- Download PDF Manual

-

PER- FORMED BY PER- FORMED AT

96,000

154 000450 MAINTAINING YOUR VEHICLE

45,000

72 00037,500

60 00030,000

48 0007,500

12 00015,000

24 000Maintenance Log and Service Chart (Diesel Engines) Noise Systems Maintenance Chart and Service Log — Insert Month, Day, Year under column mileage closest to the mileage at which service was performed. MILES 22,500

36 000

KILOME- TERS Exhaust system- inspect Air cleaner assembly- inspect ODOM- ETER READING PER- FORMED BY PER- FORMED AT52,500

84 00060,000

96 000MAINTAINING YOUR VEHICLE 451

84,000

156 00097,500

126 00090,000

144 00075,000

120 00067,500

108 000105,00

168 000Noise Systems Maintenance Chart and Service Log — Insert Month, Day, Year under column mileage closest to the mileage at which service was performed. 82,500

MILES KILOME- 132 000

TERS Exhaust system- inspect Air cleaner assembly- inspect ODOM- ETER READING PER- FORMED BY PER- FORMED AT112,500

181 000452 MAINTAINING YOUR VEHICLE

Appearance Care and Protection from Corrosion

Protection of Body and Paint from Corrosion Vehicle body care requirements vary according to geo- graphic locations and usage. Chemicals that make roads passable in snow and ice, and those that are sprayed on trees and road surfaces during other seasons, are highly corrosive to the metal in your vehicle. Outside parking, which exposes your vehicle to airborne contaminants, road surfaces on which the vehicle is operated, extreme hot or cold weather and other extreme conditions will have an adverse effect on paint, metal trim, and under- body protection. The following maintenance recommendations will enable you to obtain maximum benefit from the corrosion resistance built into your vehicle. What Causes Corrosion? Corrosion is the result of deterioration or removal of paint and protective coatings from your vehicle.

The most common causes are: • Road salt, dirt and moisture accumulation. • Stone and gravel impact. • Insects, tree sap and tar. • Salt in the air near seacoast localities. • Atmospheric fallout/industrial pollutants. Washing • Wash your vehicle regularly. Always wash your ve- hicle in the shade using Mopar威 Car Wash or a mild car wash soap, and rinse the panels completely with clear water. • If insects, tar or other similar deposits have accumu- lated on your vehicle, use Mopar威 Super Kleen Bug and Tar Remover to remove.

• Use Mopar威 Cleaner Wax to remove road film, stains and to protect your paint finish. Take care never to scratch the paint. • Avoid using abrasive compounds and power buffing that may diminish the gloss or thin out the paint finish.

CAUTION!

Do not use abrasive or strong cleaning materials such as steel wool or scouring powder, which will scratch metal and painted surfaces.

Special Care • If you drive on salted or dusty roads or if you drive near the ocean, hose off the undercarriage at least once a month.

MAINTAINING YOUR VEHICLE 453

• It is important that the drain holes in the lower edges of the doors, rocker panels and trunk be kept clear and open. • If you detect any stone chips or scratches in the paint, touch them up immediately. The cost of such repairs is considered the responsibility of the owner. • If your vehicle is damaged due to an accident or similar cause which destroys the paint and protective coating, have your vehicle repaired as soon as pos- sible. The cost of such repairs is considered the respon- sibility of the owner. • If you carry special cargo such as chemicals, fertilizers, de-icer salt, etc., be sure that such materials are well packaged and sealed. • If a lot of driving is done on gravel roads, consider

mud or stone shields behind each wheel.

454 MAINTAINING YOUR VEHICLE

• Use Mopar威 touch up paint on scratches as soon as possible. Your dealer has touch up paint to match the color of your vehicle.

Wheel and Wheel Trim Care All wheels and wheel trim, especially aluminum and chrome plated wheels should be cleaned regularly with a mild soap and water to prevent corrosion. To remove heavy soil and/or excessive brake dust, use Mopar威 Wheel Cleaner (05066247AB) or equivalent or select a nonabrasive, non-acidic cleaner. Do not use scouring pads, steel wool, a bristle brush, or metal polishes. Only Mopar威or equivalent is recommended. Do not use oven cleaner. Avoid automatic car washes that use acidic solutions or harsh brushes that may damage the wheels’ protective finish.

with a clean, dry towel.

