- 2012 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2003 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2004 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2009 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2001 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2010 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1996 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2005 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2007 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2008 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1999 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2002 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2000 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2011 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1998 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1997 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2006 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- Download PDF Manual

-

damage and could fail without warning.

4-WHEEL DRIVE MODELS

CAUTION

Always use tires of the same size, brand, construction (bias, bias-belted or radial), and tread pattern on all four wheels. Failure to do so may result in a circumference difference between tires on the front and rear axles which will cause excessive tire wear and may damage the transmission, transfer case and differential gears.

If excessive tire wear is found, it is recom-

7-27

CAUTION

ONLY use spare tires specified for each 4-wheel drive model.

Wheel balance Unbalanced wheels may affect vehicle han- dling and tire life. Even with regular use, wheels can get out of balance. Therefore, they should be balanced as required. Wheel balance service should be performed with the wheels off the vehicle. Spin balanc- ing the front wheels on the vehicle could lead to transmission damage. Care of wheels c Wash the wheels when washing the ve-

hicle to maintain their appearance.

c Clean the inner side of the wheels when the wheel is changed or the underside of the vehicle is washed.

Z X

c Do not use abrasive cleaners when

washing the wheels.

c Inspect wheel rims regularly for dents or corrosion. This may cause loss of pres- sure or damage the tire bead.

c NISSAN recommends waxing the road in

wheels to protect against road salt areas where it is used during winter.

Spare tire Your vehicle is equipped with a TEMPO- RARY USE ONLY spare tire. To avoid property damage or personal in- jury when using the TEMPORARY USE ONLY spare tire, observe the following cau- tions:

CAUTION

c The spare tire should be used for emergency use only. It should be replaced by the standard tire at the first opportunity to avoid possible tire or differential damage.

c Periodically check spare tire infla- tion pressure. Always keep the pres- sure of the T135/70D16 spare tire at 60 psi (420 kPa, 4.2 bar). Always keep the pressure of the P215/75R15

spare tire at 26 psi (180 kPa, 1.8 bar). c Do not drive the vehicle at speedsfaster than 50 MPH (80 km/h).

The transfer control lever must be in the 2H position to prevent the transfer case and differential gears from being damaged.

c Do not use tire chains on a TEMPO- RARY USE ONLY spare tire. Tire chains will not fit properly on a TEM- PORARY USE ONLY spare tire and may cause damage to the vehicle.

c When driving on roads covered with snow or ice, the TEMPORARY USE ONLY spare tire should be used on the front wheels and the original tire used on the rear wheels (drive wheels). Use tire chains only on the two rear original tires.

c Tire tread of the TEMPORARY USE ONLY spare tire will wear at a faster rate than the standard tire. Replace the TEMPORARY USE ONLY spare tire as soon as the tread wear indica- tors appear.

c Because the TEMPORARY USE ONLY spare tire is smaller than the original tire, ground clearance is re- duced. To avoid damage to the ve- hicle, do not drive over obstacles. Also, do not drive the vehicle through an automatic car wash since it might get caught.

c Drive carefully while the TEMPO- RARY USE ONLY spare tire is in- stalled. Avoid sharp turns and abrupt braking while driving.

c Do not use the TEMPORARY USE

ONLY spare tire on other vehicles.

c Do not use more than one TEMPO- RARY USE ONLY spare tire at the same time.

c Do not tow a trailer when the TEM- PORARY USE ONLY T135/70D16

spare is installed.7-28

Z X

CLUTCH HOUSING

ADI0726

Checking water entry Whenever you drive in deep water or mud, check water entry in the clutch housing by removing the blind plug at the bottom of the transmission case. After checking, be sure to reinstall the plug.

7-29

Z X

Z X

8 Maintenance schedule

General maintenance ......................................... 8-2

Periodic maintenance schedules ....................... 8-5Z X

Your new NISSAN has been designed to have minimum maintenance requirements with longer service intervals to save you both time and money. However, some day- to-day and regular maintenance is essential to maintain your NISSAN’s good mechani- cal condition, as well as its emission and engine performance. It is the owner’s responsibility to make sure that the specified maintenance, as well as general maintenance, is performed. As the vehicle owner, you are the only one who can ensure that your vehicle receives the proper maintenance care. You are a vital link in the maintenance chain. General maintenance General maintenance includes those items which should be checked during normal day-to-day operation of the vehicle. They are essential if your vehicle is to continue to operate properly. It is your responsibility to perform these procedures regularly as pre- scribed. These checks or inspections can be done by yourself, a qualified technician or, if you prefer, your NISSAN dealer.

Periodic maintenance The maintenance items listed in this section are required to be serviced at regular inter- vals. However, under severe driving conditions, additional or more frequent maintenance will be required. Where to go for service If maintenance service is required or your vehicle appears to malfunction, have the systems checked and tuned by an autho- rized NISSAN dealer. NISSAN technicians are well-trained spe- cialists and are kept up to date with the latest service information through technical bulletins, service tips, and in-dealership training programs. They are completely qualified to work on NISSAN’s vehicles before they work on your vehicle, rather than after they have worked on it. You can be confident that your NISSAN dealer’s service department performs the best job to meet the maintenance require- ments on your vehicle — in a reliable and economic way.

