- Download PDF Manual

-

weight of occupants

and cargo (data from

the Tire and Loading

Information placard)

Step 2

Example 1

Example 2

Example 3

Number of people in

the vehicle (driver

and occupants)

Distribution of the

occupants

Front: 2

Rear: 3

Weight of the

occupants

Occupant 1: 150 lbs (68 kg)

Occupant 2: 180 lbs (82 kg)

Occupant 3: 160 lbs (73 kg)

Occupant 4: 140 lbs (63 kg)

Occupant 5: 120 lbs (54 kg)

Front: 1

Occupant 1: 150 lbs (68 kg)

Front: 1

Rear: 2

Occupant 1: 200 lbs (91 kg)

Occupant 2: 190 lbs (86 kg)

Occupant 3: 150 lbs (68 kg)

Gross weight of all

750 lbs (340 kg)

540 lbs (245 kg)

150 lbs (68 kg)

occupants

All about wheels and tires

415

Example 1

Example 2

Example 3

1500 lbs (680 kg) Ò750 lbs (340 kg) = 750 lbs (340 kg)

1500 lbs (680 kg) Ò540 lbs (245 kg) =960 lbs (435 kg)

1500 lbs (680 kg) Ò150 lbs (68 kg) = 1350 lbs (612 kg)

Step 3

Permissible load

(maximum gross

vehicle weight rating

from the Tire and

Loading Information

placard minus the

gross weight of all

occupants)

Vehicle identification plate

All about wheels and tires

Even if you have calculated the total cargo carefully, you should still make sure that the gross vehicle weight rating and the gross axle weight rating are not exceeded. Details can be found on the vehicle identification plate on the B-pillar on the driver's side of the vehicle (Y page 412).

Permissible gross vehicle weight: the gross weight of the vehicle, all passengers, load and trailer load/noseweight (if applicable) must not exceed the permissible gross vehicle weight.

Gross axle weight rating: the maximum permissible weight that can be carried by one axle (front or rear axle).

To ensure that your vehicle does not exceed the maximum permissible values (gross vehicle weight and maximum gross axle weight rating), have your loaded vehicle (including driver, occupants, cargo, and full trailer load if applicable) weighed on a suitable vehicle weighbridge.

Trailer load/noseweight

The trailer load/noseweight affects the gross weight of the vehicle. If a trailer is attached, the trailer load/noseweight is included in the load along with occupants and luggage. The trailer load/noseweight is usually approximately 8% of the gross weight of the trailer and its cargo.

Uniform Tire Quality Grading

Standards

Overview of Tire Quality Grading

Standards

Uniform Tire Quality Grading Standards are U.S. government specifications. Their purpose is to provide drivers with uniform reliable information on tire performance data. Tire manufacturers have to grade tires using three performance factors: : tread wear grade, ; traction grade and = temperature grade. These regulations do not apply to Canada. Nevertheless, all tires sold in North America are provided with the corresponding quality grading markings on the sidewall of the tire.

Where applicable, the tire grading information can be found on the tire sidewall between the tread shoulder and maximum tire width.

416 All about wheels and tires

Example:

RTreadwear grade: 200

RTraction grade: AA

RTemperature grade: A

All passenger car tires must conform to the statutory safety requirements in addition to these grades.

i The actual values for tires are vehicle-

specific and may deviate from the values in the illustration.

Treadwear

The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified U.S. government course. For example, a tire graded 150 would wear one and one-half times as well on the government test track as a tire graded 100.

The relative performance of tires depends upon the actual conditions of their use, however, and may depart significantly from the norm, due to variations in driving habits, service practices and differences in road characteristics and climate conditions.

Traction

G WARNING The traction grade assigned to this tire is based on straight-ahead braking traction tests, and does not include acceleration, cornering, hydroplaning, or peak traction characteristics.

! Avoid wheelspin. This can lead to damage

to the drive train.

The traction grades, from highest to lowest, are AA, A, B, and C. Those grades represent the tire's ability to stop on a wet surface as measured under controlled conditions on specified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

The safe speed on a wet, snow covered or icy road is always lower than on dry road surfaces.

You should pay special attention to road conditions when temperatures are around freezing point.

Mercedes-Benz recommends a minimum tread depth of ã in (4 mm) on all four winter tires. Observe the legally required minimum tire tread depth (Y page 401). Winter tires can reduce the braking distance on snow-covered surfaces in comparison with summer tires. The braking distance is still much further than on surfaces that are not icy or covered with snow. Take appropriate care when driving.

Further information on winter tires (M+S tires) (Y page 402).

Temperature

G WARNING The temperature grade for this tire is established for a tire that is properly inflated and not overloaded. Excessive speed, underinflation, or excessive loading, either separately or in combination, can cause excessive heat build-up and possible tire failure.

The temperature grades are A (the highest), B, and C. These represent the tire's resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel. Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 109. Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law.

