- 2009 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2011 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2010 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2007 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2008 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2005 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- 2004 Jeep Liberty Owners Manuals

- Jeep Liberty Owners Manuals

- Download PDF Manual

-

should be used. Use higher concentrations (not to exceed 70%) if temperatures below -37°F (-38°C) are anticipated. Use only high purity water such as distilled or deionized water when mixing the water/antifreeze solution. The use of lower quality water will reduce the amount of corrosion protection in the engine cooling system. Please note that it is the owner’s responsibility to main- tain the proper level of protection against freezing ac- cording to the temperatures occurring in the area where the vehicle is operated. NOTE: Mixing coolant types will decrease the life of the engine coolant and will require more frequent engine coolant changes.

MAINTAINING YOUR VEHICLE 305

Cooling System Pressure Cap The cap must be fully tightened to prevent loss of coolant, and to insure that coolant will return to the radiator from the coolant bottle. The cap should be inspected and cleaned if there is any accumulation of foreign material on the sealing surfaces.

WARNING!

The warning words DO NOT OPEN HOT on the cooling system pressure cap are a safety precaution. Never add coolant when the engine is overheated. Do not loosen or remove the cap to cool an over- heated engine. Heat causes pressure to build up in the cooling system. To prevent scalding or injury, do not remove the pressure cap while the system is hot or under pressure.

306 MAINTAINING YOUR VEHICLE

Coolant Level The coolant recovery bottle provides a quick visual method for determining that the coolant level is ad- equate. The coolant level must be at or above the COLD FULL level on the bottle. The radiator normally remains completely full, so there is no need to remove the radiator cap unless checking for coolant freeze point or replacing coolant. Advise your service attendant of this. As long as the engine operating temperature is satisfactory, the coolant bottle need only be checked once a month. When additional coolant is needed to maintain the proper level, it should be added to the coolant recovery bottle. Do not overfill.

Points To Remember NOTE: When the vehicle is stopped after a few miles of operation, you may observe vapor coming from the front of the engine compartment. This is normally a result of

moisture from rain, snow, or high humidity accumulat- ing on the radiator and being vaporized when the thermostat opens, allowing hot water to enter the radia- tor. If an examination of your engine compartment shows no evidence of radiator or hose leaks, the vehicle may be safely driven. The vapor will soon dissipate. † Do not overfill the coolant bottle. † Check coolant freeze point in the system. † If frequent coolant additions are required, or if the level in the recovery bottle does not drop when the engine cools, the cooling system should be pressure tested for leaks. † Maintain coolant concentration to 50% ethylene glycol antifreeze (minimum) in water for proper corrosion protection of your engine that contains aluminum components.

MAINTAINING YOUR VEHICLE 307

are not kinked or obstructed.

† Make sure that the radiator and coolant bottle hoses † Do not change the thermostat for summer or winter operation. If replacement is ever necessary, install ONLY the correct type thermostat. Other designs may result in unsatisfactory cooling performance, poor gas mileage, and increased emissions.

Hoses and Vacuum/Vapor Harnesses Inspect surfaces of hoses and nylon tubing for evidence of heat and mechanical damage. Hard or soft spots, brittle rubber, cracking, tears, cuts, abrasions, and exces- sive swelling indicate deterioration of the rubber. Pay particular attention to the hoses nearest to high heat sources such as the exhaust manifold. Inspect hose rout- ing to be sure hoses do not touch any heat source or moving component that may cause heat damage or mechanical wear.

308 MAINTAINING YOUR VEHICLE

Insure nylon tubing in these areas has not melted or collapsed. Inspect all hose connections such as clamps and couplings to make sure they are secure and no leaks are present. Components should be replaced immedi- ately if there is any evidence of degradation that could cause failure. Brake System In order to assure brake system performance, all brake system components should be inspected periodically. Refer to the appropriate “Maintenance Schedule” in Section 8 for suggested service intervals.

WARNING!

Riding the brakes can lead to brake failure and possibly an accident. Driving with your foot resting or riding on the brake pedal can result in abnormally high brake temperatures, excessive lining wear, and possible brake damage. You wouldn’t have your full braking capacity in an emergency.

Brake and Power Steering System Hoses When servicing the vehicle for scheduled maintenance, inspect surface of hoses for evidence of heat and me- chanical damage. Hard and brittle rubber, cracking, tears, cuts, abrasion, and excessive swelling suggest deteriora- tion of the rubber. Particular attention should be made to examining those hose surfaces nearest to high heat sources, such as the exhaust manifold.

Inspect all hose clamps and couplings to make sure they are secure and no leaks are present. NOTE: Often fluids such as oil, power steering fluid, and brake fluid are used during assembly plant opera- tions to ease the assembly of hoses to couplings. There- fore, oil wetness at the hose-coupling area is not neces- sarily an indication of leakage. Actual dripping of hot fluid when systems are under pressure (during vehicle operation) should be noted before hose is replaced based on leakage.

MAINTAINING YOUR VEHICLE 309

Inspection of brake hoses should be done when- NOTE: ever the brake system is serviced and every engine oil change.

WARNING!

Worn brake hoses can burst and cause brake failure. You could have an accident. If you see any signs of cracking, scuffing, or worn spots, have the brake hoses replaced immediately.

310 MAINTAINING YOUR VEHICLE

Brake Master Cylinder The fluid level in the master cylinder should be checked when performing under hood services, or immediately if the “Brake Warning Light” shows system failure.

Be sure to clean the top of the master cylinder area before removing the cap. If necessary, add fluid to bring the fluid level up to the requirements described on the brake fluid reservoir. With disc brakes, fluid level can be expected to fall as the brake pads wear. However, low fluid level may be caused by a leak and a checkup may be needed. Use only manufacturer’s recommended brake fluid, refer to Recommended Fluids, Lubricants, and Genuine Parts for correct fluid type.

WARNING!

Use of a brake fluid that may have a lower initial boiling point or unidentified as to specification, may result in sudden brake failure during hard pro- longed braking. You could have an accident.

WARNING!

CAUTION!

MAINTAINING YOUR VEHICLE 311

Overfilling the brake fluid reservoir can result in spilling brake fluid on hot engine parts and the brake fluid catching fire.