8-2

GENERAL MAINTENANCE

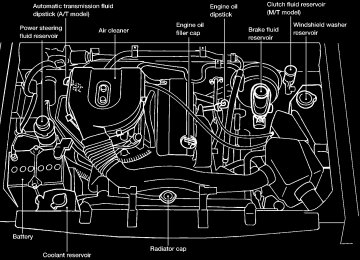

During the normal day-to-day operation of the vehicle, general maintenance should be performed regularly as prescribed in this section. If you detect any unusual sounds, vibrations or smells, be sure to check for the cause or have your NISSAN dealer do it promptly. In addition, you should notify your NISSAN dealer if you think that repairs are required. When performing any checks or mainte- nance work, closely observe the precau- tions in the ‘‘Do-it-yourself operations’’ sec- tion. OUTSIDE THE VEHICLE The maintenance items listed here should be performed from time to time, unless otherwise specified. Additional information on the following items with ‘‘*’’ is found in the ‘‘Do-it- yourself operations’’ section. Tires* Check the pressure with a gauge periodically when at a service station, in- cluding the spare, and adjust to the speci- fied pressure if necessary. Check carefully for damage, cuts or excessive wear. Wheel nuts* When checking the tires,

Z X

make sure no nuts are missing, and check for any loose nuts. Tighten if necessary. Tire rotation* Tires should be rotated every 7,500 miles (12,000 km) for 2WD vehicles and 3,750 miles (6,000 km) for 4WD ve- hicles. Wheel alignment and balance If the ve- hicle should pull to either side while driving on a straight and level road, or if you detect uneven or abnormal tire wear, there may be a need for wheel alignment. If the steering wheel or seat vibrates at normal highway speeds, wheel balancing may be needed. Windshield wiper blades* Check for cracks or wear if they do not wipe properly. Doors and engine hood Check that all doors and the engine hood operate prop- erly. Also ensure that all latches lock se- curely. Lubricate hinges, latches, rollers and links if necessary. Make sure that the sec- ondary latch keeps the hood from opening when the primary latch is released. When driving in areas using road salt or other corrosive materials, check lubrication frequently.

Lights* Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights are all operating properly and installed securely. Also check headlight aim. INSIDE THE VEHICLE The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle, etc. Additional information on the following items with ‘‘*’’ is found in the ‘‘Do-it- yourself operations’’ section. Warning lights and chimes Make sure all warning lights and chimes are operating properly. Windshield wiper and washer* Check that the wipers and washer operate properly and that the wipers do not streak. Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient quantity when operating the heater or air conditioner. Steering wheel Check for changes in the steering conditions, such as excessive free- play, hard steering or strange noises.

8-3

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to ensure they operate smoothly and all latches lock securely in every position. Check that the head restraints move up and down smoothly and the locks (if so equipped) hold securely in all latched posi- tions. Seat belts Check that all parts of the seat belt system (e.g., buckles, anchors, adjust- ers and retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for cuts, fraying, wear or damage. Accelerator pedal Check the pedal for smooth operation and make sure the pedal does not catch or require uneven effort. Keep the floor mats away from the pedal. Clutch pedal* Make sure the pedal oper- ates smoothly and check that it has the proper free travel. Brakes Check that the brakes do not pull the vehicle to one side when applied. Brake pedal and booster* Check the pedal for smooth operation and make sure it has the proper distance under it when de- pressed fully. Check the brake booster func-

Z X

tion. Be certain to keep floormats away from the pedal. Parking brake* Check that the lever has the proper travel and confirm that your vehicle is held securely on a fairly steep hill with only the parking brake applied. Automatic transmission Park position mechanism Check that the lock release button on the selector lever operates prop- erly and smoothly. On a fairly steep hill check that your vehicle is held securely with the selector lever in the P position without applying any brakes. UNDER THE HOOD AND VEHICLE The maintenance items listed here should be checked periodically (e.g., each time you check the engine oil or refuel). Additional information on the following items with ‘‘*’’ is found in the ‘‘Do-it- yourself operations’’ section. Windshield washer fluid* Check that there is adequate fluid in the tank. Engine coolant level* Check the coolant level when the engine is cold.

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that may have accumulated. Make sure the hoses have no cracks, de- formation, rot or loose connections. Brake and clutch fluid levels* Make sure that the brake and clutch fluid level is be- tween the MAX and MIN lines on the reser- voir. Battery* Check the fluid level in each cell. It should be between the MAX and MIN lines. Engine drive belts* Make sure no belt is frayed, worn, cracked or oily. Engine oil level* Check the level after parking the vehicle on a level spot and turning off the engine. Power steering fluid level* and lines Check the level when the fluid is cold and the engine is turned off. Check the lines for proper attachment, leaks, cracks, etc. Automatic transmission fluid level* Check the level after putting the selector lever in P with the engine idling. Exhaust system Make sure there are no loose supports, cracks or holes. If the sound of the exhaust seems unusual or there is a

8-4

smell of exhaust fumes, immediately locate the trouble and correct it. (See the carbon monoxide warning in the ‘‘Starting and driv- ing’’ section.) Underbody The underbody is frequently exposed to corrosive substances such as those used on icy roads or to control dust. It is very important to remove these sub- stances, otherwise rust will form on the floor pan, frame, fuel lines and around the ex- haust system. At the underbody should be thoroughly flushed with plain water, being careful to clean those areas where mud and dirt may accu- mulate. See the ‘‘Appearance and interior care’’ section for additional information. Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has been parked for a while. Water dripping from the air conditioner after use is normal. If you should notice any leaks or if gasoline fumes are evident, check for the cause and have it corrected immediately.