Tire labeling

Overview

All about wheels and tires

417

Therefore, only use tire types and sizes approved for your vehicle model. Observe the tire load rating and speed rating required for your vehicle.

: Uniform Tire Quality Grading Standard

(Y page 421)

; DOT, Tire Identification Number

(Y page 420)

= Maximum tire load (Y page 419)

? Maximum tire pressure (Y page 406)

A Manufacturer

B Tire material (Y page 420)

C Tire size designation, load-bearing

capacity and speed index (Y page 417)

D Load index (Y page 419)

E Tire name

The markings described above are on the tire in addition to the tire name (sales designation) and the manufacturer's name.

i Tire data is vehicle-specific and may deviate from the data in the example.

Tire size designation, load-bearing

capacity and speed rating

G WARNING Exceeding the stated tire load-bearing capacity and the approved maximum speed could lead to tire damage or the tire bursting. There is a risk of accident.

: Tire width

; Nominal aspect ratio in %

= Tire code

? Rim diameter

A Load bearing index

B Speed rating

General: depending on the manufacturer's standards, the size imprinted in the tire wall may not contain any letters or may contain one letter that precedes the size description.

If there is no letter preceding the size description (as shown above): these are passenger vehicle tires according to European manufacturing standards.

If "P" precedes the size description: these are passenger vehicle tires according to U.S. manufacturing standards.

If "LT" precedes the size description: these are light truck tires according to U.S. manufacturing standards.

If "T" precedes the size description: these are compact emergency spare wheels at high tire pressure, to be used only temporarily in an emergency.

Tire width: tire width : shows the nominal tire width in millimeters.

Height-width ratio: aspect ratio ; is the size ratio between the tire height and tire width and is shown in percent. The aspect

418 All about wheels and tires

ratio is calculated by dividing the tire width by the tire height.

Tire code: tire code = specifies the tire type. "R" represents radial tires; "D" represents diagonal tires; "B" represents diagonal radial tires.

Optionally, tires with a maximum speed of over 149 mph (240 km/h) may have "ZR" in the size description, depending on the manufacturer (e.g. 245/40 ZR 18).

Rim diameter: rim diameter ? is the diameter of the bead seat, not the diameter of the rim flange. The rim diameter is specified in inches (in).

Load-bearing index: load-bearing index A is a numerical code that specifies the maximum load-bearing capacity of a tire.

Do not overload the tires by exceeding the specified load limit. The maximum permissible load can be found on the vehicle's Tire and Loading Information placard on the B-pillar on the driver's side (Y page 412).

Example:

Load-bearing index 91 indicates a maximum load of 1,356 lb (615 kg) that the tires can bear. For further information on the maximum tire load in kilograms and lbs, see (Y page 419).

For further information on the load bearing index, see "Load index" (Y page 419).

Speed rating: speed rating B specifies the approved maximum speed of the tire.

i Tire data is vehicle-specific and may deviate from the data in the example.

Regardless of the speed rating, always observe the speed limits. Drive carefully and adapt your driving style to the traffic conditions.

Summer tires

Index

Speed rating

up to 100 mph (160 km/h)

up to 106 mph (170 km/h)

Index

Speed rating

up to 112 mph (180 km/h)

up to 118 mph (190 km/h)

up to 130 mph (210 km/h)

up to 149 mph (240 km/h)

up to 168 mph (270 km/h)

up to 186 mph (300 km/h)

ZR...Y

up to 186 mph (300 km/h)

ZR...(..Y)

over 186 mph (300 km/h)

ZR

over 149 mph (240 km/h)

ROptionally, tires with a maximum speed of over 149 mph (240 km/h) may have "ZR" in the size description, depending on the manufacturer (e.g. 245/40 ZR18).

The service specification is made up of load-bearing index A and speed rating B.

RIf the size description of your tire includes

"ZR" and there are no service specifications, ask the tire manufacturer in order to find out the maximum speed.

If a service specification is available, the maximum speed is limited according to the speed rating in the service specification. Example: 245/40 ZR18 97 Y. In this example, "97 Y" is the service specification. The letter "Y" represents the speed rating. The maximum speed of the tire is limited to 186 mph (300 km/h).

RThe size description for all tires with

maximum speeds of over 186 mph (300 km/h) must include "ZR", and the service specification must be given in parentheses. Example: 275/40 ZR 18 (99 Y). Speed rating "(Y)" indicates that the maximum speed of the tire is over 186 mph (300 km/h). Ask the tire manufacturer about the maximum speed.

All-weather tires and winter tires

Load index

All about wheels and tires

419

Index

Speed rating

Q M+S2

up to 100 mph (160 km/h)

T M+S2

up to 118 mph (190 km/h)

H M+S2

up to 130 mph (210 km/h)

V M+S2

up to 149 mph (240 km/h)

i Not all tires with the M+S marking provide the driving characteristics of winter tires. In addition to the M+S marking, winter tires also have the i snowflake symbol on the tire wall. Tires with this marking fulfill the requirements of the Rubber Manufacturers Association (RMA) and the Rubber Association of Canada (RAC) regarding the tire traction on snow. They have been especially developed for driving on snow.

