- 2005 Chevrolet Cobalt Owners Manuals

- Chevrolet Cobalt Owners Manuals

- 2010 Chevrolet Cobalt Owners Manuals

- Chevrolet Cobalt Owners Manuals

- 2009 Chevrolet Cobalt Owners Manuals

- Chevrolet Cobalt Owners Manuals

- 2006 Chevrolet Cobalt Owners Manuals

- Chevrolet Cobalt Owners Manuals

- 2008 Chevrolet Cobalt Owners Manuals

- Chevrolet Cobalt Owners Manuals

- 2007 Chevrolet Cobalt Owners Manuals

- Chevrolet Cobalt Owners Manuals

- Download PDF Manual

-

General Motors Tire Performance Criteria (TPC) standards.

5-74

Treadwear The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a speciï¬ed government test course. For example, a tire graded 150 would wear one and a half (1.5) times as well on the government course as a tire graded 100. The relative performance of tires depends upon the actual conditions of their use, however, and may depart signiï¬cantly from the norm due to variations in driving habits, service practices, and differences in road characteristics and climate. Traction – AA, A, B, C The traction grades, from highest to lowest, are AA, A, B, and C. Those grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on speciï¬ed government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

Temperature – A, B, C The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a speciï¬ed indoor laboratory test wheel. Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 109. Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law. It should be noted that the temperature grade for this tire is established for a tire that is properly inflated and not overloaded. Excessive speed, underinflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.

5-75

Wheel Alignment and Tire Balance The tires and wheels on your vehicle were aligned and balanced carefully at the factory to give you the longest tire life and best overall performance. Adjustments to wheel alignment and tire balancing will not be necessary on a regular basis. However, if you notice unusual tire wear or your vehicle pulling to one side or the other, the alignment might need to be checked. If you notice your vehicle vibrating when driving on a smooth road, the tires and wheels might need to be rebalanced. See your dealer/retailer for proper diagnosis.

Wheel Replacement Replace any wheel that is bent, cracked, or badly rusted or corroded. If wheel nuts keep coming loose, the wheel, wheel bolts, and wheel nuts should be replaced. If the wheel leaks air, replace it (except some aluminum wheels, which can sometimes be repaired). See your dealer/retailer if any of these conditions exist. Your dealer/retailer will know the kind of wheel you need. Each new wheel should have the same load-carrying capacity, diameter, width, offset, and be mounted the same way as the one it replaces. If you need to replace any of your wheels, wheel bolts, wheel nuts, or Tire Pressure Monitor System (TPMS) sensors, replace them only with new GM original equipment parts. This way, you will be sure to have the right wheel, wheel bolts, wheel nuts, and TPMS sensors for your vehicle.

5-76

Used Replacement Wheels

{ CAUTION:

Putting a used wheel on the vehicle is dangerous. You cannot know how it has been used or how far it has been driven. It could fail suddenly and cause a crash. If you have to replace a wheel, use a new GM original equipment wheel.

{ CAUTION:

Using the wrong replacement wheels, wheel bolts, or wheel nuts on your vehicle can be dangerous. It could affect the braking and handling of your vehicle, make your tires lose air and make you lose control. You could have a collision in which you or others could be injured. Always use the correct wheel, wheel bolts, and wheel nuts for replacement.

Notice: The wrong wheel can also cause problems with bearing life, brake cooling, speedometer or odometer calibration, headlamp aim, bumper height, vehicle ground clearance, and tire or tire chain clearance to the body and chassis. See Changing a Flat Tire on page 5-88 for more information.

5-77

Tire Chains

{ CAUTION:

If your vehicle has P195/65R15, P205/55R16, P205/50R17, or 225/40R18 size tires, do not use tire chains. They can damage your vehicle because there is not enough clearance. Tire chains used on a vehicle without the proper amount of clearance can cause damage to the brakes, suspension, or other vehicle parts. The area damaged by the tire chains could cause you to lose control of your vehicle and you or others may be injured in a crash. Use another type of traction device only if its manufacturer recommends it for use on your vehicle and tire size combination, and road conditions. Follow that manufacturer’s instructions.

CAUTION:

(Continued)

CAUTION:

(Continued)

To help avoid damage to your vehicle, drive slowly, readjust, or remove the device if it is contacting your vehicle, and do not spin your vehicle’s wheels. If you do ï¬nd traction devices that will ï¬t, install them on the front tires.

If your vehicle has a tire size other than

Notice: P195/65R15, P205/55R16, P205/50R17 or 225/40R18

size tires, use tire chains only where legal and only when you must. Use only SAE Class S-type chains that are the proper size for your tires. Install them on the front tires and tighten them as tightly as possible with the ends securely fastened. Drive slowly and follow the chain manufacturer’s instructions. If you can hear the chains contacting your vehicle, stop and retighten them. If the contact continues, slow down until it stops. Driving too fast or spinning the wheels with chains on will damage your vehicle.5-78

If a Tire Goes Flat It is unusual for a tire to blowout while you are driving, especially if you maintain the tires properly. See Tires on page 5-54. If air goes out of a tire, It is much more likely to leak out slowly. But if you should ever have a blowout, here are a few tips about what to expect and what to do: If a front tire fails, the flat tire will create a drag that pulls the vehicle toward that side. Take your foot off the accelerator pedal and grip the steering wheel ï¬rmly. Steer to maintain lane position, and then gently brake to a stop well out of the traffic lane. A rear blowout, particularly on a curve, acts much like a skid and may require the same correction you would use in a skid. In any rear blowout, remove your foot from the accelerator pedal. Get the vehicle under control by steering the way you want the vehicle to go. It may be very bumpy and noisy, but you can still steer. Gently brake to a stop, well off the road if possible. If a tire goes flat, avoid further tire and wheel damage by driving slowly to a level place and stopping. 1. Turn on the hazard warning flashers. See Hazard

Warning Flashers on page 3-6.

2. Park the vehicle. Set the parking brake ï¬rmly and

put the shift lever in P (Park).

3. Turn off the engine. 4. Inspect the flat tire.

{ CAUTION:

Lifting a vehicle and getting under it to do maintenance or repairs is dangerous without the appropriate safety equipment and training. If a jack is provided with the vehicle, it is designed only for changing a flat tire. If it is used for anything else, you or others could be badly injured or killed if the vehicle slips off the jack. If a jack is provided with the vehicle, only use it for changing a flat tire.

This vehicle may come with a jack and spare tire or a tire sealant and compressor kit. To use the jack and spare tire, see Changing a Flat Tire on page 5-88. To use the tire sealant and compressor kit, see Tire Sealant and Compressor Kit on page 5-80.

5-79

Tire Sealant and Compressor Kit

{ CAUTION:

Idling a vehicle in an enclosed area with poor ventilation is dangerous. Engine exhaust may enter the vehicle. Engine exhaust contains Carbon Monoxide (CO) which cannot be seen or smelled. It can cause unconsciousness and even death. Never run the engine in an enclosed area that has no fresh air ventilation. For more information, see Engine Exhaust on page 2-35.

{ CAUTION:

Over-inflating a tire could cause the tire to rupture and you or others could be injured. Be sure to read and follow the tire sealant and compressor kit instructions and inflate the tire to its recommended pressure. Do not exceed the recommended pressure.

5-80

{ CAUTION:

Storing the tire sealant and compressor kit or other equipment in the passenger compartment of the vehicle could cause injury. In a sudden stop or collision, loose equipment could strike someone. Store the tire sealant and compressor kit in its original location.

If this vehicle has a tire sealant and compressor kit, there may not be a spare tire, tire changing equipment, and on some vehicles there may not be a place to store a tire. The tire sealant and compressor can be used to temporarily seal punctures up to 1â„4 inch (6 mm) in the tread area of the tire. It can also be used to inflate an under inflated tire. If the tire has been separated from the wheel, has damaged sidewalls, or has a large puncture, the tire is too severely damaged for the tire sealant and compressor kit to be effective. See Roadside Assistance Program on page 7-8.

