- Download PDF Manual

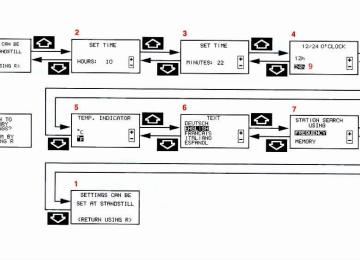

-

Malfunction and warning messages

COOLANT (coolant level)

Line 1

COOLANT

Line 2

CHECK LEVEL!

C*

* C = Category, see page 213

When this message appears while driving, the coolant level has dropped below the required level. If no leaks are noticeable and the engine temperature does not increase, continue to drive to the nearest service station and have coolant added to the coolant system.

The low engine coolant level warning should not be ignored. Extended driving with the symbol displayed may cause serious engine damage not covered by the Mercedes-Benz Limited Warranty.

Notes: Do not drive without coolant in the cooling system. The engine will overheat causing major engine damage. Monitor the coolant temperature gauge while driving. See page 237 for instructions on adding coolant.

Warning! Do not spill antifreeze on hot engine parts. Antifreeze contains ethylene glycol which may burn if it comes into contact with hot engine parts. You can be seriously burned.

219

COOLANT TEMP. (coolant temperature)

Line 1

Line 2

COOLANT TEMP.

VISIT WORKSHOP!1

C*

* C = Category, see page 213

1 Observe coolant temperature gauge, see page 82.

This may indicate that the poly-V-belt has broken. Should this

condition occur, the poly-V-belt must be replaced before continuing to operate the vehicle. Otherwise, the engine will overheat due to an inoperative water pump which may result in damage to the engine. Do not continue to drive the vehicle with this message displayed. Doing so could result in serious engine damage that is not covered by the Mercedes-Benz Limited Warranty.

During severe operating conditions and stop-and-go city traffic, the coolant temperature may rise close to the red marking. The engine should not be operated with the coolant temperature in the red zone. Doing so may cause serious engine damage which is not covered by the Mercedes-Benz Limited Warranty.

Warning! Driving when your engine is badly overheated can cause some fluids which may have leaked into the engine compartment to catch fire. You could be seriously burned. Steam from an overheated engine can cause serious burns and can occur just by opening the engine hood. Stay away from the engine if you see or hear steam coming from it. Turn off the engine, get out of the vehicle and do not stand near the vehicle until it cools down.

Malfunction and warning messages

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

220

Index

LIGHT SENSOR

STEER. WHEEL ADJUST.

With the electronic key removed and the driver’s door open, a warning sounds and the message “SWITCH OFF LIGHTS!” appears in the multifunction indicator if the vehicle’s exterior lamps (except standing lamps) are not switched off.

Line 1

Line 2

C*

STEER. WHEEL ADJUST.

* C = Category, see page 213

For locking the adjustable telescoping steering column, see page 73.

Malfunction and warning messages

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

221

Index

LIGHTING SYSTEM

Line 1

Line 2

LAMP DEFECTIVE

CHECK LAMPS!

DISPLAY DEFECTIVE

VISIT WORKSHOP!

C*

* C = Category, see page 213

When the message appears after starting the engine, or if it comes on while driving, this indicates a failure in the parking lamp, taillamp, stop lamp, or low beam headlamp. See page 256 for instructions on replacing bulbs. If an exterior lamp fails, the message will appear only when that lamp is switched on. If a brake lamp fails, the message will appear when applying the brake and stays on until the engine is turned off.

Note: If additional lighting is installed (e.g. auxiliary headlamps etc.) be certain to connect into the fuse before the failure indicator monitoring unit order to avoid damaging the system.

Malfunction and warning messages

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

222

Index

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Malfunction and warning messages

WASHER FLUID

Line 1

Line 2

WASHER FLUID

CHECK LEVEL!

C*

* C = Category, see page 213

When this message appears while the engine is running, the level of the reservoir has dropped to approx. 1/3 of the total volume. The reservoir should be refilled with the prescribed mixture of MB Windshield Washer Concentrate “S” and water or the Concentrate and commercially available premixed windshield washer solvent/antifreeze, depending on ambient temperature, at the next opportunity. The reservoir for the windshield and headlamp washer systems is located in the engine compartment. See windshield washer system on page 238 for instructions on adding washer fluid.