In addition to the load bearing index, load index : may be imprinted after the letters that identify the speed index B on the sidewall of the tire (Y page 417).

RIf no specification is given: no text (as in the

example above), represents a standard load (SL) tire

RXL or Extra Load: represents a reinforced

tire

An electronic speed limiter prevents your vehicle from exceeding the following speeds:

RLight Load: represents a light load tire

RC, D, E: represents a load range that

depends on the maximum load that the tire can carry at a certain pressure

i Tire data is vehicle-specific and may deviate from the data in the example.

Maximum load rating

Rall vehicles (except AMG vehicles):

130 mph (210 km/h)

RAMG vehicles: 155 mph (250 km/h)

RAMG vehicles with increased top speed:

174 mph (280 km/h)

The speed rating of tires mounted at the factory may be higher than the maximum speed that the electronic speed limiter permits.

Make sure that your tires have the required speed rating, e.g. when buying new tires. The required speed rating for your vehicle can be found in the "Tires" section (Y page 428).

Further information about reading tire data can be obtained from any qualified specialist workshop.

Maximum tire load : is the maximum permissible weight for which the tire is approved.

2 Or M+Si for winter tires.

420 All about wheels and tires

Do not overload the tires by exceeding the specified load limit. The maximum permissible load can be found on the vehicle's Tire and Loading Information placard on the B-pillar on the driver's side (Y page 412).

i The actual values for tires are vehicle-

specific and may deviate from the values in the illustration.

DOT, Tire Identification Number (TIN)

U.S. tire regulations prescribe that every tire manufacturer or retreader must imprint a TIN in or on the sidewall of every tire produced.

Tire size: identifier = describes the tire size.

Tire type code: tire type code ? can be used by the manufacturer as a code to describe specific characteristics of the tire.

Date of manufacture: date of manufacture A provides information about the age of a tire. The first and second positions represent the week of manufacture, starting with "01" for the first calendar week. Positions three and four represent the year of manufacture. For example, a tire that is marked with "3208", was manufactured in week 32 in 2008.

i Tire data is vehicle-specific and may deviate from the data in the example.

Tire characteristics

The TIN is a unique identification number. The TIN enables the tire manufacturers or retreaders to inform purchasers of recalls and other safety-relevant matters. It makes it possible for the purchaser to easily identify the affected tires.

The TIN is made up of manufacturer identification code ;, tire size =, tire type code ? and manufacturing date A.

DOT (Department of Transportation): tire symbol : indicates that the tire complies with the requirements of the U.S. Department of Transportation.

Manufacturer identification code: manufacturer identification code ; provides details on the tire manufacturer. New tires have a code with two symbols. Retreaded tires have a code with four symbols.

For further information about retreaded tires, see (Y page 428).

This information describes the type of tire cord and the number of layers in sidewall : and under tire tread ;.

i Tire data is vehicle-specific and may deviate from the data in the example.

Definition of terms for tires and loading

Tire ply composition and material used

Describes the number of plies or the number of layers of rubber-coated fabric in the tire tread and sidewall. These are made of steel, nylon, polyester and other materials.

Bar

Metric unit for tire pressure. 14.5038 pounds per square inch (psi) and

All about wheels and tires

421

100 kilopascals (kPa) are the equivalent of 1 bar.

vehicle identification plate on the B-pillar on the driver's side.

DOT (Department of Transportation)

Speed rating

DOT marked tires fulfill the requirements of the United States Department of Transportation.

The speed rating is part of the tire identification. It specifies the speed range for which the tire is approved.

Normal occupant weight

GTW (Gross Trailer Weight)

The number of occupants which the vehicle is designed for, multiplied by 68 kilograms (150 lb).

The GTW is the weight of a trailer including the weight of the load, luggage, accessories etc. on the trailer.

Uniform Tire Quality Grading Standards

GVW (Gross Vehicle Weight)

A uniform standard to grade the quality of tires with regards to tread quality, tire traction and temperature characteristics. Ratings are determined by tire manufacturers using U.S. government testing procedures. The ratings are molded into the sidewall of the tire.

Recommended tire pressure

The recommended tire pressure applies to the tires mounted at the factory.

The Tire and Loading Information placard contains the recommended tire pressures for cold tires on a fully loaded vehicle and for the maximum permissible vehicle speed.

The tire pressure table contains the recommended pressures for cold tires for various operating conditions, i.e. differing load and speed conditions.

Increased vehicle weight due to optional

equipment

This is the combined weight of all standard and optional equipment available for the vehicle, regardless of whether it is actually installed on the vehicle or not.

Rim

This is the part of the wheel on which the tire is mounted.