Use only brake fluid that has been in a tightly closed container to avoid contamination from foreign matter. Do not allow petroleum base fluid to contaminate the brake fluid as seal damage will result. Automatic Transmission Selection of Lubricant It is important that the proper lubricant is used in the transmission to assure optimum transmission perfor- mance. Use only manufacturer’s recommended transmis- sion fluid, refer to Recommended Fluids, Lubricants, and Genuine Parts for correct fluid type. It is important that the transmission fluid be maintained at the prescribed level using the recommended fluid.

Using a transmission fluid other than the manufac- turer’s recommended fluid may cause deterioration in transmission shift quality and/or torque converter shudder. Using a transmission fluid other than the manufacturer’s recommended fluid will result in more frequent fluid and filter changes. Refer to Recommended Fluids, Lubricants, and Genuine Parts for correct fluid type.

Fluid Level Check – 3.7L 42RLE This fluid level should be checked when the engine is fully warmed up and the fluid in the transmission is heated to its normal operating temperature. Operation of the transmission with an improper fluid level will greatly reduce the life of the transmission and of the fluid.

312 MAINTAINING YOUR VEHICLE

To check the automatic transmission fluid level properly, the following procedure must be used: 1. The vehicle must be on level ground. 2. The engine should be running at curb idle speed for a minimum of 60 seconds. 3. Fully apply parking brake. 4. Apply the brakes and shift the transmission into P (Park). 5. The fluid MUST be checked with the transmission in P (Park) to be sure that the fluid level is accurate. 6. Wipe the dipstick clean and reinsert until seated. Remove dipstick and note reading. At normal operating temperature (approximately 180° F (82° C), the fluid level is correct if it is in the HOT region

(cross-hatched area) on the oil level indicator. The fluid level indicator should be in the COLD region at 70° F (21° C) fluid temperature. If the fluid level is low, add sufficient fluid to bring to the proper level. Refer to Recommended Fluids, Lubricants and Genuine Parts for correct fluid type. Fluid is added through the dipstick tube. NOTE: To prevent dirt and water from entering the transmission after checking or replenishing fluid, make certain that the dipstick cap is properly reseated. Special Additives The manufacturer recommends against the addition of any additives to the transmission. Exception to this policy is the use of special dyes to aid in detecting fluid leaks.

Hydraulic Clutch Fluid — Manual Transmission The clutch hydraulic system is a sealed maintenance free system. In the event of leakage or other malfunction, the system must be replaced. Manual Transmission

Selection of Lubricant Use only manufacturer’s recommended manual trans- mission fluid, refer to Recommended Fluids, Lubricants, and Genuine Parts for correct fluid type. Fluid Level Check Check the fluid level by removing the fill plug. The fluid level should be between the bottom of the fill hole and a point not more than 3/16” (4.76 mm) below the bottom of the hole. Add fluid, if necessary, to maintain the proper level.

MAINTAINING YOUR VEHICLE 313

Frequency of Fluid Change Under normal operating conditions, the fluid installed at the factory will give satisfactory lubrication for the life of the vehicle. Fluid changes are not necessary unless the lubricant has become contaminated with water. If con- taminated with water, the fluid should be changed im- mediately. Transfer Case

Fluid Level Check Inspect the transfer case for fluid leaks. If a fluid leak is evident, the transfer case fluid level can be checked by removing the fill plug (B) located at the back of the transfer case.

314 MAINTAINING YOUR VEHICLE

The fluid level should be to the bottom edge of the fill hole (A) when the vehicle is in a level position.

Adding Fluid Only at filler hole until fluid runs out of the hole, when the vehicle is in a level position.

Drain First remove fill plug (B), then drain plug (C). Recom- mended tightening torque for drain and fill plugs is 15–25 ft.lbs. (20–34 N·m).

CAUTION!

When installing plugs, do not overtighten. You could damage them and cause them to leak.

Selection of Lubricant Use only manufacturer’s recommended fluid, refer to Recommended Fluids, Lubricants, and Genuine Parts for correct fluid type.

Front/Rear Axle Fluid The front axle has a threaded “fill plug” on the cover plate, and a threaded “drain plug” on the bottom side of the carrier. Fluid Level Check Lubricant should be 1/29 (1 cm) below the oil fill hole. Adding Fluid Add lubricant only at the fill hole and only to the level specified above. Selection of Lubricant Use only manufacturer’s recommended fluid, refer to Recommended Fluids, Lubricants, and Genuine Parts for correct fluid type.

MAINTAINING YOUR VEHICLE 315

Appearance Care And Protection From Corrosion

Protection Of Body And Paint From Corrosion Vehicle body care requirements vary according to geo- graphic locations and usage. Chemicals that make roads passable in snow and ice, and those that are sprayed on trees and road surfaces during other seasons, are highly corrosive to the metal in your vehicle. Outside parking, which exposes your vehicle to airborne contaminants, road surfaces on which the vehicle is operated, extreme hot or cold weather and other extreme conditions will have an adverse effect on paint, metal trim, and under- body protection. The following maintenance recommendations will enable you to obtain maximum benefit from the corrosion resistance built into your vehicle. What Causes Corrosion? Corrosion is the result of deterioration or removal of paint and protective coatings from your vehicle.

316 MAINTAINING YOUR VEHICLE

The most common causes are: † Road salt, dirt and moisture accumulation. † Stone and gravel impact. † Insects, tree sap and tar. † Salt in the air near sea-coast localities. † Atmospheric fallout/industrial pollutants. Washing † Wash your vehicle regularly. Always wash your ve- hicle in the shade using a mild car wash soap and rinse the panels completely with clear water. † If insects, tar, or other similar deposits have accumu- † Use Mopart Auto Polish to remove road film and stains and to polish your vehicle. Take care never to scratch the paint.

lated on your vehicle, wash it as soon as possible.

† Avoid using abrasive compounds and power buffing that may diminish the gloss or thin out the paint finish.

CAUTION!

Do not use abrasive or strong cleaning materials such as steel wool or scouring powder, which will scratch metal and painted surfaces.

Special Care † If you drive on salted or dusty roads or if you drive near the ocean, hose off the undercarriage at least once a month. † It is important that the drain holes in the lower edges of the doors, rocker panels and tailgate must be kept clear and open.