Read and follow all of the tire sealant and compressor kit instructions. The kit includes:

Tire Sealant Read and follow the safe handling instructions on the label adhered to the sealant canister. Check the tire sealant expiration date on the sealant canister. The sealant canister should be replaced before its expiration date. Replacement sealant canisters are available at your local dealer/retailer. See “Removal and Installation of the Sealant Canister†following. There is only enough sealant to seal one tire. After usage, the sealant canister and sealant/air hose assembly must be replaced. See “Removal and Installation of the Sealant Canister†following.

A. Air Compressor B. Tire Sealant

Canister

C. Power Plug D. On/Off Button

E. Pressure Gage F. Air Only Hose

(Black)

G. Sealant/Air Hose

(Clear)

5-81

Using the Tire Sealant and Compressor Kit to Temporarily Seal and Inflate a Punctured Tire

When using the tire sealant and compressor kit during cold temperatures, warm the kit in a heated environment for 5 minutes. This will help to inflate the tire faster.

5-82

Always do a safety check ï¬rst. See If a Tire Goes Flat on page 5-79. Do not remove any objects that have penetrated the tire. 1. Remove the tire sealant and compressor kit from its storage location. See Tire Sealant and Compressor Kit Storage on page 5-88. Make sure the on/off button (D) is in the off (O) position.

2. Unwrap the sealant/air hose (F) and the power

plug (C).

3. Place the kit on the ground.

Make sure the tire valve stem is positioned close to the ground so the hose will reach it.

4. Remove the valve stem cap from the flat tire by

turning it counterclockwise.

5. Attach the sealant/air hose (F) onto the tire valve

stem. Turn it clockwise until it is tight.

6. Plug the power plug (C) into the accessory power

outlet in the vehicle. Unplug all items from other accessory power outlets. See Accessory Power Outlet(s) on page 3-16. If the vehicle has an accessory power outlet, do not use the cigarette lighter.

If the vehicle only has a cigarette lighter, use the cigarette lighter. Do not pinch the power plug cord in the door or window.

7. Start the vehicle. The vehicle must be running while

using the air compressor.

8. Press the on/off (D) button to turn the tire sealant

and compressor kit on. The compressor will inject sealant and air into the tire. The pressure gage (E) will initially show a high pressure while the compressor pushes the sealant into the tire. Once the sealant is completely dispersed into the tire, the pressure will quickly drop and start to rise again as the tire inflates with air only. 9. Inflate the tire to the recommended inflation pressure

using the pressure gage (E). The recommended inflation pressure can be found on the Tire and Loading Information label. See Inflation - Tire Pressure on page 5-62. The pressure gage (E) may read higher than the actual tire pressure while the compressor is on. Turn the compressor off to get an accurate pressure reading. The compressor may be turned on/off until the correct pressure is reached.

If the recommended pressure cannot be

Notice: reached after approximately 25 minutes, the vehicle should not be driven farther. The tire is too severely damaged and the tire sealant and compressor kit cannot inflate the tire. Remove the power plug from the accessory power outlet and unscrew the inflating hose from the tire valve. See Roadside Assistance Program on page 7-8. 10. Press the on/off button (D) to turn the tire sealant

and compressor kit off. The tire is not sealed and will continue to leak air until the vehicle is driven and the sealant is distributed in the tire, therefore, Steps 11 through 17 must be done immediately after Step 10. Be careful while handling the tire sealant and compressor kit as it could be warm after usage. 11. Unplug the power plug (C) from the accessory

power outlet in the vehicle.

12. Turn the sealant/air hose (F) counterclockwise to

remove it from the tire valve stem.

5-83

13. Replace the tire valve stem cap. 14. Replace the sealant/air hose (F), and the power

plug (C) back in their original location.

15. If the flat tire was

able to inflate to the recommended inflation pressure, remove the maximum speed label from the sealant canister (B) and place it in a highly visible location.

The label is a reminder not to exceed 55 mph (90 km/h) until the damaged tire is repaired or replaced.

16. Return the equipment to its original storage location

in the vehicle.

17. Immediately drive the vehicle 5 miles (8 km) to

distribute the sealant in the tire.

18. Stop at a safe location and check the tire pressure. Refer to Steps 1 through 11 under “Using the Tire Sealant and Compressor Kit without Sealant to Inflate a Tire (Not Punctured).†If the tire pressure has fallen more than 10 psi (68 kPa) below the recommended inflation pressure, stop driving the vehicle. The tire is too severely damaged and the tire sealant cannot seal the tire. See Roadside Assistance Program on page 7-8. If the tire pressure has not dropped more than 10 psi (68 kPa) from the recommended inflation pressure, inflate the tire to the recommended inflation pressure.

19. Wipe off any sealant from the wheel, tire or vehicle. 20. Dispose of the used sealant canister (B) and

sealant/air hose (F) assembly at a local dealer/retailer or in accordance with local state codes and practices.

21. Replace it with a new canister available from your

dealer/retailer.

22. After temporarily sealing a tire using the tire sealant

and compressor kit, take the vehicle to an authorized dealer/retailer within a 100 miles (161 km) of driving to have the tire repaired or replaced.

5-84

Using the Tire Sealant and Compressor Kit without Sealant to Inflate a Tire (Not Punctured) To use the air compressor to inflate a tire with air only and not sealant:

Always do a safety check ï¬rst. See If a Tire Goes Flat on page 5-79. 1. Remove the tire sealant and compressor kit from its storage location. See Tire Sealant and Compressor Kit Storage on page 5-88.

2. Unlock the air only hose (F) from the sealant

canister (B) by pulling up on the lever.

3. Pull the air only hose (F) from the sealant

canister (B).

4. Remove the power plug (C) from the air

compressor (A).

5. Place the kit on the ground.

Make sure the tire valve stem is positioned close to the ground so the hose will reach it.

6. Remove the tire valve stem cap by turning it

counterclockwise.

7. Attach the air only hose (F) onto the tire valve stem

and press the lever down to secure it.

8. Plug the power plug (C) into the accessory power

outlet in the vehicle. Unplug all items from other accessory power outlets. See Accessory Power Outlet(s) on page 3-16. If the vehicle has an accessory power outlet, do not use the cigarette lighter. If the vehicle only has a cigarette lighter, use the cigarette lighter. Do not pinch the power plug cord in the door or window.

9. Start the vehicle. The vehicle must be running while

using the air compressor.

5-85

Removal and Installation of the Sealant Canister To remove the sealant canister:

10. Press the on/off (D) button to turn the compressor on.

The compressor will inflate the tire with air only.

11. Inflate the tire to the recommended inflation pressure

using the pressure gage (E). The recommended inflation pressure can be found on the Tire and Loading Information label. See Inflation - Tire Pressure on page 5-62. The pressure gage (E) may read higher than the actual tire pressure while the compressor is on. Turn the compressor off to get an accurate reading. The compressor may be turned on/off until the correct pressure is reached.

12. Press the on/off button (D) to turn the tire sealant

and compressor kit off. Be careful while handling the tire sealant and compressor kit as it could be warm after usage. 13. Unplug the power plug (C) from the accessory

power outlet in the vehicle.

14. Disconnect the air only hose (F) from the tire valve

stem, by turning it counterclockwise, and replace the tire valve stem cap.

15. Replace the air only hose (F) and the power plug (C)

back in its original location.

16. Place the equipment in the original storage location

in the vehicle.

1. Unlock the air only hose (F) from the sealant

canister (B) by pulling up on the lever.

2. Pull the air only hose (F) from the sealant

canister (B).

3. Unwrap the sealant/air hose (F) from the

compressor (A).