the end of winter,

Z X

c Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

c Driving in dusty conditions. c Driving on rough, muddy, or salt

spread roads.

c Towing a trailer, using a camper or a

car-top carrier. SCHEDULE 2

Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown in Schedule 1 apply to your driving habits.PERIODIC MAINTENANCE SCHEDULES

To ensure smooth, trouble-free, safe and economical driving, NISSAN provides two different maintenance schedules that may be used, depending upon the conditions in which you usually drive. These schedules contain both distance and time intervals, up to 60,000 miles (96,000 km)/48 months. For most people, the odometer reading will in- dicate when service is needed. However, if you drive very little, your vehicle should be serviced at the regular time intervals shown in the schedule. After 60,000 miles (96,000 km) or 48

months, continue periodic maintenance at the same mileage/time intervals. SCHEDULE 1

Follow Periodic Maintenance Schedule 1 if your driving habits frequently include one or more of the following driving conditions: c Repeated short trips of less than 5miles (8 km).

c Repeated short trips of less than 10

miles (16 km) with outside tempera- tures remaining below freezing.c Operating in hot weather in stop-

and-go ‘‘rush hour’’ traffic.

only)

Maintenance for off-road driving Whenever you drive off-road through sand, mud or water as deep as the wheel hub, more frequent maintenance may be re- quired of the following items: ¶ Brake pads and discs ¶ Brake lining and drums ¶ Brake lines and hoses ¶ Wheel bearing grease and free-running

hub grease

¶ Differential, transmission and transfer oil ¶ Steering linkage ¶ Propeller shafts and front drive shafts ¶ Air cleaner filter ¶ Clutch housing (Check for water entry. Clutch housing’’ in the

Refer to ‘‘ ‘‘Do-it-yourself operations’’ section.)

These items should be checked frequently to assure safe and proper operation of your vehicle.

8-5

Z X

SCHEDULE 1

Abbreviations: R = Replace MAINTENANCE OPERATIONI = Inspect. Correct or replace if necessary.

]: At the mileage intervals only

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Miles × 1,000

(km × 1,000) Months3.75

(6)7.5 11.25

(18) (12)15 18.75 22.5 26.25

(42) (24) 12

21(30) 15

(36) 18

30 33.75 37.5 41.25

(66) (48) 24

33(54) 27

(60) 30

45 48.75 52.5 56.25

(90) (72) 36

45(78) 39

(84) 42

Emission control system maintenance Drive belts Air cleaner filter Positive crankcase ventilation (PCV) filter Pulsated secondary air filter Vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter Spark plugs

See NOTE (1) See NOTE (3) See NOTE (2)

See NOTE (3)* See NOTE (4)

I* [R] [R]

I* I*

[R]

60

(96) 48I* [R] [R]

I* I*

R* [R]

NOTE: (1) If operating mainly in dusty conditions, more frequent maintenance may be required.

(2) If operating mainly in dusty conditions, replace every 30,000 miles (48,000 km). (3) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or

extremely high, the filters might become clogged. In such an event, replace them immediately.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months. (5) Maintenance items and intervals with ‘‘*’’ are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-6

Z X

SCHEDULE 1

Abbreviations: R = ReplaceMAINTENANCE OPERATION

I = Inspect. Correct or replace if necessary.

]: At the mileage intervals only

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Miles × 1,000

3.75

7.5 11.25

15

18.75 22.5 26.25

30

33.75 37.5 41.25

45

48.75 52.5 56.25

60

(km × 1,000)

Months

(6)

(12)

(18)

(24)

(30)

(36)

(42)

(48)

(54)

(60)

(66)

(72)

(78)

(84)

(90)

(96)

12

15

18

21

24

27

30

33

36

39

42

45

48

Chassis and body maintenance

Brake lines & cables

Brake pads, discs, drums & linings

Manual & automatic transmission, transfer & differential gear oil (exc. LSD)

See NOTE (1)

Limited-slip differential (LSD) gear oil

See NOTE (1)

Steering gear (box) & linkage, axle & suspension parts

Drive shaft boots & propeller shaft (

Steering linkage ball joints & front suspension ball joints

Front wheel bearing grease (4x2)

Front wheel bearing grease & free-running hub grease (

See NOTE (2)

Exhaust system

Supplemental air bag system

See NOTE (3)

NOTE: (1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000

miles (48,000 km) or 24 months except for LSD Change LSD gear oil every 15,000 miles (24,000 km) or 12 months.

(2) If operating frequently in water, replace grease every 3,750 miles (6,000 km) or 3 months. (3) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the F.M.V.S.S. certification label.

8-7

Z X

SCHEDULE 2

Abbreviations: R = ReplaceMAINTENANCE OPERATION

I = Inspect. Correct or replace if necessary.

]: At the mileage intervals only

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Miles × 1,000

(km × 1,000) Months7.5

(12)15

(24) 1222.5

(36) 1830

(48) 2437.5

(60) 3045

(72) 3652.5

(84) 4260

(96) 48See NOTE (1)

Emission control system maintenance Drive belts Air cleaner filter Positive crankcase ventilation (PCV) filter Vapor lines Fuel lines Fuel filter Engine coolant Engine oil Engine oil filter Spark plugs NOTE: (1) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low

See NOTE (1)* See NOTE (2)

I* [R] [R] I* I*

I* [R] [R] I* I*

R* [R]

[R]

or extremely high, the filters might become clogged. In such an event, replace them immediately. (2) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months. (3) Maintenance items and intervals with ‘‘*’’ are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-8

Z X

SCHEDULE 2

Abbreviations: R = ReplaceMAINTENANCE OPERATION

I = Inspect. Correct or replace if necessary.

