- Download PDF Manual

-

• If the vehicle has not been driven in several days, the first few seconds of operation after shifting the trans- mission into gear may seem sluggish. This is due to the fluid partially draining from the torque converter into the transmission. This condition is normal and will not cause damage to the transmission. The torque con- verter will refill within five seconds of shifting from PARK into any other gear position.

STARTING AND OPERATING 323

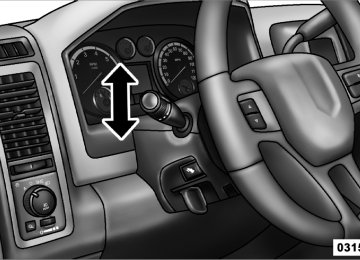

FOUR-WHEEL DRIVE OPERATION — IF EQUIPPED Four-wheel drive trucks are equipped with either a manually shifted transfer case or an electronically shifted transfer case. Refer to the operating instructions for your transfer case, located in this section for further informa- tion. Manually Shifted Transfer Case – If Equipped The transfer case provides four mode positions. • Two-wheel drive high range (2H) • Four-wheel drive high range (4H) • Neutral (N) • Four-wheel drive low range (4L) This transfer case is intended to be driven in the 2H position for normal street and highway conditions such as dry, hard surfaced roads.

324 STARTING AND OPERATING When additional traction is required, the 4H and 4L positions can be used to lock the front and rear drive- shafts together and force the front and rear wheels to rotate at the same speed. This is accomplished by simply moving the shift lever to the desired positions. The 4H and 4L positions are intended for loose, slippery road surfaces only. Driving in the 4H and 4L positions on dry, hard surfaced roads may cause increased tire wear and damage to the driveline components. The “Transfer Case Position Indicator Light” in the instrument cluster will alert the driver that the vehicle is in four-wheel drive and that the front and rear drive- shafts are locked together. This light will illuminate when the transfer case is shifted into either the 4H or 4L position. There is no light for the 2H or NEUTRAL positions. When operating your vehicle in 4L, the engine speed is approximately three times that of the 2H or 4H positions

at a given road speed. Take care not to overspeed the engine and do not exceed 25 mph (40 km/h). Proper operation of four-wheel drive vehicles depends on tires of equal size, type and circumference on each wheel. Any difference will adversely affect shifting and can cause damage to the transfer case. NOTE: Do not attempt to make a shift while only the front or rear wheels are spinning. The transfer case is not equipped with a synchronizer and therefore the front and rear driveshaft speeds must be equal for the shift to take place. Shifting while only the front or rear wheels are spinning can cause damage to the transfer case. Because four-wheel drive provides improved traction, there is a tendency to exceed safe turning and stopping speeds. Do not go faster than road conditions permit.

NOTE: Delayed shifts out of four-wheel drive may be experienced due to uneven tire wear, low or uneven tire pressures, excessive vehicle loading, or cold tempera- tures.

WARNING!

You or others could be injured if you leave the vehicle unattended with the transfer case in the NEUTRAL position without first fully engaging the parking brake. The transfer case NEUTRAL position disengages both the front and rear driveshafts from the powertrain and will allow the vehicle to move regardless of the transmission position. The parking brake should always be applied when the driver is not in the vehicle.

For additional information on the appropriate use of each transfer case mode position, see the information below:

STARTING AND OPERATING 325

2H Rear-Wheel Drive High Range - This range is for normal street and highway driving on dry hard surfaced roads. 4H Four-Wheel Drive High Range - This range locks the front and rear driveshafts together forcing the front and rear wheels to rotate at the same speed. Additional traction for loose, slippery road surfaces only. Neutral - This range disengages the front and rear driveshafts from the powertrain. To be used for flat towing behind another vehicle. Refer to “Recreational Towing” in “Starting and Operating” for further information. 4L Four-Wheel Drive Low Range - This range locks the front and rear driveshafts together forcing the front and rear wheels to rotate at the same speed. Additional traction

326 STARTING AND OPERATING and maximum pulling power for loose, slippery road surfaces only. Do not exceed 25 mph (40 km/h). Shifting Procedure – Manually Shifted Transfer Case 2H ⇔ 4H Shifting between 2H and 4H can be made with the vehicle stopped or in motion. If the vehicle is in motion, shifts can be made up to 55 mph (88 km/h). With the vehicle in motion, the transfer case will engage/ disengage faster if you momentarily release the accelera- tor pedal after completing the shift. Apply a constant force when shifting the transfer case lever. 2H or 4H ⇔ 4L With the vehicle rolling at 2 to 3 mph (3 to 5 km/h), shift the transmission into NEUTRAL. While the vehicle is coasting at 2 to 3 mph (3 to 5 km/h), shift the transfer case lever firmly to the desired position. Do not pause in transfer case NEUTRAL.

NOTE: • Pausing in transfer case NEUTRAL in vehicles equipped with an automatic transmission may require shutting the engine OFF to avoid gear clash while completing the shift. If difficulty occurs, shift the transmission into NEUTRAL, hold foot on brake, and turn the engine OFF. Make shift to the desired mode. • Shifting into or out of 4L is possible with the vehicle completely stopped, however difficulty may occur due to the mating clutch teeth not being properly aligned. Several attempts may be required for clutch teeth alignment and shift completion to occur. The preferred method is with the vehicle rolling 2 to 3 mph (3 to 5 km/h). Avoid attempting to engage or disengage 4L with the vehicle moving faster than 2 to 3 mph (3 to 5 km/h). • Do not attempt to shift into or from 4L while the

transmission is in gear.

Transfer Case Position Indicator Light The “Transfer Case Position Indicator Light” in the instrument cluster is used to alert the driver that the front axle is fully engaged and all four wheels are driving. Electronically Shifted Transfer Case (Four-Position Switch) – If Equipped This is an electronic shift transfer case and is operated by the 4WD Control Switch (Transfer Case Switch), which is located on the instrument panel.

STARTING AND OPERATING 327

Transfer Case Switch (Four-Position)

This electronically shifted transfer case provides four mode positions: • Two-wheel drive high range (2WD) • Four-wheel drive lock range (4WD LOCK) • Four-wheel drive low range (4WD LOW)

328 STARTING AND OPERATING

• Neutral (NEUTRAL) This electronically shifted transfer case is designed to be driven in the two-wheel drive position (2WD) for normal street and highway conditions on dry, hard surfaced roads. When additional traction is required, the transfer case 4WD LOCK and 4WD LOW positions can be used to lock the front and rear driveshafts together, forcing the front and rear wheels to rotate at the same speed. This is accomplished by rotating the 4WD Control Switch to the desired position. Refer to “Shifting Procedure” in this section for specific shifting instructions. The 4WD LOCK and 4WD LOW positions are designed for loose, slippery road surfaces only. Driving in the 4WD LOCK and 4WD LOW positions on dry hard surfaced roads may cause increased tire wear and damage to the driveline compo- nents.

NOTE: The transfer case NEUTRAL position is selected by pressing the recessed button located on the lower left hand corner of the 4WD Control Switch. The transfer case NEUTRAL position is to be used for recreational towing only. Refer to “Recreational Towing” in “Starting and Operating” for further information. Transfer Case Position Indicator Lights The Transfer Case Position Indicator Lights (4WD and 4LOW) are located in the instrument cluster and indicate the current and desired transfer case selection. When you select a different transfer case position, the indicator lights will do the following: If All Shift Conditions Are Met: 1. The current position indicator light will turn OFF. 2. The selected position indicator light will flash until the transfer case completes the shift.

3. When the shift is complete, the indicator light for the selected position will stop flashing and remain ON. If One Or More Shift Conditions Are Not Met: 1. The indicator light for the current position will remain ON. 2. The newly selected position indicator light will con- tinue to flash. 3. The transfer case will not shift. NOTE: Before retrying a selection, make certain that all the necessary requirements for selecting a new transfer case position have been met. To retry the selection, turn the control knob back to the current position, wait five seconds, and retry selection. To find the shift require- ments, refer to the ⬙Shifting Procedure⬙ for your transfer case, located in this section.

STARTING AND OPERATING 329

The “SVC 4WD Warning Light” monitors the electronic shift four-wheel drive system. If this light remains on after engine start up or illuminates during driving, it means that the four-wheel drive system is not function- ing properly and that service is required.WARNING!