YES Essentials威 Fabric Cleaning Procedure – If equipped YES Essentials威 seats may be cleaned in the following manner: • Remove as much of the stain as possible by blotting • Blot any remaining stain with a clean, damp towel. • For tough stains, apply Mopar威 Total Clean or a mild soap solution to a clean, damp cloth and remove stain. Use a fresh, damp towel to remove soap residue. • For grease stains, apply Mopar威 Multi-purpose cleaner to a clean, damp cloth and remove stain. Use a fresh, damp towel to remove soap residue. • Do not use any solvents or protectants on Yes Essen-

tials products.

Interior Care Use Mopar威 Total Clean to clean fabric upholstery and carpeting. Use Mopar威 Total Clean to clean vinyl upholstery. Mopar威Total Clean is specifically recommended for leather upholstery. Your leather upholstery can be best preserved by regular cleaning with a damp soft cloth. Small particles of dirt can act as an abrasive and damage the leather upholstery and should be removed promptly with a damp cloth. Stubborn soils can be removed easily with a soft cloth and Mopar威 Total Clean. Care should be taken to avoid soaking your leather upholstery with any liquid. Please do not use polishes, oils, cleaning fluids, solvents, deter- gents, or ammonia based cleaners to clean your leather upholstery. Application of a leather conditioner is not required to maintain the original condition.

MAINTAINING YOUR VEHICLE 455

WARNING!

Do not use volatile solvents for cleaning purposes. Many are potentially flammable, and if used in closed areas they may cause respiratory harm.

Cleaning Headlights Your vehicle has plastic headlights that are lighter and less susceptible to stone breakage than glass headlights. Plastic is not as scratch resistant as glass and therefore different lens cleaning procedures must be followed. To minimize the possibility of scratching the lenses and reducing light output, avoid wiping with a dry cloth. To remove road dirt, wash with a mild soap solution fol- lowed by rinsing. Do not use abrasive cleaning components, solvents, steel wool or other aggressive material to clean the lenses.

456 MAINTAINING YOUR VEHICLE

Glass Surfaces All glass surfaces should be cleaned on a regular basis with Mopar威 Glass Cleaner or any commercial household-type glass cleaner. Never use an abrasive type cleaner. Use caution when cleaning the inside rear win- dow equipped with electric defrosters or the right rear quarter window equipped with the radio antenna. Do not use scrapers or other sharp instruments which may scratch the elements. When cleaning the rear view mirror, spray cleaner on the towel or rag that you are using. Do not spray cleaner directly on the mirror. Cleaning Plastic Instrument Cluster Lenses The lenses in front of the instruments in this vehicle are molded in clear plastic. When cleaning the lenses, care must be taken to avoid scratching the plastic.

1. Clean with a wet soft rag. A mild soap solution may be used, but do not use high alcohol content or abrasive cleaners. If soap is used, wipe clean with a clean damp rag. 2. Dry with a soft tissue. Seat Belt Maintenance Do not bleach, dye or clean the belts with chemical solvents or abrasive cleaners. This will weaken the fabric. Sun damage can also weaken the fabric. If the belts need cleaning, use a mild soap solution or lukewarm water. Do not remove the belts from the car to wash them. Replace the belts if they appear frayed or worn or if the buckles do not work properly. Dry with a soft tissue.

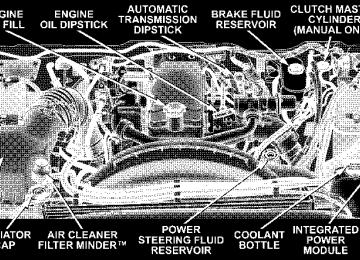

FUSES (INTEGRATED POWER MODULE) An integrated Power Module is located in the engine compartment near the battery. This center contains car- tridge fuses and mini fuses. A description of each fuse and component may be stamped on the inside cover otherwise the cavity number of each fuse is stamped on the inside cover that corresponds to the following chart.