223

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Malfunction and warning messages

OIL TEMP. (engine oil temper atur e)

ENGINE OIL LEVEL

Line 1

Line 2

OIL TEMP. TOO HIGH

REDUCE REVS.!

C*

* C = Category, see page 213

There is a danger of engine damage - change to a higher gear or reduce road speed.

Check the engine oil level as soon as the vehicle returns to operating temperature. See Engine oil level indicator on the page 108.

Line 1

Line 2

ENGINE OIL LEVEL

CHECK LEVEL!1

ENGINE OIL LEVEL

STOP, ENGINE OFF!2

ENGINE OIL LEVEL

REDUCE OIL LEVEL!3

ENGINE OIL LEVEL

VISIT WORKSHOP!4

ENGINE OIL SENSOR

VISIT WORKSHOP!5

ENGINE OIL

VISIT WORKSHOP!6

* C = Category, see page 213

C*

1 The engine oil level must be checked immediately. See Engine oil

level indicator on page 108

224

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Malfunction and warning messages

2 There is no oil in the engine. There is a danger of engine damage.

3 There is a risk of damaging the engine or catalytic converter. The engine oil level must be checked immediately. See Engine oil level indicator on page 108.

4 The engine oil level has dropped to a critical level.

Check the engine oil level immediately. See Engine oil level indicator on page 108 and check the engine for visible leakage (loss of oil).

5 The measuring system is malfunctioning.

6 It may be that there is water in the engine oil. Have the engine oil

checked.

When the “ENGINE OIL LEVEL – CHECK LEVEL” message appears while the engine is running and at operating temperature, the engine oil level has dropped to approximately the minimum mark on the dipstick. When this occurs, the warning will first come on intermittently and then stay on if the oil level drops further. If no oil leaks are noted, continue to drive to the nearest service station where the engine oil should be topped to the “full” mark on the dipstick with an approved oil. The engine oil level warnings should not be ignored. Extended driving with the symbol displayed could result in serious engine damage that is not covered by the Mercedes-Benz Limited Warranty.

225

ELEC. STABIL. PROG. (Electronic stability program)

1 A malfunction has been detected in the system. Pressing the

accelerator pedal will require greater effort. Only partial engine output will be available.

2 This message may be displayed if the power supply was

interrupted (battery disconnected or empty).

3 Synchronize ESP. See page 201

Line 1

Line 2

DISPLAY DEFECTIVE

VISIT WORKSHOP!

ELEC. STABIL. PROG.

VISIT WORKSHOP!1, 2, 3

C*

* C = Category, see page 213

Malfunction and warning messages

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

226

Index

Practical hints

First aid kit Shelf below rear window Stowing things in the vehicle Spare wheel, vehicle tools, storage compartment Vehicle jack Fuses Hood Checking engine oil level Automatic transmission fluid level Coolant level Adding coolant Windshield washer / headlamp clean.system Windshield and headlamp washer fluid mixing ratio Wheels Tire replacement Rotating wheels

228

228

228229

230

231

233

234

236

236

237238

238

239

239

240Spare wheel

Changing wheels Tire inflation pressure Battery Jump starting Towing the vehicle Transmission selector lever, manually unlocking Bulbs Adjusting headlamp aim Changing batteries in the electronic main key Synchronizing remote control Emergency operation of sliding/pop-up roof

Manual release for fuel filler flap

Replacing wiper blade insert Trunk lamp Roof rack

241

242

247

249

251

253255

256

261264

266267

268

268

270

270227

Instruments and controls

First aid kit

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

First aid kit

Shelf below rear window

The first aid kit is stored in the shelf below the rear window. Pull handle (1) to open the lid.

P86.30-2003-26

Warning! The shelf below the rear window should not be used to carry objects. This will avoid such objects from being thrown about and injuring vehicle occupants during an accident or sudden maneuver. The trunk is the preferred place to carry objects.