5-86

To install a new sealant canister: 1. Align the sealant/air hose (F) with the slot in the

air compressor.

2. Push the sealant canister (B) down and turn it

clockwise.

3. Wrap the sealant/air hose (F) around the air

compressor channel to stow it in its original location.

4. Push the air compressor inflator hose (F) onto the

sealant canister inlet and push the lever down.

5-87

4. Turn the sealant canister (B) so the inflator ï¬lling

hose is aligned with the slot in the compressor. 5. Lift the sealant canister (B) from the compressor

and replace with a new sealant canister. See your dealer/retailer for more information.

Tire Sealant and Compressor Kit Storage The tire sealant and compressor kit is located in the trunk. 1. Open the trunk. See Trunk on page 2-12. 2. Lift the trunk liner.

Changing a Flat Tire If a tire goes flat, avoid further tire and wheel damage by driving slowly to a level place. Turn on the hazard warning flashers. See Hazard Warning Flashers on page 3-6.

{ CAUTION:

Changing a tire can be dangerous. The vehicle can slip off the jack and roll over or fall on you or other people. You and they could be badly injured or even killed. Find a level place to change your tire. To help prevent the vehicle from moving:

1. Set the parking brake ï¬rmly. 2. Put an automatic transmission shift lever in

P (Park), or shift a manual transmission to 1 (First) or R (Reverse).

CAUTION:

(Continued)

3. Remove the retainer that holds the tire sealant and

compressor kit.

4. Remove the kit from the foam container. To store the tire sealant and compressor kit, reverse the steps.

5-88

CAUTION:

(Continued)

3. Turn off the engine and do not restart while

the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

To be even more certain the vehicle will not move, you should put blocks at the front and rear of the tire farthest away from the one being changed. That would be the tire on the other side, at the opposite end of the vehicle.

When the vehicle has a flat tire (B), use the following example as a guide to assist you in the placement of wheel blocks (A).

A. Wheel Block B. Flat Tire

The following information explains how to use the jack and change a tire.

5-89

Removing the Spare Tire and Tools The equipment you will need is located in the trunk. Base Models 1. Open the trunk. See Trunk on page 2-12.

2. Lift the trunk liner to access the spare tire and tools.

5-90

Uplevel Models 1. Open the trunk. See Trunk on page 2-12.

A. Cover B. Retainer C. Spare Tire D. Wing Nut E. Jack and Wheel Wrench F. Bolt

3. Remove the retainer (B) that holds down the spare

tire. See Compact Spare Tire on page 5-109 for more information.

4. Remove the spare tire (C) by gently pulling it up

and out of the trunk.

5. Remove the wing nut (D) that holds the jack and

remove the jack and wheel wrench (E).

2. Lift the trunk liner to access the spare tire and tools.

5-91

A. Retainer B. Jack and Wheel Wrench C. Spare Tire D. Foam Support E. Bolt

3. Remove the retainer (A) that holds down the jack,

wheel wrench (B) and spare tire (C).

4. Remove the spare tire by gently pulling it up and

out of the trunk.

5-92

The tools you will be using include the jack (A) and wheel wrench (B).

You will need to turn the plastic wheel nut counterclockwise to loosen the wheel wrench from the jack.

Press the button and then pull on the end of the wheel wrench to extend the handle.

5-93

Removing the Flat Tire and Installing the Spare Tire (All Models Except SS) 1. Do a safety check before proceeding. See Changing

a Flat Tire on page 5-88.

3. If necessary, use the flat end of the wheel wrench

to pry along the edge of the wheel cover until it comes off. Store the wheel cover in the trunk until the flat tire is repaired or replaced.

4. Use the wheel wrench to loosen all the wheel nuts.

Do not remove them yet.

Notice: Make sure that the jack lift head is in the correct position or you may damage your vehicle. The repairs would not be covered by your warranty.

2. If your vehicle has plastic wheel covers, use the

wheel wrench to loosen the plastic wheel nut caps. Once the plastic wheel nut caps have been loosened with the wheel wrench, you can ï¬nish loosening them with your ï¬ngers. The plastic nut caps do not come off.

5-94

{ CAUTION:

Getting under a vehicle when it is jacked up is dangerous. If the vehicle slips off the jack, you could be badly injured or killed. Never get under a vehicle when it is supported only by a jack.

{ CAUTION:

Raising your vehicle with the jack improperly positioned can damage the vehicle and even make the vehicle fall. To help avoid personal injury and vehicle damage, be sure to ï¬t the jack lift head into the proper location before raising the vehicle.

8. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the ground so there is enough room for the compact spare tire to ï¬t under the vehicle.

5-95

5. Position the jack lift head at the jack location

nearest the flat tire. The front location is about 8 inches (20 cm) behind the front wheel opening. The rear location is about 4 inches (10 cm) in front of the rear wheel opening.

6. Raise the jack head until it ï¬ts ï¬rmly in the vehicle’s frame, where the notch is located, nearest the flat tire.

7. Put the compact spare tire near the flat tire.

9. Remove all of the

wheel nuts and flat tire.

10. Remove any rust or dirt

from the wheel bolts, mounting surfaces, and spare wheel.

{ CAUTION:

Rust or dirt on a wheel, or on the parts to which it is fastened, can make wheel nuts become loose after time. The wheel could come off and cause an accident. When changing a wheel, remove any rust or dirt from places where the wheel attaches to the vehicle. In an emergency, use a cloth or a paper towel to do this; but be sure to use a scraper or wire brush later, if needed, to get all the rust or dirt off. See Changing a Flat Tire on page 5-88.

5-96

11. Place the compact spare tire on the wheel-mounting

surface.

{ CAUTION:

Never use oil or grease on bolts or nuts because the nuts might come loose. The vehicle’s wheel could fall off, causing a crash.

12. Reinstall the wheel nuts with the rounded end of the nuts toward the wheel. Tighten each nut by hand until the wheel is held against the hub.

13. Lower the vehicle by turning the jack handle counterclockwise. Lower the jack completely.

{ CAUTION:

Wheel nuts that are improperly or incorrectly tightened can cause the wheels to become loose or come off. The wheel nuts should be tightened with a torque wrench to the proper torque speciï¬cation after replacing. Follow the torque speciï¬cation supplied by the aftermarket manufacturer when using accessory locking wheel nuts. See Capacities and Speciï¬cations on page 5-124 for original equipment wheel nut torque speciï¬cations.

Improperly tightened wheel nuts can lead

Notice: to brake pulsation and rotor damage. To avoid expensive brake repairs, evenly tighten the wheel nuts in the proper sequence and to the proper torque speciï¬cation. See Capacities and Speciï¬cations on page 5-124 for the wheel nut torque speciï¬cation.

4-Wheel Nuts

5-Wheel Nuts

14. Tighten the wheel nuts ï¬rmly in a crisscross

sequence, as shown.

Notice: Wheel covers will not ï¬t on your vehicle’s compact spare. If you try to put a wheel cover on the compact spare, the cover or the spare could be damaged.

5-97

Removing the Flat Tire and Installing the Spare Tire (SS Model) The SS Model has larger performance brakes than the base model. The compact spare tire will not clear the front brakes. Do not use the compact spare tire in the event of a front flat tire. You must use the rear tire to replace the front flat tire.

To change the rear road tire: Rear Tire Changing Procedure 1. Do a safety check before proceeding.

See Changing a Flat Tire on page 5-88 for more information.

2. If your vehicle has plastic wheel covers, use the

wheel wrench to loosen the plastic wheel nut caps. Once the plastic wheel nut caps have been loosened with the wheel wrench, you can ï¬nish loosening them with your ï¬ngers. The plastic nut caps do not come off.

5-98

3. If necessary, use the flat end of the wheel wrench

to pry along the edge of the rear wheel cover until it comes off. Store the wheel cover in the trunk until the flat tire is repaired or replaced.