† If you detect any stone chips or scratches in the paint, touch them up immediately. The cost of such repairs is considered the responsibility of the owner. † If your vehicle is damaged due to an accident or similar cause which destroys the paint and protective coating have your vehicle repaired as soon as possible. The cost of such repairs is considered the responsibil- ity of the owner. † All wheels and wheel trim, especially aluminum and chrome plated wheels should be cleaned regularly with mild soap and water to prevent corrosion. To remove heavy soil, select a non-abrasive, non-acidic cleaner. Do not use scouring pads, steel wool, a bristle brush, or metal polishes. Only Mopart Cleaners are recommended. Do not use oven cleaner. Avoid auto- matic car washes that use acidic solutions or harsh brushes that may damage the wheel’s protective fin- ish.

MAINTAINING YOUR VEHICLE 317

† If you carry special cargo such as chemicals, fertilizers, de-icer salt, etc., be sure that such materials are well packaged and sealed. † If a lot of driving is done on gravel roads, consider † Use Mopart Touch Up Paint on scratches or chips as soon as possible. Your authorized dealer has touch up paint to match the color of your vehicle.

mud or stone shields behind each wheel.

Interior Care Use Mopart Fabric Cleaner to clean fabric upholstery and carpeting. Use Mopart Vinyl Cleaner to clean vinyl or leather upholstery. Mopart Vinyl Cleaner is specifically recommended for interior vinyl trim.

318 MAINTAINING YOUR VEHICLE

Leather Seat Care & Cleaning Leather is best preserved by regular cleaning with a damp soft cloth. Small particles of dirt can act as an abrasive and damage the leather surface and should be removed promptly with a damp cloth. Stubborn soils can be removed easily with a soft cloth and Mopart Total Clean. Care should be taken to avoid soaking the leather with any liquid. Please do not use polishes, oils, cleaning fluids, solvents, detergents, or ammonia based cleaners to clean the leather. Application of a leather conditioner is not required to maintain the original condition.

WARNING!

Do not use volatile solvents for cleaning purposes. Many are potentially flammable, and if used in closed areas they may cause respiratory harm.

Glass Surfaces All glass surfaces should be cleaned on a regular basis with any commercial household-type glass cleaner. Never use an abrasive type cleaner. Use caution when cleaning inside rear windows equipped with electric defrosters. Do not use scrapers or other sharp instru- ments which may scratch the elements. When cleaning the rear view mirror, spray cleaner on the towel or rag that you are using. Do not spray cleaner directly on the mirror. Carpet Vacuum your carpet regularly to prevent a soil build-up. Shampoo soiled carpet with a reliable upholstery cleaner, using a natural sponge or soft bristle brush. After carpet dries, vacuum it thoroughly.

Seat Belt Maintenance Do not bleach, dye or clean the belts with chemical solvents or abrasive cleaners. This will weaken the fabric. Sun damage will also weaken the fabric. If the belts need cleaning, use a mild soap solution or lukewarm water. Do not remove the belts from the vehicle to wash them. Replace the belts if they appear frayed or worn or if the buckles do not work properly. Maintenance After Off-Pavement Driving After extended operation in mud, sand or water, or similar dirty conditions, have your brake drums, brake linings, and axle joints inspected and cleaned as soon as possible. This will prevent any abrasive material from causing excessive wear or unpredictable braking action. Following off-pavement usage, completely inspect the underbody of your vehicle. Check tires, body structure,

MAINTAINING YOUR VEHICLE 319

steering, suspension and exhaust system for damage. Check threaded fasteners for looseness, particularly on the chassis, drivetrain components, steering and suspen- sion. Retighten, if required, to torque values specified in the Service Manual. Also check for accumulations of vegetation or brush that could become a fire hazard, or conceal damage to fuel lines, brake hoses, axle pinion seals, and propeller shafts.

CAUTION!

Under frequent heavy-duty driving conditions, change all lubricants and lubricate body compo- nents, all driveline joints and steering linkage more often than in normal service to prevent excessive wear.

320 MAINTAINING YOUR VEHICLE

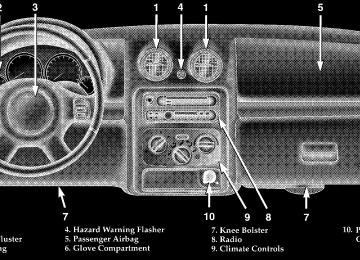

FUSE PANEL

Interior Fuses The fuse panel is on the left side of the instrument panel. A label is attached to the fuse panel cover to identify each fuse for ease of replacement.

Fuse Panel Description Cavity

Description

Fuse 15 Amp Blue Horn Relay, Power Sunroof Relay, Power Window Relay

10 Amp Red Rear Fog Lights (Export

Only) Cigar Lighter

20 Amp Yel- low 10 Amp Red Headlight Low Beam Right 10 Amp Red Headlight Low Beam Left 20 Amp Yel- low 10 Amp Red Left Park Light/Left Tail

Body Control Module/Power Door Locks

Lamp/License Plate Lamp

Spare 10 Amp Red Right Park Light/RightTail Lamp/License Plate Lamp/ Cluster

MAINTAINING YOUR VEHICLE 321

Cavity 10

11

12

13Description

Fuse Spare 15 Amp Blue Flasher 15 Amp Blue Stop Lights 10 Amp Red Body Control Module/

CMTC/Cluster/Pass. Airbag On,Off Indicator, Auto Day- light Mirror/Light Bar Switch (Renegade Only)

14

15

1617

10 Amp Red PDC Fuel Pump/AC Clutch,

Starter Relay/Engine Controller/Transmission Controller (Diesel Only)

Spare 20 Amp Yel- low 15 Amp Blue Rear Wiper

Power Outlet (Rear)

322 MAINTAINING YOUR VEHICLE

Cavity 18

19

20

21

2223

24

2526

27

28Description Radio Choke & Relay

Frt Fog Lights/Trailer Tow Stop and Turn Lights

Fuse 20 Amp Yel- low 20 Amp Yel- low Spare 10 Amp Red Radio 20 Amp Yel- low

Power Sunroof Relay/ Antenna Module (Export Only)