Stowing things in the vehicle

Warning! To help avoid personal injury during a collision or sudden maneuver, exercise care when stowing things. Put luggage or cargo in the trunk if possible. Do not pile luggage or cargo higher than the seat backs. Do not place anything on the shelf below the rear window.

228

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Spare wheel, vehicle jack

Spare wheel, vehicle tools, storage compartment

1 Trunk floor 2 Handle 3 Luggage bowl 4 Vehicle tools

Lift trunk floor and engage handle in grip molding of luggage cover.

To remove spare tire: Turn luggage bowl counterclockwise and remove.

To store spare tire: Place spare tire in wheel well and secure it with luggage bowl. Turn luggage bowl clockwise to its stop.

Note: Always lower trunk floor before closing trunk lid.

229

Vehicle jack

1 Jack arm 2 Jack base

Warning! The jack is designed exclusively for jacking up the vehicle at the jack tubes built into either side of the vehicle. To help avoid personal injury, use the jack only to lift the vehicle during a wheel change. Never get beneath the vehicle while it is supported by the jack. Keep hands and feet away from the area under the lifted vehicle. Always firmly set parking brake and block wheels before raising vehicle with jack. Do not disengage parking brake while the vehicle is raised. Be certain that the jack is always vertical when in use, especially on hills. Always try to use the jack on level surface. Be sure that the jack arm is fully inserted in the jack tube. Always lower the vehicle onto sufficient capacity jackstands before working under the vehicle.

P40.10-2027-26

See illustration for proper storage of jack. Before storing the jack on the felt in the spare wheel well, the jack arm must be lowered almost to the base of the jack.

Spare wheel, vehicle jack

241261

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

230

Index

Fuses

Fuse box in engine compartment

Before replacing a blown fuse, determine the cause of the short circuit. Spare fuses are supplied inside the main fuse box (1). Observe amperage and color of fuse. A special fuse puller is supplied with the vehicle tools. Always use a new fuse for replacement. Never attempt to repair or bridge a blown fuse. A fuse chart can be found inside the corresponding fuse box cover.

1 Main fuse box in engine compartment

To gain access to the main fuse box (1), press clamp (arrow), lift the fuse box cover up and remove it. To close the main fuse box, engage back end of cover and let front end snap into place.

Fuses

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

231

Index

Auxiliary fuse box below the trunk floor

Auxiliary fuse box in the dashboard

2 Auxiliary fuse box below the trunk floor.

3 Auxiliary fuse box to left of exterior lamp switch.

To gain access, lift trunk floor.

To gain access, open door, pry off cover (3) and remove.

Fuses

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

232

Index

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Engine compartment

Hood Warning! To help prevent personal injury, stay clear of moving parts when the hood is open and the engine is running. Be sure the hood is properly closed before driving. When closing hood, use extreme caution not to catch hands or fingers. The engine is equipped with a transistorized ignition system. Because of the high voltage it is dangerous to touch any components (ignition coils, spark plug sockets, diagnostic socket) of the ignition system

• with the engine running, • while starting the engine, • if ignition is “on” and the engine is turned

manually.

If you see flames, steam or smoke coming from the engine compartment, or if the coolant temperature gauge indicates that the engine is overheated, do not open the hood. Move away from vehicle and do not open the hood until the engine has cooled. If necessary, call a fire department.

P88.40-2025-26

To open: To unlock the hood, pull release lever (1) under the driver’s side of the instrument panel. At the same time a handle will extend out of the radiator grill (it may be necessary to lift the hood up slightly).

Caution! To avoid damage to the windshield wiper or hood, open the hood only with wiper in the parked position.

233

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Engine compartment

Checking engine oil level

P88.40-2017-26

Pull handle (2) to its stop out of radiator grill and open hood (do not pull up on handle).

To close: Lower hood and let it drop into lock from a height of approx. 1 ft. (30 cm), assisting with hands placed flat on edges of hood (3). To avoid hood damage, please make sure that hood is fully closed. If not, repeat closing procedure. Do not push down on hood to attempt to fully close it.

1 Oil dipstick 2 Oil filler cap

To check the engine oil level, park vehicle on level ground, with engine at normal operational temperature. Check engine oil level approximately 5 minutes after stopping the engine, allowing for the oil to return to the oil pan.

