intake air temperature sender G42Engine speed sender G28

Hall sender G40

Knock sensor I G61

Lambda probe G39

Coolant temperature sender G62

Throttle valve control unit J338 with Idling speed switch F60

Throttle valve potentiometer G69 Throttle valve positioner potentiometer G88Speedometer sender G22

Control unit with display unit integrated in the dash panel insert J285Additional input signals Air conditioning system compressor signal Air conditioning system pressure signal

22

Ignition transformer N152

Injectors N30, N31, N32, N33

Fuel pump relay J17

Fuel pump G6Activated charcoal filter system solenoid valve I N80

Throttle valve control unit J338 with throttle valve positioner V60

Exhaust gas recirculation valve N18

Additional output signals Engine speed signal Air conditioning system compressor signal

Immobiliser control unit J362, Diagnosis plug connection

196_002

23

Engine Management

Static high voltage distribution

The ignition transformer for the static high- voltage distribution is located at the end of the camshaft housing.

The advantages of the static high-voltage distri- bution are:

- no mechanical wear (maintenance free),

- no rotating parts, - higher ignition energy compared to the

low susceptibility to faults,

rotating ignition distribution fewer wires carrying high voltage.

196_069

The engine control unit calculates the spark timing between two ignition cycles. Engine speed and engine load are the key data which it requires for this purpose. Other influencing factors include the coolant temperature and the knock control. The engine control unit can adapt the spark timing to any operating state of the engine in this way. This increases engine efficiency, reduces fuel consumption and reduces exhaust emissions.

Electric circuit

The output stage and ignition coils are grouped together in the ignition transformer. Cylinder pairs 1 & 4 and 2 & 3 have a common ignition coil, which means that the cylinders of each pair are fired simultaneously. The one cylinder is shortly before the power stroke and the other is at the exhaust stroke.

J448

Cylinder: 1 4

196_096

Effects of failure

Without the ignition transformer or ignition coil, it is not possible to supply the spark plugs with energy.

24

The engine speed sender G28

is installed in the sealing flange and secured by a screw.

Signal utilisation

The engine speed sender scans a 60-2 sender wheel with 58 teeth and a gap the size of two teeth serving as a reference mark. The sender wheel is positioned on the crankshaft.

The engine control unit uses the signal which the engine speed sender supplies to determine the engine speed and the exact position of the crank-shaft. This data defines the injection and spark timing.

Engine speed sender G28

60-2 sender wheel

Reference mark

Sealing flange

196_008

Electric circuit

Effects of signal failure

J448

If the engine speed sender fails, the engine con- trol unit enters emergency mode. The control unit then calculates the engine speed and and deter- mines the position of the camshaft from the infor- mation which Hall sender G40 supplies. To protect the engine, maximum engine speed is reduced. It is still possible to restart the engine.

G28

196_094

Make sure that the engine speed sender is used by two different manufacturers.

25

Engine Management

Hall sender G40

is located on the flywheel side of the camshaft housing above the intake camshaft. Attached to the intake camshaft are three cast teeth which the Hall sender scans.

Signal utilisation

The signals which the Hall sender and engine speed sender supply are used for determining the ignition TDC of the first cylinder. This informa- tion is necessary for cylinder-selective knock con- trol and sequential injection.

Effects of signal failure

If the sender fails, the engine continues to run and can also be restarted. The engine control unit enters emergency mode. Fuel is then injected into the cylinders in parallel and no longer sequentially.

Bearing cover

26

Electric circuit

As with the throttle valve potentiometer G69, the Hall sender is supplied with power by the engine control unit.

J448

G69

G40

196_095

Hall sender G40

196_019

Intake camshaft with cast sender wheel

Camshaft housing

Hall sender G40

Rising edge

Solenoid field of the sensor

196_078

Signal from engine speed sender

196_079

Signal length corresponds to tooth length

General function

A Hall voltage is generated whenever a tooth passes the Hall sender. The duration of the Hall voltage pulse corresponds to the length of the tooth. This Hall voltage is transmitted to the engine control unit and evaluated here.