Spare 10 Amp Red PDC Blower Motor 10 Amp Red Heated Seat Switches/HVAC

Control Head/Trailer Tow Battery Charge

10 Amp Red Headlight High Beam Right 10 Amp Red Headlight High Beam Left Spare

Cavity 29

30

31

3233

34

35

36Fuse 10 Amp Red Heated Mirrors/Rear Win-

Description

dow Defroster Indicator

15 Amp Blue Heated Seat Module Spare 10 Amp Red Wiper Switch/Front and

Rear Wipers

10 Amp Red SKIM Module/Data Link

Connector

15 Amp Blue Body Control Module/ Cluster/Interior Lights, Hands Free Module/Radio/ CMTC/ITM Module & Siren (Export Only)

Spare 10 Amp Red Airbag Control Module/ Occupation Classification Module (Right Front Seat)

MAINTAINING YOUR VEHICLE 323

center identifies each component for ease of replacement, if necessary. “Cartridge” fuses and relays can be obtained from your authorized dealer.

Cavity 37

3839

Description

Fuse 10 Amp Red Airbag Control Module 10 Amp Red ABS Controller/Shifter As-

sembly

10 Amp Red Hazard Flasher (Turn

Signals)/Backup Lamp Switch (Manual Transmission Only)/Transmission Range Switch (Automatic Transmis- sion Only)

Underhood Fuses (Power Distribution Center) Your vehicle is equipped with an electrical power distri- bution center located in the engine compartment near the battery. This power center houses plug-in “Cartridge” fuses which replace in-line fusible links. The power center also contains “Mini” fuses and plug-in full and micro ISO relays. A label inside the latching cover of the

324 MAINTAINING YOUR VEHICLE

Center labeled Ignition-Off Draw (IOD).

Center location #11 labeled “IOD Storage.”

VEHICLE STORAGE If you are leaving your vehicle dormant for more than 21

days you may want to take steps to protect your battery. You may: † Remove Cartridge fuse #15 in the Power Distribution † Store the removed IOD fuse in the Power Distribution † Or, disconnect the negative cable from the battery. † Anytime you store your vehicle, or keep it out of service (i.e. vacation) for two weeks or more, run the air conditioning system at idle for about five minutes in the fresh air and high blower setting. This will insure adequate system lubrication to minimize the possibility of compressor damage when the system is started again.REPLACEMENT BULBS

Interior Lights Bulb Type A/C Heater . . . . . . . . . . . . . . . . . . . . Not Serviceable Ashtray Receiver Light . . . . . . . . . . . . . . . . . . . . 161

Climate Control (Manual A/C). . . . . . . . . . . . . . . . 74

Front Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Rear Cargo Light . . . . . . . . . . . . . . . . . . . . . . . 214–2

Lighted Vanity Mirror *. . . . . . . . . . . . . . P/N 6501966

Underpanel Courtesy Lights. . . . . . . . . . . . . . . . . 906

Instrument Cluster (General Illumination) . . . . . . . 103

Telltale/Hazard Light . . . . . . . . . . . . . . . . . . . . . . 74

* Available only from authorized dealers.MAINTAINING YOUR VEHICLE 325

NOTE: Numbers refer to commercial bulb types that can be purchased from your authorized dealer. If a bulb needs to be replaced, visit your authorized dealer.

Exterior Lights Bulb Type Backup Lights . . . . . . . . . . . . . . . . . . . . 3157 P27/7W Center High-Mounted Stoplight . . . . . . . . . 921/W16W Fog Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9145

Front Park/Turn Lights . . . . . . . . . . . . . 3157 P27/7W Front Side Marker . . . . . . . . . . . . . . . . . . . . . . . . 168

Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . 9007QL Rear License Plate Light. . . . . . . . . . . . . . . . . . . . 168

Rear Stop/Tail Lights . . . . . . . . . . . . . . . 3157 P27/7W Rear Turn Signal Lights (2) . . . . . . . . . . . 3157 P27/7W Underhood Light. . . . . . . . . . . . . . . . . . . . . . . . . 561326 MAINTAINING YOUR VEHICLE

FLUID CAPACITIES

Fuel (Approximate) Engine Oil with Filter 2.4 & 3.7 Liter Engine (SAE 5W-30, API Certified Engine Oil) Cooling System *

2.4 Liter Engine (Mopart Antifreeze/Coolant 5 Year/100,000

Mile Formula)

3.7 Liter Engine (Mopart Antifreeze/Coolant 5 Year/100,000

Mile Formula)

* Includes heater and coolant recovery bottle filled to MAX level.

U.S.

19.5 Gallons

5 Qts

10 Qts

14 Qts

Metric 74 Liters

4.7 Liters

9.5 Liters

13.2 Liters

MAINTAINING YOUR VEHICLE 327

RECOMMENDED FLUIDS, LUBRICANTS AND GENUINE PARTS Engine Component Engine Coolant

Engine Oil

Oil Filter (2.4L Engine) Oil Filter (3.7L Engine) Spark Plugs

Fuel Selection

Fluid, Lubricant, or Genuine Part Mopart Antifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or- ganic Additive Technology) Use API Certified SAE 5W-30 Engine Oil. Refer to oil viscosity chart for cor- rect SAE grade meeting DaimlerChrysler Material Standard MS-6395. Mopart Oil Filter (P/N 4105409) Mopart Oil Filter (P/N 04781452AA) Refer to the Vehicle Emission Control Information label in the engine com- partment. 87 Octane (89 Octane should be used for trailer towing purposes - 3.7L Only).