Always engage the parking brake when powering down the vehicle if the “SVC 4WD Warning Light” is illuminated. Not engaging the parking brake may allow the vehicle to roll, which may cause personal injury.

NOTE: Do not attempt to make a shift while only the front or rear wheels are spinning, as this can cause damage to driveline components.

330 STARTING AND OPERATING When operating your vehicle in 4WD LOW, the engine speed is approximately three times that of the 2WD or 4WD LOCK positions at a given road speed. Take care not to overspeed the engine and do not exceed 25 mph (40 km/h). Proper operation of four-wheel drive vehicles depends on tires of equal size, type and circumference on each wheel. Any difference in tire size can cause damage to the transfer case. Because four-wheel drive provides improved traction, there is a tendency to exceed safe turning and stopping speeds. Do not go faster than road conditions permit.

WARNING!

You or others could be injured if you leave the vehicle unattended with the transfer case in the NEUTRAL position without first fully engaging the parking brake. The transfer case NEUTRAL position disengages both the front and rear driveshafts from the powertrain and will allow the vehicle to move regardless of the transmission position. The parking brake should always be applied when the driver is not in the vehicle.

For additional information on the appropriate use of each transfer case mode position, see the information below: 2WD Rear Wheel Drive High Range - This range is for normal street and highway driving on dry, hard surfaced roads.

4WD LOCK Four-Wheel Drive Lock Range - This range locks the front and rear driveshafts together forcing the front and rear wheels to rotate at the same speed. This range provides additional traction for loose, slippery road surfaces only. 4WD LOW Four-Wheel Drive Low Range - This range provides low speed four-wheel drive. It locks the front and rear driveshafts together forcing the front and rear wheels to rotate at the same speed. This range provides additional traction and maximum pulling power for loose, slippery road surfaces only. Do not exceed 25 mph (40 km/h). Neutral - This range disengages both the front and rear driveshafts from the powertrain. To be used for flat towing behind another vehicle. Refer to “Recreational Towing” in “Starting and Operating” for further information.

STARTING AND OPERATING 331

Shifting Procedure NOTE: • If any of the requirements to select a new transfer case position have not been met, the transfer case will not shift. The position indicator light for the previous position will remain ON and the newly selected posi- tion indicator light will continue to flash until all the requirements for the selected position have been met. To retry a shift: return the control knob back to the original position, make certain all shift requirements have been met, wait five seconds and try the shift again. • If all the requirements to select a new transfer case position have been met, the current position indicator light will turn OFF, the selected position indicator light will flash until the transfer case completes the shift.

332 STARTING AND OPERATING

When the shift is complete, the position indicator light for the selected position will stop flashing and remain ON.

2WD⇔ 4WD LOCK Rotate the 4WD control switch to the desired position. Shifts between 2WD and 4WD LOCK can be done with the vehicle stopped or in motion. With the vehicle in motion, the transfer case will engage/disengage faster if you momentarily release the accelerator pedal after turn- ing the control switch. If the vehicle is stopped, the ignition switch must be in the ON position with the engine either running or off. This shift cannot be com- pleted if the ignition switch is in the ACC position. NOTE: The four-wheel drive system will not allow shifts between 2WD/4WD LOCK if the front and/or rear wheels are spinning (no traction). In this situation, the

selected position indicator light will flash and the origi- nal position indicator light will remain ON. At this time, reduce speed and stop spinning the wheels to complete the shift. 2WD or 4WD LOCK⇔ 4WD LOW NOTE: When shifting into or out of 4WD LOW some gear noise may be heard. This noise is normal and is not detrimental to the vehicle or occupants. Shifting can be performed with the vehicle rolling 2 to 3 mph (3 to 5 km/h) or completely stopped. You can use either of the following procedures: Preferred Procedure 1. With the engine running, slow the vehicle to 2 to 3 mph (3 to 5 km/h). 2. Shift the transmission into NEUTRAL.

3. While still rolling, rotate the transfer case control switch to the desired position. 4. After the desired position indicator light is ON (not flashing), shift the transmission back into gear. Alternate Procedure 1. Bring the vehicle to a complete stop. 2. With the ignition switch in the ON position and the engine either OFF or running, shift the transmission into NEUTRAL. 3. Rotate the transfer case control switch to the desired position. 4. After the desired position indicator light is ON (not flashing), shift the transmission back into gear.

STARTING AND OPERATING 333

NOTE: • If Steps 1 or 2 of either the Preferred or Alternate Procedure are not satisfied prior to attempting the shift, then the desired position indicator light will flash continuously while the original position indicator light is ON, until all requirements have been met. • The ignition switch must be in the ON position for a shift to take place and for the position indicator lights to be operable. If the ignition switch is not in the ON position, the shift will not take place and no position indicator lights will be on or flashing.

334 STARTING AND OPERATING Electronically Shifted Transfer Case (Five-Position Switch) – If Equipped This is an electronic shift transfer case and is operated by the 4WD Control Switch (Transfer Case Switch), which is located on the instrument panel.

Transfer Case Switch (Five–Position)

This electronically shifted transfer case provides five mode positions: • Two-wheel drive high range (2WD) • Four-wheel drive automatic range (4WD AUTO) • Four-wheel drive lock range (4WD LOCK) • Four-wheel drive low range (4WD LOW) • Neutral (NEUTRAL) This electronically shifted transfer case is designed to be driven in the two–wheel drive position (2WD) or four- wheel drive position (4WD AUTO) for normal street and highway conditions on dry hard surfaced roads). Driving the vehicle in 2WD will have greater fuel economy benefits as the front axle is not engaged in 2WD. For variable driving conditions, the 4WD AUTO mode can be used. In this mode, the front axle is engaged, but the vehicle’s power is sent to the rear wheels. Four-wheel

drive will be automatically engaged when the vehicle senses a loss of traction. Because the front axle is en- gaged, this mode will result in lower fuel economy than the 2WD mode. When additional traction is required, the transfer case 4WD LOCK and 4WD LOW positions can be used to lock the front and rear driveshafts together forcing the front and rear wheels to rotate at the same speed. This is accomplished by rotating the 4WD Control Switch to the desired position. Refer to “Shifting Procedure” for spe- cific shifting instructions. The 4WD LOCK and 4WD LOW positions are designed for loose, slippery road surfaces only. Driving in the 4WD LOCK and 4WD LOW positions on dry hard surfaced roads may cause in- creased tire wear and damage to the driveline compo- nents. NOTE: The transfer case NEUTRAL position is selected by depressing the recessed button located on the lower

STARTING AND OPERATING 335

left hand corner of the 4WD Control Switch. The transfer case NEUTRAL position is to be used for recreational towing only. Refer to “Recreational Towing” in “Starting and Operating” for further information. Transfer Case Position Indicator Lights The Transfer Case Position Indicator Lights (4WD, 4LOW, and 4WD AUTO) are located on the instrument cluster and indicate the current and desired transfer case selection. When you select a different transfer case posi- tion, the position indicator lights will do the following: If All Shift Conditions Are Met: 1. The current position indicator light will turn OFF. 2. The selected position indicator light will flash until the transfer case completes the shift. 3. When the shift is complete, the indicator light for the selected position will stop flashing and remain ON.336 STARTING AND OPERATING If One Or More Shift Conditions Are Not Met: 1. The indicator light for the current position will remain ON. 2. The newly selected position indicator light will con- tinue to flash. 3. The transfer case will not shift. NOTE: Before retrying a selection, make certain that all the necessary requirements for selecting a new transfer case position have been met. To retry the selection, turn the control knob back to the current position, wait five seconds, and retry selection. To find the shift require- ments, refer to the ⬙Shifting Procedure⬙ for your transfer case, located in this section of the owner’s manual. The “SVC 4WD Warning Light” monitors the electronic shift four-wheel drive system. If this light remains on

after engine start up or illuminates during driving, it means that the four-wheel drive system is not function- ing properly and that service is required.

WARNING!

Always engage the parking brake when powering down the vehicle if the “SVC 4WD Warning Light” is illuminated. Not engaging the parking brake may allow the vehicle to roll which may cause personal injury.