4. Use the wheel wrench to loosen all the rear wheel

nuts. Do not remove them yet.

Notice: Make sure that the jack lift head is in the correct position or you may damage your vehicle. The repairs would not be covered by your warranty.

6. Raise the jack head until it ï¬ts ï¬rmly in the vehicle’s

frame, where the notch is located, nearest the flat tire.

7. Put the compact spare tire near the rear tire.

{ CAUTION:

Getting under a vehicle when it is jacked up is dangerous. If the vehicle slips off the jack, you could be badly injured or killed. Never get under a vehicle when it is supported only by a jack.

{ CAUTION:

Raising your vehicle with the jack improperly positioned can damage the vehicle and even make the vehicle fall. To help avoid personal injury and vehicle damage, be sure to ï¬t the jack lift head into the proper location before raising the vehicle.

8. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the ground so there is enough room for the compact spare tire to ï¬t under the vehicle.

5-99

5. Position the jack lift head at the rear jack location

nearest the rear tire. The rear location is about 4 inches (10 cm) in front of the rear wheel opening.

9. Remove all of the

wheel nuts.

10. Place the compact spare tire on the wheel-mounting

surface.

{ CAUTION:

Never use oil or grease on bolts or nuts because the nuts might come loose. The vehicle’s wheel could fall off, causing a crash.

11. Remove any rust or dirt

from the wheel bolts, mounting surfaces, and spare wheel.

Reinstall the wheel nuts with the rounded end of the nuts toward the wheel. Tighten each nut by hand until the wheel is held against the hub.

{ CAUTION:

Rust or dirt on a wheel, or on the parts to which it is fastened, can make wheel nuts become loose after time. The wheel could come off and cause an accident. When changing a wheel, remove any rust or dirt from places where the wheel attaches to the vehicle. In an emergency, use a cloth or a paper towel to do this; but be sure to use a scraper or wire brush later, if needed, to get all the rust or dirt off. See Changing a Flat Tire on page 5-88.

5-100

13. Tighten the wheel nuts

ï¬rmly in a crisscross sequence, as shown.

5-Wheel Nuts

Notice: Wheel covers will not ï¬t on your vehicle’s compact spare. If you try to put a wheel cover on the compact spare, the cover or the spare could be damaged.

12. Lower the vehicle by turning the jack handle counterclockwise. Lower the jack completely.

{ CAUTION:

Wheel nuts that are improperly or incorrectly tightened can cause the wheels to become loose or come off. The wheel nuts should be tightened with a torque wrench to the proper torque speciï¬cation after replacing. Follow the torque speciï¬cation supplied by the aftermarket manufacturer when using accessory locking wheel nuts. See Capacities and Speciï¬cations on page 5-124 for original equipment wheel nut torque speciï¬cations.

Improperly tightened wheel nuts can lead

Notice: to brake pulsation and rotor damage. To avoid expensive brake repairs, evenly tighten the wheel nuts in the proper sequence and to the proper torque speciï¬cation. See Capacities and Speciï¬cations on page 5-124 for the wheel nut torque speciï¬cation.

5-101

To change the front flat tire: Front Flat Tire Changing Procedure: 1. Perform a rear tire change by removing the rear tire

and installing the compact spare tire in the rear wheel location. The rear road tire will be used to replace the front flat tire. See Rear Tire Changing Procedure in this section.

2. Do a safety check before proceeding. See Changing

a Flat Tire on page 5-88.

Once the plastic wheel nut caps have been loosened with the wheel wrench, you can ï¬nish loosening them with your ï¬ngers. The plastic nut caps do not come off.

4. If necessary, use the flat end of the wheel wrench

to pry along the edge of the wheel cover until it comes off. Store the wheel cover in the trunk until the flat tire is repaired or replaced.

5. Use the wheel wrench to loosen all the wheel nuts

on the flat tire. Do not remove them yet.

Notice: Make sure that the jack lift head is in the correct position or you may damage your vehicle. The repairs would not be covered by your warranty.

3. If your vehicle has plastic wheel covers, use the

wheel wrench to loosen the plastic wheel nut caps.

5-102

6. Position the jack lift head at the jack location

nearest the flat tire. The front location is about 8 inches (20 cm) behind the front wheel opening.

7. Raise the jack head until it ï¬ts ï¬rmly in the vehicle’s

frame, where the notch is located, nearest the flat tire.

8. Put the tire near the flat tire.

{ CAUTION:

Getting under a vehicle when it is jacked up is dangerous. If the vehicle slips off the jack, you could be badly injured or killed. Never get under a vehicle when it is supported only by a jack.

{ CAUTION:

Raising your vehicle with the jack improperly positioned can damage the vehicle and even make the vehicle fall. To help avoid personal injury and vehicle damage, be sure to ï¬t the jack lift head into the proper location before raising the vehicle.

9. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the ground so there is enough room for the compact spare tire to ï¬t under the vehicle.

5-103

10. Remove all of the

wheel nuts.

11. Remove any rust or dirt

from the wheel bolts, mounting surfaces, and spare wheel.

5-104

{ CAUTION:

Rust or dirt on a wheel, or on the parts to which it is fastened, can make wheel nuts become loose after time. The wheel could come off and cause an accident. When changing a wheel, remove any rust or dirt from places where the wheel attaches to the vehicle. In an emergency, use a cloth or a paper towel to do this; but be sure to use a scraper or wire brush later, if needed, to get all the rust or dirt off. See Changing a Flat Tire on page 5-88.

12. Place the tire on the wheel-mounting surface.

{ CAUTION:

Never use oil or grease on bolts or nuts because the nuts might come loose. The vehicle’s wheel could fall off, causing a crash.

13. Reinstall the wheel nuts with the rounded end of the nuts toward the wheel. Tighten each nut by hand until the wheel is held against the hub. 14. Lower the vehicle by turning the jack handle counterclockwise. Lower the jack completely.

5-105

{ CAUTION:

Wheel nuts that are improperly or incorrectly tightened can cause the wheels to become loose or come off. The wheel nuts should be tightened with a torque wrench to the proper torque speciï¬cation after replacing. Follow the torque speciï¬cation supplied by the aftermarket manufacturer when using accessory locking wheel nuts. See Capacities and Speciï¬cations on page 5-124 for original equipment wheel nut torque speciï¬cations.

Improperly tightened wheel nuts can lead

Notice: to brake pulsation and rotor damage. To avoid expensive brake repairs, evenly tighten the wheel nuts in the proper sequence and to the proper torque speciï¬cation. See Capacities and Speciï¬cations on page 5-124 for the wheel nut torque speciï¬cation.

5-106

15. Tighten the wheel nuts

ï¬rmly in a crisscross sequence, as shown.

5-Wheel Nuts

Notice: Wheel covers will not ï¬t on your vehicle’s compact spare. If you try to put a wheel cover on the compact spare, the cover or the spare could be damaged. Storing a Flat or Spare Tire and Tools

{ CAUTION:

Storing a jack, a tire, or other equipment in the passenger compartment of the vehicle could cause injury. In a sudden stop or collision, loose equipment could strike someone. Store all these in the proper place.

A. Cover B. Retainer C. Jack and Wheel Wrench D. Stow Bolt Extension Rod E. Flat Tire F. Bolt

Base Model

5-107

A. Cover B. Retainer C. Jack and Wheel Wrench D. Stow Bolt Extension Rod E. Flat Tire F. Foam Support G. Bolt

To store a flat tire and tools: 1. Remove the stow bolt extension rod and sleeve

from the jack.

2. Screw the stow bolt extension rod and the sleeve

into the existing spare tire hold-down bolt.

