- 2009 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2011 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2010 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2007 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2008 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2005 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2004 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- Download PDF Manual

-

If you have added aftermarket accessories to the NOTE: spare tire mounted carrier, it cannot exceed a gross weight of 50 lbs (23 kg) including the weight of the spare tire. Preparations For Jacking Park the vehicle on a firm level surface, avoid ice or slippery areas, set the parking brake and place auto- matic transmission in P (Park), or manual transmission in R (Reverse). Turn OFF the ignition.

WARNING!

Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pull far enough off the road to avoid being hit when operating the jack or changing the wheel. • Turn on the Hazard Warning Flasher.

306 WHAT TO DO IN EMERGENCIES

• Block both the front and rear of the wheel diagonally oppo- site of the jacking position. For example, if changing the right front tire, block the left rear wheel. • Passengers should not remain in the vehicle when the

vehicle is being jacked.

4. Locate the jack as shown. For the front tires, place it in the notch on the body weld seam behind wheel to be changed. For the rear tires, place it under the axle by the wheel to be changed. Position the jack handle on the jack. Do not raise the vehicle until you are sure the jack is fully engaged.

Jacking Instructions

1. Remove spare tire. 2. Loosen (but do not remove) the wheel lug nuts by turning them to the left one turn while the wheel is still on the ground. 3. Remove jack and tools from mounting bracket. As- semble the tools by connecting the driver to the exten- sion, and then to the lug wrench.

Front Jacking Location

WHAT TO DO IN EMERGENCIES 307

WARNING!

Raising the vehicle higher than necessary can make the vehicle less stable and cause an accident. It could slip off the jack and hurt someone near it. Raise the vehicle only enough to remove the tire.

6. Remove the lug nuts and wheel. 7. Position the spare wheel/tire on the vehicle and install lug nuts with cone-shaped end toward wheel. Lightly tighten the nuts. To avoid the risk of forcing the vehicle off the jack, do not tighten the nuts fully until the vehicle has been lowered. 8. Lower the vehicle by turning the jack screw to the left, and remove the jack and wheel blocks. 9. Finish tightening the lug nuts. Push down on the wrench while tightening for increased leverage. Alternate

Rear Jacking Location

5. Raise the vehicle by turning the jack screw to the right. Raise the vehicle only until the tire just clears the surface and enough clearance is obtained to install the spare tire. Minimum tire lift provides maximum stability.

308 WHAT TO DO IN EMERGENCIES

nuts until each nut has been tightened twice. Correct wheel nut tightness is 130 N·m (95 ft. lbs). If in doubt about the correct tightness, have them checked with a torque wrench by your authorized dealer or at a service station. 10. Lower the jack to it’s fully closed position.

WARNING!

A loose tire or jack, thrown forward in a collision or hard stop could endanger the occupants of the ve- hicle. Always stow the jack parts and the spare tire in the places provided.

11. Secure the tire, jack, and tools in their proper loca- tions.

JUMP STARTING If the vehicle has a discharged battery, booster cables may be used to obtain a start from a booster battery or the battery in another vehicle. This type of start can be dangerous if done improperly, so follow this procedure carefully.

WARNING!

Battery fluid is a corrosive acid solution; do not allow battery fluid to contact eyes, skin or clothing. Don’t lean over battery when attaching clamps or allow the clamps to touch each other. If acid splashes in eyes or on skin, flush contaminated area immedi- ately with large quantities of water. A battery generates hydrogen gas which is flam- mable and explosive. Keep flame or spark away from the vent holes. Do not use a booster battery or any other booster source that has a greater than 12 volt system, i.e. Do not use a 24 volt power source.

1. Remove all metal jewelry such as watch bands or bracelets which might make an unintended electrical contact.

WHAT TO DO IN EMERGENCIES 309

2. Park the booster vehicle within cable reach but with- out letting the vehicles touch. Set the parking brake on both vehicles, place the automatic transmission in P (Park) or the manual transmission in N (Neutral), and turn the ignition OFF. 3. Turn off the heater, radio, and all unnecessary electri- cal loads. 4. Connect one end of a jumper cable to the positive terminal of the booster battery. Connect the other end of the same cable to the positive terminal of the discharged battery.

WARNING!

Do not permit vehicles to touch each other as this could establish a ground connection and personal injury could result.

310 WHAT TO DO IN EMERGENCIES

5. Connect the other cable, first to the negative terminal of the booster battery and then to the engine of the vehicle with the discharged battery. Make sure you have a good contact on the engine.

WARNING!

ing or towing.

• You should not try to start your vehicle by push- • Do not connect the cable to the negative post of the discharge battery. The resulting electrical spark could cause the battery to explode. • During cold weather when temperatures are be- low freezing point, electrolyte in a discharged battery may freeze. Do not attempt jump starting because the battery could rupture or explode. The battery temperature must be brought up above freezing point before attempting jump start.

6. Start the engine in the vehicle which has the booster battery, let the engine idle a few minutes, then start the engine in the vehicle with the discharged battery. 7. When removing the jumper cables, reverse the above sequence exactly. Be careful of the moving belts and fan.

WARNING!

Any procedure other than above could result in: 1. Personal injury caused by electrolyte squirting out the battery vent; 2. Personal injury or property damage due to battery explosion; 3. Damage to charging system of booster vehicle or of immobilized vehicle.

EMERGENCY TOW HOOKS — IF EQUIPPED If your vehicle is equipped with tow hooks, they are mounted in the front and the rear.

CAUTION!

Tow hooks are for emergency use only, to rescue a vehicle stranded off road. Do not use tow hooks for tow truck hookup or highway towing. You could damage your vehicle. Tow straps are recommended when tow- ing the vehicle, chains may cause vehicle damage.

WARNING!

Stand clear of vehicles when pulling with tow hooks. Tow straps and chains may break, causing serious injury.

WHAT TO DO IN EMERGENCIES 311

TOWING A DISABLED VEHICLE

2WD Models Only Provided the transmission is operable, tow only in N (Neutral) at speeds not exceeding 30 mph (48 km/h), for distances of not more than 15 miles (24 km). Towing at more than 30 mph (48 km/h) or for more than 15 miles (24 km) can cause severe transmission damage. If the transmission is not operable, or the vehicle must be towed faster than 30 mph (48 km/h) or farther than 15

miles (24 km), tow with all four wheels OFF the ground. Acceptable methods are to tow the vehicle on a flatbed or with one end of the vehicle raised and the other end on a towing dolly. Removing the driveshaft for towing is not recommended since this can allow fluid to drain from the transmission.312 WHAT TO DO IN EMERGENCIES

4WD Models Only The manufacturer recommends towing with all four wheels OFF the ground. Acceptable methods are to tow the vehicle on a flatbed or with one end of the vehicle raised and the other end on a towing dolly.

MAINTAINING YOUR VEHICLE

CONTENTS

䡵 Engine Compartment – 3.7L . . . . . . . . . . . . . . . 316

䡵 Onboard Diagnostic System — OBD II . . . . . . . . 317

▫ Loose Fuel Filler Cap Message . . . . . . . . . . . . 317䡵 Emissions Inspection And

Maintenance Programs . . . . . . . . . . . . . . . . . . . 318

䡵 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . 319

䡵 Dealer Service . . . . . . . . . . . . . . . . . . . . . . . . . 319

䡵 Maintenance Procedures . . . . . . . . . . . . . . . . . . 320

. . . . . . . . . . . . . . . . . . . . . . . . . . 320▫ Engine Oil

▫ Drive Belts — Check Condition And Tension . . 323

▫ Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . 324

▫ Spark Plug Wires . . . . . . . . . . . . . . . . . . . . . 324

▫ Engine Air Cleaner Filter . . . . . . . . . . . . . . . . 324

▫ Catalytic Converter . . . . . . . . . . . . . . . . . . . . 325

▫ Crankcase Emission Control System . . . . . . . . 327

▫ Maintenance-Free Battery . . . . . . . . . . . . . . . . 327

▫ Air Conditioner Maintenance . . . . . . . . . . . . . 329

▫ Power Steering Fluid Check . . . . . . . . . . . . . . 330314 MAINTAINING YOUR VEHICLE