Integrated Power Module Location

Cavity Cartridge

Fuse

MAINTAINING YOUR VEHICLE 457

Mini Fuse 20 Amp Yellow 20 Amp Yellow

– 15 Amp Blue 20 Amp Yellow 10 Amp Red 15 Amp Blue

Description

Power Outlet Console

Cabin Compartment Node (CCN) Door Locks/Brake Trans- mission Shift Interlock (BTSI) – Aisin Transmission Controls (Diesel Only) Power Sunroof

VIST Fan/Wastegate

Reverse Lockout Sole- noid Battery (SRT-10

Only)458 MAINTAINING YOUR VEHICLE

Cavity Cartridge

Fuse

10

30 Amp Pink

Mini Fuse 10 Amp Red

5 Amp Orange

Description

Heated Mirrors

Off Road Module Power Trx-Off Rd Pkg Sen (Gas Engine Only)

NOTE: Insert a 5 amp fuse in this cavity to enable

11

the TRX capability. 20 Amp Yellow

Ignition Off Draw (IOD)-Cabin Compart- ment Node (CCN)/ Radio/Under Hood Lamp/Wireless Con- trol Module (WCM)/ Satellite Digital Audio Receiver (SDARS)/ Hands Free Module (HFM)

12

13

14

15

16

17

1819

20

Cavity Cartridge

Fuse 30 Amp Pink

Mini Fuse

25 Amp Natural

15 Amp Blue 20 Amp Yellow 15 Amp Blue –

Description

Electric Brake

Power-Battery RWAL/ABS Module Feed Park Lamps Left

Trailer Park Lamps

Park Lamps Right

– ABS Pump

Trailer Tow

10 Amp Red

Occupant Restraints Controller (ORC) 2

40 Amp Green 30 Amp Pink

Mini Fuse 10 Amp Red

2 Amp Gray 10 Amp Red

10 Amp Red 20 Amp Yellow

Cavity Cartridge

Fuse

21

22

23

24

25

26

27

20 Amp Blue

40 Amp Green

Description

Cavity Cartridge

Fuse

Occupant Restraints Controller (ORC) Pre- set Carrier IGN Switch Feed

Engine Control Mod- ule (ECM)/Wireless Control Module (WCM)/HVC Subwoofer Amplifier (SRT-10 Only) Power Mirror

Brake Switch/Center High Mount Stop Lamp (CHMSL) Power Seats

28

29

30

31

32

33

34

MAINTAINING YOUR VEHICLE 459

Mini Fuse 10 Amp Red

10 Amp Red 15 Amp Blue 10 Amp Red 10 Amp Red

10 Amp Red –

Description

Start-NCC/Wireless Control Module (WCM)/ABS/RWAL Switches/EC Mirror/ Smart Bar Power/Run

PCM/Transfer Case Brake HVAC/Ajustable Pedals/Heated Seats Switch LED/Exhaust Brake Power-IGN Run Misc

–

460 MAINTAINING YOUR VEHICLE

Cavity Cartridge

Fuse

35

36

37

38

39

40

41

4230 Amp Pink

Mini Fuse 15 Amp Blue

25 Amp Natural 15 Amp Blue 20 Amp Yellow 10 Amp Red 20 Amp Yellow –

Description

Cabin Compartment Node (CCN) Illumina- tion Audio_Amplifier

Spare

Power Outlet IP

Sunroof/Seatbelt Ten- sioner Cigar Lighter

– Diesel PCM (Diesel Only)

CAUTION!

• When installing the Integrated Power Module cover, it is important to ensure the cover is prop- erly positioned and fully latched. Failure to do so may allow water to get into the Integrated Power Module, and possibly result in a electrical system failure. • When replacing a blown fuse, it is important to use only a fuse having the correct amperage rating. The use of a fuse with a rating other than indicated may result in a dangerous electrical system overload. If a properly rated fuse contin- ues to blow, it indicates a problem in the circuit that must be corrected.

VEHICLE STORAGE If you are storing your vehicle for more than 21 days, we recommend that you take the following steps to mini- mize the drain on your vehicle’s battery: • Disconnect the Ignition-Off Draw fuse (I.O.D.) fuse located in the Integrated Power Module, located in the engine compartment. The I.O.D. cavity includes a snap-in retainer that allows the fuse to be discon- nected, without removing it from the fuse block. • The electronic shift transfer case should be placed in the 4HI mode and kept in this position to minimize the battery drain. • As an alternative to the above steps you may, discon- • Anytime you store your vehicle, or keep it out of service (i.e. vacation) for two weeks or more, run the air conditioning system at idle for about five minutes

nect the negative cables from both batteries.