328 MAINTAINING YOUR VEHICLE

Chassis Component Automatic Transmission Manual Transmission Transfer Case Axle Differential (front-rear)

Brake Master Cylinder

Power Steering Reservoir Ball Joints, Prop Shafts, U-Joints, Yokes, & Wheel Bearings

Fluid, Lubricant, or Genuine Part Mopart ATF+4 Automatic Transmission Fluid Mopart Manual Transmission Lubricant (P/N 04874464) Mopart ATF+4 Automatic Transmission Fluid Mopart SAE 75W-140 (API GL5) Synthetic Gear Lubricant or equivalent. The 8.25 Corporate Rear Axle should use a SAE 75W-90 Gear Lubricant. For trailer towing, the lubricant should be replaced with SAE 75W-140

Synthetic Gear Lubricant. Models equipped with Trac-Lok™ require a fric- tion modifier additive. Mopart DOT 3, SAE J1703 should be used. If DOT 3, SAE J1703 brake fluid is not available, then DOT 4 is acceptable. Use only recommended brake fluids. Mopart ATF+4 Automatic Transmission Fluid Mopart Multi-Purpose Lube NLGI Grade 2 EP, GC-LBMAINTENANCE SCHEDULES

CONTENTS

m Emission Control System Maintenance . . . . . . . . 330

m Maintenance Schedules . . . . . . . . . . . . . . . . . . . 330N Schedule “B” . . . . . . . . . . . . . . . . . . . . . . . . 333

N Schedule “A” . . . . . . . . . . . . . . . . . . . . . . . . 342M

330 MAINTENANCE SCHEDULES

EMISSION CONTROL SYSTEM MAINTENANCE The “Scheduled” maintenance services, listed in bold type must be done at the times or mileages specified to assure the continued proper functioning of the emission control system. These, and all other maintenance services included in this manual, should be done to provide best vehicle performance and reliability. More frequent main- tenance may be needed for vehicles in severe operating conditions such as dusty areas and very short trip driving. Inspection and service also should be done any time a malfunction is suspected. NOTE: Maintenance, replacement, or repair of the emis- sion control devices and systems on your vehicle may be performed by any automotive repair establishment or individual using any automotive part which has been certified pursuant to U.S. EPA or, in the State of Califor- nia, California Air Resources Board regulations.

MAINTENANCE SCHEDULES There are two maintenance schedules that show the required service for your vehicle. First is Schedule (B(. It is for vehicles that are operated under the conditions that are listed below and at the beginning of the schedule. † Day or night temperatures are below 32°F (0°C). † Stop and go driving. † Extensive engine idling. † Driving in dusty conditions. † Short trips of less than 10 miles (16.2 km). † More than 50% of your driving is at sustained high † Trailer towing. † Taxi, police, or delivery service (commercial service).

speeds during hot weather, above 90°F (32°C).

† Off-road or desert driving. NOTE: Most vehicles are operated under the conditions listed for Schedule “B.” Second is Schedule “A”. It is for vehicles that are not operated under any of the conditions listed under Sched- ule “B.” Use the schedule that best describes your driving condi- tions. Where time and mileage are listed, follow the interval that occurs first.

CAUTION!

Failure to perform the required maintenance items may result in damage to the vehicle.

MAINTENANCE SCHEDULES 331

At Each Stop for Fuel † Check the engine oil level about 5 minutes after a fully warmed engine is shut off. Checking the oil level while the vehicle is on level ground will improve the accu- racy of the oil level reading. Add oil only when the level is at or below the ADD or MIN mark. † Check the windshield washer solvent, add as required. Once a Month † Check the tire pressure and look for unusual wear or † Inspect the battery, and clean and tighten the terminals † Check the fluid levels of the coolant reservoir, brake master cylinder, and transmission, and add as needed. † Check all lights and all other electrical items for correct

as required.

damage.

operation.

332 MAINTENANCE SCHEDULES

At Each Oil Change † Change the engine oil filter. † Inspect the exhaust system. † Inspect brake hoses. † Check the coolant level, hoses, and clamps. † Inspect manual

equipped.

transmission fluid level — if

† Rotate the tires at each oil change interval shown on Schedule “A” 6,000 miles (10 000 km) or every other interval shown on Schedule “B” 6,000 miles (10 000

km). † After completion of off-road operation, the underside of the vehicle should be thoroughly inspected. Exam- ine threaded fasteners for looseness.Schedule “B” Follow schedule “B” if you usually operate your vehicle under one or more of the following conditions. † Day or night temperatures are below 32°F (0°C). † Stop and go driving. † Extensive engine idling. † Driving in dusty conditions. Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Inspect the brake linings. Drain and refill the front and rear axle fluid‡

SCHEDULE “B” 333

speeds during hot weather, above 90°F (32°C).

† Short trips of less than 10 miles (16.2 km). † More than 50% of your driving is at sustained high † Trailer towing. † Taxi, police, or delivery service (commercial service). † Off-road or desert driving.

3,000

(5 000)6,000

(10 000)9,000

(14 000)12,000

(19 000)15,000

(24 000)334 SCHEDULE “B”

Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Replace the spark plugs. Inspect and replace the PCV valve, if necessary.L Inspect the brake linings. Drain and refill the front and rear axle fluid‡ Inspect the transfer case fluid, add if necessary.

18,000

(29 000)21,000

(34 000)27,000

(43 000)24,000

(38 000)30,000

(48 000)SCHEDULE “B” 335

Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Inspect the brake linings. Drain and refill the front and rear axle fluid‡ Inspect the drive belt and replace as needed.

33,000

(53 000)36,000

(58 000)39,000

(62 000)42,000

(67 000)45,000

(72 000)M

336 SCHEDULE “B”

Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Replace the spark plugs. Inspect and replace the PCV valve, if necessary.L Replace the ignition cables (2.4L Only). Inspect the brake linings. Drain and refill the front and rear axle fluid‡ Drain and refill the automatic transmission fluid, and replace main sump filter. Inspect the drive belt and replace as needed. Not required if belt was previously Drain and refill the transfer case fluid.

48,000

(77 000)51,000

(82 000)54,000

(86 000)57,000

(91 000)60,000

(96 000)Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Inspect the brake linings. Drain and refill the front and rear axle fluid‡ Inspect the drive belt and replace as needed. Not required if belt was previously replaced.

63,000

(101 000)66,000

(106 000)69,000

(110 000)72,000

(115 000)75,000

(120 000)SCHEDULE “B” 337

338 SCHEDULE “B”

Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Replace the spark plugs. Inspect and replace the PCV valve, if necessary.L Inspect the brake linings. Drain and refill the front and rear axle fluid‡ Inspect the drive belt and replace as needed. Not required if belt was previously replaced. Replace the timing belt (2.4L Only). Inspect the transfer case fluid, add if necessary.

78,000

(125 000)81,000

(130 000)84,000

(134 000)87,000

(139 000)90,000

(144 000)Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Inspect the brake linings. Drain and refill the front and rear axle fluid‡ Inspect the drive belt and replace as needed. Not required if belt was previously replaced. Flush and replace the engine coolant.