▫ Driveline And Steering Component

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . 331

▫ Body Lubrication . . . . . . . . . . . . . . . . . . . . . 331

▫ Windshield Wiper Blades . . . . . . . . . . . . . . . . 331

▫ Windshield Washers . . . . . . . . . . . . . . . . . . . 332

▫ Exhaust System . . . . . . . . . . . . . . . . . . . . . . 333

▫ Cooling System . . . . . . . . . . . . . . . . . . . . . . . 333

▫ Hoses And Vacuum/Vapor Harnesses . . . . . . . 338

▫ Fuel System Connections . . . . . . . . . . . . . . . . 339

▫ Brake System . . . . . . . . . . . . . . . . . . . . . . . . 339

▫ Clutch Hydraulic System —Manual Transmission Only . . . . . . . . . . . . . . 342

▫ Front/Rear Axle Fluid . . . . . . . . . . . . . . . . . . 342

▫ Transfer Case . . . . . . . . . . . . . . . . . . . . . . . . 343▫ Manual Transmission . . . . . . . . . . . . . . . . . . 344

▫ Automatic Transmission . . . . . . . . . . . . . . . . 345

▫ Appearance Care And ProtectionFrom Corrosion . . . . . . . . . . . . . . . . . . . . . . 347

. . . . . . . . . . . . . . . . . . . . . . . . . . . 353

▫ Interior Fuses . . . . . . . . . . . . . . . . . . . . . . . . 353

▫ Underhood Fuses䡵 Fuse Panel

(Power Distribution Center) . . . . . . . . . . . . . . 356

䡵 Vehicle Storage . . . . . . . . . . . . . . . . . . . . . . . . 361

䡵 Replacement Bulbs . . . . . . . . . . . . . . . . . . . . . . 361

䡵 Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . 362

▫ Head Light . . . . . . . . . . . . . . . . . . . . . . . . . . 362

▫ Front Turn Signal . . . . . . . . . . . . . . . . . . . . . 363

▫ Front Fog Light (Front Fascia Mounted) . . . . . 364▫ Rear Tail, Stop, Turn Signal, And

Back-Up Lights . . . . . . . . . . . . . . . . . . . . . . . 365

▫ Center High Mounted Stop Light (CHMSL) . . . 365

. . . . . . . . . . . . . . . . . . . 366䡵 Fluids And Capacities

MAINTAINING YOUR VEHICLE 315

䡵 Fluids, Lubricants, And Genuine Parts . . . . . . . . 367

▫ Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

▫ Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368316 MAINTAINING YOUR VEHICLE

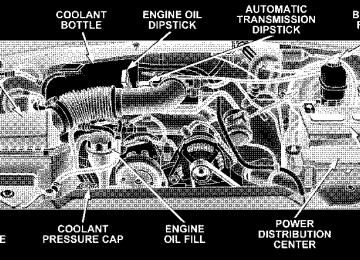

ENGINE COMPARTMENT – 3.7L

ONBOARD DIAGNOSTIC SYSTEM — OBD II Your vehicle is equipped with a sophisticated onboard diagnostic system called OBD II. This system monitors the performance of the emissions, engine, and automatic transmission control systems. When these systems are operating properly, your vehicle will provide excellent performance and fuel economy, as well as engine emis- sions well within current government regulations. If any of these systems require service, the OBD II system will turn on the “Malfunction Indicator Light.” It will also store diagnostic codes and other information to assist your service technician in making repairs. Al- though your vehicle will usually be drivable and not need towing, see your dealer for service as soon as possible.

MAINTAINING YOUR VEHICLE 317

CAUTION!

• Prolonged driving with the “Malfunction Indica- tor Light” on could cause further damage to the emission control system. It could also affect fuel economy and driveability. The vehicle must be serviced before any emissions tests can be per- formed. • If the “Malfunction Indicator Light” is flashing while the engine is running, severe catalytic con- verter damage and power loss will soon occur. Immediate service is required.

Loose Fuel Filler Cap Message If the vehicle diagnostic system determines that the fuel filler cap is loose, improperly installed, or damaged, a “GAS CAP” message will be displayed in the odometer (located on the instrument cluster). Replace, or tighten

318 MAINTAINING YOUR VEHICLE

the fuel filler cap properly to turn the message off (light will time out). If the problem continues, the message will appear the next time the vehicle is started.

EMISSIONS INSPECTION AND MAINTENANCE PROGRAMS In some localities, it may be a legal requirement to pass an inspection of your vehicle’s emissions control system. Failure to pass could prevent vehicle registration.

For states, which have an I/M (Inspection and Maintenance) requirement, this check verifies the following: the MIL (Malfunction Indicator Lamp) is functioning and is not on when the engine is running, and that the OBD (On Board Diagnostic) system is ready for testing. Normally, the OBD system will be ready. The OBD system may not be ready if your vehicle was recently serviced, if you recently had a dead battery, or a battery

replacement. If the OBD system should be determined not ready for the I/M test, your vehicle may fail the test. Your vehicle has a simple ignition key actuated test, which you can use prior to going to the test station. To check if your vehicle’s OBD system is ready, you must do the following: 1. Insert your ignition key into the ignition switch. 2. Turn the ignition to the ON position, but do not crank or start the engine. 3. If you crank or start the engine, you will have to start this test over. 4. As soon as you turn your key to the ON position, you will see your MIL symbol come on as part of a normal bulb check. 5. Approximately 15 seconds later, one of two things will happen:

a. The MIL will flash for about 10 seconds and then return to being fully illuminated until you turn off the ignition key or start the engine. This means that your vehicle’s OBD system is not ready and you should not proceed to the I/M station. b. The MIL will not flash at all and will remain fully illuminated until you turn off the ignition key or start the engine. This means that your vehicle’s OBD system is ready and you can proceed to the I/M station.

If your OBD system is not ready, you should see your authorized dealer or repair facility. If your vehicle was recently serviced or had a battery failure or replacement, you may need to do nothing more than drive your vehicle as you normally would in order for your OBD system to update. A recheck with the above test routine may then indicate that the system is now ready. Regardless of whether your vehicle’s OBD system is ready or not ready, if the MIL symbol is illuminated

MAINTAINING YOUR VEHICLE 319

during normal vehicle operation, you should have your vehicle serviced before going to the I/M station. The I/M station can fail your vehicle because the MIL symbol is on with the engine running.

REPLACEMENT PARTS Use of genuine Mopar威 parts for normal/scheduled maintenance and repairs is highly recommended to in- sure the designed performance. Damage or failures caused by the use of non-Mopar威 parts for maintenance and repairs will not be covered by the manufacturer’s warranty.

DEALER SERVICE Your dealer has the qualified service personnel, special tools, and equipment to perform all service operations in an expert manner. Service Manuals are available which include detailed service information for your vehicle. Refer to these manuals before attempting any procedure yourself.

320 MAINTAINING YOUR VEHICLE

NOTE: systems can result against you.

Intentional tampering with emissions control in civil penalties being assessed

WARNING!

You can be badly injured working on or around a motor vehicle. Only do service work for which you have the knowledge and the proper equipment. If you have any doubt about your ability to perform a service job, take your vehicle to a competent mechanic.

MAINTENANCE PROCEDURES The pages that follow contain the required maintenance services determined by the engineers who designed your vehicle. Besides the maintenance items for which there are fixed maintenance intervals, there are other items that should operate satisfactorily without periodic maintenance.

However, if a malfunction of these items does occur, it could adversely affect the engine or vehicle performance. These items should be inspected if a malfunction is observed or suspected. Engine Oil

Checking Oil Level To assure proper lubrication of your vehicle’s engine, the engine oil must be maintained at the correct level. Check the oil level at regular intervals, such as every fuel stop. The best time to check the engine oil level is about 5

minutes after a fully warmed engine has been shut off, or before starting the engine after it has sat overnight. Checking the oil while the vehicle is on level ground will improve the accuracy of the oil level readings. Maintain the oil level between the ADD and SAFE markings on the dipstick. Adding 1 U.S. Quart (0.95L) of oil when the reading is at the ADD mark will result in a SAFE reading on these engines.CAUTION!

Overfilling or underfilling the crankcase will cause aeration or loss of oil pressure. This could damage your engine.