MAINTAINING YOUR VEHICLE 461

in the fresh air and high blower setting. This will insure adequate system lubrication to minimize the possibility of compressor damage when the system is started again.

NOTE: When reinstalling the IOD fuse push firmly until fully seated, the gages in the Instrument Cluster will do a full sweep, when the ignition key is cycled to RUN. This is a normal condition.

REPLACEMENT LIGHT BULBS

LIGHT BULBS — Inside Bulb No. Overhead Console Lights . . . . . . . . . . . . . . . TS 212-2

Dome Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7679

NOTE: For lighted switches, see your dealer for replace- ment instructions. All of the inside bulbs are brass or glass wedge base. Aluminum base bulbs are not approved.462 MAINTAINING YOUR VEHICLE

LIGHT BULBS — Exterior Bulb No. Back-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1156

Center High Mounted Stop Lamp . . . . . . . . . . . . . 912

Fog Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 9006LL Headlamp (Halogen) . . . . . . . . . . . . . . . . . . . . . H13

Side Marker, Park & Turn Signal . . . . . . . . . . . . . 1157

Rear License Plate Lamp. . . . . . . . . . . . . . . . . . . 1157

Rear Cargo Light. . . . . . . . . . . . . . . . . . . . . . . . . 912

Tail & Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1157

Cab Clearance Lights . . . . . . . . . . . . . . . . . . . . . . 168BULB REPLACEMENT

Headlight (Halogen)/Front Park and Turn Lights

CAUTION!

This is a halogen bulb. Avoid touching the glass with your fingers. Reduced bulb life will result.

1. Open the hood 2. Remove the two (2) bolts from the front of the head- light housing.

Front Headlight Housing Bolts

3. Remove the plug from the inner fender well and remove the nut through the access hole.

MAINTAINING YOUR VEHICLE 463

Inner Fender Plug

Rear Headlight Housing Nut Access

4. Pull the housing out from the fender to allow room to disconnect the electrical connectors.

464 MAINTAINING YOUR VEHICLE

NOTE: For easier removal, pull the headlight assembly straight forward, applying the greatest amount of force to the outer edge of the headlight assembly.

Headlight Removal

Bulb Removal

5. Unlock and pull connector straight from the base of the headlight halogen bulb. 6. Twist connector on the side marker/turn signal/park light bulb 1⁄4 turn and remove connector and bulb from housing.

7. Remove housing from vehicle with headlight halogen bulb in housing. 8. Twist the headlight halogen bulb 1⁄4 turn and remove headlight bulb from the housing. 9. Replace headlight or side marker/turn signal/park light bulb. Do not touch the headlight halogen bulb. 10. Reverse procedure for installation of bulbs and hous- ing. Fog Lights

1. Reach under the vehicle, unlock and twist connector counterclockwise 1⁄4 turn and remove connector and bulb from housing.

MAINTAINING YOUR VEHICLE 465

466 MAINTAINING YOUR VEHICLE

2. Pull bulb straight from the connector.

Cab Top Clearance Lights — If Equipped

1. Remove the two screws from the top of the light.

3. Reverse procedure for installation of bulbs and hous- ing.

2. Rotate the socket 1⁄4 turn and pull it from the light assembly.

3. Pull the bulb straight from it’s socket and replace.

MAINTAINING YOUR VEHICLE 467

468 MAINTAINING YOUR VEHICLE

FLUID AND CAPACITIES

U.S.

Metric

Fuel (Appoximate) 6.7L HO Turbo Diesel Engine

Standard Rear Tank

Optional Midship Tank Fuel (Appoximate) 5.7L Gas Engine

Standard Rear Tank

Optional Midship Tank Engine Oil (with filter) 6.7L HO Turbo Diesel

Engine (SAE 15W-40, API CJ-4 Certified, that meets

CES 20081 Standards.)

52 gal. 22 gal.

52 gal. 22 gal.

12 qts.

198 L 85L

197L 83L

11.4L

U.S.

7.0 qts.

Metric

6.6L

7.0 qts.