]: At the mileage intervals only

MAINTENANCE INTERVAL

Perform at number of miles, kilometers or months, whichever comes first.

Miles × 1,000

(km × 1,000) Months7.5

(12)15

(24) 1222.5

(36) 1830

(48) 2437.5

(60) 3045

(72) 3652.5

(84) 4260

(96) 48Chassis and body maintenance Brake lines & cables Brake pads, discs, drums & linings Manual & automatic transmission, transfer & differential gear oil (exc. LSD) Limited-slip differential (LSD) gear oil Steering gear (box) & linkage, axle & suspension parts Drive shaft boots ( Steering linkage ball joints & front suspension ball joints Front wheel bearing grease (4x2) Front wheel bearing grease & free-running hub grease ( Exhaust system Supplemental air bag system

See NOTE (1)

NOTE: (1) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the F.M.V.S.S. certification label.

8-9

Z X

EXPLANATION OF MAINTE- NANCE ITEMS Additional information on the following items with ‘‘*’’ is found in the ‘‘Do-it- yourself operations’’ section. Emission control system mainte- nance Drive belts* Check drive belts for wear, fraying or cracking and also for proper ten- sion. Replace the drive belts if found dam- aged or in accordance with the mainte- nance schedule. Air cleaner filter Under normal driving con- ditions, the air cleaner filter should be re- placed in accordance with the maintenance schedule. However, driving the vehicle in dusty areas may cause more rapid clogging of the element. Consequently, the element may have to be replaced more frequently. Positive crankcase ventilation (PCV) fil- ter Under normal driving conditions, the filter should be replaced in accordance with the maintenance schedule. If the vehicle is operated under extremely adverse weather conditions or in areas where ambient tem- peratures are either extremely low or ex-

tremely high, the filter may become clogged more rapidly. In such an event, replace the filter immediately. Vapor lines Check vapor lines and connec- tions for failure or looseness. If leaks are found, replace the lines. Fuel lines (hoses, piping, connections, etc.) Check the fuel hoses, piping and con- nections for leaks, looseness or deteriora- tion. Replace any parts if they are damaged. Fuel filter If the vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are ei- ther extremely low or extremely high, the filter might become clogged. In such an event, replace the filter immediately. Engine coolant* Flush and refill the cooling system. Engine oil & oil filter* Under normal driving conditions, the engine oil and oil filter should be replaced in accordance with the mainte- nance schedule. However, under severe driving conditions, they may have to be replaced more frequently. Spark plugs* Replace with new plugs hav- ing the correct heat range.

8-10

Chassis and body maintenance Brake lines & cables Check the brake lines and hoses (including brake booster vacuum hoses, connections & check valve) and parking brake cables for proper attachment, leaks, cracks, chafing, abrasion, deteriora- tion, etc. Brake pads, discs, drums & linings Check these and the other neighboring brake components for wear, deterioration and leaks. Under severe driving conditions, they may have to be inspected more fre- quently. Manual and automatic transmission, transfer & differential gear oil Visually inspect for signs of leakage and replace oil limited-slip differential. Under severe for driving conditions, the oil should be re- placed at the specified interval. Steering gear (box) & linkage, axle & suspension parts & drive shaft boots Check for damage, looseness and leakage of oil or grease. Under severe driving con- ditions, more frequent inspection should be performed. Steering linkage ball joints & front sus- pension ball joints Check the ball joints for

Z X

only).

looseness and grease leakage. damage, Under severe driving conditions, more fre- quent inspection should be performed. Propeller shaft(s) Check the propeller shaft(s) for damage, looseness and grease leakage under severe driving conditions Front wheel bearing grease & free- running hub grease Check the wheel bearing for grease leakage around grease seals, axial end play and smooth turning. Repack these in accordance with the main- tenance schedule (4x2). Check the wheel bearing and free running hub for grease leakage around grease seals, axial end play and smooth turning. Repack these in accordance with the main- tenance schedule. In case of frequent driv- ing in muddy water, the bearing grease and free-running hub grease inspection should be performed more frequently ( Exhaust system Visually check the ex- haust pipes, muffler, and hangers for proper attachment, leaks, cracks, chafing, abra- sion, deterioration, etc. Under severe driv- ing conditions, inspection should be per- formed more frequently.

).

Supplemental air bag system Check the supplemental air bag system components for proper attachment, damage, deformities, cracks, rust, etc. Work around and on the supplemental air bag system should be done by an authorized NISSAN dealer.

8-11

Z X

Z X

9 Technical and consumer information

Capacities and recommended fuel/lubricants .... 9-2

Engine ................................................................ 9-9

Wheel/tire size .................................................. 9-10

Dimensions and weights .................................. 9-11

Registering your vehicle in another country .... 9-12

Vehicle identification ......................................... 9-12

Trailer towing .................................................... 9-16

Towing load/specification chart ........................ 9-18

Uniform tire quality grading .............................. 9-21

Emission control system warranty ................... 9-22

Truck-camper loading ....................................... 9-23

Reporting safety defects (USA) ....................... 9-25

NISSAN Service/Owner’s Manual Order Form . 9-26Z X

CAPACITIES AND RECOMMENDED FUEL/LUBRICANTS The following are approximate capacities. The actual refill capacities may be a little different. When refilling, follow the procedure described in the ‘‘Do-it-yourself operations’’ section to determine the proper refill capacity.