GAWR (Gross Axle Weight Rating)

The GAWR is the maximum gross axle weight rating. The actual load on an axle must never exceed the gross axle weight rating. The gross axle weight rating can be found on the

The gross vehicle weight includes the weight of the vehicle including fuel, tools, the spare wheel, accessories installed, occupants, luggage and the drawbar noseweight, if applicable. The gross vehicle weight must not exceed the gross vehicle weight rating GVWR as specified on the vehicle identification plate on the B-pillar on the driver's side.

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permissible gross weight of a fully loaded vehicle (the weight of the vehicle including all accessories, occupants, fuel, luggage and the drawbar noseweight, if applicable). The gross vehicle weight rating is specified on the vehicle identification plate on the B-pillar on the driver's side.

Maximum loaded vehicle weight

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa corresponds to 1 psi. Another unit for tire pressure is bar. There are 100 kilopascals (kPa) to 1 bar.

422 All about wheels and tires

Load index

In addition to the load-bearing index, the load index may also be imprinted on the sidewall of the tire. This specifies the load-bearing capacity more precisely.

Curb weight

The weight of a vehicle with standard equipment including the maximum capacity of fuel, oil and coolant. It also includes the air- conditioning system and optional equipment if these are installed in the vehicle, but does not include passengers or luggage.

Maximum load rating

The maximum tire load is the maximum permissible weight in kilograms or lbs for which a tire is approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by dividing the maximum axle load of one axle by two.

PSI (pounds per square inch)

A standard unit of measure for tire pressure.

Aspect ratio

Relationship between tire height and tire width in percent.

Tire pressure

This is pressure inside the tire applying an outward force to each square inch of the tire's surface. The tire pressure is specified in pounds per square inch (psi), in kilopascal (kPa) or in bar. The tire pressure should only be corrected when the tires are cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked without

direct sunlight on the tires for at least three hours and

Rif the vehicle has been driven for less than

1 mile (1.6 km).

Tread

The part of the tire that comes into contact with the road.

Bead

The tire bead ensures that the tire sits securely on the wheel. There are several steel wires in the bead to prevent the tire from coming loose from the wheel rim.

Sidewall

The part of the tire between the tread and the bead.

Weight of optional extras

The combined weight of those optional extras that weigh more than the replaced standard parts and more than 2.3 kilograms (5 lbs). These optional extras, such as high- performance brakes, level control, a roof rack or a high-performance battery, are not included in the curb weight and the weight of the accessories.

TIN (Tire Identification Number)

This is a unique identifier which can be used by a tire manufacturer to identify tires, for example for a product recall, and thus identify the purchasers. The TIN is made up of the manufacturer's identity code, tire size, tire type code and the manufacturing date.

Load bearing index

The load bearing index (also load index) is a code that contains the maximum load bearing capacity of a tire.

Traction

Rotating the wheels

Changing a wheel

423

Traction is the result of friction between the tires and the road surface.

TWR (Tongue Weight Rating)

The TWR specifies the maximum permissible weight that the ball coupling of the trailer tow hitch can support.

Treadwear indicators

Narrow bars (tread wear bars) that are distributed over the tire tread. If the tire tread is level with the bars, the wear limit of á in (1.6 mm) has been reached.

Occupant distribution

The distribution of occupants in a vehicle at their designated seating positions.

Total load limit

Rated cargo and luggage load plus 68 kilograms (150 lb) multiplied by the number of seats in the vehicle.

Changing a wheel

Flat tire

You can find information on what to do in the event of a flat tire in the "Breakdown assistance" section (Y page 383). Information on driving with MOExtended tires in the event of a flat tire can be found under "MOExtended tires (tires with run-flat characteristics" (Y page 384).

The "Breakdown assistance" section (Y page 383) contains information and notes on how to deal with a flat tire. Information on driving with MOExtended tires in the event of a flat tire can be found under "MOExtended tires (tires with run-flat characteristics" (Y page 384).

Vehicles with an emergency spare wheel: in the event of a flat tire, mount the emergency spare wheel according to the description under "Mounting a wheel" (Y page 424).

G WARNING Interchanging the front and rear wheels may severely impair the driving characteristics if the wheels or tires have different dimensions. The wheel brakes or suspension components may also be damaged. There is a risk of accident.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are located in the wheel.

Tire-mounting tools should not be used near the valve. This could damage the electronic components.

Only have tires changed at a qualified specialist workshop.

Always observe the instructions and safety notes in the "Mounting a wheel" section (Y page 424).

The wear patterns on the front and rear tires differ, depending on the operating conditions. Rotate the wheels before a clear wear pattern has formed on the tires. Front tires typically wear more on the shoulders and the rear tires in the center.

If your vehicle's tire configuration allows, you can rotate the wheels according to the intervals in the tire manufacturer's warranty book in your vehicle documents. If this is not available, the tires should then be rotated every 3000 to 6000 miles (5000 to 10,000 km), or earlier if the tire wear requires this. Do not change the direction of wheel rotation.