6.6L

22.6 qts. 18.7 qts.

21.4L 17.7L

5.7L Gas Engine V-8 (SAE

5W-30, API Certified). For trucks operating un-

der a gross combined weight rating greater

than 14,000 lbs.

5.7L Gas Engine V-8 (SAE 5W-20, API Certified). For trucks operating un- der a gross combined weight rating less than 14,000 lbs.

Cooling System

6.7L Diesel Engine I-6

5.7L Gas Engine (Mopar威

Antifreeze/Coolant 5

Year/100,000 Mile For-mula) or equivalent

FLUIDS, LUBRICANTS AND GENUINE PARTS

MAINTAINING YOUR VEHICLE 469

Engine Component Engine Coolant

Fluids, Lubricants and Genuine Parts Mopar威 Antifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or- ganic Additive Technology) or equivalent.

Use SAE 5W-20, API Certified, meeting material standard MS-6395.

6.7L HO Turbo Diesel Engine Oil Use (SAE 15W-40, API CJ-4 Certified, that meets CES 20081 Standards.) 5.7LGas Engine Oil (For trucks operating under a gross combined weight rating less than 14,000 lbs.) 5.7L Gas Engine Oil (For trucks operating under a gross combined weight rating greater than 14,000

lbs.) Engine Oil Filter ( 5.7L Gas En- gine ) Engine Oil Filter ( 6.7L Diesel En- gine )Use SAE 5W-30, API Certified, meeting material standard MS-6395.

Mopar威 Engine Oil Filter, P/N 05083285AA or equivalent.

Mopar威 Engine Oil Filter, P/N 5281090 or equivalent.

470 MAINTAINING YOUR VEHICLE

Component Engine Fuel Filter ( 6.7L Diesel Engine )

Crankcase Ventilation Filter ( 6.7L Diesel Engine ) Fuel Selection ( 5.7L Gas Engine ) Fuel Selection ( 6.7L Diesel En- gine )

Fluids, Lubricants and Genuine Parts Mopar威 Fuel Filter, P/N 05183410AA or equivalent. Must meet 7 micron rat- ing. Using a fuel filter that does not meet the manufacturers filtration and water separating requirements can severely impact fuel system life and re- liability. Mopar威 CCV Filter, P/N 68001433AA or equivalent.

89 Octane, (R=M)/2 Method, Mid-Grade Preferred (87 Octane acceptable). Use good quality diesel fuel from a reputable supplier in your vehicle. Fed- eral law requires that you must fuel this vehicle with Ultra Low Sulfur High- way Diesel fuel (15 ppm Sulfur maximum) and prohibits the use of Low Sul- fur Highway Diesel fuel (500 ppm Sulfur maximum) to avoid damage to the emissions control system. For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15 will provide good perfor- mance. If the vehicle is exposed to extreme cold (below 20°F or -7°C), or is required to operate at colder-than-normal conditions for prolonged periods, use climatized No. 2 diesel fuel or dilute the No. 2 diesel fuel with 50% No. 1 diesel fuel. This will provide better protection from fuel gelling or wax- plugging of the fuel filters. This vehicle is fully compatible with biodiesel blends up to 5% biodiesel meeting ASTM specification D-975.

MAINTAINING YOUR VEHICLE 471

Chassis Component Automatic Transmission (5 Speed 545RFE) Automatic Transmission (6 Speed AS68RC) Transfer Case Manual Transmission Fluid G-56

Clutch Linkage Front and Rear Axle FluidBrake Master Cylinder

Power Steering Reservoir

Fluids, Lubricants and Genuine Parts. Mopar威 ATF+4, Automatic Transmission Fluid.