Change Engine Oil Road conditions as well as your kind of driving affect the interval at which your oil should be changed. Check the following to determine if any apply to you: • Day or night temperatures are below 32°F (0°C) • Stop and go driving • Extensive engine idling • Driving in dusty conditions • Short trip driving of less than 10 miles (16.2 km)

MAINTAINING YOUR VEHICLE 321

speeds during hot weather, above 90°F (32°C)

• More than 50% of your driving is at sustained high • Taxi, Police, or delivery service (commercial service) • Trailer towing • Off-road or desert driving If ANY of these apply to you, then change your engine oil at every interval shown in schedule “B” of the “Mainte- nance Schedules” section of this manual. If none of these apply to you, then change your engine oil at every interval shown on schedule “A” of the “Main- tenance Schedules” section of this manual NOTE: Under no circumstances should oil change in- tervals exceed 6,000 miles (10 000 km) or 6 months whichever comes first.

322 MAINTAINING YOUR VEHICLE

Engine Oil Selection For best performance and maximum protection for all engines under all types of operating conditions, the manufacturer recommends engine oils that are API Cer- tified and meet the requirements of DaimlerChrysler Material Standard MS-6395. American Petroleum Institute (API) Engine Oil Identification Symbol

This symbol means that the oil has been certified by the American Petroleum Institute (API). The manufacturer only 0recommends API Certified engine oils.

Engine Oil Viscosity SAE 5W-20 engine oil is recommended for all operating temperatures. This engine oil improves low tempera- ture starting and vehicle fuel economy. Your engine oil filler cap also shows the recommended engine oil viscosity for your vehicle. For information on engine oil filler cap location, see the Engine Compartment illustration in this section. Lubricants which do not have both, the engine oil certi- fication mark and the correct SAE viscosity grade num- ber should not be used. Synthetic Engine Oils You may use synthetic engine oils provided the recom- mended oil quality requirements are met, and the recom- mended maintenance intervals for oil and filter changes are followed.

Materials Added To Engine Oils The manufacturer strongly recommends against the ad- dition of any additives (other than leak detection dyes) to engine oil. Engine oil is an engineered product and it’s performance may be impaired by supplemental addi- tives. Disposing of Used Engine Oil and Oil Filters Care should be taken in disposing of used engine oil and oil filters from your vehicle. Used oil and oil filters, indiscriminately discarded, can present a problem to the environment. Contact your authorized dealer, service station, or governmental agency for advice on how and where used oil and oil filters can be safely discarded in your area. Engine Oil Filter The engine oil filter should be replaced at every engine oil change.

MAINTAINING YOUR VEHICLE 323

Engine Oil Filter Selection All of the manufacturer’s engines have a full-flow type disposable oil filter. Use a filter of this type for replace- ment. The quality of replacement filters varies consider- ably. Only high quality filters should be used to assure most efficient service. Mopar威 engine oil filters are high quality oil filters and are recommended. Drive Belts — Check Condition and Tension At the mileage shown in the appropriate “Maintenance Schedule,” check all drive belts for condition and proper tension. Improper belt tension can cause belt slippage and failure. Inspect the drive belt for evidence of cuts, cracks, or glazing and replace them if there is any sign of damage which could result in belt failure. If adjustment is re- quired, adjust the belts according to the specifications and procedures shown in the Service Manual.

324 MAINTAINING YOUR VEHICLE

Special tools are required to properly measure tension and to restore belt tension to factory specifications. Also, check belt routing to make sure there is no interference between the belts and other engine components. Spark Plugs Spark plugs must fire properly to assure engine perfor- mance and emission control. New plugs should be in- stalled at the mileage specified in the appropriate main- tenance chart. The entire set should be replaced if there is any malfunction due to a faulty spark plug. Refer to the “Vehicle Emission Control Information” label in the engine compartment for spark plug information. Spark Plug Wires The spark plug wires should be kept clean and properly connected. Terminals should be fully seated. Cracked, damaged, or faulty wires should be replaced.

Engine Air Cleaner Filter Under normal driving conditions, replace the air filter at the intervals shown on “Maintenance Schedule A.” If, however, you drive the vehicle frequently under dusty or severe conditions, the filter element should be inspected periodically and replaced if necessary at the intervals shown on “Maintenance Schedule B.”

WARNING!

The air induction system (air cleaner, hoses, etc) can provide a measure of protection in the case of engine backfire. Do not remove the air induction system (air cleaner, hoses, etc) unless such removal is necessary for repair or maintenance. Make sure that no one is near the engine compartment before starting the vehicle with the air induction system (air cleaner, hoses, etc) removed. Failure to do so can result in serious personal injury.

Catalytic Converter The catalytic converter requires the use of unleaded fuel only. Leaded gasoline will destroy the effectiveness of the converter as an emission control device. Under normal operating conditions, the catalytic con- verter will not require maintenance. However, it is im- portant to keep the engine properly tuned to assure proper catalyst operation and prevent possible catalyst damage.

MAINTAINING YOUR VEHICLE 325

CAUTION!

Damage to the catalytic converter can result if your vehicle is not kept in proper operating condition. In the event of engine malfunction, particularly involv- ing engine misfire or other apparent loss of perfor- mance, have your vehicle serviced promptly. Contin- ued operation of your vehicle with a severe malfunction could cause the converter to overheat, resulting in possible damage to the converter and vehicle.

NOTE: systems can result against you.

Intentional tampering with emissions control in civil penalties being assessed

326 MAINTAINING YOUR VEHICLE

WARNING!

A hot exhaust system can start a fire if you park over materials that can burn. Such materials might be grass or leaves coming into contact with your ex- haust system. Do not park or operate your vehicle in areas where your exhaust system can contact any- thing that can burn.

In unusual situations involving grossly malfunctioning engine operation, a scorching odor may suggest severe and abnormal catalyst overheating. If this occurs, stop the vehicle, turn off the engine and allow it to cool. Service, including a tune up to manufacturer’s specifica- tions, should be obtained immediately.

To minimize the possibility of catalytic converter damage: • Do not shut off the engine or interrupt the ignition when the transmission is in gear and the vehicle is in motion. • Do not try to start the engine by pushing or towing the • Do not idle the engine with any spark plug wires disconnected or removed, such as when diagnostic testing, or for prolonged periods during very rough idle or malfunctioning operating conditions.

vehicle.

Crankcase Emission Control System Proper operation of this system depends on freedom from sticking or plugging due to deposits. As vehicle mileage builds up, the PCV valve and passages may accumulate deposits. If a valve is not working properly, replace it with a new valve. DO NOT ATTEMPT TO CLEAN THE OLD PCV VALVE! Check ventilation hose for indication of damage or plugging deposits. Replace if necessary. Maintenance-Free Battery Your vehicle is equipped with a maintenance-free battery. You will never have to add water, nor is periodic main- tenance required.

MAINTAINING YOUR VEHICLE 327

WARNING!

• Battery fluid is a corrosive acid solution and can burn or even blind you. Don’t allow battery fluid to contact your eyes, skin or clothing. Don’t lean over a battery when attaching clamps. If acid splashes in eyes or on skin, flush the area imme- diately with large amounts of water. • Battery gas is flammable and explosive. Keep flame or sparks away from the battery. Don’t use a booster battery or any other booster source with an output greater than 12 volts. Don’t allow cable clamps to touch each other. • Battery posts, terminals, and related accessories contain lead and lead compounds. Always wash hands after handling the battery.

328 MAINTAINING YOUR VEHICLE

To determine the battery charge, check the battery test indicator (if equipped) on top of the battery. Refer to the illustration.

CAUTION!

• It is essential when replacing the cables on the battery that the positive cable is attached to the positive post and the negative cable is attached to the negative post. Battery posts are marked (+) positive and negative (-) and identified on the battery case. • If a “fast charger” is used while battery is in the vehicle, disconnect both vehicle battery cables before connecting the charger to battery. Do not use a “fast charger” to provide starting voltage.

Air Conditioner Maintenance For best possible performance, your air conditioner should be checked and serviced by an Authorized Dealer at the start of each warm season. This service should include cleaning of the condenser fins and a performance test. Drive belt tension should also be checked at this time.

MAINTAINING YOUR VEHICLE 329

WARNING!