The signals can be displayed with the digital memory oscilloscope of the VAS 5051.

Cylinder 1 recognition function

If the engine control unit simultaneously receives a Hall voltage from the Hall sender and the refe- rence mark signal from the engine speed sender, this means the engine is in the compression stroke of the 1st cylinder. The engine control unit counts the teeth of the speed sender wheel after the reference mark signal and thus determines the crankshaft posi- tion.

For example: the 14th tooth after the reference mark corresponds to TDC of the 1st cylinder.

Quick start recognition function

The momentary position of the camshaft relative to the crankshaft can be ascertained quickly using only three teeth. This enables the first combustion cycle to be initiated sooner and the engine to start more quickly.

196_080

27

Functional Diagram

Components A/+ Battery positive terminal F60

Idling speed switch

30

15J17

Fuel level indicator sender Coolant temperature sender Fuel pump Engine speed sender Lambda probe

G2

G6

G28

G39

G40 Hall sender G42

G61

G62 Coolant temperature sender Throttle valve potentiometer G69

G71

Intake manifold pressure sender Throttle valve positioner potentiometer G88Intake air temperature sender Knock sensor I

Fuel pump relay

J17

J285 Control unit with display unitintegrated in the dash panel insert Throttle valve control unit Immobiliser control unit Control unit for 4AV (injection system)

J338

J362

J448Exhaust gas recirculation valve Injection valve, cylinder 1

Injection valve, cylinder 2

Injection valve, cylinder 3

Injection valve, cylinder 4N18

N30

N31

N32

N33

N80 Solenoid valve 1 foractivated charcoal system

N152 Ignition transformer

Spark plug connector Spark plugs Fuse

V60

Throttle valve positioner

Signals

Air conditioning system pressure signal Air conditioning system compressor signal Diagnosis connection Fuel consumption indicator of J448 for multifunction display Speed signal from J448

28

A/+

N18

N30 N31 N32 N33

G6

N80

G39

G71

Input signal Output signal Positive Earth

S

N152

J448

G61

J285

J362

V60

F60

G69

G88

G42

J338

G40

G62

G2

G28

30

15196_001

Depending on vehicle type, the immobiliser control unit is located in the dash panel insert (e.g. Golf (cid:212)98) or in the dash panel (e.g. Polo).

29

Self-diagnosis

The following functions can be read out with fault reader V.A.G. 1551, system tester V.A.G. 1552 or the vehicle diagnosis, testing and information system VAS 5051:

01 Interrogate control unit version 02Interrogate fault memory 03 Actuator diagnosis 04 Start basic adjustment 05 Erase fault memory 06 End of output 08 Read measured value block

(cid:222)

196_103

196_104

196_102

Function 02 Interrogate fault memory

Fault in the colour-coded sensors and actuators saved to fault memory.

G42

G71G28

G40

G61

G39

G62

J338

F60

G69

G88G22

N152

N30, N31, N32, N33

J17

N80

J338

V60N18

30

196_083

Function 03 Actuator diagnosis

During actuator diagnosis, the following components are activated one after the other:

Throttle valve positioner V60,

- Solenoid valve 1 for activated charcoal system N80, - Exhaust gas recirculation valve N18, - Engine speed signal, - Fuel pump relay J17

- Engine/air conditioning compressor (electrical connection)Function 04 Basic adjustment

The basic adjustment procedure must be performed if the engine control unit, the throttle valve control unit or the engine are to be replaced together with the throttle valve control unit.

Function 08 Read measured value block

The measured value block provides assistance with troubleshooting and inspecting the actuators and sensors. The signals of the coloured-coded components are output in function 08.