Clean the contact surfaces of the wheel and the brake disc thoroughly every time a wheel is interchanged. Check the tire pressure and, if necessary, restart the tire pressure loss warning system or the tire pressure monitor.

424 Changing a wheel

Direction of rotation

X Switch off the engine.

X Vehicles without KEYLESS-GO: remove

the SmartKey from the ignition lock.

X Vehicles with KEYLESS-GO: open the

driver's door. The on-board electronics have status 0, which is the same as the SmartKey having been removed.

X Vehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock (Y page 163).

X If included in the vehicle equipment, take the tire-change tool kit out of the vehicle.

X Secure the vehicle to prevent it from rolling

away.

i Apart from certain country-specific

variations, vehicles are not equipped with a tire-change tool kit. For information on which tools are required to perform a wheel change on your vehicle, consult an authorized Mercedes-Benz Center.

Necessary wheel-changing tools can include, for example:

RJack

RWheel chock

RLug wrench

Securing the vehicle to prevent it from

rolling away

Tires with a specified direction of rotation have additional benefits, e.g. if there is a risk of hydroplaning. You will only gain these benefits if the correct direction of rotation is observed.

An arrow on the sidewall of the tire indicates its correct direction of rotation.

Storing wheels

Store wheels that are not being used in a cool, dry and preferably dark place. Protect the tires from oil, grease, gasoline and diesel.

Cleaning the wheels

G WARNING The water jet from a circular jet nozzle (dirt blasters) can cause invisible exterior damage to the tires or chassis components. Components damaged in this way may fail unexpectedly. There is a risk of an accident.

Do not use power washers with circular jet nozzles to clean the vehicle. Have damaged tires or chassis components replaced immediately.

Mounting a wheel

Preparing the vehicle

X Vehicle with emergency spare wheel:

when mounting the emergency spare wheel in the event of a flat tire, follow the additional notes on vehicle preparation under "Flat tire" (Y page 383).

X Park the vehicle on firm, non-slippery and

level ground.

X Unload heavy luggage.

X Apply the electric parking brake manually.

X Bring the front wheels into the straight-

ahead position.

If your vehicle is equipped with a wheel chock, it can be found in the tire-change tool kit (Y page 382).

X Shift the transmission to position P.

The folding wheel chock is an additional securing measure to prevent the vehicle from rolling away, for example when changing a wheel.

X Fold both plates upwards :.

X Fold out lower plate ;.

X Guide the lugs on the lower plate fully into

the openings in base plate =.

Securing the vehicle on level ground

X On level ground: place chocks or other

suitable items under the front and rear of the wheel that is diagonally opposite the wheel you wish to change.

Securing the vehicle on slight downhill gradients

X On light downhill gradients: place

chocks or other suitable items in front of the wheels of the front and rear axle.

Raising the vehicle

G WARNING If you do not position the jack correctly at the appropriate jacking point of the vehicle, the

Changing a wheel

425

jack could tip over with the vehicle raised. There is a risk of injury.

Only position the jack at the appropriate jacking point of the vehicle. The base of the jack must be positioned vertically, directly under the jacking point of the vehicle.

! AMG vehicles with "Minispare" emergency spare wheel: use the "Minispare" emergency spare wheel only on the rear axle. If you mount the "Minispare" emergency spare wheel on the front axle, this could result in damage to the brake system.

If a tire on the front axle is defective, an intact wheel from the rear axle must first be replaced with the "Minispare" emergency spare wheel. The defective wheel on the front axle can then be replaced with the intact wheel from the rear axle.

Make sure to note the placard on the "Minispare" emergency spare wheel.

! The jack is designed exclusively for

jacking up the vehicle at the jacking points. Otherwise, your vehicle could be damaged.

The following must be observed when raising the vehicle:

Rto raise the vehicle, only use the vehicle-

specific jack that has been tested and approved by Mercedes-Benz. If used incorrectly, the jack could tip over with the vehicle raised.

Rthe jack is designed only to raise and hold the vehicle for a short time while a wheel is being changed. It is not suited for performing maintenance work under the vehicle.

Ravoid changing the wheel on uphill and

downhill slopes.

Rbefore raising the vehicle, secure it from

rolling away by applying the parking brake and inserting wheel chocks. Never disengage the parking brake while the vehicle is raised.

426 Changing a wheel

Rthe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large, load-bearing underlay must be used. On a slippery surface, a non-slip underlay must be used, e.g. rubber mats.

Rdo not use wooden blocks or similar

objects as a jack underlay. Otherwise, the jack will not be able to achieve its load- bearing capacity due to the restricted height.

Rmake sure that the distance between the

underside of the tires and the ground does not exceed 1.2 in (3 cm).

Rnever place your hands and feet under the

raised vehicle.

Rnever lie under the raised vehicle.

Rnever start the engine when the vehicle is

raised.

Rnever open or close a door or the tailgate

when the vehicle is raised.

Rmake sure that no persons are present in

the vehicle when the vehicle is raised.