Mopar威 AS68RC™ Automatic Transmission Fluid

Mopar威 ATF+4, Automatic Transmission Fluid. Mopar威 ATF+4, Automatic Transmission Fluid. Multipurpose Grease, NLGI Grade 2 E.P. or equivalent. GL-5 SAE 75W-90 Synthetic or equivalent. 3500 axles do not require lim- ited slip additive. Mopar威 DOT 3 and SAE J1703 should be used or equivalent. If DOT 3

brake fluid is not available, then DOT 4 is acceptable. Use only recom- mended brake fluids. Mopar威 ATF+4, Automatic Transmission Fluid.MAINTENANCE SCHEDULES

CONTENTS

䡵 Emission Control System Maintenance . . . . . . . . 474

䡵 Maintenance Schedules — 6.7L Turbo Diesel . . . . 474

▫ Maintenance Schedule . . . . . . . . . . . . . . . . . . 476䡵 Maintenance Schedules – Gas Engines . . . . . . . . 484

▫ Schedule “B” . . . . . . . . . . . . . . . . . . . . . . . . 487

▫ Schedule “A” . . . . . . . . . . . . . . . . . . . . . . . . 498M

474 MAINTENANCE SCHEDULES

EMISSION CONTROL SYSTEM MAINTENANCE The “Scheduled” maintenance services, listed in bold type in this section (Section 8) must be done at the times or mileages specified to assure the continued proper functioning of the emission control system. These, and all other maintenance services included in this manual, should be done to provide best vehicle performance and reliability. More frequent maintenance may be needed for vehicles in severe operating conditions such as dusty areas and very short trip driving. Inspection and service also should be done any time a malfunction is suspected. NOTE: Maintenance, replacement, or repair of the emis- sion control devices and systems on your vehicle may be performed by any automotive repair establishment or individual using any automotive part which has been certified pursuant to U.S. EPA or, in the State of Califor- nia, California Air Resources Board regulations.

MAINTENANCE SCHEDULES — 6.7L TURBO DIESEL

CAUTION!

Failure to perform the required maintenance items may result in damage to the vehicle.

At Each Stop for Fuel • Check the engine oil level about 15 minutes after a fully warmed engine is shut off. Checking the oil level while the vehicle is on level ground will improve the accuracy of the oil level reading. Add oil only when the level is at or below the ADD or MIN mark. • Check the windshield washer solvent and add if required. When refilling the washer fluid reservoir,

damage.

nals as required.

take some washer fluid and apply it to a cloth or towel and wipe clean the wiper blades, this will help blade performance. Once a Month • Check tire pressure and look for unusual wear or • Inspect the batteries and clean and tighten the termi- • Check the fluid levels of coolant reservoir, brake master cylinder, and transmission and transfer case (if equipped), add as needed. • Check Filter Minder™. Replace air cleaner filter • Check all lights and all other electrical items for correct • Drain water from the fuel filter.

element if necessary.

operation.

MAINTENANCE SCHEDULES 475

sion components.

At Each Oil Change • Change the engine oil filter. • Inspect the exhaust system. • Inspect the brake hoses. • Inspect the U-Joints ( if equipped) and front suspen- • Check the automatic transmission fluid level. • Check the manual transmission fluid level. • Check the coolant level, hoses, and clamps. • Lubricate outer tie rod ends (4X4) models only. • Lubricate Front Drive Shaft Fitting ( 4X4). Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all re- ceipts.

M

476 MAINTENANCE SCHEDULES

Maintenance Schedule Miles (Kilometers) [Months] Change engine oil and engine oil filter. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and correct stowage. Lubricate outer tie rod ends. Check transfer case fluid level (4X4). Change front and rear axle fluid (4X4). Change automatic transmission fluid. Replace fuel filter element. Inspect brake linings. Inspect and adjust parking brake if necessary. Inspect fan hub.

7,500

(12 000)15,000

(24 000)22,500

(36 000)30,000

(48 000)37,500

(60 000)[6]

[12]

[30]

[18]

[24]

Miles (Kilometers) [Months] Inspect damper. Inspect front wheel bearings.

MAINTENANCE SCHEDULES 477

7,500

(12 000)[6]

15,000

(24 000)[12]

22,500

(36 000)[18]

37,500

(60 000)[30]

30,000

(48 000)[24]

M

478 MAINTENANCE SCHEDULES

Miles (Kilometers) [Months] Change engine oil and engine oil filter. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and correct stowage. Lubricate outer tie rod ends. Drain and refill transfer case fluid (4X4). Change front and rear axle fluid (4X4). Change automatic transmission fluid. Change manual transmission fluid. Flush and replace engine coolant at 60 months, if not replaced at 100,000 miles (160 000 km). Inspect drive belt, replace as necessary. Replace fuel filter element.