93,000

(149 000)96,000

(154 000)99,000

(158 000)102,000

(163 000)105,000

(168 000)SCHEDULE “B” 339

M

340 SCHEDULE “B”

Miles (Kilometers) Change the engine oil and engine oil filter. Inspect the engine air filter element, replace if necessary. Replace the spark plugs. Inspect and replace the PCV valve, if necessary.L Replace the ignition cables (2.4L Only). Inspect the brake linings. Drain and refill the front and rear axle fluid‡ Drain and refill the automatic transmission fluid, and replace main sump filter. Inspect the drive belt and replace as needed. Not required if belt was previously replaced. Drain and refill the transfer case fluid.

108,000

(173 000)111,000

(178 000)114,000

(182 000)117,000

(187 000)120,000

(192 000)Inspection and service should be performed anytime a malfunction is observed or suspected. Retain all receipts. L This maintenance is recommended by the manufac- turer to the owner, but it is not required to maintain emissions warranty.

‡Off-highway operation, trailer towing, taxi, limousine, bus, snow plowing, or other types of commercial service or prolonged operation with heavy loading, especially in hot weather, require front and rear axle service indicated with a ‡ in Schedule “B”. Perform these services if the vehicle is usually operated under these conditions.

SCHEDULE “B” 341

342 SCHEDULE “A”

Schedule “A” Miles (Kilometers) [Months] Change the engine oil and engine oil filter. Inspect the engine air filter element, and replace if necessary. Replace the spark plugs. Inspect the brake linings. Inspect the transfer case fluid.

6,000

(10 000)[6]

12,000

(19 000)[12]

18,000

(29 000)24,000

(38 000)30,000

(48 000)[24]

[18]

[30]

Miles (Kilometers) [Months] Change the engine oil and engine oil filter. Inspect the brake linings.

SCHEDULE “A” 343

36,000

(58 000)[36]

42,000

(67 000)[42]

48,000

(77 000)[48]

54,000

(86 000)[54]

M

344 SCHEDULE “A”

Miles (Kilometers) [Months] Change the engine oil and engine oil filter. Inspect the brake linings. Inspect the engine air filter element, and replace if nec- essary. Replace the spark plugs. Inspect the ignition cables, and replace if necessary (2.4L Only). Inspect and replace the PCV valve, if necessary.L Inspect the drive belt and replace, if needed. Inspect the drive belt and replace as needed. Not re- quired if previously replaced. Flush and replace the engine coolant at 60 months, re- gardless of mileage. Inspect the transfer case fluid.

60,000

(96 000)[60]

66,000

(106 000)72,000

(115 000)78,000

(125 000)[66]

[78]

[72]

Miles (Kilometers) [Months] Change the engine oil and engine oil filter. Inspect the brake linings. Inspect the engine air filter element, and replace if nec- essary. Replace the spark plugs. Inspect and replace the PCV valve, if necessary.L Inspect the drive belt and replace as needed. Not required if previously replaced. Flush and replace the engine coolant if not done at 60

months. Inspect the transfer case fluid.SCHEDULE “A” 345

84,000

(134 000)90,000

(144 000)96,000

(154 000)102,000

(163 000)[84]

[90]

[96]

[102]

M

346 SCHEDULE “A”

Miles (Kilometers) [Months] Change the engine oil and engine oil filter. Inspect the brake linings. Inspect the engine air filter element, and replace if necessary. Replace the spark plugs. Inspect and replace the PCV valve, if necessary.L Inspect the ignition cables, and replace if necessary (2.4L Only). Inspect the drive belt and replace as needed. Not required if pre- viously replaced. Flush and replace the engine coolant if not done at 163 000 km (102,000 miles). Replace the timing belt (2.4L Only). Drain and refill the transfer case fluid. Inspection and service should be performed anytime a malfunction is observed or suspected. Retain all receipts.

114,000

(182 000)[114]

108,000

(173 000)[108]

120,000

(192 000)[120]

L This maintenance is recommended by the manufac- turer to the owner, but it is not required to maintain emissions warranty.

IF YOU NEED CONSUMER ASSISTANCE

CONTENTS

m Suggestions For Obtaining Service For Your

Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

N Prepare For The Appointment . . . . . . . . . . . . 348

N Prepare A List . . . . . . . . . . . . . . . . . . . . . . . . 348

N Be Reasonable With Requests . . . . . . . . . . . . . 348

m If You Need Assistance . . . . . . . . . . . . . . . . . . . 348m Warranty Information . . . . . . . . . . . . . . . . . . . . 351

m Mopart Parts . . . . . . . . . . . . . . . . . . . . . . . . . 353

m Reporting Safety Defects . . . . . . . . . . . . . . . . . . 353

N In Canada . . . . . . . . . . . . . . . . . . . . . . . . . . 353

m Publication Order Forms . . . . . . . . . . . . . . . . . . 354348 IF YOU NEED CONSUMER ASSISTANCE

SUGGESTIONS FOR OBTAINING SERVICE FOR YOUR VEHICLE

Prepare For The Appointment If you’re having warranty work done, be sure to have the right papers with you. Take your warranty folder. All work to be performed may not be covered by the warranty, discuss additional charges with the service manager. Keep a maintenance log of your vehicle’s service history. This can often provide a clue to the current problem. Prepare A List Make a written list of your vehicle’s problems or the specific work you want done. If you’ve had an accident, or work done that is not on your maintenance log, let the service advisor know.

Be Reasonable With Requests If you list a number of items, and you must have your vehicle by the end of the day, discuss the situation with the service advisor and list the items in order of priority. At many dealers you may obtain a rental vehicle at a minimal daily charge. If you need a rental, it is advisable to make these arrangements when you call for an ap- pointment.

IF YOU NEED ASSISTANCE The manufacturer and its dealers are vitally interested in your satisfaction. We want you to be happy with our products and services. Your selling dealer is best equipped and most anxious to provide prompt resolution for any warranty issue or related matter that you may experience. The manufactur- er’s dealers have the facilities, factory-trained techni- cians, special tools, and the latest information to assure your vehicle is fixed correctly and in a timely manner.