• Use only refrigerants and compressor lubricants approved by the manufacturer for your air condi- tioning system. Some unapproved refrigerants are flammable and can explode, injuring you. Other unapproved refrigerants or lubricants can cause the system to fail, requiring costly repairs. Refer to Section 3 of the Warranty Information Book for additional warranty information. • The air conditioning system contains refrigerant under high pressure. To avoid risk of personal injury or damage to the system, adding refrigerant or any repair requiring lines to be disconnected should be done by an experienced repairman.

330 MAINTAINING YOUR VEHICLE

Refrigerant Recovery and Recycling R-134a Air Conditioning Refrigerant is a hydrofluorocar- bon (HFC) that is endorsed by the Environmental Pro- tection Agency and is an ozone-saving product. How- ever, the manufacturer recommends that air conditioning service be performed by dealers or other service facilities using recovery and recycling equipment. Power Steering Fluid Check Checking the power steering fluid level at a defined service interval is not required. The fluid should only be checked if a leak is suspected, abnormal noises are apparent, and/or the system is not functioning as antici- pated. Coordinate inspection efforts through a certified “DaimlerChrysler Dealership.”

WARNING!

Fluid level should be checked on a level surface with the engine off to prevent injury from moving parts, and to insure accurate fluid level reading. Do not overfill. Use only the manufacturer’s recommended fluid.

If necessary, add fluid to restore to the proper indicated level. With a clean cloth, wipe any spilled fluid from all surfaces. Refer to Fluids, Lubricants, and Genuine Parts for correct fluid type. NOTE: Upon initial start-up in cold weather, the power steering pump may make noise for a short period of time. This is due to the cold, thick fluid in the steering system. This noise should be considered normal, and does not in any way damage the steering system.

Driveline And Steering Component Lubrication U-joints (cardan joints) are sealed and do not require lubrication. Prop shafts, yokes, ball joints and other driveline and steering components may be provided with grease fittings for lubrication. Lubrication of these com- ponents at the intervals specified in the appropriate “Maintenance Schedule” in Section 8 is very important, particularly if your vehicle is subjected to off-road or other heavy-duty use. See your authorized dealer for complete service information. Body Lubrication Locks and all body pivot points, including such items as seat tracks, doors, swing gate and hood hinges, should be lubricated periodically to assure quiet, easy operation and to protect against rust and wear. Prior to the appli- cation of any lubricant, the parts concerned should be wiped clean to remove dust and grit; after lubricating excess oil and grease should be removed. Particular

MAINTAINING YOUR VEHICLE 331

attention should also be given to hood latching compo- nents to insure proper function. When performing other underhood services, the hood latch, release mechanism and safety catch should be cleaned and lubricated. The external lock cylinders should be lubricated twice a year, preferably in the fall and spring. Apply a small amount of a high quality lubricant such as Mopar威 Lock Cylinder Lubricant directly into the lock cylinder. Windshield Wiper Blades Clean the rubber edges of the wiper blades and the windshield periodically with a sponge or soft cloth and a mild non-abrasive cleaner. This will remove accumula- tions of salt or road film. Operation of the wipers on dry glass for long periods may cause deterioration of the wiper blades. Always use washer fluid when using the wipers to remove salt or dirt from a dry windshield.

332 MAINTAINING YOUR VEHICLE

Avoid using the wiper blades to remove frost or ice from the windshield. Keep the blade rubber out of contact with petroleum products such as engine oil, gasoline, etc. Windshield Washers The fluid reservoir for the windshield washers and the rear window washer is shared. It is located in the front of the engine compartment on the passenger side and should be checked for fluid level at regular intervals. Fill the reservoir with windshield washer solvent (not antifreeze/coolant) and operate the system for a few seconds to flush out the residual water.

WARNING!

Commercial windshield washer solvents are flam- mable. They could ignite and burn you. Care must be exercised when filling or working around the washer solution.

Exhaust System The best protection against carbon monoxide entry into the vehicle body is a properly maintained engine exhaust system. If you notice a change in the sound of the exhaust system; or if the exhaust fumes can be detected inside the vehicle; or when the underside or rear of the vehicle is damaged; have an authorized technician inspect the complete ex- haust system and adjacent body areas for broken, dam- aged, deteriorated, or mispositioned parts. Open seams or loose connections could permit exhaust fumes to seep into the passenger compartment. In addition, inspect the exhaust system each time the vehicle is raised for lubri- cation or oil change. Replace as required.

MAINTAINING YOUR VEHICLE 333

Cooling System

WARNING!

You or others can be badly burned by hot antifreeze/ coolant or steam from your radiator. If you see or hear steam coming from under the hood, don’t open the hood until the radiator has had time to cool. Never try to open a cooling system pressure cap when the radiator or coolant bottle is hot.

Engine Coolant Checks Check antifreeze/coolant protection every 12 months (before the onset of freezing weather, where applicable). If antifreeze/coolant is dirty or rusty in appearance, the system should be drained, flushed and refilled with fresh antifreeze/coolant. Check the front of the A/C condenser (if equipped) or radiator for any accumulation of bugs,

334 MAINTAINING YOUR VEHICLE

leaves, etc. If dirty, clean by gently spraying water from a garden hose vertically down the face of the A/C con- denser (if equipped) or the radiator core. Check the engine cooling system hoses for brittle rubber, cracking, tears, cuts, and tightness of connection at the coolant recovery bottle and radiator. Inspect the entire system for leaks. Cooling System — Drain, Flush, And Refill At the intervals shown on the appropriate “Maintenance Schedule” the system should be drained, flushed, and refilled.

If the coolant solution is dirty or contains a considerable amount of sediment, clean and flush with a reliable cooling system cleaner (see your authorized dealer for recommendations). Follow with a thorough rinsing to remove all deposits and chemicals. Properly dispose of old antifreeze/coolant solution. Selection Of Coolant Use only the manufacturer’s recommended antifreeze/ coolant, refer to Fluids, Lubricants, and Genuine Parts for correct antifreeze/coolant type.

CAUTION!

• Mixing of antifreeze/coolant other than the speci- fied HOAT antifreeze/coolant may result in de- creased corrosion protection and engine damage. If a non-HOAT antifreeze/coolant is introduced into the cooling system in an emergency, it should be replaced with the specified antifreeze/coolant as soon as possible. • Do not use plain water alone or alcohol base antifreeze/coolant products. Do not use additional rust inhibitors or antirust products, as they may not be compatible with the antifreeze/coolant and may plug the radiator. • This vehicle has not been designed for use with Propylene Glycol based antifreeze/coolant. Use of Propylene Glycol base antifreeze/coolant is not recommended.

MAINTAINING YOUR VEHICLE 335

Adding Coolant Your vehicle has been built with an improved antifreeze/ coolant that allows extended maintenance intervals. This antifreeze/coolant can be used up to 5 Years or 100,000

miles before replacement. To prevent reducing this ex- tended maintenance period, it is important that you use the same antifreeze/coolant throughout the life of your vehicle. Please review these recommendations for using Hybrid Organic Additive Technology (HOAT) coolant. When adding antifreeze/coolant, a minimum solution of 50% recommended Mopar威 Antifreeze/Coolant 5 Year/ 100,000 Mile Formula HOAT (Hybrid Organic Additive Technology), or equivalent, in water should be used. Use higher concentrations (not to exceed 70%) if temperatures below -34°F (-37°C) are anticipated.336 MAINTAINING YOUR VEHICLE

Use only high purity water such as distilled or deionized water when mixing the water/antifreeze (coolant) solu- tion. The use of lower quality water will reduce the amount of corrosion protection in the engine cooling system. Please note that it is the owner’s responsibility to main- tain the proper level of protection against freezing ac- cording to the temperatures occurring in the area where the vehicle is operated. NOTE: Mixing antifreeze/coolant types will decrease the life of the antifreeze/coolant and will require more frequent antifreeze/coolant changes. Cooling System Pressure Cap The cap must be fully tightened to prevent loss of antifreeze/coolant, and to insure that antifreeze/coolant will return to the radiator from the coolant recovery bottle.

The cap should be inspected and cleaned if there is any accumulation of foreign material on the sealing surfaces.

WARNING!

• The warning words DO NOT OPEN HOT on the cooling system pressure cap are a safety precau- tion. Never add antifreeze/coolant when the en- gine is overheated. Do not loosen or remove the cap to cool an overheated engine. Heat causes pressure to build up in the cooling system. To prevent scalding or injury, do not remove the pressure cap while the system is hot or under pressure. • Do not use a pressure cap other than the one specified for your vehicle. Personal injury or engine damage may result.