G42

G28

G39

G62

J338

F60

G69

G88G22

N80

Air cond. compressor input Battery voltage

196_084

31

Service

Special-purpose tools

For repair work on the 1.4-ltr. 16V 55kW engine, you also require the following special-purpose tools:

Designation

Tool

Usage

T10016

Camshaft locking toolFor locking the camshaft gears when removing the camshaft housing

T10017

Assembly deviceReplacing the crankshaft sealing flange on the flysheel side

T10022 - Sleeve

Replacing the crankshaft sealing ring on the belt pulley side

T10022/1 - Thrust piece T10022/2 - Spindle

Replacing the crankshaft sealing ring on the belt pulley side

32

Test your Knowledge

1. What functions differentiate the Magneti Marelli 4AV engine control unit from version 1AV?

a) Cylinder-sequential injection

b) Static high-voltage distribution

c) Camshaft sensor at the intake camshaft

d) Engine speed sender at the crankshaft

e) Diagnostic capability

2. What are the functions of Hall sender G40?

a) It is for engine speed recognition only.

b) Recognition of the 1st cylinder.

c) It facilitates the quick start function.

3. Which of the following statements is true?

a) The speed sender G28 is inserted into the crankcase from the exterior.

b) The speed sender G28 is installed in the sealing flange and

secured by a screw.

c) The speed sender G28 is mounted in the crankcase and can only be accessed by removing

the sump.

4. What cylinders are supplied with ignition voltage by what coil?

J448

a) b) c) d)

a)

b)

c)

d)

Cylinder

Cylinder

Cylinder

Cylinder

33

Notes

34

4.a) cylinder 1, b) cylinder 4, c) cylinder 2, d) cylinder 3

3.b) 2.b), c) 1.b), c), d) Page 33d) hydr. support element, e) Intake camshaft, f) roller-type cam follower

4. a)Exhaust camshaft, b) camshaftn housing, c) cylinder head lower section, 3. b) 2. b), c) 1. a), b) Page 20

Solutions:

35

Service.

196

For internal use only ' VOLKSWAGEN AG, Wolfsburg

All rights reserved. Subject to technical modifications.

740.2810.13.00 Technical status: 03/98

This paper is produced from

non-chlorine-bleached paper.

The 1.4-ltr. 16V 55kW Engine with roller-type cam follower

Design and Function

DY STU

SELF

Whether it(cid:213)s a matter of better fuel economy, higher engine output or lower exhaust emissions - the demands on engines are constantly increasing. This presents our engineers with new tasks, with the result that the Volkswagen engine range is constantly growing.

Example: weight saving

During development, the weight of the new 1.4-ltr. 16V 55kW engine was reduced by about 10 kg by modifying its design.

This self-study programme explains the technical innovations in our engine range using the 1.4-ltr. 16V 55kW engine as an example.

These differences arise out of the various techni- cal demands on the engines and are described in this Self-Study Programme.

196_168

Apart from minor differences in the engine mechanics, the 1.6-lr. 16V 88kW engine for the Polo GTI will have these new features, too.

The Self-Study Programme is not a Workshop Manual.

Precise instructions for testing, adjustment and repair can be found in the appropriate Workshop Manual.

New

Importan

At a glance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Valve actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

toothed belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sealing flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Con rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19Engine management . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Static high-voltage distribution . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Hall sender G40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Self-diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Special-purpose tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Introduction

One of a (cid:210)new generation(cid:211)

The 1.4-ltr. 16V 55kW engine is the first of a new generation of engines featuring roller-type cam followers. It is fundamentally different from the 1.4-ltr. 16V 74kW engine with bucket tappets.

The main differences are:

the die cast aluminium crankcase the cylinder head, where only the existing valve clearance and angle have been adopted.