NOTE: Do not attempt to make a shift while only the front or rear wheels are spinning. This could cause damage to driveline components. When operating your vehicle in 4WD LOW, the engine speed is approximately three times that of the 2WD, 4WD

AUTO or 4WD LOCK positions at a given road speed. Take care not to overspeed the engine and do not exceed 25 mph (40 km/h). Proper operation of four-wheel drive vehicles depends on tires of equal size, type and circumference on each wheel. Any difference in tire size can cause damage to the transfer case. Because four-wheel drive provides improved traction, there is a tendency to exceed safe turning and stopping speeds. Do not go faster than road conditions permit.

STARTING AND OPERATING 337

WARNING!

You or others could be injured if you leave the vehicle unattended with the transfer case in the NEUTRAL position without first fully engaging the parking brake. The transfer case NEUTRAL position disengages both the front and rear driveshafts from the powertrain and will allow the vehicle to move regardless of the transmission position. The parking brake should always be applied when the driver is not in the vehicle.

For additional information on the appropriate use of each transfer case mode position, see the information below: 2WD Rear-Wheel Drive High Range - This range is for normal street and highway driving on dry hard surfaced roads.

338 STARTING AND OPERATING 4WD AUTO Four-Wheel Drive Auto Range - This range sends power to the rear wheels. The four–wheel drive system will be automatically engaged when the vehicle senses a loss of traction. Additional traction for varying road conditions. 4WD LOCK Four-Wheel Drive Lock Range - This range locks the front and rear driveshafts together forcing the front and rear wheels to rotate at the same speed. Additional traction for loose, slippery road surfaces only. 4WD LOW Four-Wheel Drive Low Range - This range provides low speed four-wheel drive. Locks the front and rear drive- shafts together forcing the front and rear wheels to rotate at the same speed. Additional traction and maximum pulling power for loose, slippery road surfaces only. Do not exceed 25 mph (40 km/h).

Neutral - This range disengages both the front and rear driveshafts from the powertrain. To be used for flat towing behind another vehicle. Refer to “Recreational Towing” in “Starting and Operating” for further information. Shifting Procedure NOTE: • If any of the requirements to select a new transfer case position have not been met, the transfer case will not shift. The position indicator light for the previous position will remain ON, and the newly selected position indicator light will continue to flash until all the requirements for the selected position have been met. To retry a shift: return the control knob back to the original position, make certain all shift requirements have been met, wait five seconds and try the shift again.

• If all the requirements to select a new transfer case position have been met, the current position indicator light will turn OFF, the selected position indicator light will flash until the transfer case completes the shift. When the shift is complete, the position indicator light for the selected position will stop flashing and remain ON.

2WD ⇔ 4WD AUTO or 4WD LOCK Rotate the 4WD Control Switch to the desired position. Shifts between 2WD and 4WD AUTO and 4WD LOCK can be done with the vehicle stopped or in motion. With the vehicle in motion, the transfer case will engage/ disengage faster if you momentarily release the accelera- tor pedal after turning the control switch. If the vehicle is stopped, the ignition switch must be in the ON position with the engine either running or OFF. This shift cannot be completed if the ignition switch is in the ACC position.

STARTING AND OPERATING 339

2WD or 4WD AUTO or 4WD LOCK ⇔ 4WD LOW NOTE: When shifting into or out of 4WD LOW some gear noise may be heard. This noise is normal and is not detrimental to the vehicle or occupants. Shifting can be performed with the vehicle rolling 2 to 3 mph (3 to 5 km/h) or completely stopped. Use either of the following procedures: Preferred Procedure 1. With the engine running, slow the vehicle to 2 to 3 mph (3 to 5 km/h). 2. Shift the transmission into NEUTRAL. 3. While still rolling, rotate the transfer case control switch to the desired position. 4. After the desired position indicator light is ON (not flashing), shift the transmission back into gear.

340 STARTING AND OPERATING Alternate Procedure 1. Bring the vehicle to complete stop. 2. With the ignition switch in the ON position and the engine either OFF or running, shift the transmission into NEUTRAL. 3. Rotate the transfer case control switch to the desired position. 4. After the desired position indicator light is ON (not flashing), shift the transmission back into gear. If Steps 1 or 2 of either the Preferred or Alternate NOTE: Procedure are not satisfied prior to attempting the shift or if they no longer are being met while the shift attempt is in process, the desired position indicator light will flash continuously while the original position indicator light is ON, until all requirements have been met.

NOTE: The ignition switch must be in the ON position for a shift to take place and for the position indicator lights to be operable. If the ignition switch is not in the ON position, then the shift will not take place and no position indicator lights will be on or flashing.

AXLE LOCKER SYSTEM (2500 MODELS ONLY) — IF EQUIPPED This vehicle is equipped with electronically locking front and rear differentials. These differentials, when engaged, mechanically lock together the axle shafts forcing the wheels to spin at an equal rate. This allows the vehicle to maintain its momentum and prevents it from becoming stuck. The locking front and rear differentials should only be engaged during low-speed, extreme off-road situa- tions where one wheel is likely to not be in contact with the ground. It is not recommended to drive the vehicle with the differentials locked on pavement due to the reduced ability to turn and speed limitations.

CAUTION!

• Do not lock the front or rear axle on hard surfaced roads. The ability to steer the vehicle is reduced and damage to the drivetrain may occur when the axles are locked on hard surfaced roads. • Do not try to lock the rear axle if the vehicle is stuck and the tires are spinning. You can damage drivetrain components. Lock the rear axle before attempting situations or navigating terrain, which could possibly cause the vehicle to become stuck.

The locking axles are controlled by the axle locker switch. The switch has three positions, AXLE UNLOCK, REAR LOCK, and FRONT/REAR LOCK. Under normal driv- ing conditions, the switch should be left in the AXLE UNLOCK position. In the AXLE UNLOCK position, the front and rear axles are unlocked. In the REAR LOCK

STARTING AND OPERATING 341

position, the rear axle is locked. In the FRONT/REAR LOCK position, the front and rear axles are locked. NOTE: Even when the axles are in the AXLE UNLOCK position, the limited slip differential in the rear axle still provides torque biasing capability for moderate low traction environments. During the command to lock the axle, the indicator light will flash until the axle is locked. After the lock command has been successfully executed, the light will remain on solid. To lock the rear axle, place the vehicle in 4LO. Refer to “Four Wheel Drive Operation” in “Starting and Operat- ing” for further information. Move the axle locker switch position to REAR LOCK while traveling less than 3 mph (5 km/h). The RR indicator light will remain on when the rear axle is locked.342 STARTING AND OPERATING NOTE: Left to right wheel speed difference may be necessary to allow the axle to fully lock. If the indicator light is flashing after placing the switch in the REAR LOCK or FRONT/REAR LOCK position, drive the ve- hicle in a turn or on loose gravel to expedite the locking action.

WARNING!

Do not use the locked axle position for normal driving. A locked front axle is intended for off-road driving only. Locking the front axle during on-road driving will reduce the steering ability. This could cause a collision and you may be seriously injured.

To lock the front axle; move the axle locker switch to FRONT/REAR LOCK while traveling less than 3 mph (5 km/h). The indicator light will be solid when the front axle is locked.

NOTE: The rear axle must be locked before the front axle will lock. To unlock the front axle; move the axle locker switch to REAR LOCK. The FRONT/REAR LOCK indicator light will go out when the axle is unlocked. NOTE: The axle lockers could be torque locked due to side to side loads on the axle. Driving slowly while turning the steering wheel from a left hand turn to a right hand turn or driving in REVERSE for a short distance may be required to release the torque lock and unlock the axles. To unlock the rear axle; move the axle locker switch to AXLE UNLOCK. The REAR LOCK indicator light will go out when the rear axle is unlocked.