Disposal of Used Engine Coolant Used Hybrid Organic Additive Technology (HOAT) antifreeze/coolant is a regulated substance requiring proper disposal. Check with your local authorities to determine the disposal rules for your community. To prevent ingestion by animals or children, do not store HOAT antifreeze/coolant in open containers, or allow it to remain in puddles on the ground. If ingested by a child, contact a physician immediately. Clean up ground spills immediately. Coolant Level The coolant recovery bottle provides a quick visual method for determining that the antifreeze/coolant level is adequate. With the engine idling, and warm to normal operating temperature, the level of the antifreeze/coolant should be between the ranges indicated on the bottle. The radiator normally remains completely full, so there is no need to remove the radiator cap unless checking for

MAINTAINING YOUR VEHICLE 337

antifreeze/coolant freeze point or replacing coolant. Ad- vise your service attendant of this. As long as the engine operating temperature is satisfactory, the coolant bottle need only be checked once a month. When additional antifreeze/coolant is needed to main- tain the proper level, it should be added to the coolant recovery bottle. Do not overfill. Points To Remember NOTE: When the vehicle is stopped after a few miles (kilometers) of operation, you may observe vapor coming from the front of the engine compartment. This is nor- mally a result of moisture from rain, snow, or high humidity accumulating on the radiator and being vapor- ized when the thermostat opens, allowing hot water to enter the radiator.

338 MAINTAINING YOUR VEHICLE

If an examination of your engine compartment shows no evidence of radiator or hose leaks, the vehicle may be safely driven. The vapor will soon dissipate. • Do not overfill the coolant recovery bottle. • Check antifreeze/coolant freeze point in the system. • If frequent antifreeze/coolant additions are required, or if the level in the recovery bottle does not drop when the engine cools, the cooling system should be pressure tested for leaks. • Maintain engine coolant/anti-freeze concentration to 50% HOAT engine coolant/anti-freeze (minimum) and distilled water for proper corrosion protection of your engine which contains aluminum components. • Make sure that the radiator and coolant recovery

bottle hoses are not kinked or obstructed.

• Keep the front of the radiator clean. Also, if your vehicle is equipped with air conditioning, keep the front of the condenser clean. • Do not change the thermostat for summer or winter operation. If replacement is ever necessary, install ONLY the correct type thermostat. Other designs may result in unsatisfactory cooling performance, poor gas mileage, and increased emissions.

Hoses and Vacuum/Vapor Harnesses Inspect surfaces of hoses and nylon tubing for evidence of heat and mechanical damage. Hard or soft spots, brittle rubber, cracking, tears, cuts, abrasions, and exces- sive swelling indicate deterioration of the rubber. Pay particular attention to the hoses nearest to high heat sources such as the exhaust manifold. Inspect hose rout- ing to be sure hoses do not touch any heat source or moving component that may cause heat damage or mechanical wear.

Insure nylon tubing in these areas has not melted or collapsed. Inspect all hose connections such as clamps and couplings to make sure they are secure and no leaks are present. Components should be replaced immedi- ately if there is any evidence of degradation that could cause failure. Fuel System Connections Electronic Fuel Injection high pressure fuel systems are designed with tubes and special connects, connections and clamps which have unique material characteristics to provide adequate sealing and resist attack by deterio- rated gasoline. You are urged to use only the manufactures-specified tubes, connections and clamps, or their equivalent in material and specification, in any fuel system servicing.

MAINTAINING YOUR VEHICLE 339

Brake System In order to assure brake system performance, all brake system components should be inspected periodically. Refer to the appropriate “Maintenance Schedule” in Section 8 for suggested service intervals.

WARNING!

Riding the brakes can lead to brake failure and possibly an accident. Driving with your foot resting or riding on the brake pedal can result in abnormally high brake temperatures, excessive lining wear, and possible brake damage. You wouldn’t have your full braking capacity in an emergency.

Brake and Power Steering System Hoses When servicing the vehicle for scheduled maintenance, inspect surface of hoses for evidence of heat and me- chanical damage. Hard and brittle rubber, cracking, tears,

340 MAINTAINING YOUR VEHICLE

cuts, abrasion, and excessive swelling suggest deteriora- tion of the rubber. Particular attention should be made to examining those hose surfaces nearest to high heat sources, such as the exhaust manifold. Inspect all hose clamps and couplings to make sure they are secure and no leaks are present. NOTE: Often fluids such as oil, power steering fluid, and brake fluid are used during assembly plant opera- tions to ease the assembly of hoses to couplings. There- fore, oil wetness at the hose-coupling area is not neces- sarily an indication of leakage. Actual dripping of hot fluid when systems are under pressure (during vehicle operation) should be noted before hose is replaced based on leakage.

Inspection of brake hoses should be done when- NOTE: ever the brake system is serviced and every engine oil change.

WARNING!

Worn brake hoses can burst and cause brake failure. You could have an accident. If you see any signs of cracking, scuffing, or worn spots, have the brake hoses replaced immediately.

Brake Master Cylinder — Brake Fluid Level Check The fluid level in the master cylinder should be checked when performing under hood services, or immediately if the “Brake Warning Light” shows system failure.

Be sure to clean the top of the master cylinder area before removing the cap. If necessary, add fluid to bring the fluid level up to the requirements described on the brake

MAINTAINING YOUR VEHICLE 341

fluid reservoir. With disc brakes, fluid level can be expected to fall as the brake pads wear. However, low fluid level may be caused by a leak and a checkup may be needed. Use only manufacturer’s recommended brake fluid, refer to Fluids, Lubricants, and Genuine Parts for correct fluid type.

WARNING!

Use of a brake fluid that may have a lower initial boiling point or unidentified as to specification, may result in sudden brake failure during hard pro- longed braking. You could have an accident.

342 MAINTAINING YOUR VEHICLE

WARNING!

Overfilling the brake fluid reservoir can result in spilling brake fluid on hot engine parts and the brake fluid catching fire.

Use only brake fluid that has been in a tightly closed container to avoid contamination from foreign matter. Do not allow petroleum base fluid to contaminate the brake fluid as seal damage will result. Clutch Hydraulic System — Manual Transmission Only The clutch hydraulic system is a sealed maintenance free system. In the event of leakage or other malfunction, the system must be replaced.

Front/Rear Axle Fluid The front axle has a threaded “fill plug” on the cover plate, and a threaded “drain plug” on the bottom side of the carrier. Fluid Level Check Lubricant should be 1/2⬙ (1 cm) below the oil fill hole. Adding Fluid Add lubricant only at the fill hole and only to the level specified above. Selection of Lubricant Use only manufacturer’s recommended fluid, refer to Fluids, Lubricants, and Genuine Parts for correct fluid type.

MAINTAINING YOUR VEHICLE 343

Transfer Case

Fluid Level Check Inspect the transfer case for fluid leaks. If a fluid leak is evident, the transfer case fluid level can be checked by removing the fill plug (B) located at the back of the transfer case. The fluid level should be to the bottom edge of the fill hole (A) when the vehicle is in a level position.

Adding Fluid Only at filler hole until fluid runs out of the hole, when the vehicle is in a level position. Drain First remove fill plug (B), then drain plug (C). Recom- mended tightening torque for drain and fill plugs is 15–25 ft. lbs. (20–34 N·m).

344 MAINTAINING YOUR VEHICLE

CAUTION!

When installing plugs, do not overtighten. You could damage them and cause them to leak.

Selection of Lubricant Use only manufacturer’s recommended fluid, refer to Fluids, Lubricants, and Genuine Parts for correct fluid type. Manual Transmission

Selection of Lubricant Use only manufacturer’s recommended manual trans- mission fluid, refer to Fluids, Lubricants, and Genuine Parts for correct fluid type.

Fluid Level Check Check the fluid level by removing the fill plug. The fluid level should be between the bottom of the fill hole and a point not more than 3/16” (4.76 mm) below the bottom of the hole. Add fluid, if necessary, to maintain the proper level. Frequency of Fluid Change Under normal operating conditions, the fluid installed at the factory will give satisfactory lubrication for the life of the vehicle. Fluid changes are not necessary unless the lubricant has become contaminated with water. If con- taminated with water, the fluid should be changed im- mediately.