X Using lug wrench :, loosen the bolts on

the wheel you wish to change by about one full turn. Do not unscrew the bolts completely.

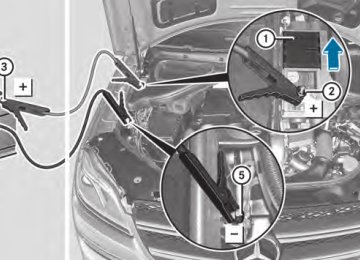

The jacking points are located just behind the front wheel housings and just in front of the rear wheel housings (arrows).

X Take the ratchet wrench out of the vehicle tool kit and place it on the hexagon nut of the jack so that the letters AUF are visible.

; Jacking points

= Jack

? Crank

X Position jack = at jacking point ;.

The alignment bolt on the jack must be inserted into the intended jacking point hole.

Changing a wheel

427

Mounting a new wheel

G WARNING Oiled or greased wheel bolts or damaged wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could lose a wheel while driving. There is a risk of accident.

Never oil or grease wheel bolts. In the event of damage to the threads, contact a qualified specialist workshop immediately. Have the damaged wheel bolts or hub threads replaced/renewed. Do not continue driving.

G WARNING If you tighten the wheel bolts or wheel nuts when the vehicle is raised, the jack could tip over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts when the vehicle is on the ground.

! To prevent damage to the paintwork, hold the wheel securely against the wheel hub while screwing in the first wheel bolt.

Always pay attention to the instructions and safety notes in the "Changing a wheel" section (Y page 423).

Only use wheel bolts that have been designed for the wheel and the vehicle. For safety reasons, Mercedes-Benz recommends that you only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective wheel.

! Always use wheel bolts ; to mount the "Minispare" emergency spare wheel. Using other wheel bolts to mount the "Minispare" emergency spare wheel could damage the brake system.

Example

X Make sure the foot of the jack is directly

beneath the jacking point.

X Turn ratchet wrench ? until jack = sits

completely on jacking point ; and the base of the jack lies evenly on the ground.

X Turn ratchet wrench ? until the tire is

raised a maximum of 1.2 in (3 cm) from the ground.

Removing a wheel

! Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub threads could otherwise be damaged when you screw them in.

X Unscrew the uppermost wheel bolt

completely.

X Screw alignment bolt : into the thread

instead of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

428 Wheel and tire combinations

: Wheel bolts for all wheels supplied by the

factory

; Wheel bolts for the "Minispare"

emergency spare wheel

X Place the ratchet wrench onto the hexagon

nut of the jack so that the letters AB are visible.

X Turn the ratchet wrench until the vehicle is once again standing firmly on the ground.

X Place the jack to one side.

X Tighten the wheel bolts evenly in a crosswise pattern in the sequence indicated (: to A). The tightening torque must be 110 lb-ft (150 Nm).

X Turn the jack back to its initial position.

X Stow the jack and the rest of the tire-

change tool kit in the stowage well under the cargo compartment floor again.

X Clean the wheel and wheel hub contact

X Check the tire pressure of the newly

surfaces.

X Slide the wheel to be mounted onto the

alignment bolt and push it on.

X Tighten the wheel bolts until they are

finger-tight.

X Unscrew the alignment bolt.

X Tighten the last wheel bolt until it is finger-

tight.

Lowering the vehicle

G WARNING The wheels could work loose if the wheel nuts and bolts are not tightened to the specified tightening torque. There is a risk of accident.

Have the tightening torque immediately checked at a qualified specialist workshop after a wheel is changed.

installed wheel and adjust it if necessary.

Observe the recommended tire pressure (Y page 404).

i Vehicles with tire pressure monitor: all wheels mounted must be equipped with functioning sensors.

Wheel and tire combinations

General notes

! For safety reasons, Mercedes-Benz

recommends that you only use tires and wheels which have been approved by Mercedes-Benz specifically for your vehicle.

Wheel and tire combinations

429

These tires have been specially adapted for use with the control systems, such as ABS or ESP®, and are marked as follows:

RMO = Mercedes-Benz Original

RMOE = Mercedes-Benz Original Extended

The recommended pressures for various operating conditions can be found:

Ron the Tire and Loading Information placard

with the recommended tire pressures on the B-pillar on the driver's side

(tires featuring run-flat characteristics)

Rin the tire pressure table on the inside of

RMO1 = Mercedes-Benz Original (only

the fuel filler flap

certain AMG tires)

Mercedes-Benz Original Extended tires may only be used on wheels that have been specifically approved by Mercedes-Benz.

Only use tires, wheels or accessories tested and approved by Mercedes-Benz. Certain characteristics, e.g. handling, vehicle noise emissions or fuel consumption, may otherwise be adversely affected. In addition, when driving with a load, tire dimension variations could cause the tires to come into contact with the bodywork and axle components. This could result in damage to the tires or the vehicle.

Mercedes-Benz accepts no liability for damage resulting from the use of tires, wheels or accessories other than those tested and approved.