234

Wipe oil dipstick clean prior to checking the engine oil level. Fully insert dipstick in tube, and remove after three seconds to obtain accurate reading.

Oil level must be between the lower (min) and upper (max) mark of the dipstick.

Fill quantity between upper and lower dipstick marking level is approximately 2.1 US qt (2.0 l).

Do not overfill the engine. Excessive oil must be drained or siphoned. It could cause damage to engine and catalytic converter not covered by the Mercedes-Benz Limited Warranty. if See malfunction and warning messages on page 2 31 an engine oil level display appears on the multifunction display when the engine is running.

Note: See page 108 for engine oil level indicator.

Engine compartment

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

235

Index

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Engine compartment

Coolant level

Automatic transmission fluid level The transmission has a permanent fill of automatic transmission fluid. Regular automatic transmission fluid level checks and changes are not required. For this reason the dipstick is omitted. If you notice fluid leaks or gear shifting malfunctions, have your authorized Mercedes-Benz Center check the transmission fluid level.

P20.30-2032-26

To check the coolant level, the vehicle must be parked on level ground and the engine stopped. Check coolant level only when coolant is cold. The coolant level should reach the black top part of the reservoir.

236

Adding coolant If coolant has to be added, a 50/50 mixture of water and MB anticorrosion/antifreeze should be added. The drain plugs for the cooling system are located on the right side of the engine block and at the bottom of the radiator. Anticorrosion/antifreeze mixture, see page 287.

Warning! In order to avoid possible serious burns or injury:

• Use extreme caution when opening the hood if there are any signs of steam or coolant leaking from the cooling system, or if the coolant temperature gauge indicates that the coolant is overheated.

• Do not remove pressure cap on coolant

reservoir if engine temperature is above 194°F (90°C). Allow engine to cool down before removing cap. The coolant reservoir contains hot fluid and is under pressure.

• Using a rag, slowly open cap approximately

1/2 turn to relieve excess pressure. If opened immediately, scalding hot fluid and steam will be blown out under pressure.

• Do not spill antifreeze on hot engine parts.

Antifreeze contains ethylene glycol which may burn if it comes into contact with hot engine parts.

Engine compartment

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

237

Index

Windshield washer/headlamp cleaning system

Warning! Washer solvent/antifreeze is highly flammable. Do not spill washer solvent/antifreeze on hot engine parts, because it may burn. You can be seriously burned.

Windshield and headlamp washer fluid mixing ratio

1 Windshield washer/headlamp cleaning system fluid

reservoir

P82.35-2017-26

The reservoir should be refilled with MB Windshield washer concentrate and water (or commercially available premixed windshield washer solvent/ antifreeze, depending on ambient temperatures).

For temperatures above freezing: MB Windshield Washer Concentrate “S” and water. 1 part “S” to 100 parts water (40 ml “S” to 1 gallon water).

For temperature below freezing: MB Windshield Washer Concentrate “S” and commercially available premixed windshield washer solvent/antifreeze. 1 part “S” to 100 parts solvent (40 ml “S” to 1 gallon solvent).

Engine compartment

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

238

Index

Instruments and controls

Tires, Wheels

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Wheels Replace rims or tires with the same designation, manufacturer and type as shown on the original part. See your authorized Mercedes-Benz Center for further information. See your authorized Mercedes-Benz Center for information on tested and recommended rims and tires for summer and winter operation. They can also offer advice concerning tire service and purchase.

Tire replacement Front tires should be replaced in sets. Rims and tires must be of the correct size and type. For dimensions, see “Technical Data” We recommend that you break in new tires for approx. 60 miles (100 km) at moderate speed.

It is imperative that the wheel mounting bolts be fastened to a tightening torque of 80 ft.lb. (110 Nm) whenever wheels are mounted. For rim and tire specifications, refer to “Technical Data”

Warning! Worn, old tires can cause accidents. If the tire tread is badly worn, or if the tires have sustained damage, replace them. When replacing rims, use only genuine Mercedes-Benz wheel bolts specified for the particular rim type. Failure to do so can result in the bolts loosening and possibly an accident.