Liter

60

3.9

3.5

4.1

3.88.1

9.0Recommended Specifications

Unleaded gasoline with an octane rating of at least 87 AKI (RON 91)*1

API SG or SH and Energy Conserving II *2

API Certification Mark *2Anti-freeze coolant (Ethylene glycol base)

Fuel

Engine oil (Refill)

Capacity (Approximate)

US

measure

Imp

measure

15-7/8 gal

13-1/4 gal

4x2

4x4

With oil filter Without oil filter With oil filter Without oil filter

Cooling system (with heater and reservoir tank)

4x2

4x44-1/8 qt 3-3/4 qt 4-3/8 qt 4 qt

8-5/8 qt 9-1/2 qt

*1: For further details, see ‘‘Fuel recommendation’’. *2: For further details, see ‘‘Recommended SAE engine oil viscosity’’.

3-3/8 qt 3-1/8 qt 3-5/8 qt 3-3/8 qt

7-1/8 qt 7-7/8 qt

9-2

Z X

Manual transmission gear oil

Manual steering gear oil

Final drive

Transfer fluid

Automatic transmission fluid

Power steering fluid

Brake and clutch fluid

Capacity (Approximate)

4x2

4x44x2 M/T

Regular cab King cab

4x2 A/T 4x4 Front Rear

US

measure 4-1/4 pt 8-1/2 pt 1-3/8 pt

3-1/8 pt 2-3/4 pt. 3-1/8 pt. 2-3/4 pt. 5-7/8 pt.

—

Imp

measure 8-1/2 pt

7 pt

1-1/8 pt

2-5/8 pt 2-1/4 pt. 2-5/8 pt. 2-1/4 pt. 4-7/8 pt.

—

Liter

2.0

4.0

0.621.5

1.3

1.5

1.3

2.8

—Refill to the proper oil level according to the instructions in the ‘‘Do-it-yourself operations’’ section.

Multi-purpose grease Air conditioning system refrigerant Air conditioning system lubricant

lb (kg)

1.65 - 1.87 (0.75 - 0.85)

—

—

—

6.8 oz

7.0 oz

200 ml

Recommended Specifications

API GL-4*1

API GL-4*1

c Without LSD: API GL-5*1

c With LSD: Only LSD gear oil. API GL-5 and SAE 80W-90*2 approved for NISSAN LSD*3

Type DEXRONTM Nissan Matic ‘D’ (Continental U.S. and Alaska) or Genuine Nissan Automatic Transmission Fluid (Canada). *4

Type DEXRON IIETM, DEXRON IIITM, or equivalent Genuine Nissan Brake Fluid*5 or equivalent DOT 3 (US FMVSS No. 116) NLGI No. 2 (Lithium Complex) HFC-134a (R-134a)*6

Nissan A/C System Oil Type R or equivalent*6*1: For further details, see ‘‘Recommended SAE gear oil viscosity’’. *2: SAE 90 is acceptable in temperatures above 0°F (−18°C). *3: Contact your NISSAN dealer for a list of approved oils. *4: Dexron® III/Mercon® or equivalent may also be used. Outside the Continental United States and Alaska contact a Nissan dealership for more information regarding suitable

fluids, including recommended brand(s) of Dexron® III/Mercon® or Dexron® IIE/Mercon® Automatic Transmission Fluid.

*5: Available in mainland U.S.A. through your NISSAN dealer. *6: For further details, see ‘‘Air conditioner specification label’’.

9-3

Z X

FUEL RECOMMENDATION All models are designed to operate on unleaded gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research octane number 91).

CAUTION

c Using a fuel other than that specified could adversely affect the emission control devices and systems, and could also affect the warranty coverage.

c Under no circumstances should a leaded gasoline be used, since this will damage the three-way catalyst.

Reformulated Gasoline Some fuel suppliers are now producing re- formulated gasolines. These gasolines are specially designed to reduce vehicle emis- sions. NISSAN supports efforts towards cleaner air and suggest that you use refor- mulated gasoline when available. Gasoline containing oxygenates Some fuel suppliers sell gasoline containing oxygenates such as ethanol, MTBE and

methanol with or without advertising their presence. Nissan does not recommend the use of fuels of which the oxygenate content and the fuel compatibility for your NISSAN cannot be readily determined. If in doubt, ask your service station manager. If you use oxygenate-blend gasoline, please take the following precautions as the usage of such fuels may cause vehicle perfor- mance problems and/or fuel system dam- age. c The fuel should be unleaded and have an octane rating no lower than that recommended for unleaded gasoline. c If an oxygenate-blend, excepting a methanol blend, it should contain no more than 10% oxygenate. (MTBE may, however, be added up to 15%.)

is used,

c If a methanol blend is used, it should contain no more than 5% methanol (methyl alcohol, wood alcohol). It should also contain a suitable amount of appropriate cosolvents and corro- sion inhibitors. If not properly formu- lated with appropriate cosolvents and corrosion inhibitors, such methanol

9-4

blends may cause fuel system dam- age and/or vehicle performance prob- lems. At this time, sufficient data is not available to ensure that all metha- nol blends are suitable for use in NIS- SAN vehicles.