3. If your vehicle has aluminum wheels, ï¬rst remove

the center cap with your hand or the wheel wrench. 4. Place the flat tire face down into the spare tire tub. 5. Re-attach the wheel wrench to the jack. 6. Place the jack into the center of the flat tire, being

careful not to scratch the inside of the wheel. 7. Remove the plastic sleeve from the stow bolt

extension rod. Secure the jack and road wheel using the larger plastic retainer.

Uplevel Model

5-108

8. If used in the vehicle, place the smaller jack

retainer nut in a safe place until you are ready to store the compact spare tire in the trunk again.

To store the compact spare tire and tools, follow the previous procedure without using the stow bolt extension rod and see Removing the Spare Tire and Tools on page 5-90 and follow the removal procedure, in reverse, for the proper jack storage instructions for this vehicle. The compact spare tire is for temporary use only. Replace the compact spare with a full-size tire as soon as possible.

Compact Spare Tire

{ CAUTION:

Driving with more than one compact spare tire at a time could result in loss of braking and handling. This could lead to a crash and you or others could be injured. Use only one compact spare tire at a time.

This vehicle may have a compact spare tire. Although the compact spare tire was fully inflated when the vehicle was new, it can lose air after a time. Check the inflation pressure regularly. It should be 60 psi (420 kPa).

After installing the compact spare on the vehicle, if the vehicle has one, stop as soon as possible and make sure the spare tire is correctly inflated. The compact spare is made to perform well at speeds up to 65 mph (105 km/h) for distances up to 3,000 miles (5 000 km), so you can ï¬nish your trip and have the full-size tire repaired or replaced at your convenience. Of course, it is best to replace the spare with a full-size tire as soon as possible. The spare tire will last longer and be in good shape in case it is needed again. Notice: When the compact spare is installed, do not take the vehicle through an automatic car wash with guide rails. The compact spare can get caught on the rails which can damage the tire, wheel and other parts of the vehicle. Do not use the compact spare on other vehicles. And do not mix the compact spare tire or wheel with other wheels or tires. They will not ï¬t. Keep the spare tire and its wheel together. Notice: Tire chains will not ï¬t the compact spare. Using them can damage the vehicle and can damage the chains too. Do not use tire chains on the compact spare.

5-109

Appearance Care

Interior Cleaning The vehicle’s interior will continue to look its best if it is cleaned often. Although not always visible, dust and dirt can accumulate on the upholstery. Dirt can damage carpet, fabric, leather, and plastic surfaces. Regular vacuuming is recommended to remove particles from the upholstery. It is important to keep the upholstery from becoming and remaining heavily soiled. Soils should be removed as quickly as possible. The vehicle’s interior may experience extremes of heat that could cause stains to set rapidly. Lighter colored interiors may require more frequent cleaning. Use care because newspapers and garments that transfer color to home furnishings may also transfer color to the vehicle’s interior. When cleaning the vehicle’s interior, only use cleaners speciï¬cally designed for the surfaces being cleaned. Permanent damage may result from using cleaners on surfaces for which they were not intended. Use glass cleaner only on glass. Remove any accidental over-spray from other surfaces immediately. To prevent over-spray, apply cleaner directly to the cleaning cloth.

Notice: Using abrasive cleaners when cleaning glass surfaces on the vehicle, could scratch the glass and/or cause damage to the rear window defogger. When cleaning the glass on the vehicle, use only a soft cloth and glass cleaner. Many cleaners contain solvents that may become concentrated in the vehicle’s breathing space. Before using cleaners, read and adhere to all safety instructions on the label. While cleaning the vehicle’s interior, maintain adequate ventilation by opening the vehicle’s doors and windows. Dust may be removed from small buttons and knobs using a small brush with soft bristles. Products that remove odors from the vehicle’s upholstery and clean the vehicle’s glass can be obtained from your dealer/retailer. Do not clean the vehicle using: (cid:129) A knife or any other sharp object to remove a soil

from any interior surface.

(cid:129) A stiff brush. It can cause damage to the vehicle’s

interior surfaces.

(cid:129) Heavy pressure or aggressive rubbing with a

cleaning cloth. Use of heavy pressure can damage the interior and does not improve the effectiveness of soil removal.

5-110

Laundry detergents or dishwashing soaps with degreasers can leave residue that streaks and attracts dirt. For liquid cleaners, about 20 drops per gallon (3.78 L) of water is a good guide. Use only mild, neutral-pH soaps. Too much cleaner that saturates the upholstery.

(cid:129) Organic solvents such as naptha, alcohol, etc. that

can damage the vehicle’s interior.

Fabric/Carpet Use a vacuum cleaner with a soft brush attachment frequently to remove dust and loose dirt. A canister vacuum with a beater bar in the nozzle may only be used on floor carpet and carpeted floor mats. For any soil, always try to remove it ï¬rst with plain water or club soda. Before cleaning, gently remove as much of the soil as possible using one of the following techniques:

For liquids: gently blot the remaining soil with a paper towel. Allow the soil to absorb into the paper towel until no more can be removed. For solid dry soils: remove as much as possible and then vacuum.

To clean: 1. Saturate a lint-free, clean white cloth with water or

club soda.

2. Wring the cloth to remove excess moisture. 3. Start on the outside edge of the soil and gently rub toward the center. Continue cleaning, using a clean area of the cloth each time it becomes soiled. 4. Continue to gently rub the soiled area until the

cleaning cloth remains clean.

5. If the soil is not completely removed, use a mild

soap solution and repeat the cleaning process that was used with plain water.

If any of the soil remains, a commercial fabric cleaner or spot lifter may be necessary. When a commercial upholstery cleaner or spot lifter is to be used, test a small hidden area for colorfastness ï¬rst. If the locally cleaned area gives any impression that a ring formation may result, clean the entire surface. After the cleaning process has been completed, a paper towel can be used to blot excess moisture from the fabric or carpet.

5-111

(cid:129) (cid:129) (cid:129) (cid:129) Leather A soft cloth dampened with water can be used to remove dust. If a more thorough cleaning is necessary, a soft cloth dampened with a mild soap solution can be used. Allow the leather to dry naturally. Do not use heat to dry. Never use steam to clean leather. Never use spot lifters or spot removers on leather. Many commercial leather cleaners and coatings that are sold to preserve and protect leather may permanently change the appearance and feel of the leather and are not recommended. Do not use silicone or wax-based products, or those containing organic solvents to clean the vehicle’s interior because they can alter the appearance by increasing the gloss in a non-uniform manner. Never use shoe polish on leather.

Instrument Panel, Vinyl, and Other Plastic Surfaces A soft cloth dampened with water may be used to remove dust. If a more thorough cleaning is necessary, a clean soft cloth dampened with a mild soap solution can be used to gently remove dust and dirt. Never use spot lifters or removers on plastic surfaces.

Many commercial cleaners and coatings that are sold to preserve and protect soft plastic surfaces may permanently change the appearance and feel of the interior and are not recommended. Do not use silicone or wax-based products, or those containing organic solvents to clean the vehicle’s interior because they can alter the appearance by increasing the gloss in a non-uniform manner. Some commercial products may increase gloss on the instrument panel. The increase in gloss may cause annoying reflections in the windshield and even make it difficult to see through the windshield under certain conditions.

Care of Safety Belts Keep belts clean and dry.

{ CAUTION:

Do not bleach or dye safety belts. It may severely weaken them. In a crash, they might not be able to provide adequate protection. Clean safety belts only with mild soap and lukewarm water.

5-112

Weatherstrips Silicone grease on weatherstrips will make them last longer, seal better, and not stick or squeak. Apply silicone grease with a clean cloth. During very cold, damp weather frequent application may be required. See Recommended Fluids and Lubricants on page 6-12.