SAFE OFF-ROAD DRIVING — POWER WAGON ONLY

Off-Road Driving Tips and Vehicle Characteristics Your vehicle has excellent on and off-road capabilities. These off-road capabilities will allow you to explore those wilderness trails where few travel, providing a source of exciting and satisfying recreation. Before you venture out, you should contact your local governmental agency to determine the designated off-road vehicle (ORV) trails or recreation areas. You should always tread lightly and only use established roads, trails or ORV recreational areas. The National Forest Service, Bureau of Land Management or local Department of Natural Re- sources are a wealth of information and usually have maps with marked trails. Skid Plates And Underbody Protection Steel skid plates protect the major driveline components of the truck including the fuel tank, transfer case and

STARTING AND OPERATING 343

steering damper. In addition, this vehicle is equipped with boxed cross members and fore/aft rails. This addi- tional protection allows the vehicle to be utilized in severe off-road situations that would be considered im- passable by a normal truck. Ramp Travel Index (RTI) The ramp travel index is the distance, in inches, that you can drive your vehicle with one wheel on a 20-degree ramp without lifting any other wheel off the ground. This distance up the ramp divided by the wheelbase of the vehicle and multiplied by 1,000 is the RTI. This vehicle has an RTI of 655, which means you can articulate one front wheel 32 inches in the air while the other three wheels remain in contact with the ground. Water Fording Characteristics Water fording characteristic is the vehicle’s ability to cross a body of still water, where the powertrain and drivetrain are safe from water ingestion. This vehicle has344 STARTING AND OPERATING high water fording characteristics with the ability to cross a pool of water, without stopping, 24 inches deep at a maximum speed of 10 mph (16 km/h) and a pool of water 30 inches deep at a maximum speed of 5 mph (8 km/h), both with an entrance ramp angle of 1.3

degrees.CAUTION!

The door sill height is 25 inches. Water may intrude into the interior of the vehicle at greater depths.

Simultaneous Brake And Throttle Operation Many off-road driving conditions require the simulta- neous use of the brake and throttle (two footed driving). When climbing rocks, logs, or other stepped objects, using light brake pressure with light throttle will keep the vehicle from jerking or lurching. This technique is also used when you need to stop and restart a vehicle on a steep incline.

The Basics Of Off-Road Driving You will encounter many types of terrain driving off- road. You should be familiar with the terrain and area before proceeding. There are many types of surface conditions: hard packed dirt, gravel, rocks, grass, sand, mud, snow and ice. Every surface has a different effect on your vehicle’s steering, handling and traction. Control- ling your vehicle is one of the keys to successful off-road driving, so always keep a firm grip on the steering wheel and maintain a good driving posture. Avoid sudden accelerations, turns or braking. In most cases there are no road signs, posted speed limits or signal lights. Therefore you will need to use your own good judgment on what is safe and what isn’t. When on a trail you should always be looking ahead for surface obstacles and changes in terrain. The key is to plan your future driving route while remembering what you are currently driving over.

CAUTION!

Never park your vehicle over dry grass or other combustible materials. The heat from your vehicle exhaust system could cause a fire.

WARNING!

Always wear your seat belt and firmly tie down cargo. Unsecured cargo can become projectiles in an off-road situation.

When To Use Low Range When driving off-road, shift into 4L (Low Range) for additional traction or to improve handling and control on slippery or difficult terrain. Due to the lower gearing, low range will allow the engine to operate in a higher power range. This will allow you to idle over obstacles and down hills, with improved control and less effort. Also,

STARTING AND OPERATING 345

use 4L (Low Range) in rain, ice, snow, mud, sand, to get heavy loads rolling, improve traction, or whenever 4H (High Range) traction will not do the job. Driving In Snow, Mud And Sand There is a drastic reduction in traction when driving in snow, mud or sand. The vehicle will be less responsive to steering, acceleration and braking inputs. Therefore you should accelerate slowly, leave greater stopping distances and avoid abrupt vehicle maneuvers. You want to keep a slow constant steady pace. The key is to maintain the vehicle’s momentum. • Snow – In heavy snow or for additional control and traction at slower speeds, shift the transmission to a low gear and shift the transfer case to 4L (Low Range) if necessary. Do not shift to a lower gear than neces- sary to maintain headway. Over-revving the engine can spin the wheels and traction will be lost. If you start to slow to a stop, try turning your steering wheel346 STARTING AND OPERATING

no more than a 1⁄4 turn quickly back and forth, while still applying throttle. This will allow the tires to get a fresh ⬙bite⬙ and help maintain your momentum.

CAUTION!

On icy or slippery roads, do not downshift at high engine RPMs or vehicle speeds because engine brak- ing may cause skidding and loss of control. • Mud – Deep mud creates a great deal of suction around the tires and is very difficult to get through. You should use 4L (Low Range) with a gear low enough to maintain your momentum without shifting. If you start to slow to a stop, try turning your steering wheel no more than a 1⁄4 turn quickly back and forth for additional traction. Mud holes pose an increased threat of vehicle damage and getting stuck. They are normally full of debris from previous vehicles getting stuck. As a good practice before entering any mud

hole, get out and determine how deep it is, if there are any hidden obstacles and if the vehicle can be safely recovered if stuck. • Sand – Soft sand is very difficult to travel through with full tire pressure. When crossing soft sandy spots in a trail maintain your vehicle’s momentum and do not stop. The key to driving in soft sand using the appropriate tire pressure, accelerating slowly, avoid- ing abrupt maneuvers and maintaining the vehicle’s momentum. If you are going to be driving on large soft sandy areas or dunes, reduce your tire pressure to a minimum of 15 psi (103 kPa) to allow for a greater tire surface area. Reduced tire pressure will drastically improve your traction and handling, while driving on the soft sand, but you must return the tires to normal air pressure before driving on pavement or other hard surfaces. Be sure you have a way to air the tires back up prior to reducing the pressure.

CAUTION!

Reduced tire pressures may cause tire unseating and total loss of air pressure. To reduce the risk of tire unseating, while at a reduced tire pressure, reduce your speed and avoid sharp turns or abrupt maneu- vers.

Crossing Obstacles (Rocks And Other High Points) While driving off road, you will encounter many types of terrain. These varying types of terrain bring different types of obstacles. Before proceeding review the path ahead to determine the correct approach and your ability to safely recover the vehicle if something goes wrong. Keeping a firm grip on the steering wheel, bring the vehicle to a complete stop and then inch the vehicle

STARTING AND OPERATING 347

forward until it makes contact with the object. Apply the throttle lightly while holding a light brake pressure and ease the vehicle up and over the object.WARNING!

Crossing obstacles can cause abrupt steering system loading which could cause you to loose control of your vehicle.

Using a Spotter There are many times where it is hard to see the obstacle or determine the correct path. Determining the correct path can be extremely difficult when you are confronting many obstacles. In these cases have someone guide you over, through, or around the obstacle. Have the person stand a safe distance in front of you where they can see the obstacle, watch your tires and undercarriage, and guide you through.

348 STARTING AND OPERATING Crossing Large Rocks When approaching large rocks, choose a path which ensures you drive over the largest with your tires. This will lift your undercarriage over the obstacle. The tread of the tire is tougher and thicker than the side wall and is designed to take the abuse. Always look ahead and make every effort to cross the large rocks with your tires.

CAUTION!

• Never attempt to straddle a rock that is large • Never attempt to drive over a rock which is large

enough to strike your axles or undercarriage.

enough to contact the door sills.

independently. You need to use caution when crossing large obstacles with steep sides. Do not attempt to cross any large obstacle with steep sides at an angle great enough to put the vehicle at risk of a rollover. If you get caught in a rut, dig a small trench to the right or left at a 45-degree angle ahead of the front tires. Use the removed dirt to fill the rut ahead of the turnout you just created. You should now be able to drive out following the trench you just created at a 45-degree angle.

WARNING!

There is an increased risk of rollover when crossing an obstacle, at any angle, with steep sides.

Crossing a Ravine, Gully, Ditch, Washout or Rut When crossing a ravine, gully, ditch, washout or a large rut, the angled approach is the key to maintaining your vehicle’s mobility. Approach these obstacles at a 45- degree angle and let each tire go through the obstacle

Crossing Logs To cross a log, approach it at a slight angle (approxi- mately 10 to 15 degrees). This allows one front tire to be on top of the log while the other just starts to climb the log. While climbing the log, modulate your brake and

accelerator to avoid spinning the log out from under your tires. Then ease the vehicle off the log using your brakes.

STARTING AND OPERATING 349

CAUTION!

CAUTION!

Winching or rocking the vehicle off hard objects increases the risk of underbody damage.

Do not attempt to cross a log with a greater diameter than the running ground clearance or the vehicle will become high centered.