239

Rotating wheels

The wheels can be rotated according to the degree of tire wear while retaining the same direction of travel. Rotating, however, should be carried out as recommended by the tire manufacturer, before the characteristic tire wear pattern (shoulder wear on front wheels and tread center wear on rear wheels) becomes visible, as otherwise the driving properties deteriorate.

Important! Unidirectional tires must always be mounted with arrow on tire sidewall pointing in direction of vehicle forward movement.

Notes: Thoroughly clean the inner side of the wheels any time you rotate the wheels or wash the vehicle underside. The use of retread tires is not recommended. Retread tires may adversely affect the handling characteristics and safety of the vehicle. Dented or bent rims can cause tire pressure loss and damage to the tire beads. For this reason, check rims for damage at regular intervals. The rim flanges must be checked for wear before a tire is mounted. Remove burrs, if any. Check and ensure proper tire inflation pressure after rotating the wheels. For tire inflation pressure see inside of fuel filler flap and also page 247.

Tires, Wheels

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

240

Index

Spare wheel

Important! The spare wheel rim size is 71/2 J x 17 H 2. The spare wheel rim is mounted with a full size tire of the same type as on the vehicle’s front axle, and is fully functional. However, that spare wheel rim is weight optimized and has a limited service life of 12 000 miles (20 000 km) use before a standard wheel rim must replace it. In the case of a rear axle flat tire, you may temporarily use the spare wheel, when observing the following restrictions: • Do not exceed vehicle speed of 50 mph (80 km/h). • Drive to the nearest tire repair facility to have the

flat tire repaired or replaced as appropriate.

• Do not operate vehicle with more than one spare

wheel mounted.

If the arrow on tire side wall does not point in direction of vehicle forward movement when using the spare wheel, observe the following restriction:

Unidirectional tires must always be mounted with arrow on tire sidewall pointing in direction of vehicle forward movement. For rim and tire specifications, refer to “Technical Data”.

Warning! The spare wheel rim is for temporary use only. Use for over a total of 12 000 miles (20 000 km) (aggregate of all uses) may cause wheel rim failure leading to an accident and possible injuries. The dimensions of the spare wheel are different from those of the road wheels of the rear axle. As a result, the vehicle handling characteristics change when driving with a spare wheel mounted on the rear axle. The spare wheel should only be used temporarily, and replaced with a regular road wheel as quick as possible.

Tires, Wheels

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

241

Index

Instruments and controls

Tires, Wheels

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Changing wheels

Warning! The jack is designed exclusively for jacking up the vehicle at the jack tubes built into either side of the vehicle. To help avoid personal injury, use the jack only to lift the vehicle during a wheel change. Never get beneath the vehicle while it is supported by the jack. Keep hands and feet away from the area under the lifted vehicle. Always firmly set parking brake and block wheels before raising vehicle with jack. Do not disengage parking brake while the vehicle is raised. Be certain that the jack is always vertical when in use, especially on hills. Always try to use the jack on level surface. Be sure that the jack arm is fully inserted in the jack tube. Always lower the vehicle onto sufficient capacity jackstands before working under the vehicle.

Move vehicle to a level area which is a safe distance from the roadway.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine.

3. Prevent vehicle from rolling away by blocking wheels with wheel chocks (not supplied with vehicle) or sizable wood block or stone. When changing a wheel on a hill, place chocks on the downhill side blocking both wheels of the other axle. On a level road, place one chock in front of and one behind the wheel that is diagonally opposite to the wheel being changed.

242

4. Using the wrench, loosen but do not yet remove the

wheel bolts.

5. Remove the protective cover from the jack support

tube opening by inserting the screwdriver (supplied in the tool kit) in the opening and prying it out. The tube openings are located directly behind the front wheel housings and in front of the rear wheel housings.

Tires, Wheels

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

243

Index

Instruments and controls

Tires, Wheels

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

262

P40.10-2169-26

P40.10-2167-26

6. Insert jack arm fully into the tube hole up to the

stop. Place jack on firm ground. Position the jack so that it is always vertical (plumb-line) as seen from the side (see arrow), even if the vehicle is parked on an incline.