The manufacturer has empowered its dealers to make warranty and repair decisions that ensure you are not inconvenienced. There is no need for you to wait for a decision from the manufacturer. If a special circumstance occurs that requires information from the manufacturer, we have asked the dealer’s service management to make the contact on your behalf. This is why you should always talk to your dealer’s service manager first. Most matters can be resolved with this process. † If for some reason you are still not satisfied, talk to the general manager or owner of the dealership. They want to know if you need assistance. † If your dealership is unable to resolve the concern, you

may contact the Manufacturer’s Customer Center.

IF YOU NEED CONSUMER ASSISTANCE 349

Any communication to the Manufacturer’s Customer Center should include the following information: † Owner’s name and address † Owner’s telephone number (home and office) † Dealership name † Vehicle identification number † Vehicle delivery date and mileage DaimlerChrysler Motors Corporation Customer Center P.O. Box 21–8004

Auburn Hills, MI 48321–8004

Phone: (800) 992-1997

DaimlerChrysler Canada Inc. Customer Center P.O. Box 1621

Windsor, Ontario N9A 4H6

Phone —(800) 465–2001350 IF YOU NEED CONSUMER ASSISTANCE

In Mexico contact: Av. Prolongacion Paseo de la Reforma, 1240

Sante Fe C.P. 05109

Mexico, D. F. In Mexico (915) 729–1248 or 729–1240

Outside Mexico (525) 729–1248 or 729–1240

Customer Assistance For The Hearing Or Speech Impaired (TDD/TTY) To assist customers who have hearing difficulties, the manufacturer has installed special TDD (Telecommuni- cation Devices for the Deaf) equipment at its Customer Center. Any hearing or speech impaired customer who has access to a TDD or a conventional teletypewriter (TTY) in the United States can communicate with the manufacturer by dialing 1–800–380–CHRY.Service Contract You may have purchased a service contract for your vehicle to help protect you from the high cost of unex- pected repairs after your manufacturer’s new vehicle limited warranty expires. The manufacturer stands be- hind only the manufacturer’s Service Contracts. If you purchased a manufacturer’s Service Contract, you will receive Plan Provisions and an Owner Identification Card in the mail within three weeks of your vehicle delivery date. If you have any questions about your service contract, call the manufacturer’s Service Contract Na- tional Customer Hotline at 1-800-521-9922.

The manufacturer will not stand behind any service contract that is not the manufacturer’s Service Contract. It is not responsible for any service contract other than the manufacturer’s Service Contract. If you purchased a service contract that is not a manufacturer’s Service Contract, and you require service after your manufactur- er’s new vehicle limited warranty expires, please refer to your contract documents, and contact the person listed in those documents. We appreciate that you have made a major investment when you purchased your new vehicle. Your dealer has also made a major investment in facilities, tools, and training to assure that you are absolutely delighted with your ownership experience. You’ll be pleased with their sincere efforts to resolve any warranty issues or related concerns.

IF YOU NEED CONSUMER ASSISTANCE 351

WARRANTY INFORMATION See your manufacturer’s Warranty Information Booklet for information on warranty coverage and transfer of warranty.

352 IF YOU NEED CONSUMER ASSISTANCE

MOPART PARTS Mopart fluids, lubricants, parts, and accessories are available from your dealer. They will help you keep your vehicle operating at its best.

REPORTING SAFETY DEFECTS In the 50 United States and Washington D.C.: If you believe that your vehicle has a defect which could cause a crash or cause injury or death, you should immediately inform the National Highway Traffic Safety Administra- tion (NHTSA) in addition to notifying the manufacturer. If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your dealer, and the manufacturer.

IF YOU NEED CONSUMER ASSISTANCE 353

To contact NHTSA, you may either call the Auto Safety Hotline toll free at 1-800-424-9393 (or 366-0123 in Wash- ington DC area) or write to: NHTSA, U.S. Dept. of Transportation, Washington DC 20590. You can also obtain other information about motor vehicle safety from the Hotline. In Canada: If you believe that your vehicle has a safety defect, you should contact the Customer Service Department imme- diately. Canadian customers who wish to report a safety defect to the Canadian government should write to Transport Canada, Motor Vehicle Defect Investigations and Recalls, 2780 Sheffield Road, Ottawa, Ontario K1B 3V9.

354 IF YOU NEED CONSUMER ASSISTANCE

PUBLICATION ORDER FORMS To order the following manuals, you may use either the website or the phone numbers listed below. Visa, Mas- tercard, American Express, and Discover orders are ac- cepted. If you prefer mailing your payment, please call for an order form. NOTE: A street address is required when ordering manuals. (No P.O. Boxes). † Service Manuals.

These comprehensive service manuals provide the information that students and professional technicians need in diagnosing/troubleshooting, problem solving, maintaining, servicing and repairing DaimlerChrysler Corporation vehicles. A complete working knowledge of the vehicle, system and/or components is written in straightforward language with illustrations, diagrams and charts.

† Diagnostic Procedure Manuals.

Filled with diagrams, charts and detailed illustrations, these practical manuals make it easy for students and technicians to find and fix problems on computer- controlled vehicle systems and features. They show exactly how to find and correct problems the first time, using step-by-step troubleshooting and driveability procedures, proven diagnostic tests and a complete list of all tools and equipment.

† Owner’s Manuals.

These manuals have been prepared with the assistance of service and engineering specialists to acquaint you with specific Chrysler group vehicles. Included are starting, operating, emergency and maintenance pro- cedures as well as specifications, capabilities and safety tips.