Automatic Transmission

Selection of Lubricant It is important that the proper lubricant is used in the transmission to assure optimum transmission perfor- mance. Use only manufacturer’s recommended transmis- sion fluid, refer to Fluids, Lubricants, and Genuine Parts for correct fluid type. It is important that the transmission fluid be maintained at the prescribed level using the recommended fluid.

MAINTAINING YOUR VEHICLE 345

CAUTION!

Using a transmission fluid other than the manufac- turer’s recommended fluid may cause deterioration in transmission shift quality and/or torque converter shudder. Using a transmission fluid other than the manufacturer’s recommended fluid will result in more frequent fluid and filter changes. Refer to Fluids, Lubricants, and Genuine Parts for correct fluid type.

Fluid Level Check This fluid level should be checked when the engine is fully warmed up and the fluid in the transmission is heated to its normal operating temperature. Operation of the transmission with an improper fluid level will greatly reduce the life of the transmission and of the fluid.

346 MAINTAINING YOUR VEHICLE

To check the automatic transmission fluid level properly, the following procedure must be used: 1. The vehicle must be on level ground. 2. The engine should be running at curb idle speed for a minimum of 60 seconds. 3. Fully apply parking brake. 4. Apply the brakes and shift the transmission into P (Park). 5. The fluid MUST be checked with the transmission in P (Park) to be sure that the fluid level is accurate. 6. Wipe the dipstick clean and reinsert until seated. Remove dipstick and note reading. At normal operating temperature (approximately 180° F (82° C), the fluid level is correct if it is in the HOT region

(cross-hatched area) on the oil level indicator. The fluid level indicator should be in the COLD region at 70° F (21° C) fluid temperature. If the fluid level is low, add sufficient fluid to bring to the proper level. Refer to Fluids, Lubricants and Genuine Parts for correct fluid type. Fluid is added through the dipstick tube. NOTE: To prevent dirt and water from entering the transmission after checking or replenishing fluid, make certain that the dipstick cap is properly reseated. Special Additives The manufacturer recommends against the addition of any additives to the transmission. Exception to this policy is the use of special dyes to aid in detecting fluid leaks.

Maintenance After Off-Road Driving After extended operation in mud, sand or water, or similar dirty conditions, have your brake drums, brake linings, and axle joints inspected and cleaned as soon as possible. This will prevent any abrasive material from causing excessive wear or unpredictable braking action. After off-road driving, completely inspect the underbody of your vehicle. Check tires, body structure, steering, suspension and exhaust system for damage. Check threaded fasteners for looseness, particularly on the chassis, drivetrain components, steering and suspension. Retighten, if required, to torque values specified in the Service Manual. Also check for accumulations of vegeta- tion or brush that could become a fire hazard, or conceal damage to fuel lines, brake hoses, axle pinion seals, and propeller shafts.

MAINTAINING YOUR VEHICLE 347

CAUTION!

Under frequent heavy-duty driving conditions, change all lubricants and lubricate body compo- nents, all driveline joints and steering linkage more often than in normal service to prevent excessive wear.

Appearance Care And Protection From Corrosion

Protection Of Body And Paint From Corrosion Vehicle body care requirements vary according to geo- graphic locations and usage. Chemicals that make roads passable in snow and ice, and those that are sprayed on trees and road surfaces during other seasons, are highly corrosive to the metal in your vehicle. Outside parking, which exposes your vehicle to airborne contaminants, road surfaces on which the vehicle is operated, extreme

348 MAINTAINING YOUR VEHICLE

hot or cold weather and other extreme conditions will have an adverse effect on paint, metal trim, and under- body protection. The following maintenance recommendations will enable you to obtain maximum benefit from the corrosion resistance built into your vehicle. What Causes Corrosion? Corrosion is the result of deterioration or removal of paint and protective coatings from your vehicle. The most common causes are: • Road salt, dirt and moisture accumulation. • Stone and gravel impact. • Insects, tree sap and tar. • Salt in the air near sea-coast localities. • Atmospheric fallout/industrial pollutants.

Washing • Wash your vehicle regularly. Always wash your ve- hicle in the shade using Mopar威 Car Wash or a mild car wash soap, and rinse the panels completely with clear water. • If insects, tar, or other similar deposits have accumu- lated on your vehicle, use Mopar威 Super Kleen Bug and Tar Remover to remove. • Use Mopar威 Cleaner Wax to remove road film, stains, and to protect your paint finish. Take care never to scratch the paint. • Avoid using abrasive compounds and power buffing that may diminish the gloss or thin out the paint finish.

CAUTION!

Do not use abrasive or strong cleaning materials such as steel wool or scouring powder, which will scratch metal and painted surfaces.

Special Care • If you drive on salted or dusty roads or if you drive near the ocean, hose off the undercarriage at least once a month. • It is important that the drain holes in the lower edges of the doors, rocker panels and tailgate must be kept clear and open. • If you detect any stone chips or scratches in the paint, touch them up immediately. The cost of such repairs is considered the responsibility of the owner.

MAINTAINING YOUR VEHICLE 349

• If your vehicle is damaged due to an accident or similar cause which destroys the paint and protective coating have your vehicle repaired as soon as possible. The cost of such repairs is considered the responsibil- ity of the owner. • Aluminum wheels should be cleaned regularly with a mild soap and water to prevent corrosion. To remove heavy soil, use Mopar威 Wheel Cleaner or select a nonabrasive, non-acidic cleaner. Do not use scouring pads, steel wool, a bristle brush or metal polishes. Only Mopar威 cleaners are recommended. Do not use oven cleaner. Avoid automatic car washes that use acidic solutions or harsh brushes that may damage the wheels’ protective finish. • If you carry special cargo such as chemicals, fertilizers, de-icer salt, etc., assure that such materials are well packaged and sealed.

350 MAINTAINING YOUR VEHICLE

mud or stone shields behind each wheel.

• If a lot of driving is done on gravel roads, consider • Use Mopar威 Touch Up Paint on scratches or chips as soon as possible. Your authorized dealer has touch up paint to match the color of your vehicle.

Wheel and Wheel Trim Care All wheels and wheel trim, especially aluminum and chrome plated wheels should be cleaned regularly with a mild soap and water to prevent corrosion. To remove heavy soil, use Mopar威 Wheel Cleaner or select a non- abrasive, non-acidic cleaner. Do not use scouring pads, steel wool, a bristle brush or metal polishes. Only Mo- par威 cleaners are recommended. Do not use oven cleaner. Avoid automatic car washes that use acidic solutions or harsh brushes that may damage the wheels’ protective finish.

Interior Care Use Mopar威 Total Clean to clean fabric upholstery and carpeting. Interior Trim should be cleaned starting with a damp cloth, a damp cloth with Mopar威 Total Clean, then Mopar威 Spot & Stain Remover if absolutely necessary. Do not use harsh cleaners or Armorall. Use Mopar威 Total Clean to clean vinyl upholstery. Leather Seat Care & Cleaning Mopar威 Total Clean is specifically recommended for leather upholstery. Your leather upholstery can be best preserved by regular cleaning with a damp soft cloth. Small particles of dirt can act as an abrasive and damage the leather upholstery and should be removed promptly with a damp cloth. Stubborn soils can be removed easily with a soft cloth and Mopar威 Total Clean. Care should be taken to avoid soaking your leather upholstery with any liquid. Please

do not use polishes, oils, cleaning fluids, solvents, deter- gents, or ammonia based cleaners to clean your leather upholstery. Application of a leather conditioner is not required to maintain the original condition.

WARNING!

Do not use volatile solvents for cleaning purposes. Many are potentially flammable, and if used in closed areas they may cause respiratory harm.

Cleaning Headlights Your vehicle has plastic headlights that are lighter and less susceptible to stone breakage than glass headlights. Plastic is not as scratch resistant as glass and therefore different lens cleaning procedures must be followed.