Information on tires, wheels and approved combinations can be obtained from any qualified specialist workshop.

! Retreaded tires are neither tested nor recommended by Mercedes-Benz, since previous damage cannot always be detected on retreaded tires. As a result, Mercedes-Benz cannot guarantee vehicle safety if retreaded tires are mounted. Do not mount used tires if you have no information about their previous usage.

Overview of abbreviations used in the following tire tables:

RBA: both axles

RFA: front axle

RRA: rear axle

Observe the notes on recommended tire pressures under various operating conditions (Y page 404).

Check tire pressures regularly, and only when the tires are cold. Comply with the maintenance recommendations of the tire manufacturer in the vehicle document wallet.

Notes on the vehicle equipment – always equip the vehicle with:

Rtires of the same size on a given axle (left/

right)

Rthe same type of tires at a given time

(summer tires, winter tires, MOExtended tires)

Vehicles with MOExtended tires are not equipped with a TIREFIT kit at the factory. It is therefore recommended that you additionally equip your vehicle with a TIREFIT kit if you mount tires that do not feature run- flat properties, e.g. winter tires. A TIREFIT kit may be obtained from a qualified specialist workshop.

i Not all wheel and tire combinations are available at the factory for all countries.

i On the following pages, you can find

information on approved wheel rims and tire sizes for equipping your vehicle with winter tires. Winter tires are not available at the factory as standard equipment or optional extras.

If you would like to equip your vehicle with approved winter tires, you may also, in certain circumstances, require rims of the appropriate size. The sizes of the approved winter tires may deviate from that of the standard tires. This is dependent on the model and the equipment installed at the factory.

430 Wheel and tire combinations

The tires and wheel rims, as well as further information, can be obtained at a qualified specialist workshop.

Tires

GL 350 BlueTEC 4MATIC

All-weather tires

R 19

Tires

BA: 275/50 R 19 111 H M+S3

R 20

Tires

BA: 275/50 R 20 109 H M+S3

Wheel and tire combinations

431

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

Alloy wheels

BA: 8.5 J x 20 H2

Wheel offset: 2.44 in (62 mm)

BA: 275/50 R 20 109 H M+SMOExtended3, 4

BA: 8.5 J x 20 H2

Wheel offset: 2.44 in (62 mm)

All-terrain tires

R 18

Tires

BA: 265/60 R 18 110 H M+S

R 19

Tires

BA: 275/55 R 19 111 H M+S3

Winter tires

R 18

Tires

BA: 265/60 R 18 110 H M+Si

Alloy wheels

BA: 8.0 J x 18 H2

Wheel offset: 2.22 in (56.5 mm)

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

Alloy wheels

BA: 8.0 J x 18 H2

Wheel offset: 2.22 in (56.5 mm)

3 Use of snow chains not permitted. Observe the notes under "Snow chains". 4 MOExtended tires (tires featuring run-flat characteristics) only in combination with an activated tire pressure

loss warning system or tire pressure monitor.

432 Wheel and tire combinations

R 19

Tires

BA: 265/55 R 19 109 H M+Si

GL 450 4MATIC BlueEFFICIENCY

All-weather tires

R 19

Tires

BA: 275/50 R 19 111 H M+S3

R 20

Tires

BA: 275/50 R 20 109 H M+S3

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

Alloy wheels

BA: 8.5 J x 20 H2

Wheel offset: 2.44 in (62 mm)

BA: 275/50 R 20 109 H M+SMOExtended3, 4

BA: 8.5 J x 20 H2

Wheel offset: 2.44 in (62 mm)

All-terrain tires

R 19

Tires

BA: 275/55 R 19 111 H M+S3

Winter tires

R 19

Tires

BA: 265/55 R 19 109 H M+Si

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

3 Use of snow chains not permitted. Observe the notes under "Snow chains". 4 MOExtended tires (tires featuring run-flat characteristics) only in combination with an activated tire pressure

loss warning system or tire pressure monitor.

Wheel and tire combinations

433

GL 550 4MATIC BlueEFFICIENCY

All-weather tires

R 19

Tires

BA: 275/50 R 19 111 H M+S3

R 20

Tires

BA: 275/50 R 20 109 H M+S3

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

Alloy wheels

BA: 8.5 J x 20 H2

Wheel offset: 2.44 in (62 mm)

BA: 275/50 R 20 109 H M+SMOExtended3, 4

BA: 8.5 J x 20 H2

Wheel offset: 2.44 in (62 mm)

R 21

Tires

BA: 295/40 R 21 111 V XL M+S3

All-terrain tires

R 19

Tires

BA: 275/55 R 19 111 H M+S3

Winter tires

R 19

Tires

BA: 265/55 R 19 109 H M+Si

Alloy wheels

BA: 10.0 J x 21 H2

Wheel offset: 1.81 in (46 mm)

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

Alloy wheels

BA: 8.5 J x 19 H2

Wheel offset: 2.44 in (62 mm)

3 Use of snow chains not permitted. Observe the notes under "Snow chains". 4 MOExtended tires (tires featuring run-flat characteristics) only in combination with an activated tire pressure

loss warning system or tire pressure monitor.