7. Jack up the vehicle until the wheel is clear of the ground. Never start engine while vehicle is raised.

8. Unscrew upper-most wheel bolt and install

alignment bolt (1) supplied in the tool kit. Remove the remaining bolts. Keep bolt threads protected from dirt and sand.

9. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.

244

11

10. Clean contact surfaces of wheel and wheel hub.

Install spare wheel on wheel hub. Insert wheel bolts and tighten them slightly. To avoid paint damage, place wheel flat against hub and hold it there while installing first wheel bolt. Unscrew the alignment bolt (1) to install the last wheel bolt.

11. Lower vehicle. Remove jack and insert jack tube

cover.

12. Using the wrench, tighten the five bolts evenly,

following the sequence illustrated, until all bolts are tight. Observe a tightening torque of 80 ft.lb. (110 Nm). Before storing the jack, the jack arm must be lowered almost to the base of the jack. For proper storage of vehicle jack see page 258.

13. Ensure proper tire pressure.

Tires, Wheels

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

245

Index

Instruments and controls

Tires, Wheels

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Warning! Always replace wheel bolts that are damaged or rusted. Never apply oil or grease to wheel bolts. Damaged wheel hub threads should be repaired immediately. Incorrect mounting bolts or improperly tightened mounting bolts can cause the wheel to come off. This could cause an accident. Be sure to use the correct mounting bolts.

Warning! The spare wheel rim is for temporary use only. Use for over a total of 12 000 miles (20 000 km) (aggregate of all uses) may cause wheel rim failure leading to an accident and possible injuries. The dimensions of the spare wheel are different from those of the road wheels of the rear axle. As a result, the vehicle handling characteristics change when driving with a spare wheel mounted on the rear axle. The spare wheel should only be used temporarily, and replaced with a regular road wheel as quick as possible.

246

Tire inflation pressure A table (see fuel filler flap) lists the tire inflation pressures specified for Mercedes-Benz recommended tires as well as for the varying operating conditions.

Important! Tire pressure changes by approx. 1.5 psi (0.1 bar) per 18°F (10°C) of air temperature change. Keep this in mind when checking tire pressure inside a garage – especially in the winter. Example: If garage temperature = approx. +68°F (+20°C) and ambient temperature = approx. +32°F (0°C) then the adjusted air pressure = specified air pressure +3 psi (+0.2 bar).

Tire pressures listed for light loads are minimum values offering high driving comfort. Increased inflation pressures for heavy loads produce favorable handling characteristics with lighter loads and are perfectly permissible. The ride of the vehicle, however, will become somewhat harder. Tire temperature and pressure increase with the vehicle speed. Tire pressure should therefore only be checked and corrected on cold tires. Correct tire pressure in warm tires only if pressure has dropped below the pressure listed in the table and the respective operating conditions are taken into consideration. An underinflated tire due to a slow leak (e.g. due to a nail in the tire) may cause damage such as tread separation, bulging etc.. Regular tire pressure checks (including the spare tire) at intervals of no more than 14 days are therefore essential.

Tires, Wheels

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

247

Index

Instruments and controls

Battery

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

If a tire constantly loses air, it should be inspected for damage. The spare tire should be checked periodically for condition and inflation. Spare tire will age and become worn over time even if never used, and thus should be inspected and replaced when necessary.

Warning! Do not overinflate tires. Overinflating tires can result in sudden deflation (blowout) because they are more likely to become punctured or damaged by road debris, potholes etc.. Follow recommended inflation pressures. Do not overload the tires by exceeding the specified vehicle capacity weight (as indicated by the label on the driver’s door latch post). Overloading the tires can overheat them, possibly causing a blowout.

248

Instruments and controls

Battery

Battery

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Warning! Failure to follow these instructions can result in severe injury or death. Never lean over batteries while connecting, you might get injured. Battery fluid contains sulfuric acid. Do not allow this fluid to come in contact with eyes, skin or clothing. In case it does, immediately flush affected area with water and seek medical help if necessary. A battery will also produce hydrogen gas, which is flammable and explosive. Keep flames or sparks away from battery, avoid improper connection of jumper cables, smoking etc..

Important! Battery replacement information: The maintenance-free battery is located in the trunk under the trunk floor. The service life of the battery is dependent on its condition of charge. The battery should always be kept sufficiently charged, in order to last an optimum length of time.