If any driveability problems such as engine stalling and hard hot starting are experi- enced after using oxygenate-blend fuels, immediately change to a non-oxygenate fuel or a fuel with a low blend of MTBE. Take care not to spill gasoline during refueling. Gasoline containing oxygen- ates can cause paint damage. After Market Fuel Additives NISSAN does not recommend the use of any fuel additives (i.e., fuel injector cleaner, octane booster, intake valve deposit remov- ers, etc.) which are sold commercially. Many of these additives intended for gum, varnish or deposit removal may contain active solvents or similar ingredients that can be harmful to the fuel system and engine.

Z X

damage to the engine. If any of the above symptoms are encountered, have your ve- hicle checked at a NISSAN dealer or other competent service facility. However, now and then you may notice light spark knock for a short time while accelerating or driving up hills. This is no cause for concern, because you get the greatest fuel benefit when there is light spark knock for a short time under heavy engine load.

Octane rating tips In most parts of North America, you should use unleaded gasoline with an octane rating of at least 87 AKI (Anti-Knock Index). How- ever, you may use unleaded gasoline with an octane rating as low as 85 AKI in high altitude areas (over 4,000 ft [1,219 m]) such as: Colorado, Montana, New Mexico, Utah, Wyoming, northeastern Nevada, southern Idaho, western South Dakota, western Ne- braska, and that part of Texas which is directly south of New Mexico. Using unleaded gasoline with an octane rating lower than stated above can cause persistent, heavy ‘‘spark knock’’. (‘‘Spark knock’’ is a metallic rapping noise.) If severe, this can lead to engine damage. If you detect a persistent heavy spark knock even when using gasoline of the stated octane rating, or if you hear steady spark knock while holding a steady speed on level roads, have your dealer correct the condition. Failure to correct the con- dition is misuse of the vehicle, for which NISSAN is not responsible. Incorrect ignition timing results in knocking, after-run and/or overheating. This in turn may cause excessive fuel consumption or

9-5

Z X

ENGINE OIL AND OIL FILTER RECOMMENDATION Selecting the correct oil

It is essential to chose the correct quality and viscosity oil to ensure satisfactory en- gine life and performance. Nissan recom- mends the use of a low friction oil (energy conserving oil) in order to improve fuel economy and conserve energy. Oils which do not have the specified quality label should not be used as they could cause engine damage.

ATI0507

Only those engine oils with the American Petroleum Institute (API) CERTIFICATION MARK on the front of the container should be used. This type of oil supersedes the existing API SG or SH and Energy Conserv- ing II categories. If you cannot find engine oil with the CERTI- FICATION MARK, an API SG or SH and Energy Conserving II oil with API Service Symbol may be used. An oil with a single designation SG or SH, or in combination with other categories (for example, SG/CC or SG/CD) may also be used if one with the API CERTIFICATION MARK cannot be found.

9-6

Mineral based or synthetic type oils may be used in your NISSAN vehicle. These oils must however, meet the API quality and SAE viscosity ratings specified for your ve- hicle. Do not mix mineral based and syn- thetic type oils in the engine at the same time. Oil additives NISSAN does not recommend the use of oil additives. The use of an oil additive is not necessary when the proper oil type is used and maintenance intervals are followed. Oil which may contain foreign matter or has been previously used should not be used. Oil viscosity The engine oil viscosity or thickness changes with temperature. Because of this, it is important that the engine oil viscosity be selected based on the temperatures at which the vehicle will be operated before the next oil change. The chart ‘‘Recom- mended SAE viscosity number’’ shows the recommended oil viscosities for the ex- pected ambient temperatures. Choosing an oil viscosity other than that recommended could cause serious engine damage.

Z X

for

Selecting the correct oil filter Your new vehicle is equipped with a high- quality genuine NISSAN oil filter. When replacing, use the genuine oil filter or its equivalent the reason described in ‘‘Change intervals’’. Change intervals The oil and oil filter change intervals for your engine are based on the use of the specified quality oils and filters. Oil and filter other than the specified quality, or oil and filter change intervals longer than recommended could reduce engine life. Damage to en- gines caused by improper maintenance or use of incorrect oil and filter quality and/or viscosity is not covered by the new NISSAN vehicle warranties. Your engine was filled with a high quality engine oil when it was built. You do not have to change the oil before the first recom- mended change interval. Oil and filter change intervals depend upon how you use your vehicle. Operation under the following conditions may require more frequent oil and filter changes: — repeated short distance driving at cold

outside temperatures,

— driving in dusty conditions, — extensive idling, — towing a trailer.

RECOMMENDED SAE VISCOSITY NUMBER

ATI0509

c SAE 5W-30 viscosity oil is preferred for all temperatures. SAE 10W-30 vis- cosity oil may be used if the ambient temperature is above 0°F (-18°C).

9-7

Z X

AIR CONDITIONING SYSTEM REFRIGERANT AND LUBRICANT RECOMMENDATIONS The air conditioning system in this NIS- SAN vehicle must be charged with the refrigerant HFC-134a (R-134a) and the lubricant, NISSAN A/C system lubricant Type R or the exact equivalents.

CAUTION

Use of any other refrigerant or lubricant will cause severe damage and you will need to replace your vehicle’s entire air conditioning system.