434 Emergency spare wheel

GL 63 AMG 4MATIC

Summer tires

R 21

Tires

Alloy wheels

BA: 295/40 ZR 21 111 Y XL3

BA: 10.0 J x 21 H2 ET 46

Winter tires

R 20

Tires

Alloy wheels

BA: 275/45 R 20 110 V XL M+Si

BA: 9.0 J x 20 H2 ET 41

Emergency spare wheel

Important safety notes

G WARNING The wheel or tire size as well as the tire type of the spare wheel or emergency spare wheel and the wheel to be replaced may differ. Mounting an emergency spare wheel may severely impair the driving characteristics. There is a risk of an accident.

To avoid hazardous situations:

Radapt your driving style accordingly and

drive carefully.

Rnever mount more than one spare wheel or emergency spare wheel that differs in size.

Ronly use a spare wheel or emergency spare

wheel of a different size briefly.

Rdo not switch ESP® off.

Rhave a spare wheel or emergency spare wheel of a different size replaced at the nearest qualified specialist workshop. Observe that the wheel and tire dimensions as well as the tire type must be correct.

! AMG vehicles with "Minispare" emergency spare wheel: use the "Minispare" emergency spare wheel only on the rear axle. If you mount the "Minispare" emergency spare wheel on the

front axle, this could result in damage to the brake system.

If a tire on the front axle is defective, an intact wheel from the rear axle must first be replaced with the "Minispare" emergency spare wheel. The defective wheel on the front axle can then be replaced with the intact wheel from the rear axle.

Make sure to note the placard on the "Minispare" emergency spare wheel.

When using an emergency spare wheel or spare wheel of a different size, you must not exceed the maximum speed of 50 mph (80 km/h).

Snow chains must not be mounted on emergency spare wheels.

General notes

Mounting the emergency spare wheel is described under "Mounting a wheel" (Y page 424).

You should regularly check the pressure of the emergency spare wheel, particularly prior to long trips, and correct the pressure as necessary (Y page 404). The applicable value can be found on the wheel or under "Technical data" (Y page 436).

3 Use of snow chains not permitted. Observe the notes under "Snow chains".

An emergency spare wheel may also be mounted against the direction of rotation. Observe the time restriction on use as well as the speed limitation specified on the emergency spare wheel.

Replace the tires after six years at the latest, regardless of wear. This also applies to the emergency spare wheel.

Removing the emergency spare wheel

Emergency spare wheel (example: vehicle without lockable cargo compartment floor) : Emergency spare wheel retainer

; Stowage well

= "Minispare" emergency spare wheel

The "Minispare" emergency spare wheel can be found in the stowage well under the cargo compartment floor.

X Lift the cargo compartment floor up

(Y page 343).

X Vehicles with a lockable cargo

compartment floor: remove the stowage tray.

X Release the Velcro fastener (Ypage 382).

X Take out the jack.

X Turn emergency spare wheel retainer :

counter-clockwise and remove it.

X Remove stowage well ;.

X Remove "Minispare" emergency spare

wheel =.

Emergency spare wheel

435

In vehicles with a Bang & Olufsen sound system, the "Minispare" emergency spare wheel is stored in a bag. The bag is secured to the cargo tie-down rings in the cargo compartment.

To stow the "Minispare" emergency spare wheel, the rear seats in the third row must be folded in (Y page 107).

X To remove the emergency spare

wheel: open the tailgate.

X Loosen tensioning straps ; on both sides.

X Unhook retaining spring hooks : and = on tensioning straps ; from the cargo tie- down rings.

X Remove the bag with the "Minispare"

emergency spare wheel.

X Open the bag and remove the "Minispare"

emergency spare wheel.

X To stow the emergency spare wheel: place the "Minispare" emergency spare wheel in the bag and close the bag.

X Place the bag with the "Minispare"

emergency spare wheel in the cargo compartment.

X Hook retaining spring hooks : and = on tensioning straps ; in the cargo tie-down rings.

X Tighten tensioning straps ; on both sides.

For further information on changing and mounting a wheel, see (Y page 424).

436 Emergency spare wheel

Technical data

"Minispare" emergency spare wheel

Tires

T 165/90 R19 119 M

Alloy wheels

4.5 B x 19 H2

Tire pressure: 420 kPa (4.2 bar/61 psi)

Wheel offset: 1.58 in (40 mm)

Useful information ............................ 438

Information regarding technical data .................................................... 438

Warranty ............................................ 438

Identification plates ......................... 438

Service products and filling capaci- ties ..................................................... 439

Vehicle data ...................................... 446

Trailer tow hitch ................................ 448

437

438

Identification plates

Useful information

i This Operator's Manual describes all models and all standard and optional equipment of your vehicle available at the