Getting High Centered If you get hung up or high centered on an object, get out of the vehicle and try to determine what the vehicle is hung up on, where it is contacting the underbody and what is the best direction to recover the vehicle. Depend- ing on what you are in contact with, jack the vehicle up and place a few rocks under the tires so the weight is off of the high point when you let the vehicle down. You can also try rocking the vehicle or winching the vehicle off the object.

Hill Climbing Hill climbing requires good judgment and a good under- standing of your abilities and your vehicle’s limitations. Hills can cause serious problems. Some are just too steep to climb and should not be attempted. You should always feel confident with the vehicle and your abilities. You should always climb hills straight up and down. Never attempt to climb a hill on an angle. • Before Climbing A Steep Hill – As you approach a hill consider its grade or steepness. Determine if it is too steep. Look to see what the traction is on the hill side trail. Is the trail straight up and down? What is on top and the other side? Are there ruts, rocks, branches or other obstacles on the path? Can you safely recover

350 STARTING AND OPERATING

the vehicle if something goes wrong? If everything looks good and you feel confident, then change trans- mission into a lower gear, shift the transfer case into 4L (Low) and proceed with caution. You should use first gear and 4L (Low Range) for very steep hills. • Driving Up Hill – Once you have determined your ability to proceed and have shifted into the appropri- ate gear, line your vehicle up for the straightest possible run. Accelerate with an easy constant throttle and apply more power as you start up the hill. Do not race forward into a steep grade, the abrupt change of grade could cause you to lose control. If the front end begins to bounce, ease off the throttle slightly to bring all four tires back on the ground. As you approach the crest of the hill ease off the throttle and slowly proceed over the top. If the wheels start to slip as you approach the crest of a hill, ease off the accelerator and maintain headway by turning the steering wheel no more than a 1⁄4 turn quickly back and forth. This will provide a

fresh ⬙bite⬙ into the surface and will usually provide enough traction to complete the climb. If you do not make it to the top, place the vehicle in REVERSE and back straight down the grade using engine resistance along with the vehicle brakes.

WARNING!

Never attempt to climb a hill at an angle or turn around on a steep grade. Driving across an incline increases the risk of a roll over, which may result in severe injury. • Driving Down Hill – Before driving down a steep hill you need to determine if it is too steep for a safe descent. What is the surface traction? Is the grade too steep to maintain a slow controlled descent? Are there obstacles? Is it a straight descent? Is there plenty of distance at the base of the hill to regain control if the vehicle descends too fast? If you feel confident in your

ability to proceed then make sure you are in 4L (Low Range) with the transmission in first gear (manually select first gear on automatic transmissions) and pro- ceed with caution. Allow engine braking to control the descent and apply your brakes if necessary, but do not allow the tires to lock.

WARNING!

Do not descend a steep grade in NEUTRAL. Use vehicle brakes in conjunction with engine braking. Descending a grade too fast could cause you to lose control and be seriously injured. • Driving Across An Incline – If at all possible avoid driving across an incline. If it is necessary, know your vehicle’s abilities. Driving across an incline places more weight on the down hill wheels, which increases the possibilities of a down hill slide or rollover. Make

STARTING AND OPERATING 351

sure the surface has good traction with firm and stable soils. If possible transverse the incline at an angle heading slightly up or down.WARNING!

Driving across an incline increases the risk of a rollover, which may result in severe injury. • If You Stall Or Begin To Lose Headway – If you stall or begin to lose headway while climbing a steep hill, allow your vehicle to come to a stop and immediately apply the brake. Restart the engine and shift into REVERSE. Back slowly down the hill allowing the compression braking of the engine and transmission to help regulate your speed. If the brakes are required to control vehicle speed, apply them lightly and avoid locking or skidding the tires.

352 STARTING AND OPERATING

WARNING!

If the engine stalls or you lose headway or cannot make it to the top of a steep hill or grade, never attempt to turn around. To do so may result in tipping and rolling the vehicle, which may result in severe injury. Always back carefully straight down a hill in REVERSE. Never back down a hill in NEU- TRAL using only the vehicle brakes. Never drive diagonally across a hill, always drive straight up or down.

Driving Through Water Extreme care should be taken crossing any type of water. Water crossings should be avoided if possible and only be attempted when necessary, in a safe responsible manner. You should only drive through areas which are designated and approved. You should tread lightly and avoid damage to the environment. You should know

your vehicle’s abilities and be able to recover it if something goes wrong. You should never stop or shut a vehicle off when crossing deep water unless you ingested water into the engine air intake. If the engine stalls do not attempt to restart it. Determine if it has ingested water first. The key to any crossing is low and slow. You want to use first gear in 4L (Low Range) and proceed very slowly with a constant slow speed (3-5 mph [5–8 km/h] maximum) and light throttle. Keep the vehicle moving; do not try to accelerate through the crossing. After crossing any water higher than the bottom of the axle differentials, you should inspect all of the vehicle fluids for signs of water ingestion.

CAUTION!

Water ingestion into the axles, transmission, transfer case, engine or vehicle interior can occur if you drive too fast or through too deep of water. Water can cause permanent damage to engine, driveline or other vehicle components and your brakes will be less effective once wet and/or muddy • Before You Cross Any Type Of Water – As you approach any type of water you need to determine if you can cross it safely and responsibly. If necessary, get out and walk through the water or probe it with a stick. You need to be sure of its depth, approach angle, current and bottom condition. Be careful of murky or muddy waters, check for hidden obstacles. Make sure you will not be intruding on any wildlife and you can recover the vehicle if necessary. The key to a safe

STARTING AND OPERATING 353

crossing is the water depth, current and bottom con- ditions. On soft bottoms the vehicle will sink in, effectively increasing the water level on the vehicle. Be sure to consider this when determining the depth and the ability to safely cross. • Crossing Puddles, Pools, Flooded Areas Or Other Standing Water – Puddles, pools, flooded or other standing water areas normally contain murky or muddy waters. These water types normally contain hidden obstacles and make it difficult to determine an accurate water depth, approach angle, and bottom condition. Murky or muddy water holes are where you want to hook up tow straps prior to entering. This makes for a faster, cleaner and easier vehicle recovery. If you are able to determine you can safely cross, than proceed using the low and slow method.354 STARTING AND OPERATING

CAUTION!

Muddy waters can reduce the cooling system effec- tiveness by depositing debris onto the radiator. • Crossing Ditches, Streams, Shallow Rivers Or Other Flowing Water – Flowing water can be extremely dangerous. Never attempt to cross a fast running stream or river even in shallow water. Fast moving water can easily push your vehicle downstream sweeping it out of control. Even in very shallow water, a high current can still wash the dirt out from around your tires putting you and your vehicle in jeopardy. There is still a high risk of personal injury and vehicle damage with slower water currents in depths greater than the vehicle’s running ground clearance. You should never attempt to cross flowing water which is deeper than the vehicle’s running ground clearance. Even the slowest current can push the heaviest vehicle

downstream out of control if the water is deep enough to push on the large surface area of the vehicle’s body. Before you proceed determine the speed of the current, the water’s depth, approach angle, bottom condition and if there are any obstacles, then cross at an angle heading slightly upstream using the low and slow technique.

WARNING!

Never drive through fast moving deep water. It can push your vehicle downstream, sweeping it out of control. This could put you and your passengers at risk of injury or drowning.

Airing Down For Off-Road Driving Running lower tire pressure off-road can improve your ride comfort and vehicle traction. Reducing the tire air pressure allows the tire to bulge slightly, improving its surface area for better flotation and ability to mold or

form to the ground contour. Different terrain, tires, and vehicles require different tire pressure. Hard surfaces like rock and heavier vehicles require higher pressures than softer surfaces such as sand and lighter vehicles. You will need to experiment to determine what is right for your situation. It is easier and faster to let air out than it is to replace it so, start high and lower it as required. Remem- ber you must return the tires to normal air pressure before driving on road or at highway conditions. Be sure you have a way to return the tires to their normal on road air pressure.

CAUTION!

Reduced tire pressure increases the risk of tire dam- age and may cause tire unseating with total loss of air pressure. To reduce the risk of tire unseating, while at a reduced tire pressure, drive at slower speeds and avoid sharp turns or abrupt maneuvers.