Washing Your Vehicle The best way to preserve the vehicle’s ï¬nish is to keep it clean by washing it often. Notice: Certain cleaners contain chemicals that can damage the emblems or nameplates on the vehicle. Check the cleaning product label. If it states that it should not be used on plastic parts, do not use it on the vehicle or damage may occur and it would not be covered by the warranty. Do not wash the vehicle in direct sunlight. Use a car washing soap. Do not use cleaning agents that are petroleum based or that contain acid or abrasives, as they can damage the paint, metal or plastic on

the vehicle. Approved cleaning products can be obtained from your dealer/retailer. Follow all manufacturers’ directions regarding correct product usage, necessary safety precautions and appropriate disposal of any vehicle care product. Rinse the vehicle well, before washing and after to remove all cleaning agents completely. If they are allowed to dry on the surface, they could stain. Dry the ï¬nish with a soft, clean chamois or an all-cotton towel to avoid surface scratches and water spotting. High pressure car washes may cause water to enter the vehicle. Avoid using high pressure washes closer than 12 inches (30 cm) to the surface of the vehicle. Use of power washers exceeding 1,200 psi (8 274 kPa) can result in damage or removal of paint and decals.

Cleaning Exterior Lamps/Lenses Use only lukewarm or cold water, a soft cloth and a car washing soap to clean exterior lamps and lenses. Follow instructions under Washing Your Vehicle on page 5-113.

5-113

Finish Care Occasional waxing or mild polishing of the vehicle by hand may be necessary to remove residue from the paint ï¬nish. Approved cleaning products can be obtained from your dealer/retailer. If the vehicle has a basecoat/clearcoat paint ï¬nish, the clearcoat gives more depth and gloss to the colored basecoat. Always use waxes and polishes that are non-abrasive and made for a basecoat/clearcoat paint ï¬nish. Notice: Machine compounding or aggressive polishing on a basecoat/clearcoat paint ï¬nish may damage it. Use only non-abrasive waxes and polishes that are made for a basecoat/clearcoat paint ï¬nish on the vehicle. Foreign materials such as calcium chloride and other salts, ice melting agents, road oil and tar, tree sap, bird droppings, chemicals from industrial chimneys, etc., can damage the vehicle’s ï¬nish if they remain on painted surfaces. Wash the vehicle as soon as possible. If necessary, use non-abrasive cleaners that are marked safe for painted surfaces to remove foreign matter. Exterior painted surfaces are subject to aging, weather and chemical fallout that can take their toll over a period of years. To help keep the paint ï¬nish looking new, keep the vehicle garaged or covered whenever possible.

5-114

Protecting Exterior Bright Metal Parts Bright metal parts should be cleaned regularly to keep their luster. Washing with water is all that is usually needed. However, chrome polish may be used on chrome or stainless steel trim, if necessary. Use special care with aluminum trim. To avoid damaging protective trim, never use auto or chrome polish, steam or caustic soap to clean aluminum. A coating of wax, rubbed to high polish, is recommended for all bright metal parts.

Windshield and Wiper Blades Clean the outside of the windshield with glass cleaner. Clean the rubber blades using a lint free cloth or paper towel soaked with windshield washer fluid or a mild detergent. Wash the windshield thoroughly when cleaning the blades. Bugs, road grime, sap, and a buildup of vehicle wash/wax treatments may cause wiper streaking. Replace the wiper blades if they are worn or damaged. Wipers can be damaged by: (cid:129) Extreme dusty conditions (cid:129) Sand and salt (cid:129) Heat and sun (cid:129) Snow and ice, without proper removal

Aluminum or Chrome-Plated Wheels and Trim The vehicle may have either aluminum or chrome-plated wheels. Keep the wheels clean using a soft clean cloth with mild soap and water. Rinse with clean water. After rinsing thoroughly, dry with a soft clean towel. A wax may then be applied. Notice: Chrome wheels and other chrome trim may be damaged if the vehicle is not washed after driving on roads that have been sprayed with magnesium, calcium or sodium chloride. These chlorides are used on roads for conditions such as ice and dust. Always wash the vehicle’s chrome with soap and water after exposure. Notice: Using strong soaps, chemicals, abrasive polishes, cleaners, brushes, or cleaners that contain acid on aluminum or chrome-plated wheels, could damage the surface of the wheel(s). The repairs would not be covered by the vehicle warranty. Use only approved cleaners on aluminum or chrome-plated wheels.

The surface of these wheels is similar to the painted surface of the vehicle. Do not use strong soaps, chemicals, abrasive polishes, abrasive cleaners, cleaners with acid, or abrasive cleaning brushes on them because they could damage the surface. Do not use chrome polish on aluminum wheels. Notice: Using chrome polish on aluminum wheels could damage the wheels. The repairs would not be covered by the vehicle warranty. Use chrome polish on chrome wheels only. Use chrome polish only on chrome-plated wheels, but avoid any painted surface of the wheel, and buff off immediately after application. Notice: Driving the vehicle through an automatic car wash that has silicone carbide tire cleaning brushes, could damage the aluminum or chrome-plated wheels. The repairs would not be covered by the vehicle warranty. Never drive a vehicle that has aluminum or chrome-plated wheels through an automatic car wash that uses silicone carbide tire cleaning brushes.

5-115

Tires To clean the tires, use a stiff brush with tire cleaner. Notice: Using petroleum-based tire dressing products on the vehicle may damage the paint ï¬nish and/or tires. When applying a tire dressing, always wipe off any overspray from all painted surfaces on the vehicle.

Sheet Metal Damage If the vehicle is damaged and requires sheet metal repair or replacement, make sure the body repair shop applies anti-corrosion material to parts repaired or replaced to restore corrosion protection. Original manufacturer replacement parts will provide the corrosion protection while maintaining the vehicle warranty.

Finish Damage Any stone chips, fractures or deep scratches in the ï¬nish should be repaired right away. Bare metal will corrode quickly and may develop into major repair expense. Minor chips and scratches can be repaired with touch-up materials available from your dealer/retailer. Larger areas of ï¬nish damage can be corrected in your dealer’s/retailer’s body and paint shop.

5-116

Underbody Maintenance Chemicals used for ice and snow removal and dust control can collect on the underbody. If these are not removed, corrosion and rust can develop on the underbody parts such as fuel lines, frame, floor pan, and exhaust system even though they have corrosion protection. At least every spring, flush these materials from the underbody with plain water. Clean any areas where mud and debris can collect. Dirt packed in close areas of the frame should be loosened before being flushed. Your dealer/retailer or an underbody car washing system can do this.

Chemical Paint Spotting Some weather and atmospheric conditions can create a chemical fallout. Airborne pollutants can fall upon and attack painted surfaces on the vehicle. This damage can take two forms: blotchy, ring-shaped discolorations, and small, irregular dark spots etched into the paint surface. Although no defect in the paint job causes this, we will repair, at no charge to the owner, the surfaces of new vehicles damaged by this fallout condition within 12 months or 12,000 miles (20 000 km) of purchase, whichever occurs ï¬rst.

Vehicle Identiï¬cation

Vehicle Identiï¬cation Number (VIN)

This is the legal identiï¬er for the vehicle. It appears on a plate in the front corner of the instrument panel, on the driver side. It can be seen through the windshield from outside the vehicle. The VIN also appears on the Vehicle Certiï¬cation and Service Parts labels and the certiï¬cates of title and registration. Engine Identiï¬cation The eighth character in the VIN is the engine code. This code helps identify the vehicle’s engine, speciï¬cations, and replacement parts. See “Engine Speciï¬cations†under Capacities and Speciï¬cations on page 5-124 for the vehicle’s engine code.

Service Parts Identiï¬cation Label This label is in the trunk, on the driver side, near the spare tire cover. It is very helpful if parts need to be ordered. The label has the following information: (cid:129) Vehicle Identiï¬cation Number (VIN) (cid:129) Model designation (cid:129) Paint information (cid:129) Production options and special equipment Do not remove this label from the vehicle. Electrical System Add-On Electrical Equipment Notice: Do not add anything electrical to the vehicle unless you check with your dealer/retailer ï¬rst. Some electrical equipment can damage the vehicle and the damage would not be covered by the vehicle’s warranty. Some add-on electrical equipment can keep other components from working as they should. Add-on equipment can drain the vehicle battery, even if the vehicle is not operating. The vehicle has an airbag system. Before attempting to add anything electrical to the vehicle, see Servicing Your Airbag-Equipped Vehicle on page 1-72.