45,000

(72 000)52,500

(84 000)60,000

(97 000)67,500

(109 000)75,000

(121 000)[36]

[42]

[54]

[48]

[60]

Miles (Kilometers) [Months] Inspect brake linings. Inspect and adjust parking brake if necessary. Inspect fan hub. Inspect damper. Inspect front wheel bearings. Replace fuel filter element. Replace Crankcase Ventilation Filter (CCV).

MAINTENANCE SCHEDULES 479

45,000

(72 000)[36]

52,500

(84 000)[42]

60,000

(97 000)[48]

75,000

(121 000)[60]

67,500

(109 000)[54]

M

480 MAINTENANCE SCHEDULES

Miles (Kilometers) [Months] Change engine oil and engine oil filter. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and correct stowage. Lubricate outer tie rod ends. Flush and replace engine coolant, if not replaced at 60 mos. Check transfer case fluid level (4X4). Change front and rear axle fluid (4X4). Change automatic transmission fluid. Inspect drive belt, replace as required.* Inspect fan hub. Inspect damper.

82,500

(133 000)90,000

(145 000)97,500

(157 000)100,000

(161 000)105,000

(169 000)[66]

[72]

[78]

[84]

Miles (Kilometers) [Months] Replace fuel filter element. Inspect front wheel bearings. Inspect brake linings. Inspect and adjust parking brake if necessary.

82,500

(133 000)[66]

90,000

(145 000)[72]

MAINTENANCE SCHEDULES 481

97,500

(157 000)[78]

100,000

(161 000)105,000

(169 000)[84]

M

482 MAINTENANCE SCHEDULES

Miles (Kilometers) [Months] Change engine oil and engine oil filter. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and cor- rect stowage. Lubricate outer tie rod ends. Flush and replace engine coolant at 120

months, if not replaced at 100,000 miles (161

000 km). Inspect drive belt, replace as required.* Drain and refill transfer case fluid (4X4). Check transfer case fluid level (4X4). Change front and rear axle fluid (4X4). Change automatic transmission fluid.112,500

(181 000)120,000

(193 000)127,500

(205 000)135,000

(217 000)142,500

(229 000)150,000

(241 000)[90]

[96]

[102]

[108]

[114]

[120]

112,500

(181 000)[90]

Miles (Kilometers) [Months] Change manual transmission fluid. Inspect fan hub. Inspect damper. Replace fuel filter element. Inspect front wheel bearings. Inspect brake linings. Inspect and adjust parking brake if necessary. Adjust valve lash clearance. Replace Crankcase Ventilation Filter (CCV). Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all re- ceipts.

MAINTENANCE SCHEDULES 483

120,000

(193 000)127,500

(205 000)135,000

(217 000)142,500

(229 000)150,000

(241 000)[96]

[102]

[108]

[114]

[120]

*This maintenance is not required if belt was previously replaced.

M

484 MAINTENANCE SCHEDULES

WARNING!

You can be badly injured working on or around a motor vehicle. Do only that service work for which you have the knowledge and the right equipment. If you have any doubt about your ability to perform a service job, take your vehicle to a competent me- chanic.

MAINTENANCE SCHEDULES – GAS ENGINES There are two maintenance schedules that show the required service for your vehicle. First is Schedule “B”. It is for vehicles that are operated under one or more of the following conditions that are listed below and at the beginning of the schedule. • Day or night temperatures are below 32° F (0° C). • Stop and go driving.

speeds during hot weather, above 90° F (32°C).

• Extensive engine idling. • Driving in dusty conditions. • Short trips of less than 10 miles (16 km). • More than 50% of your driving is at sustained high • Trailer towing. • Snowplowing. • Heavy Loading. • Taxi, police, or delivery service (commercial service). • Off-road or desert operation. • If equipped for and operating with E-85 (ethanol)

fuel.

If ANY of these apply to you then change your NOTE: engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. If ANY of these apply to you then flush and NOTE: replace your engine coolant every 102,000 miles (170 000

km) or 60 months, whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. NOTE: Most vehicles are operated under the conditions listed for Schedule ⬙B⬙. Second is Schedule “A”. It is for vehicles that are not operated under any of the conditions listed under Sched- ule ⬙B⬙. Use the schedule that best describes your driving condi- tions. Where time and mileage are listed, follow the interval that occurs first.MAINTENANCE SCHEDULES 485

NOTE: Under no circumstances should oil change in- tervals exceed 6000 miles (10 000 km) or 6 months whichever comes first.