STARTING AND OPERATING 355

Vehicle Recovery If you drive off-road, you may encounter a situation where you will need to recover your vehicle. Vehicle recovery should always be given consideration before attempting a questionable obstacle. You should never go off-road driving without the ability to recover your vehicle from a situation. Having another vehicle with you usually works best for most situations. The first thing to do is assess the situation. Why are you stuck? Are you hung up on something? Would it be easier to go forward or to go backward? Can you still move the vehicle? Is there an anchor point to winch to? Are you alone or do you have another vehicle to help? Is there high risk of vehicle damage during the recovery process? Answering these questions will help you determine the best method of recovery. If you can still move the vehicle slightly and the only issue is slick ground, then rock cycling your vehicle would be the first choice. If you have ample room, an additional vehicle and there is low risk of

356 STARTING AND OPERATING vehicle impingement on the surroundings, then using a tow strap to the vehicle tow hooks would be fast and easy. If the vehicle is severely hung up or in a situation where great care needs to be taken during the recovery, then nothing can do the job better than a winch. If you are severely hung up on something you should jack the vehicle up and stack something under the wheels to allow the vehicle to roll off the object without causing further damage. This should be tried before attempting any recovery method.

CAUTION!

Pulling the vehicle off an obstacle, without first clearing the object, may result in additional under- body damage. • Rock Cycling Your Vehicle – Rock cycling your ve- hicle is one of the easiest, fastest and most commonly used methods. This simply involves shifting your

vehicle from DRIVE to REVERSE, while applying throttle after each shift. During this process, for addi- tional traction, try turning your steering wheel quickly back and forth no more than a 1⁄4 turn. If you are stuck in mud, sand, or snow try spinning your tires during this process to clean the debris from the tread and improve the traction. You want to create a rocking motion with the vehicle. This helps build vehicle momentum, which hopefully gets you out. Remember to ease off and on the accelerator before and after the shift. If after a few rock cycles your vehicle is not free, stop and try another method of recovery. Continuous rock cycling will only cause unnecessary damage to your vehicle and the environment.

CAUTION!

Damage can occur when spinning your tires at an excessive high speed. Do not spin your tires faster than an indicated 35 mph (56 km/h). • Using the Tow Hooks With a Tow Strap – Tow straps are a quick and easy way to recover your vehicle from minor situations if you have a secondary vehicle which is not stuck. The tow hooks on your vehicle are designed to take the abusive force generated during vehicle recovery. Do not use the bumper or any other vehicle component as an attachment point. Using tow straps requires coordination between the two drivers. Good communication and line of sight are required for a safe recovery. First connect the tow strap to the correct attachment points on both vehicles. There should be a least 20 to 30 feet between the vehicles to allow for a safe recovery. If necessary join two tow

STARTING AND OPERATING 357

straps together using a 1 1⁄2 inch hard wood dowel. This will keep the straps from becoming knotted and is safer than using a clevis pin if the strap breaks. Next have the tow vehicle backup, leaving two to three feet worth of slack in the strap. Then the tow vehicle, using light throttle, should accelerate tightening the strap providing the pulling force needed to free the vehicle. The vehicle being recovered should assist in the recov- ery, at the time of the snap, by slowly spinning the tires in the same direction as the pulling vehicle. After the vehicle becomes free, the driver of the previously stuck vehicle should signal they are free and should hit their brakes stopping both vehicles. The driver of the pulling vehicle should let off the throttle without using the brakes, once signaled by the other driver. This sequence is important to avoid having the recov- ered vehicle hit the pulling vehicle.358 STARTING AND OPERATING

WARNING!

Never use tow straps with end hooks or link two straps with a clevis pin. These heavy metal objects could become projectiles if a strap breaks, which could cause severe injury. Never leave more than two or three feet of slack in the strap. More slack than this greatly increases the risk of injury and vehicle dam- age. Always keep everyone at least 30 feet away from a strapping or winching situation. • Winching (Refer to “Winch Operation” for addi- tional information) – Winching is most commonly used in the following situations: there is no support vehicle available, a high controlled force is required to recover the vehicle, there is a high risk of environmen- tal or vehicle damage, or where nothing else seems to work. A winch can deliver a high pulling force with a great deal of control. It allows you to walk the vehicle

out of the situation in a slow controlled manner. This control works well for avoiding further vehicle dam- age. Once you decide it is time to use the winch look for a good anchor point. It needs to be strong enough to hold more than the vehicle’s weight and provide a direction of pull as straight as possible. Use block and tackle if necessary to improve the angle of pull or increase the winch’s pulling force. If the anchor point is a tree use a strap around its base and hook the cable to the strap. If it is another vehicle, then place that vehicle in PARK and block the front tires. If you cannot find an anchor point within reach try using your spare tire by burying it. Once you have determined an anchor point hook up the cable, ensuring there are a least five wraps of cable left on the drum, and place a floor mat or something else over the strung out cable. Placing something over the strung out cable helps keep the cable on the ground if it breaks. Next, place the vehicle in first gear and apply a very light throttle

as you power the winch in. Be careful not to allow slack in the cable as you recover the vehicle. Do not try to guide the cable into the drum. If it starts to bunch up on one end, let it. You can re-spool the cable afterwards. Never use a winch cable as a tow strap and always stand back while winching.

WARNING!

Winch cables are under high tension when in use and can become a projectile if they fail. Never stand over or straddle the winch cable. Never jerk or overload the winch cable. Never stand in front of the vehicle while winching. Failure to follow these instructions can result in serious or fatal injury.

After Driving Off-Road Off-road operation puts more stress on your vehicle than does most on-road driving. After going off-road, it is

STARTING AND OPERATING 359

always a good idea to check for damage. That way you can get any problems taken care of right away and have your vehicle ready when you need it. • Completely inspect the underbody of your vehicle. Check tires, body structure, steering, suspension, and exhaust system for damage. • Inspect the radiator for mud and debris and clean as • Check threaded fasteners for looseness, particularly on the chassis, drivetrain components, steering, and sus- pension. Retighten them, if required, and torque to the values specified in the Service Manual. • Check for accumulations of plants or brush. These things could be a fire hazard. They might hide damage to fuel lines, brake hoses, axle pinion seals, and propeller shafts.required.

360 STARTING AND OPERATING

• After extended operation in mud, sand, water, or similar dirty conditions, have the radiator, fan, brake rotors, wheels, brake linings, and axle yokes inspected and cleaned as soon as possible.

WARNING!

Abrasive material in any part of the brakes may cause excessive wear or unpredictable braking. You might not have full braking power when you need it to prevent a collision. If you have been operating your vehicle in dirty conditions, get your brakes checked and cleaned as necessary. • If you experience unusual vibration after driving in mud, slush or similar conditions, check the wheels for impacted material. Impacted material can cause a wheel imbalance and freeing the wheels of it will correct the situation.

LIMITED-SLIP DIFFERENTIAL The limited-slip differential provides additional traction on snow, ice, mud, sand and gravel, particularly when there is a difference between the traction characteristics of the surface under the right and left rear wheels. During normal driving and cornering, the limited-slip unit per- forms similarly to a conventional differential. On slip- pery surfaces, however, the differential delivers more of the driving effort to the rear wheel having the better traction. The limited-slip differential is especially helpful during slippery driving conditions. With both rear wheels on a slippery surface, a slight application of the accelerator will supply maximum traction. When starting with only one rear wheel on an excessively slippery surface, slight momentary application of the parking brake may be necessary to gain maximum traction.

WARNING!

On vehicles equipped with a limited-slip differential never run the engine with one rear wheel off the ground since the vehicle may drive through the rear wheel remaining on the ground. You could lose control of the vehicle.

Care should be taken to avoid sudden accelerations when both rear wheels are on a slippery surface. This could cause both rear wheels to spin, and allow the vehicle to slide sideways on the crowned surface of a road or in a turn.

STARTING AND OPERATING 361

DRIVING ON SLIPPERY SURFACES

Acceleration Rapid acceleration on snow covered, wet, or other slip- pery surfaces may cause the rear wheels to pull errati- cally to the right or left. This phenomenon occurs when there is a difference in the surface traction under the rear (driving) wheels.

WARNING!

Rapid acceleration on slippery surfaces is dangerous. Unequal traction can cause sudden pulling of the rear wheels. You could lose control of the vehicle and possibly have a collision. Accelerate slowly and carefully whenever there is likely to be poor traction (ice, snow, wet mud, loose sand, etc.).