MAINTAINING YOUR VEHICLE 351

To minimize the possibility of scratching the lenses and reducing light output, avoid wiping with a dry cloth. To remove road dirt, wash with a mild soap solution fol- lowed by rinsing. Do not use abrasive cleaning components, solvents, steel wool or other aggressive material to clean the lenses. Glass Surfaces All glass surfaces should be cleaned on a regular basis with Mopar威 Glass Cleaner or any commercial household-type glass cleaner. Never use an abrasive type cleaner. Use caution when cleaning inside rear windows equipped with electric defrosters. Do not use scrapers or other sharp instruments which may scratch the elements. When cleaning the rear view mirror, spray cleaner on the towel or rag that you are using. Do not spray cleaner directly on the mirror.

352 MAINTAINING YOUR VEHICLE

Cleaning Plastic Instrument Cluster Lenses The lenses in front of the instruments in this vehicle are molded in clear plastic. When cleaning the lenses, care must be taken to avoid scratching the plastic. 1. Clean with a wet soft rag. A mild soap solution may be used, but do not use high alcohol content or abrasive cleaners. If soap is used, wipe clean with a clean damp rag. 2. Dry with a soft tissue.

Seat Belt Maintenance Do not bleach, dye or clean the belts with chemical solvents or abrasive cleaners. This will weaken the fabric. Sun damage will also weaken the fabric. If the belts need cleaning, use Mopar威 Total Clean, a mild soap solution, or lukewarm water. Do not remove the belts from the vehicle to wash them. Replace the belts if they appear frayed or worn or if the buckles do not work properly.

FUSE PANEL

Interior Fuses The fuse panel is on the left side of the instrument panel. A label is attached to the fuse panel cover to identify each fuse for ease of replacement.

Cavity

MAINTAINING YOUR VEHICLE 353

Description

Fuse 15 Amp Blue Horn Relay, Power Sunroof Relay, Power Window Relay Rear Fog Lights (Export Only) Cigar Lighter

10 Amp Red 20 Amp Yel- low 10 Amp Red Headlight Low Beam Right 10 Amp Red Headlight Low Beam Left 20 Amp Yel- low 10 Amp Red

Body Control Module/Power Door Locks Left Park Light/Left Tail Lamp/License Plate Lamp

Spare 10 Amp Red

Right Park Light/RightTail Lamp/License Plate Lamp/ Cluster

Fuse Panel

10

11Spare 15 Amp Blue

Flasher

354 MAINTAINING YOUR VEHICLE

Cavity 12

13Fuse 15 Amp Blue 10 Amp Red

14

15

1617

1819

10 Amp Red

Spare 20 Amp Yel- low 15 Amp Blue 20 Amp Yel- low 20 Amp Yel- low

Description Stop Lights Body Control Module/CMTC/ Cluster/Pass. Airbag On,Off Indicator, Auto Daylight Mirror/Light Bar Switch (Ren- egade Only) PDC Fuel Pump/AC Clutch, Starter Relay/Engine Controller/Transmission Con- troller (Diesel Only)

Power Outlet (Rear)

Rear Wiper Radio Choke & Relay

Frt Fog Lights/Trailer Tow Stop and Turn Lights

Cavity 20

21

2223

24

2526

27

28

2930

31Description

Fuse Spare 10 Amp Red 20 Amp Yel- low Spare 10 Amp Red 10 Amp Red Heated Seat Switches/HVAC

Radio Power Sunroof Relay/Antenna Module (Export Only)

PDC Blower Motor

Control Head/Trailer Tow Bat- tery Charge

10 Amp Red Headlight High Beam Right 10 Amp Red Headlight High Beam Left Spare 10 Amp Red Heated Mirrors/Rear Window

Defroster Indicator

15 Amp Blue Heated Seat Module Spare

Fuse 10 Amp Red Wiper Switch/Front and Rear

Description

Cavity 36

Fuse 10 Amp Red

Cavity 32

33

34

10 Amp Red

15 Amp Blue

35

Spare

Wipers SKIM Module/Data Link Con- nector Body Control Module/ Cluster/Interior Lights, Hands Free Module/Radio/CMTC/ ITM Module & Siren (Export Only)

37

3839

MAINTAINING YOUR VEHICLE 355

Description Airbag Control Module/ Occupation Classification Module (Right Front Seat) Airbag Control Module ABS Controller/Shifter Assem- bly

10 Amp Red 10 Amp Red

10 Amp Red Hazard Flasher (Turn Signals)/ Backup Lamp Switch (Manual Transmission Only)/ Transmission Range Switch (Automatic Transmission Only)

356 MAINTAINING YOUR VEHICLE

Underhood Fuses (Power Distribution Center) Your vehicle is equipped with an electrical power distri- bution center located in the engine compartment near the battery. This power center houses plug-in “Cartridge” fuses which replace in-line fusible links. The power center also contains “Mini” fuses and plug-in full and micro ISO relays. A label inside the latching cover of the center identifies each component for ease of replacement, if necessary. “Cartridge” fuses and relays can be obtained from your authorized dealer.

Power Distribution Center

Power Distribution Center (Gasoline Engines) Cavity F1

Description Blower Motor

Fuse 40 Amp Green 40 Amp Green 50 Amp Red 40 Amp Green 20 Amp Yel- low 30 Amp Pink ASD 50 Amp Red 40 Amp Green 50 Amp Red 30 Amp Pink

Radiator Fan

JB Power ABS Pump

NGC Trans

JB Power Ign/Start

JB Power Trailer Tow Open

F2

F3

F4F5

F6

F7

F8F9

F10

F11Cavity F12

F13F14

F15

F16

F17

F18

F19

F20

F21F22

F23

F24MAINTAINING YOUR VEHICLE 357

Fuse 30 Amp Pink 40 Amp Green 40 Amp Green 50 Amp Red

Description Light Bar Windows

Ignition Switch

JB Power Open Open Open

30 Amp Pink Rear Window Defogger (HBL)

Open A/C Clutch

Open Open Fuel Pump

20 Amp Yel- low

20 Amp Yel- low

358 MAINTAINING YOUR VEHICLE

Cavity F25

F26

F27

F28

R29R30

R31

R32

R33

R34Fuse 20 Amp Yel- low 25 Amp Natu- ral

Description ABS Valves

Injectors

Open Starter Fuel Pump

Starter

15 Amp Blue Half ISO Re- lay Half ISO Re- lay Half ISO Re- lay Half ISO Re- lay Full ISO Relay H. Blower Full ISO Relay Rad. Fan Hi

Wiper Hi/Lo

Wiper On/Off

Cavity R35

R36

R37R38

R39

R40Fuse Half ISO Re- lay

Half ISO Re- lay

Description A/C Clutch

Open NGC Trans

Open Full ISO Relay ASD Full ISO Relay Rad. Fan Lo

Power Distribution Center (Diesel Engines) Cavity F1

Description Blower Motor

Fuse 40 Amp Green 40 Amp Green 50 Amp Red 40 Amp Green

Radiator Fan

JB Power ABS Pump

JB Power Ign/Start

Open 30 Amp Pink ASD 50 Amp Red 40 Amp Green 50 Amp Red 30 Amp Pink 20 Amp Yel- low

JB Power Trailer Tow Fuel Heater

F2

F3

F4F5

F6

F7

F8F9

F10

F11MAINTAINING YOUR VEHICLE 359

Cavity F12

F13F14

F15

F16

F17

F18

F19

F20

F21F22

F23

F24Description Light Bar Windows

Fuse 30 Amp Pink 40 Amp Green 40 Amp Green JB Power 50 Amp Red 15 Amp Blue ASD Feed

Ignition Switch

Open Open

30 Amp Pink Rear Window Defogger (HBL)

20 Amp Yel- low

Open A/C Clutch

Open Open Open

360 MAINTAINING YOUR VEHICLE

Cavity F25

F26

F27

F28

R29R30

R31

R32

R33

R34Fuse 20 Amp Yel- low 25 Amp Natu- ral

Description ABS Valves

Injectors

Open Starter Fuel Heater

Starter

15 Amp Blue Half ISO Relay Half ISO Relay Half ISO Relay Half ISO Relay Full ISO Relay H. Blower Full ISO Relay Rad. Fan Hi

Wiper Hi/Lo

Wiper On/Off

Cavity R35

R36

R37

R38

R39

R40Fuse Half ISO Relay Half ISO Relay

Description A/C Clutch

Viscous Heat

Open Open Full ISO Relay ASD Full ISO Relay Rad. Fan Lo

Center labeled Ignition-Off Draw (IOD).