5-117

Headlamp Wiring The headlamp wiring is protected by fuses. Should the headlamps fail to function, have the headlamp system checked right away.

Windshield Wiper Fuses The windshield wiper motor is protected by a circuit breaker and a fuse. If the motor overheats due to heavy snow, etc., the wiper will stop until the motor cools. If the overload is caused by some electrical problem, have it ï¬xed.

Power Windows and Other Power Options Fuses in the fuse block protect the power windows. When the current load is too heavy, the fuse opens protecting the circuit until the problem is ï¬xed.

Fuses and Circuit Breakers The wiring circuits in the vehicle are protected from short circuits by a combination of fuses, circuit breakers and fusible thermal links. This greatly reduces the chance of damage caused by electrical problems. Look at the silver-colored band inside the fuse. If the band is broken or melted, replace the fuse. Be sure you replace a bad fuse with a new one of the identical size and rating. If you ever have a problem on the road and do not have a spare fuse, you can “borrow†one that has the same amperage. Just pick some feature of the vehicle that you can get along without — like the radio or cigarette lighter — and use its fuse if it is the correct amperage. Replace it as soon as you can. There are two fuse blocks in the vehicle: the floor console fuse block and the engine compartment fuse block. There is one additional fuse located in the back of the vehicle near the battery.

5-118

Floor Console Fuse Block

The floor console fuse block is located on the passenger side of the floor console behind the forward panel. The panel has three clips. Pull the panel to disconnect the three clips, and access the fuses. Use the fuse puller to remove fuses.

Fuses

Usage

Fuse Puller Empty Empty Empty Empty Ampliï¬er

5-119

Fuses

Usage

Fuses

Usage

10

11

12

13

14

15

16

17

1819

20

21

22

23

24Cluster Ignition Switch, PASS-Key® III+ Stoplamp Heating, Ventilation, Air Conditioning, PASS-Key® III+ Empty Spare Airbag Spare Windshield Wiper Climate Control System, Ignition Window Retained Accessory Power Empty Electric Power Steering, Steering Wheel Control Sunroof Spare Empty Audio System XM Radio™, OnStar™

25

26

27

28

29Engine Control Module, Transmission Control Module Door Locks Interior Lights Steering Wheel Control Illumination Power Windows

Relays

30

31

32Usage

Climate Control System Empty Retained Accessory Power (RAP)

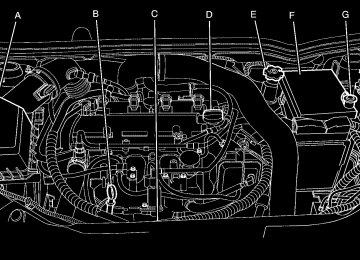

Engine Compartment Fuse Block The engine compartment fuse block is located on the driver side of the vehicle. Lift off the cover to check the fuses. See Engine Compartment Overview on page 5-12 for more information on location. Notice: Spilling liquid on any electrical components on the vehicle may damage it. Always keep the covers on any electrical component.

5-120

Fuses

Usage

Spares Antilock Brake System Blank Blank

SPARES ABS Blank Blank REAR DEFOG Rear Defogger COOL FAN2

CRNK COOL FAN 1

BCM3

BCM2

FOG LAMP HORN RT HI BEAM LT HI BEAM RT LO BEAM LT LO BEAM DRL FUEL PUMPEngine Cooling Fan High Speed Starter Engine Cooling Fan Low Speed Body Control Module 3

Body Control Module 2

Fog Lamps Horn Passenger Side High Beam Lamp Driver Side High Beam Lamp Passenger Side Low Beam Lamp Driver Side Low Beam Lamp Daytime Running Lamps Fuel Pump5-121

Fuses

Blank

ECM/TRANS

BCK UP TRUNK/ HTD SEATS Blank Blank

SDM

ABS3

OUTLET MIR DLC CNSTR VENTUsage

Blank Engine Control Module, Transmission Back-Up Lamps

Trunk, Heated Seats

Blank Blank Sensing Diagnostic Module (Airbags) Antilock Brake System 3

Auxiliary Power Outlet Mirrors Data Link Connector Canister VentFuses

Usage

Exhaust Emissions

EXH ENG VLV SOL Engine Valve Solenoid INJ AIR SOL Blank

Injectors AIR Solenoid Blank Powertrain Control Module/Engine Control Module Electric Power Steering AIR Pump Parking Lamps Windshield Wiper Ignition Air Conditioning Clutch Center High Mount Stop Lamp Antilock Brake System 2

PCM/ECM

EPS AIR PUMP PRK LAMP WPR IP IGN A/C CLTCH CHMSL ABS2

5-122

AIR Solenoid (L61)/Engine Cooling Fan 2 (LNF)

Windshield Wiper High/Low Speed Starter

Relays

Usage

REAR DEFOG Rear Defogger AIR SOL (TURBO: COOL FAN 2) WPR HI/LO CRNK COOL FAN 2

(TURBO: COOL FANS) FUEL PUMP WPR ON/OFF Windshield Wiper On/Off COOL FAN 1Engine Cooling Fan 1

Fuel Pump

Engine Cooling Fan (L61, LE5)/ Engine Cooling Fans (LNF)

Relays PWR/TRN AIR PUMP A/C CLTCH CHMSL RUN/CRNK

Misc. PLR

Usage

Powertrain AIR Pump Air Conditioning Clutch Center High Mount Stop Lamp Run, Crank

Usage

Fuse Puller

5-123

Capacities and Speciï¬cations The following approximate capacities are given in English and metric conversions. Please refer to Recommended Fluids and Lubricants on page 6-12 for more information.

Application

Air Conditioning Refrigerant R134a

Cooling System

2.0L L4 Engine 2.2L L4 Engine

Engine Oil with Filter

2.0L L4 Engine 2.2L L4 Engine

Fuel Tank

2.0L L4 Engine 2.2L L4 Engine (with NU6 emissions) 2.2L L4 Engine (without NU6 emissions)

5-124

Capacities

English

Metric

For the air conditioning system refrigerant charge amount, see the refrigerant caution label located under the hood. See your dealer/retailer for more

information.

9.2 qt 7.4 qt

5.0 qt 5.0 qt

13.2 gal 13.5 gal 13.0 gal

8.7 L 7.0 L

4.7 L 4.7 L

50.0 L 51.1 L 49.2 L

Application

Transmission Fluid (Complete Drain and Reï¬ll)

Automatic Transmission Manual Transmission, 2.0L L4 Engine Manual Transmission, 2.2L L4 Engine

Capacities

English

7.0 qt 2.0 qt 1.7 qt 100 lb ft

Metric

6.6 L 1.9 L 1.6 L

Wheel Nut Torque All capacities are approximate. When adding, be sure to ï¬ll to the approximate level, as recommended in this manual.

140 Y

Engine

VIN Code

Transmission

Engine Speciï¬cations

2.0L L4 Engine

2.2L L4 Engine

Manual

Automatic

Manual

Spark Plug Gap 0.035 in (0.89 mm)

0.040 in (1.01 mm)

5-125

✠NOTES

5-126

Section 6

Maintenance Schedule

Maintenance Schedule ......................................6-2

Introduction ...................................................6-2

Maintenance Requirements ..............................6-2

Your Vehicle and the Environment ....................6-2

Using the Maintenance Schedule ......................6-2

Scheduled Maintenance ...................................6-4

Additional Required Services ............................6-6

Maintenance Footnotes ...................................6-7Owner Checks and Services ............................6-8

At Each Fuel Fill ............................................6-8

At Least Once a Month ...................................6-9

At Least Once a Year .....................................6-9

Recommended Fluids and Lubricants ...............6-12

Maintenance Replacement Parts .....................6-14

Engine Drive Belt Routing ..............................6-15

Maintenance Record .....................................6-166-1

Maintenance Schedule

Introduction Important: Keep engine oil at the proper level and change as recommended.