The refrigerant HFC-134a (R-134a) in your NISSAN vehicle does not harm the earth’s ozone layer. Although this refrigerant does not affect the earth’s atmosphere, certain government regulations require the recov- ery and recycling of any refrigerant during automotive air conditioning system service. Your NISSAN dealer has the trained tech- nicians and equipment needed to recover and recycle your air conditioning system refrigerant. Contact your NISSAN dealer when servic- ing your air conditioning system.

9-8

Z X

c 80W-90 is preferable for ambient tem-

peratures below 104°F (40°C).

ATI0510

ENGINE

Model Type Cylinder arrangement Bore × Stroke Displacement Firing order Idle speed Ignition timing (BTDC) CO percentage at idle speed Spark plug

Spark plug gap Camshaft operation Alternator belt size Width × Length

KA24E Gasoline, 4-cycle 4-cylinder in-line 3.504 × 3.780 (89.0 × 96.0) 145.78 (2,389) 1-3-4-2

See the ‘‘Emission Control Label’’ on the underside of the hood.

ZFR4E-11 (Hot) ZFR5E-11 (Standard) ZFR6E-11 (Cold) 0.039 to 0.043 (1.0 to 1.1) Timing chain

in (mm) cu in (cm3)

rpm degree/rpm [No air] %

in (mm)

in (mm)

0.429 × 36.81 (10.9 × 935)

The spark ignition system of this ve- hicle meets all requirements of the Canadian Interference - Causing Equipment Regulations.

9-9

Z X

WHEEL/TIRE SIZE

4x2

Regular cab:

King cab:

4x4

Regular cab:

King cab:

Grade

STD

XE

XE

SE

XE

XE

SE

Road wheel/offset in (mm)

Tire

Spare tire size

14x5J/1.57 (40) Silver, painted steel

14x5J/1.57 (40) Silver, painted steel 14x5J/1.57 (40) Silver, w/full wheel cover 14x6JJ/1.18 (30) Alloy

14x5J/1.57 (40) Silver, painted steel 14x5J/1.57 (40) Silver, w/full wheel cover 14x6JJ/1.18 (30) Alloy

14x6JJ/1.18 (30) Alloy

15x6JJ/1.18 (25) Titanium finish 15x7JJ/0.98 (25) Alloy

15x6JJ/1.18 (25) Titanium finish 15x7JJ/0.98 (25) Alloy

P195/75R14

P195/75R14

P215/70R14

P195/75R14

P215/70R14

P215/70R14

P235/75R15

T135/70D16

T135/70D16

T135/70D16

T135/70D16

T135/70D16

T135/70D16

P215/75R15

P235/75R15

P215/75R15

15x7JJ/0.98 (25) Alloy

P235/75R15

P215/75R15

9-10

Z X

DIMENSIONS AND WEIGHTS

4x2

4x4

Regular Cab

174.6 (4,435)

65.0 (1,650)

62.0 (1,575)

54.9 (1,395)

54.5 (1,385)

104.3 (2,650)

King Cab

190.0 (4,825)

65.0 (1,650)

62.0 (1,575)

54.9 (1,395)

54.5 (1,385)

116.1 (2,950)

Regular Cab

174.6 (4,435)

66.5 (1,690)

67.1 (1,705)

58.5 (1,486)

57.9 (1,471)

104.3 (2,650)

Unit: in (mm)

King Cab

190.0 (4,825)

66.5 (1,690)

67.1 (1,705)

58.5 (1,486)

57.9 (1,471)

116.1 (2,950)

See the ‘‘F.M.V.S.S. certification label’’ on the driver side lock pillar.

Overall length*1

Overall width

Overall height

Front tread

Rear tread

Wheelbase

Gross vehicle weight rating

lb (kg)

Gross axle weight rating

Front

Rear

lb (kg)

lb (kg)

*1: On step bumper equipped models, the bumper adds 5.5 in (140 mm) to the overall length.

9-11

Z X

REGISTERING YOUR VEHICLE IN ANOTHER COUNTRY When planning to drive your NISSAN vehicle in another country, you should first find out if the fuel available is suitable for your vehicle’s engine. Using fuel with too low an octane rating may cause engine damage. All gasoline vehicles can be operated with unleaded gasoline. Therefore, avoid driving your vehicle in ar- eas where appropriate fuel is not available. When transferring the registration of your vehicle to another country, state, province or district, it may be necessary to modify the vehicle to meet local laws and regulations. The laws and regulations for motor vehicle emission control and safety standards vary according to the country, state, province or district; therefore, vehicle specifications may differ. When any vehicle is to be taken into another country, state, province or dis- trict and registered, its modifications, transportation and registration are the responsibility of the user. NISSAN is not responsible for any inconvenience that may result.

VEHICLE IDENTIFICATION

CA0018

CA0030

VEHICLE IDENTIFICATION NUM- BER PLATE The vehicle identification number plate is attached to the top of the instrument panel on the driver’s side. This number is the identification for your vehicle and is used in the vehicle registration.

VEHICLE IDENTIFICATION NUMBER (Chassis number)

9-12

Z X

TI1006M

CA0021

TI1078M

ENGINE SERIAL NUMBER The number is stamped on the engine as shown.

F.M.V.S.S. CERTIFICATION LABEL The Federal Motor Vehicle Safety Standard (F.M.V.S.S.) certification label is affixed as shown. This label contains valuable vehicle information, such as: Gross Vehicle Weight Rating (GVWR), Gross Axle Weight Rating (GAWR), month and year of manufacture, Vehicle Identification Number (VIN), etc. Review it carefully.