362 STARTING AND OPERATING Traction When driving on wet or slushy roads, it is possible for a wedge of water to build up between the tire and road surface. This is known as hydroplaning and may cause partial or complete loss of vehicle control and stopping ability. To reduce this possibility, the following precau- tions should be observed: 1. Slow down during rainstorms or when the roads are slushy. 2. Slow down if the road has standing water or puddles. 3. Replace tires when tread wear indicators first become visible. 4. Keep tires properly inflated. 5. Maintain sufficient distance between your vehicle and the vehicle in front of you to avoid a collision in a sudden stop.

DRIVING THROUGH WATER Driving through water more than a few inches/ centimeters deep will require extra caution to ensure safety and prevent damage to your vehicle. Flowing/Rising Water

WARNING!

Do not drive on or across a road or path where water is flowing and/or rising (as in storm run-off). Flow- ing water can wear away the road or path’s surface and cause your vehicle to sink into deeper water. Furthermore, flowing and/or rising water can carry your vehicle away swiftly. Failure to follow this warning may result in injuries that are serious or fatal to you, your passengers, and others around you.

Shallow Standing Water Although your vehicle is capable of driving through shallow standing water, consider the following Caution and Warning before doing so.

CAUTION!

• Always check the depth of the standing water before driving through it. Never drive through standing water that is deeper than the bottom of the tire rims mounted on the vehicle. • Determine the condition of the road or the path that is under water and if there are any obstacles in the way before driving through the standing wa- ter. • Do not exceed 5 mph (8 km/h) when driving through standing water. This will minimize wave effects.

(Continued)

STARTING AND OPERATING 363

CAUTION! (Continued)

• Driving through standing water may cause dam- age to your vehicle’s drivetrain components. Al- ways inspect your vehicle’s fluids (i.e., engine oil, transmission, axle, etc.) for signs of contamination (i.e., fluid that is milky or foamy in appearance) after driving through standing water. Do not con- tinue to operate the vehicle if any fluid appears contaminated, as this may result in further dam- age. Such damage is not covered by the New Vehicle Limited Warranty. • Getting water inside your vehicle’s engine can cause it to lock up and stall out, and cause serious internal damage to the engine. Such damage is not covered by the New Vehicle Limited Warranty.

364 STARTING AND OPERATING

WARNING!

• Driving through standing water limits your vehi- cle’s traction capabilities. Do not exceed 5 mph (8 km/h) when driving through standing water. • Driving through standing water limits your vehi- cle’s braking capabilities, which increases stop- ping distances. Therefore, after driving through standing water, drive slowly and lightly press on the brake pedal several times to dry the brakes. • Getting water inside your vehicle’s engine can cause it to lock up and stall out, and leave you stranded. • Failure to follow these warnings may result in injuries that are serious or fatal to you, your passengers, and others around you.

OFF-ROAD DRIVING TIPS Care should be taken when attempting to climb steep hills or driving diagonally across a hill or slope. If natural obstacles force you to travel diagonally up or down a hill, choose a mild angle and keep as little side tilt as possible. Keep the vehicle moving and make turns slowly and cautiously. If you must back down a hill, back straight down using REVERSE gear. Never back down in NEUTRAL or diago- nally across the hill. When driving over sand, mud, and other soft terrain, shift to low gear and drive steadily. Apply the accelerator slowly to avoid spinning the wheels. Do not reduce the tire pressures for this type of driving. After Driving Off-Road Off-road operation puts more stress on your vehicle than does most on-road driving. After going off-road, it is

required.

always a good idea to check for damage. That way you can get any problems taken care of right away and have your vehicle ready when you need it. • Completely inspect the underbody of your vehicle. Check tires, body structure, steering, suspension, and exhaust system for damage. • Inspect the radiator for mud and debris and clean as • Check threaded fasteners for looseness, particularly on the chassis, drivetrain components, steering, and sus- pension. Retighten them, if required, and torque to the values specified in the Service Manual. • Check for accumulations of plants or brush. These things could be a fire hazard. They might hide damage to fuel lines, brake hoses, axle pinion seals, and propeller shafts.

STARTING AND OPERATING 365

• After extended operation in mud, sand, water, or similar dirty conditions, have the radiator, fan, brake rotors, wheels, brake linings, and axle yokes inspected and cleaned as soon as possible.

WARNING!

Abrasive material in any part of the brakes may cause excessive wear or unpredictable braking. You might not have full braking power when you need it to prevent a collision. If you have been operating your vehicle in dirty conditions, get your brakes checked and cleaned as necessary. • If you experience unusual vibration after driving in mud, slush or similar conditions, check the wheels for impacted material. Impacted material can cause a wheel imbalance and freeing the wheels of it will correct the situation.

366 STARTING AND OPERATING WINCH USAGE (POWER WAGON ONLY) — IF EQUIPPED

Things To Know Before Using Your Winch

General Winch Information Your vehicle is equipped with an electric vehicle recovery winch. This winch uses the electrical power from the vehicle charging system to power a motor that winds wire rope into the winch drum via planetary gear reduc- tion. By nature, a winch is capable of generating very high forces and should be used with care. Do not operate the winch without reading and understanding the com- plete winch owner’s manual. Tensioning the Wire Rope The winch rope must be properly tensioned before use. Follow the instructions below to tension the rope: 1. Un-spool the wire rope leaving five wraps of rope on the winch drum.

2. Attach the hook to a suitable anchor point.

CAUTION!

Be certain the anchor will withstand the load re- quired to tension the wire rope.

3. Apply at least 500 lbs (227 kg) of tension to the rope while winding the rope. Always use care to ensure the rope does not pile up on one side of the drum and is neatly wound onto the drum.

CAUTION!

Wire rope must spool on the winch drum in the direction indicated on the drum rotation decal on the winch.

Low Voltage Interrupt Your winch is equipped with a device that will interrupt winch function if the vehicle charging system voltage drops to a low level. The winch will not power-in or out for 30 seconds if this device is tripped. If the interrupt is tripped, the vehicle should be operated at high idle for a few minutes to allow the vehicle charging system to recover before continuing to winch.

Winch Motor Thermal Protection Your winch is equipped with a thermal protection device in the motor. If the winch is operated for an excessive duration, the device may interrupt motor function to protect the winch motor. During this time the winch will power-out but will not power-in. Allow the winch motor to cool for a few minutes before continuing to winch. The winch will resume normal function once the motor cools.

STARTING AND OPERATING 367

368 STARTING AND OPERATING Understanding The Features Of Your Winch

Winch Components

1. Motor: The winch motor is powered by the vehicle charging system and features a thermal protection switch that automatically stops motor function in the power-in direction if the motor gets too hot. 2. Remote Socket: The remote socket allows the remote control to be attached to the control pack to allow the winch to function. 3. Winch Drum with Integral Brake: The winch drum allows the wire rope to be stored on the winch and transmits force to the wire rope. The winch is equipped with an integral brake that will stop rotation of the winch drum if the winch motor is stopped. 4. 3-Stage Planetary Gear Set: Provides balance between speed and pulling power. 5. Wire Rope: The wire rope allows the winch to be connected to an anchor to provide a pulling force.

STARTING AND OPERATING 369

6. Clutch Lever: The clutch lever allows the winch drum to be disconnected from the winch motor to allow the wire rope to be pulled from the winch by hand. 7. Remote Control: The remote control provides the interface between the winch operator and the winch. The remote control provides the ability to power the winch in, out, and stop the winch. To operate the winch, the toggle switch is pressed down to power the winch in and up to power the winch out. The winch will stop if the switch is left in the neutral (center) position.CAUTION!

If not installed, the hook strap must be placed on the hook.

Fairlead: The fairlead acts as a guide for the wire rope and minimizes damage to the rope.

370 STARTING AND OPERATING Winch Accessories

The following accessories are necessary to attach the winch to anchors, change direction of pull, and for safe winching.