Center location #11 labeled “IOD Storage.”

VEHICLE STORAGE If you are leaving your vehicle dormant for more than 21

days you may want to take steps to protect your battery. You may: • Remove Cartridge fuse #15 in the Power Distribution • Store the removed IOD fuse in the Power Distribution • Or, disconnect the negative cable from the battery. • Anytime you store your vehicle, or keep it out of service (i.e. vacation) for two weeks or more, run the air conditioning system at idle for about five minutes in the fresh air and high blower setting. This will insure adequate system lubrication to minimize the possibility of compressor damage when the system is started again.MAINTAINING YOUR VEHICLE 361

REPLACEMENT BULBS

Interior Lights Bulb Type A/C Heater . . . . . . . . . . . . . . . . . . . . Not Serviceable Ashtray Receiver Light . . . . . . . . . . . . . . . . . . . . 161

Climate Control (Manual A/C). . . . . . . . . . . . . . . . 74

Front Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Rear Cargo Light . . . . . . . . . . . . . . . . . . . . . . . 214–2

Lighted Vanity Mirror *. . . . . . . . . . . . . . P/N 6501966

Underpanel Courtesy Lights. . . . . . . . . . . . . . . . . 906

Instrument Cluster (General Illumination) . . . . . . . 103

Telltale/Hazard Light . . . . . . . . . . . . . . . . . . . . . . 74

* Available only from authorized dealers.Exterior Lights Bulb Type Backup Lights . . . . . . . . . . . . . . . . . . . . 3157 P27/7W Center High-Mounted Stoplight . . . . . . . . . 921/W16W Fog Lights (Sport/Limited Only). . . . . . . . . . . . . 9145

Front Park/Turn Lights . . . . . . . . . . . . . 3157 P27/7W362 MAINTAINING YOUR VEHICLE

Exterior Lights Bulb Type Front Side Marker . . . . . . . . . . . . . . . . . . . . . . . . 168

Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . 9007QL Rear License Plate Light. . . . . . . . . . . . . . . . . . . . 168

Rear Stop/Tail Lights . . . . . . . . . . . . . . . 3157 P27/7W Rear Turn Signal Lights (2) . . . . . . . . . 3757 APY27/7W NOTE: Numbers refer to commercial bulb types that can be purchased from your authorized dealer. If a bulb needs to be replaced, visit your authorized dealer.BULB REPLACEMENT

Head Light

1. Open the hood. 2. Reach behind the headlamp unit in the engine com- partment to access the headlamp bulb lock ring.

3. Firmly grasp the lock ring on the back of the headlamp unit housing. 4. Rotate the lock ring on the back of the headlamp housing counter-clockwise to unlock it.

CAUTION!

Do not touch the new bulb with your fingers. Oil contamination will severely shorten bulb life. If the bulb comes in contact with any oily surface, clean the bulb with rubbing alcohol.

5. Disconnect the electrical connector and replace the bulb.

Front Turn Signal

3. Rotate the bulb socket counter-clockwise to unlock it.

1. Remove the screw from the turn signal/park lamp unit.

CAUTION!

MAINTAINING YOUR VEHICLE 363

Do not touch the new bulb with your fingers. Oil contamination will severely shorten bulb life. If the bulb comes in contact with any oily surface, clean the bulb with rubbing alcohol.

4. Disconnect the electrical connector and replace the bulb.

2. Pull the inboard side of the lamp away enough to disengage the tab that secures the outboard side of the lamp from the slot in the front bumper fascia.

364 MAINTAINING YOUR VEHICLE

Front Fog Light (Front Fascia Mounted)

1. Remove the three screws from the backside of the lamp housing.

2. Pull the bezel and lens away from the lamp housing far enough to access and disconnect the wiring connector from the bulb pigtail wire.

3. Pinch together the two hooked ends of the bulb retainer clip and disengage them from the slots in the mounting flange on the back of the lens reflector. 4. Pivot the retainer clip up off of the bulb flange and out of the way.

CAUTION!

Do not touch the new bulb with your fingers. Oil contamination will severely shorten bulb life. If the bulb comes in contact with any oily surface, clean the bulb with rubbing alcohol.

5. Pull the bulb straight out of the mounting flange and replace the bulb.

Rear Tail, Stop, Turn Signal, and Back-Up Lights 1. Open the swing gate. 2. Remove the two Torx fasteners.

Center High Mounted Stop Light (CHMSL) 1. Remove the two screws securing the CHMSL.

MAINTAINING YOUR VEHICLE 365

3. Remove rear lamp assembly. 4. Rotate the socket on the back of the lamp housing counter-clockwise to unlock it. 5. Replace the bulb.

2. Twist the bulb socket to remove from the CHMSL housing. 3. Pull the bulb out of the socket. 4. Replace the bulb, reinstall the socket and reattach the CHMSL.

366 MAINTAINING YOUR VEHICLE

FLUIDS AND CAPACITIES

Fuel (Approximate) Engine Oil with Filter 3.7 Liter Engines (SAE 5W-20, API Certified) Cooling System * 3.7 Liter Engine (Mopar威 Antifreeze/Coolant 5 Year/100,000

Mile Formula) * Includes heater and coolant recovery bottle filled to MAX level.U.S.

20.5 Gallons

5 Qts

14 Qts

Metric 78 Liters

4.7 Liters

13.2 Liters

MAINTAINING YOUR VEHICLE 367

FLUIDS, LUBRICANTS, AND GENUINE PARTS Engine Component Engine Coolant

Engine Oil (3.7L Engine)

Oil Filter (3.7L Engine) Spark Plugs

Fuel Selection

Fluid, Lubricant, or Genuine Part Mopar威 Antifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or- ganic Additive Technology) Use API Certified SAE 5W-20 Engine Oil, meeting the requirements of DaimlerChrysler Material Standard MS-6395. Mopar威 Oil Filter (P/N 4781452AA or 4781452BB) Refer to the Vehicle Emission Control Information label in the engine com- partment. 87 Octane (89 Octane should be used for trailer towing purposes)

368 MAINTAINING YOUR VEHICLE

Chassis Component Automatic Transmission Manual Transmission

Transfer Case Axle Differential (Front) Axle Differential (Rear)

Brake Master Cylinder

Power Steering Reservoir

Fluid, Lubricant, or Genuine Part Mopar威 ATF+4 Automatic Transmission Fluid Mopar威 Manual Transmission Lubricant or equivalent (meeting the re- quirements of DaimlerChrysler Material Standard MS-9224) Mopar威 ATF+4 Automatic Transmission Fluid Mopar威 Gear & Axle Lubricant (SAE 80W-90) or equivalent. Mopar威 Synthetic Gear Lubricant (SAE 75W-90) or equivalent. For trailer towing, the lubricant should be replaced with Mopar威 Synthetic Gear & Axle Lubricant (SAE 75W-140) or equivalent. Models equipped with Trac- Lok™ require a limited-slip additive. Mopar威 DOT 3 Brake Fluid, SAE J1703 should be used. If DOT 3, SAE J1703 brake fluid is not available, then DOT 4 is acceptable. Use only rec- ommended brake fluids. Mopar威 ATF+4 Automatic Transmission Fluid

MAINTENANCE SCHEDULES

CONTENTS

䡵 Emission Control System Maintenance . . . . . . . . 370

䡵 Maintenance Schedules . . . . . . . . . . . . . . . . . . . 370▫ Schedule “B” . . . . . . . . . . . . . . . . . . . . . . . . 373

▫ Schedule “A” . . . . . . . . . . . . . . . . . . . . . . . . 385M

370 MAINTENANCE SCHEDULES

EMISSION CONTROL SYSTEM MAINTENANCE The “Scheduled” maintenance services, listed in bold type must be done at the times or mileages specified to assure the continued proper functioning of the emission control system. These, and all other maintenance services included in this manual, should be done to provide best vehicle performance and reliability. More frequent main- tenance may be needed for vehicles in severe operating conditions such as dusty areas and very short trip driving. Inspection and service also should be done any time a malfunction is suspected. NOTE: Maintenance, replacement, or repair of the emis- sion control devices and systems on your vehicle may be performed by any automotive repair establishment or individual using any automotive part, which has been