9-13

Z X

CA0022

STI0016

TI1083

EMISSION CONTROL INFORMATION LABEL The emission control attached as shown.

information label

TIRE PLACARD The cold tire pressure is shown on the tire placard affixed to the inside of the glove box.

is

AIR CONDITIONER SPECIFICATION LABEL The label is affixed to the firewall as shown.

9-14

Z X

VEHICLE LOADING INFORMA- TION

WARNING

c It is extremely dangerous to ride in a cargo area inside of a vehicle. In a collision, people riding in these ar- eas are move likely to be seriously injured or killed.

c Do not allow people to ride in any area of your vehicle that is not equipped with seats and seat belts. c Be sure everyone in your vehicle is in a

seat and using a seat belt properly.

Terms It is important to familiarize yourself with the following terms before loading your vehicle: c Curb Weight (actual weight of your ve- hicle) - vehicle weight including: standard and optional equipment, fluids, emer- gency tools, and spare tire assembly. This weight does not include passen- gers and cargo.

c GVW (Gross Vehicle Weight)

- curb weight plus the combined weight of pas- sengers and cargo.

c GVWR (Gross Vehicle Weight Rating) - maximum total weight (load) limit speci- fied for the vehicle.

c GAWR (Gross Axle Weight Rating) - maximum weight (load) limit specified for the front or rear axle.

Determining Vehicle Load Capacity The load capacity of this vehicle is deter- mined by weight, not by available cargo space. For example, a luggage rack, bike carrier, cartop carrier or similar equipment does not increase load carrying capacity of your vehicle. To determine vehicle load capacity: Vehicle weight can be determined by using a commercial-grade scale, found at places such as a truck stop, gravel quarry, grain elevator, or a scrap metal recycling facility. 1) Determine the curb weight of your ve-

hicle.

2) Compare the curb weight amount to the GVWR specified for your vehicle to de- termine how much more weight your vehicle can carry.

3) After loading (cargo and passengers),

9-15

re-weigh your vehicle to determine if either GVWR or GAWR for your vehicle is exceeded. If GVWR is exceeded, re- move cargo as necessary. If either the front or rear GAWR is exceeded, shift the load or remove cargo as necessary.

Loading Tips c The GVW must not exceed GVWR or GAWR as specified on the F.M.V.S.S. Certification Label.

c Do not load the front and rear axle to the GAWR. Doing so will exceed the GVWR.

CAUTION

c Properly secure all cargo to help prevent it from sliding or shifting. In a sudden stop or collision, unse- cured cargo could cause personal injury.

c Do not load your vehicle any heavier than the GVWR or the maximum front and rear GAWRs. If you do, parts on your vehicle can break, or it can change the way your vehicle handles. This could result in loss of control and cause personal injury.

Z X

TRAILER TOWING

c Overloading can shorten the life of your vehicle. Failures caused by overloading are not covered by your warranty.

CA0009

Your new vehicle was designed to be used primarily to carry passengers and cargo. Remember that towing a trailer will place additional loads on your vehicle’s engine, drive train, steering, braking and other sys- tems. A Nissan Trailer Towing Guide is avail- able from your NISSAN dealer. This guide includes information on trailer towing ability and the special equipment required for proper towing.

9-16

Maximum load limits Maximum trailer loads Never allow the total trailer load to exceed the value specified in the following Towing Load/Specification Chart. The total trailer load equals trailer weight plus its cargo weight. c When towing a trailer load of 1,000 lb (454 kg) or more, trailers with a brake system MUST be used.

The maximum GCWR (Gross Combined Weight Rating) should not exceed the value specified in the following Towing Load/ Specification Chart. The GCWR equals the combined weight of the towing vehicle (including passengers and cargo) plus the total trailer load. Towing loads greater than these or using improper towing equipment could adversely affect vehicle handling, braking and performance.

WARNING

Vehicle damage and/or personal injury resulting from improper towing proce- dures is not covered by NISSAN war-

Z X

ranties. Information on trailer towing and required towing equipment should be obtained from dealers who special- ize in providing trailers or other towing equipment.

Tongue load Keep the tongue load between 9 to 11% of the total trailer load within the maximum tongue load limits shown in the following Towing Load/Specification Chart. the tongue load becomes excessive, rearrange cargo to allow for proper tongue load.

If

CA0036

Maximum gross vehicle weight/maximum gross axle weight The gross vehicle weight of the towing vehicle must not exceed the gross vehicle weight rating (GVWR) shown on the F.M.V.S.S. certification label. The gross ve- hicle weight equals the combined weight of the unloaded vehicle, passengers, luggage, hitch, trailer tongue load and any other optional equipment. In addition, front or rear gross axle weight must not exceed the gross axle weight rating (GAWR) shown on the F.M.V.S.S. certification label.

9-17

Z X

TOWING LOAD/ SPECIFICATION CHART

WEIGHT

M/T

A/T

MODEL

2WD TRUCK

Unit: lb (kg)

4WD TRUCK

MAXIMUM

TRAILER WEIGHT*1

MAXIMUM TONGUE

LOAD

GROSS

COMBINED

WEIGHT RATING

RECOMMENDED EQUIPMENT*2

3,500 (1,588)

2,000 (907)

3,500 (1,588)

350 (159)

200 (91)

350 (159)

7,000 (3,175)

5,500 (2,495)

7,700 (3,493)

Sway Control