Gloves: Wire rope, through use, will develop ⬙barbs⬙ which can slice skin. It is ex- tremely important to wear pro- tective gloves while operating the winch or handling the wire rope. Avoid fitting clothes or anything that could become entangled in the wire rope and other moving parts.

loose

Snatch/Block Pulley: Used properly, the multi-purpose snatch block allows you to (1) increase the winch’s pulling power; and (2) change your direction without pulling damaging the wire rope. Proper use of the snatch block is covered in ⬙Before You Pull.⬙

The Clevis/D-Shackles: D-Shackle is a safe means of connecting the looped ends of cables, and snatch blocks. The shackle’s pin is threaded to allow easy re- moval.

straps

Tree Trunk Protector: Typi- cally made of tough, high- quality nylon, it provides the operator an attachment point for the winch rope to a wide variety of anchor points and objects, as well as protect liv- ing trees.

STARTING AND OPERATING 371

Operating Your Winch

WARNING!

when spooling wire rope in or out.

Failure to observe any of these warnings regarding proper winch usage may result in severe injury. • Always use supplied hook strap to hold the hook • Never use as a hoist. • Never use to move persons. • Never exceed winch or wire rope rated capacity. • Always wear heavy leather gloves when handling • Never touch wire rope or hook while in tension or • Never engage or disengage clutch if winch is under load, wire rope is in tension, or wire rope drum is moving.

the wire rope.

under load.

(Continued)

372 STARTING AND OPERATING

WARNING! (Continued)

others away during winching.

• Always stand clear of wire rope and load and keep • Always keep hands and clothing clear of the wire rope, hook and fairlead opening during operation and when spooling. • Never wrap wire rope back onto itself. Always use a choker chain, wire choker rope or tree trunk protector on the anchor. • Never attach a recovery strap to the winch hook to • Never attempt to tow a vehicle with the recovery • Never use ⴖbungeeⴖ straps that develop tremen- dous and potentially dangerous amounts of force when stretched.

strap attached directly to the winch hook.

increase the length of a pull.

(Continued)

WARNING! (Continued)

use.

of wire rope around the winch drum.

• Always disconnect the remote control when not in • Never winch when there are less than five wraps • Always pass remote control through a window to avoid pinching lead in door, then using remote inside a vehicle. • Never leave the remote control plugged into the winch while free spooling, rigging or sitting idle.

General Information Practice using your winch before you get stuck. Some key points to remember when using your winch are: 1. Always take your time to assess the situation and plan your pull carefully. 2. Always take your time when using a winch. 3. Use the right equipment for the situation. 4. Always wear leather gloves and do not allow the wire rope to slip through your hands when handling the rope. 5. Only the operator should handle the wire rope and remote control. 6. Think safety at all times.

Vehicle Recovery Using the Winch

STARTING AND OPERATING 373

CAUTION!

• Always Know Your Winch: Take the time to fully read and understand the included Installation and Operations Guide, and Basic Guide to Winching Techniques, in order to understand your winch and the winching operation. • Always inspect winch installation and wire rope condition before operating the winch. Frayed, kinked or damaged wire rope must be replaced immediately. Loose or damaged winch installation must be corrected immediately. • Always be sure any element which can interfere with safe winching operations is removed prior to initiating winching.

(Continued)

374 STARTING AND OPERATING

CAUTION! (Continued)

drum, wire rope and rigging.

• Always keep remote control lead clear of the • Inspect for cracks, pinches, frayed wires, or loose • Be careful not to pull the Winch Cable Collar through the rollers. Watch and listen to Winch for proper snugness.

connections. Replace if damaged.

1. Inspect the winch, winch mount, and wire rope for damage. Do not use the winch if the mount is loose or rope shows excessive wear or damage. 2. Put on gloves.

3. Disengage the clutch to allow free spooling of the winch drum, rotate the clutch lever on the winch to disengage. Freespooling conserves battery power.

STARTING AND OPERATING 375

Free Spool

4. Free the winch hook and attach the hook strap. Free the winch hook from its anchor point. Attach the hook strap to the hook (if not attached).

Hook Strap

5. Pull the wire to the anchor point. Pull out enough wire rope to reach your anchor point. Be sure to keep a certain amount of tension on the wire as it can become twisted and over-wrapped when slackened, leading to wire rope damage. To prevent losing the end, hold the hook strap while you work.

376 STARTING AND OPERATING

6. Secure to the anchor point. Once you have established your anchor point, secure the tree-trunk protector or choker-chain around the object.

Tree Trunk Protector

CAUTION!

Always be certain the anchor you select will with- stand the load.

NOTE: How to choose an anchor point: A secure anchor is critical to winching operations. An anchor must be strong enough to hold while winching. Natural an- chors include trees, stumps and rocks. Hook the cable as low as possible. If no natural anchors are available when recovering another vehicle, your vehicle becomes the anchor point. In this case, be sure to put the transmission in NEUTRAL, apply the hand brake and block its wheels to prevent your vehicle from moving. Ideally, you’ll want an anchor point that will enable you to pull straight in the direction the vehicle will move. This allows the wire rope to wind tightly and evenly onto the spooling drum. An anchor point as far away as possible will provide the winch with its greatest pulling power. 7. Attach the Clevis/D-shackle and Tree Trunk Protector. Attach the shackle to the two ends of the strap or chain and through the hook loop, being careful not to over tighten (tighten and back-off 1/2 turn).

STARTING AND OPERATING 377

Clevis/D-Shackles

8. Lock the clutch. Lock the winch drum by rotating the clutch lever on the winch to engage. NOTE: Always ensure the clutch is fully engaged or disengaged.

378 STARTING AND OPERATING 9. Connect the remote control to the winch control box, located behind the front bumper. Be careful not to let the remote control cord dangle in front of the winch. If you choose to control the winch from inside your vehicle, always pass the remote through a window to avoid pinching the cord in the door. Always disconnect the remote control when not in use.

10. Put wire rope under tension. Using the remote con- trol switch, slowly wind the wire rope until no slack remains. Once the wire rope is under tension, stand well clear of it and never step over it.

11. Check your anchor. Make sure all connections are secured and free of debris before continuing with the winching procedure.

12. Check wire rope. The wire rope should be neatly wound around the spooling drum. Improper winding can cause damage to the wire rope.

STARTING AND OPERATING 379

In certain situations you 13. may decide to throw a heavy blanket or similar object over the wire rope. A heavy blan- ket can absorb energy should the wire rope break. Place it on the wire rope midway be- tween the winch and the an- chor point. Do this before the wire rope is put under ten- sion. Do not approach or move the blanket once tension is applied. Do not allow it to get pulled into the fairlead. If it is necessary to move or remove the blanket, slack the tension on the wire rope first. 14. Establish ⴖno peopleⴖ zones: Make your intentions clear. Be sure that everyone in the immediate vicinity surrounding the winching operation is completely aware of your intentions before you pull. Declare where the spectators should not stand - never behind or in front of380 STARTING AND OPERATING the vehicle and never near the wire rope or snatch block. Your situation may have other ⴖno peopleⴖ zones.

For additional assistance, the winched vehicle can be slowly driven while being pulled by the winch. Continue pulling until the vehicle is on stable ground. If you are able to drive the vehicle, the winching operation is complete.

No People Zones

15. Begin winching. With the winching vehicles engine on and light tension already on the wire rope, begin winching slowly and steadily. Be sure that the wire rope is winding evenly and tightly around the spooling drum.

Using The Remote Control

NOTE: • Avoid overheating the winch motor. For extended winching, stop at reasonable intervals to allow the winch motor to cool down. • What to look for under load: The wire rope must always spool onto the drum as indicated by the drum rotation decal on the winch. As you power-in, make sure the wire rope winds evenly and tightly on the drum. This prevents the outer wire wraps from draw- ing into the inner wraps, binding and damaging the wire rope. Avoid shock loads by using the control switch intermittently to take up wire rope slack. Shock loads can momentarily far exceed the winch and wire rope ratings. During side pulls the wire rope tends to stack up at one end of the drum. This stack can become

STARTING AND OPERATING 381

large enough to cause serious damage to the winch. So, line up pulls as straight ahead as possible and stop winching if the wire rope comes close to the tie rods or mounting plate. To fix an uneven stack, spool out that section of the rope and reposition it to the opposite end of the drum, which will free up space for continued winching.16. Secure vehicle. Once recovery of the vehicle’s is complete, be sure to secure the vehicle’s brakes and put the transmission in PARK. Release tension in the wire rope. 17. Disconnect the wire rope, and disconnect from the anchor.