New and advanced developments include:

196_068

The overall effects of these design modificati- ons are:

significant reduction in fuel consumption,

- performance on a par with

predecessor models, - weight savings and

compliance with the more stringent exhaust gas limit values now in effect in Germany.

the plastic intake manifold

the cylinder head and camshaft housing

valves are activated by roller-type cam followers

the crankcase is made of die cast aluminium

the duocentric oil pump

the exhaust manifold

the Magneti Marelli 4AV engine management system

Specifications

1.4-ltr. 16V 55kW engine

The 1.4-ltr. engine develops 128Nm of torque at 3200rpm. Maximum output is 55kW at 5000rpm.

1.6-ltr. 16V 88kW engine

By comparison, the 1.6-ltr. engine develops 148Nm of torque at 3400rpm and a maximum output of 88kW at 6200rpm.

Torque [Nm]

Output [kW]

196_070

Engine speed [rpm]

Output [kW]

Torque [Nm]

196_088

Engine speed [rpm]

1.4-ltr. engine

1.6-ltr. engine

AHW AKQ exhaust emission level D3

AJV exhasut emission level D3

1390

76.5 / 75.6

10.5:1

1598

76.5 / 86.9

10.6:1

Magneti Marelli 4AV

Magneti Marelli 4AV

Engine code

Displacement [cm

Bore/stroke [mm]

Compression ratio

Mixture preparation Engine management system

Fuel [RON]

95 / 91

98 / 95

Exhaust gas post-treatment

Lambda control, main catalytic converter for MVEG-A II for the AHW engine additional micro catalytic con- verter for exhaust emission level D3 for the AKQ engine

Lambda control, primary and main catalytic converters for exhaust emission level D3

The knock control lets you run the 1.4- ltr. and 1.6-ltr. engines on RON 91 and RON 95 fuel respec- tively. This may result in a slight loss of power and torque.

Engine Mechanics

The plastic intake manifold

consists of three component parts which are wel- ded together. The material is made of high- grade polyamide which is resistant to tempera- tures of up to 140¡C for short periods of time.

The use of plastics has made it possible to keep the weight of the intake manifold down to three kilograms. As a result, the intake manifold is rou- ghly 36% lighter than a comparable intake mani- fold made of aluminium. The plastic intake manifold also has a very smooth surface, and this improves the induced air flow.

The following components are mounted in the plastic intake manifold:

the injectors, the fuel distributor, the throttle valve control unit and the intake manifold pressure sender and the intake air temperature sender.

The air filter housing is secured to the pla- stic intake manifold by two screws. The max. permissible tightening torque is 3.5Nm.

induced air

Upper shell

Middle section

Upper/lower parts of intake manifold

The plastic intake manifold of the 1.4-ltr. engine

196_071

An aluminium intake manifold is used for the 1.6-ltr. 16V 88kW engine. It has been adapted to the engine(cid:213)s requirements.

Valve gear

is accommodated in the cylinder head and camshaft housing.

The camshaft housing is by and large identical to the cylinder head cover which was previously used as standard. What(cid:213)s new is that the camshafts are

now inserted into the housing. The bearing covers and camshaft housing limit the axial clea- rance of the camshafts. The camshafts run in three bearings.

The valve assembly comprising valves, roller- type cam followers and hydraulic support ele- ments is located in the cylinder head.

Exhaust camshaft

Camshaft housing Hydraulic support element

Intake camshaft

Cylinder head

Roller-type cam follower

196_018

Bearing cover

Inserted camshaft

Camshaft housing

196_075

Cylinder head

The gasket between the camshaft housing and the cylinder head is in the form of a fluid seal. Do not apply the sealant too thickly, since this may cause excess sealant to enter the oil drillings and damage the engine.

Engine Mechanics

Valve activation

With this engine generation, the valves are activ- ated via a roller-type cam follower with a hydraulic support element.

Advantages:

less friction fewer moving masses.

Conclusion:

Less engine power is required to drive the cam- shafts.

Camshaft

Cam roll

Roller-type cam follower

Valve

196_010

Hydraulic support element

Low-friction roller bearing

Design