Have you purchased the GM Protection Plan? The Plan supplements the vehicle warranties. See the Warranty and Owner Assistance booklet or your dealer/retailer for details.

Maintenance Requirements Notice: Maintenance intervals, checks, inspections, replacement parts, and recommended fluids and lubricants as prescribed in this manual are necessary to keep this vehicle in good working condition. Any damage caused by failure to follow scheduled maintenance might not be covered by the vehicle warranty.

6-2

Your Vehicle and the Environment Proper vehicle maintenance not only helps to keep the vehicle in good working condition, but also helps the environment. All recommended maintenance is important. Improper vehicle maintenance can even affect the quality of the air we breathe. Improper fluid levels or the wrong tire inflation can increase the level of emissions from the vehicle. To help protect the environment, and to keep the vehicle in good condition, be sure to maintain the vehicle properly.

Using the Maintenance Schedule We want to help keep this vehicle in good working condition. But we do not know exactly how you will drive it. You might drive very short distances only a few times a week. Or you might drive long distances all the time in very hot, dusty weather. You might use the vehicle in making deliveries. Or you might drive it to work, to do errands, or in many other ways. Because of all the different ways people use their vehicles, maintenance needs vary. You might need more frequent checks and replacements. So please read the following and note how you drive. If you have any questions on how to keep the vehicle in good condition, see your dealer/retailer.

This schedule is for vehicles that:

carry passengers and cargo within recommended limits on the Tire and Loading Information label. See Loading the Vehicle on page 4-26. are driven on reasonable road surfaces within legal driving limits. use the recommended fuel. See Gasoline Octane on page 5-5.

The services in Scheduled Maintenance on page 6-4

should be performed when indicated. See Additional Required Services on page 6-6 and Maintenance Footnotes on page 6-7 for further information.{ CAUTION:

Performing maintenance work on a vehicle can be dangerous. In trying to do some jobs, you can be seriously injured. Do your own maintenance work only if you have the required know-how and the proper tools and equipment for the job. If you have any doubt, see your dealer/retailer to have a qualiï¬ed technician do the work. See Doing Your Own Service Work on page 5-4.

Some maintenance services can be complex. So, unless you are technically qualiï¬ed and have the necessary equipment, have your dealer/retailer do these jobs. When you go to your dealer/retailer for service, trained and supported service technicians will perform the work using genuine parts. To purchase service information, see Service Publications Ordering Information on page 7-17. Owner Checks and Services on page 6-8 tells what should be checked, when to check it, and what can easily be done to help keep the vehicle in good condition. The proper replacement parts, fluids, and lubricants to use are listed in Recommended Fluids and Lubricants on page 6-12 and Maintenance Replacement Parts on page 6-14. When the vehicle is serviced, make sure these are used. All parts should be replaced and all necessary repairs done before you or anyone else drives the vehicle. We recommend the use of genuine parts from your dealer/retailer.

6-3

(cid:129) (cid:129) (cid:129) Scheduled Maintenance When the CHANGE OIL SOON message displays in the Driver Information Center (DIC), service is required for the vehicle. See DIC Warnings and Messages on page 3-46. Have the vehicle serviced as soon as possible within the next 600 miles (1 000 km). It is possible that, if driving under the best conditions, the engine oil life system may not indicate that vehicle service is necessary for over a year. However, the engine oil and ï¬lter must be changed at least once a year and at this time the system must be reset. Your dealer/retailer has trained service technicians who will perform this work using genuine parts and reset the system. If the engine oil life system is ever reset accidentally, service the vehicle within 3,000 miles (5 000 km) since the last service. Remember to reset the oil life system whenever the oil is changed. See Engine Oil Life System on page 5-19 for information on the Engine Oil Life System and resetting the system.

When the CHANGE OIL SOON message appears, certain services, checks, and inspections are required. Required services are described in the following for “Maintenance I†and “Maintenance II.†Generally, it is recommended that the ï¬rst service be Maintenance I, the second service be Maintenance II, and then alternate Maintenance I and Maintenance II thereafter. However, in some cases, Maintenance II may be required more often. Maintenance I — Use Maintenance I if the CHANGE OIL SOON message displays within 10 months since the vehicle was purchased or Maintenance II was performed. Maintenance II — Use Maintenance II if the previous service performed was Maintenance I. Always use Maintenance II whenever the CHANGE OIL SOON message displays 10 months or more since the last service or if the message has not come on at all for one year.

6-4

Scheduled Maintenance

Service

Maintenance I Maintenance II

Change engine oil and ï¬lter. See Engine Oil on page 5-15. Reset oil life system. See Engine Oil Life System on page 5-19. An Emission Control Service. Visually check for any leaks or damage. See footnote (j). Inspect engine air cleaner ï¬lter. If necessary, replace ï¬lter. See Engine Air Cleaner/Filter (2.0L Turbo Engine) on page 5-21 or Engine Air Cleaner/Filter (2.2L Engine) on page 5-24. See footnote (k). Rotate tires and check inflation pressures and wear. See Tire Inspection and Rotation on page 5-70 and “Tire Wear Inspection†in At Least Once a Month on page 6-9. Inspect brake system. See footnote (a). Check engine coolant and windshield washer fluid levels. Add fluid as needed. Perform any needed additional services. See “Additional Required Services†in this section. Inspect suspension and steering components. See footnote (b). Inspect engine cooling system. See footnote (c). Inspect wiper blades. See footnote (d). Inspect restraint system components. See footnote (e). Lubricate body components. See footnote (f). Replace passenger compartment air ï¬lter. See footnote (l). Inspect throttle system. See footnote (g).

•

•

•

• •

•

•

•

•

•

• •

•

• • • • • • •

6-5

Additional Required Services The following services should be performed at the ï¬rst maintenance service (I or II) after the indicated miles (kilometers) shown for each item.

Service and Miles (Kilometers)

Additional Required Services 75,000

25,000

(40 000)50,000

(80 000)(120 000)

100,000

(160 000)125,000

(200 000)150,000

(240 000)Inspect fuel system for damage or leaks. Inspect exhaust system for loose or damaged components. Replace engine air cleaner ï¬lter. See Engine Air Cleaner/Filter (2.0L Turbo Engine) on page 5-21 or Engine Air Cleaner/Filter (2.2L Engine) on page 5-24. Change automatic transmission fluid and ï¬lter (severe service only). See footnote (h). Replace spark plugs. An Emission Control Service. Engine cooling system service (or every ï¬ve years, whichever occurs ï¬rst). An Emission Control Service. See footnote (i). Inspect engine accessory drive belt. An Emission Control Service. See footnote (m).

6-6

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Maintenance Footnotes (a) Visually inspect brake lines and hoses for proper hook-up, binding, leaks, cracks, chaï¬ng, etc. Inspect disc brake pads for wear and rotors for surface condition. Inspect drum brake linings/shoes for wear or cracks. Inspect other brake parts, including drums, wheel cylinders, calipers, parking brake, etc. (b) Visually inspect front and rear suspension and steering system for damaged, loose, or missing parts or signs of wear. Inspect power steering cables for proper hook-up, binding, cracks, chaï¬ng, etc. (c) Visually inspect hoses and have them replaced if they are cracked, swollen, or deteriorated. Inspect all pipes, ï¬ttings and clamps; replace with genuine parts as needed. To help ensure proper operation, a pressure test