CAUTION!

Failure to perform the required maintenance items may result in damage to the vehicle.

At Each Stop for Fuel • Check the engine oil level about 5 minutes after a fully warmed engine is shut off. Checking the oil level while the vehicle is on level ground will improve the accu- racy of the oil level reading. Add oil only when the level is at or below the ADD or MIN mark.

M

486 MAINTENANCE SCHEDULES

• Check the windshield washer solvent and add if required. When refilling the washer fluid reservoir, take some washer fluid and apply it to a cloth or towel and wipe clean the wiper blades, this will help blade performance. Once a Month • Check tire pressure and look for unusual wear or • Inspect the battery and clean and tighten the terminals • Check the fluid levels of coolant bottle, brake master • Check all lights and all other electrical items for correct

cylinder, and transmission and add as needed.

as required.

damage.

operation.

tings (if equipped)

At Each Oil Change • Change the engine oil filter. • Lubricate Drivetrain/Steering/Suspension Grease Fit- • Inspect the exhaust system. • Inspect the brake hoses. • Inspect the CV joints/U— joints (if equipped) and • Check the automatic transmission fluid level. • Check the manual transmission fluid level. • Check the coolant level, hoses, and clamps. • Lubricate Front Drive Shaft Fitting (4X4).

front suspension components.

Schedule “B” Follow schedule “B” if you usually operate your vehicle under one or more of the following conditions. • Day or night temperatures are below 32° F (0° C). • Stop and go driving. • Extensive engine idling. • Driving in dusty conditions. • Short trips of less than 10 miles (16 km). • More than 50% of your driving is at sustained high • Trailer towing. • Snowplowing. • Heavy Loading. • Taxi, police, or delivery service (commercial service).

speeds during hot weather, above 90° F (32° C).

• Off-road or desert operation. • If equipped for and operating with E-85 (ethanol)

SCHEDULE “B” 487

fuel.

If ANY of these apply to you then change your NOTE: engine oil every 3,000 miles (5 000 km) or 3 months, whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. If ANY of these apply to you then flush and NOTE: replace your engine coolant every 102,000 miles (170 000

km) or 60 months, whichever comes first and follow schedule “B” of the ⬙Maintenance Schedules⬙ section of this manual. If none of these apply to you, then change your NOTE: engine oil at every interval shown on schedule ⬙A⬙ of the ⬙Maintenance Schedules⬙ section of this manual.488 SCHEDULE “B”

Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and correct stowage. Lubricate outer tie rod ends. Change front and rear axle fluid (4X4). Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary.

3,000

(5 000)6,000

(10 000)9,000

(15 000)12,000

(20 000)15,000

(25 000)Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and correct stowage. Lubricate outer tie rod ends. Change front and rear axle fluid (4X4). Check transfer case fluid level (4X4). Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary. Replace spark plugs. Inspect PCV valve, replace as necessary.

SCHEDULE “B” 489

18,000

(30 000)21,000

(35 000)24,000

(40 000)27,000

(45 000)30,000

(50 000)490 SCHEDULE “B”

Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and correct stowage. Lubricate outer tie rod ends. Change front and rear axle fluid (4X4). Inspect brake linings. Inspect engine air cleaner filter, replace if neces- sary.

33,000

(55 000)36,000

(60 000)39,000

(65 000)42,000

(70 000)45,000

(75 000)Miles (Kilometers) Change engine oil and engine oil filter at interval shown or 3 months, whichever comes first. Lubricate Front Drive Shaft Fitting (4X4). Rotate tires. Check spare tire for proper pressure and correct stowage. Lubricate outer tie rod ends. Flush and replace engine coolant. Drain and refill transfer case fluid (4X4). Change front and rear axle fluid (4X4). Change manual transmission fluid. Drain and refill automatic transmission fluid and change main sump filter and spin-on cooler return filter (if equipped).** Inspect brake linings.

SCHEDULE “B” 491

48,000

(80 000)51,000

(85 000)54,000

(90 000)57,000

(95 000)60,000

(100 000)