IF YOU NEED CONSUMER ASSISTANCE 355

Call Toll Free at 1–800–890–4038 (U.S.) or 1–800–387–1143

(Canada) Or Visit us on the World Wide Web at: www.techauthority.daimlerchrysler.com or www.daimlerchrysler.ca/manualsINDEX

10

358 INDEX

Adding Washer Fluid . . . . . . . . . . . . . . . . . . . . . 204

Air Cleaner, Engine . . . . . . . . . . . . . . . . . . . . . . 297

Air Conditioner Maintenance . . . . . . . . . . . . . . . 299

Air Conditioning . . . . . . . . . . . . . . . . . . . . . . . . 200

Air Conditioning Controls . . . . . . . . . . . . . . . 200,201

. . . . . . . . . . . . 202

Air Conditioning, Operating Tips Air Conditioning Refrigerant . . . . . . . . . . . . . . . 300

Air Conditioning System . . . . . . . . . . . . . . . . . . 200

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Air Pressure, Tires . . . . . . . . . . . . . . . . . . . . . . . 249

Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Airbag Deployment . . . . . . . . . . . . . . . . . . . . . . . 55

Airbag Light . . . . . . . . . . . . . . . . . . . . . . . 51,58,157

Airbag Maintenance . . . . . . . . . . . . . . . . . . . . . . . 57

Airbag, Window . . . . . . . . . . . . . . . . . . . . . . . . . 47

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Alarm, Panic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . 253

Alignment and Balance Alterations/Modifications, Vehicle . . . . . . . . . . . . . 8Antenna, Satellite Radio . . . . . . . . . . . . . . . . . . . 193

Antifreeze (Engine Coolant) . . . . . . . . . . . . . . . . 326

Anti-Lock Brake System . . . . . . . . . . . . . . . . . . . 234

Anti-Lock Warning Light . . . . . . . . . . . . . . . . . . 152

Appearance Care . . . . . . . . . . . . . . . . . . . . . . . . 315

Arming Theft System . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . 33

Auto Down Power Windows Automatic Dimming Mirror . . . . . . . . . . . . . . . . . 76

Automatic Door Locks . . . . . . . . . . . . . . . . . . . . . 21

Automatic Transmission . . . . . . . . . . . . . . . . 216,311

Adding Fluid . . . . . . . . . . . . . . . . . . . . . . . . . 312

Fluid and Filter Changes . . . . . . . . . . . . . . . . . 311

Fluid Level Check . . . . . . . . . . . . . . . . . . . . . . 311

Fluid Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Gear Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Special Additives . . . . . . . . . . . . . . . . . . . . . . 312

. . . . . . . . . . . . . . . . . . . . . . 221

Torque Converter Auxiliary Electrical Outlet . . . . . . . . . . . . . . . . . . 133Auxiliary Power Outlet

. . . . . . . . . . . . . . . . . . . 133

Bulbs, Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

INDEX 359

Bar, Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Emergency Starting . . . . . . . . . . . . . . . . . . . . . 279

Keyless Transmitter Replacement . . . . . . . . . . . . 27

Saving Feature . . . . . . . . . . . . . . . . . . . . . . . . 102

Belts, Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Body Mechanism Lubrication . . . . . . . . . . . . . . . 301

B-Pillar Location . . . . . . . . . . . . . . . . . . . . . . . . 244

Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Anti-Lock . . . . . . . . . . . . . . . . . . . . . . . . . 152,234

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Hoses Master Cylinder . . . . . . . . . . . . . . . . . . . . . . . 310

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Warning Light . . . . . . . . . . . . . . . . . . . . . . . . 155

Brake/Transmission Interlock . . . . . . . . . . . . . . . 216

Break-In Recommendations, New Vehicle . . . . . . . . 68

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . 324Calibration, Compass . . . . . . . . . . . . . . . . . . . . . 122

Capacities, Fluid . . . . . . . . . . . . . . . . . . . . . . . . 326

Caps, FillerFuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Car Washes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Cargo Area Cover . . . . . . . . . . . . . . . . . . . . . . . 137

Cargo Area Features . . . . . . . . . . . . . . . . . . . . . . 137

Cargo Compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99,137

Light Luggage Carrier . . . . . . . . . . . . . . . . . . . . . . . 142

Cargo Light . . . . . . . . . . . . . . . . . . . . . . . . . . 99,137

Cargo Organizer . . . . . . . . . . . . . . . . . . . . . . . . 140

Cargo Tie-Downs . . . . . . . . . . . . . . . . . . . . . . . . 138

Carpeting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Cassette Tape and Player Maintenance . . . . . . . . . 196

Cassette Tape Player . . . . . . . . . . . . . 160,162,174,17810

360 INDEX

Catalytic Converter . . . . . . . . . . . . . . . . . . . . . . 295

Caution, Exhaust Gas . . . . . . . . . . . . . . . . . . . . . . 68

CD Changer . . . . . . . . . . . . . . . . . . . . . . 164,171,182

CD Player . . . . . . . . . . . . . . . 167,169,174,180,183,186

CD Player Maintenance . . . . . . . . . . . . . . . . . . . 197

Cellular Phone . . . . . . . . . . . . . . . . . . . . . . . . 78,198

Chains, Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Changing A Flat Tire . . . . . . . . . . . . . . . . . . . . . 274

Charging System Light . . . . . . . . . . . . . . . . . . . . 153

Chart, Tire Sizing . . . . . . . . . . . . . . . . . . . . . . . . 241

Child Restraint . . . . . . . . . . . . . . . . . . . . . . 58,63,65

Child Restraint Tether Anchors . . . . . . . . . . . . . 62,63

Child Safety Locks . . . . . . . . . . . . . . . . . . . . . . . . 22

Cigar Lighter . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Climate Control . . . . . . . . . . . . . . . . . . . . . . . . . 198

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Clutch Interlocking Ignition System . . . . . . . . 210,215

Command-Trac Operation . . . . . . . . . . . . . . . . . . 222

Compact Disc Maintenance . . . . . . . . . . . . . . . . . 197Compass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Compass Calibration . . . . . . . . . . . . . . . . . . . . . 122

Compass Variance . . . . . . . . . . . . . . . . . . . . . . . 123

Computer, Trip/Travel . . . . . . . . . . . . . . . . . . . . 120

Console, Overhead . . . . . . . . . . . . . . . . . . . . . . . 110

Contract, Service . . . . . . . . . . . . . . . . . . . . . . . . 350

Converter, Catalytic . . . . . . . . . . . . . . . . . . . . . . 295

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . 303

Adding Coolant (Antifreeze) . . . . . . . . . . . . . . 305

Coolant Capacity . . . . . . . . . . . . . . . . . . . . . . 326

. . . . . . . . . . . . . . . . . . . . . . . . . 306

Coolant Level Disposal of Used Coolant . . . . . . . . . . . . . . . . 304

Drain, Flush, and Refill . . . . . . . . . . . . . . . . . . 303