Therefore, we strongly recommend that you have the battery charge checked frequently, and corrected if necessary, especially if you use the vehicle less than approximately 200 miles (300 km) per month, mostly for short distance trips, or if it is not used for long periods of time. Only charge a battery with a battery charger after the battery has been disconnected from the vehicle’s electrical circuit. Always disconnect the battery negative lead first and connect last. When removing and connecting the battery, always make sure that all electrical consumers are off and the electronic key is in steering lock position 0. The battery and its filler caps must always be securely installed when the vehicle is in operation. During removal and installation always protect the disconnected battery positive (+) terminal with the cover attached to the battery. While the engine is running the battery terminal clamps must not be loosened or detached, otherwise the generator and other electronic components would be damaged.

249

Notes: After reconnecting the battery also resynchronize the front seats, the express feature of the power windows (see page 142), and the electronic stability program (ESP) (see page 201).

front seat head restraints (see page 49),

Battery recycling Batteries contain material that can harm the environment with improper disposal. Large 12 Volt storage batteries contain lead. Recycling of batteries is the preferred method of disposal. Many states require sellers of batteries to accept old batteries for recycling.

Battery

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

250

Index

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Jump starting

Jump starting

Warning! Failure to follow these directions will cause damage to the electronic components, and can lead to a battery explosion and severe injury or death. Never lean over batteries while connecting or jump starting, you might get injured. Battery fluid contains sulfuric acid. Do not allow this fluid to come in contact with eyes, skin or clothing. In case it does, immediately flush affected area with water, and seek medical help if necessary. A battery will also produce hydrogen gas, which is flammable and very explosive. Keep flames or sparks away from battery, avoid improper connection of jumper cables, smoking etc.. Read all instructions before proceeding.

If the battery is discharged, the engine should be started with jumper cables and the (12 V) battery of another vehicle. Only use 12 V battery to jump start your vehicle. Jump starting with more powerful battery could damage the vehicle’s electrical systems, which will not be covered by the Mercedes-Benz Limited Warranty. The battery is located in the trunk under the trunk floor.

Proceed as follows:

1. Position the vehicle with the charged battery so that

the jumper cables will reach, but never let the vehicles touch. Make sure the jumper cables do not have loose or missing insulation.

2. On both vehicles:

• Turn off engine and all lights and accessories, except hazard warning flashers or work lights. • Apply parking brake and shift selector lever to

position “P”.

251

Important!

3. Clamp one end of the first jumper cable to the

positive (+) under hood terminal of the discharged battery and the other end to the positive (+) terminal of the charged battery. Make sure the cable clamps do not touch any other metal parts.

4. Clamp one end of the second jumper cable to the

grounded negative (–) terminal of the charged battery and the final connection to the negative (–) terminal (2) of the discharged battery.

Important!

5. Start engine of the vehicle with the charged battery

and run at high idle. Make sure the cables are not on or near pulleys, fans, or other parts that move when the engine is started. Allow the discharged battery to charge for a few minutes. Start engine of the disabled vehicle in the usual manner.

6. After the engine has started, remove jumper cables

by exactly reversing the above installation sequence, starting with the last connection made first. When removing each clamp, make sure that it does not touch any other metal while the other end is still attached.

Important! A discharged battery can freeze at approx. +14°F (–10°C). In that case, it must be thawed out before jumper cables are used. Attempting to jump start a frozen battery can result in it exploding, causing personal injury. Jumper cable specifications: • Minimum cable cross-section of 25 mm2 or approx.

2 AWG

• Maximum length of 11.5 ft. (3.5 m).

Notes: If engine does not run after several unsuccessful starting attempts, have it checked at the nearest authorized Mercedes-Benz Center. Excessive unburned fuel may damage the catalytic converter.

Jump starting

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

252

Index

Instruments and controls

Towing

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Towing the vehicle

Prior to towing the vehicle with all wheels on the ground, make certain that the electronic key is in steering lock position 2. If the electronic key is left in the steering lock position 0 for an extended period of time, it can no longer be turned in the lock. In this case, the steering is locked. To unlock, remove electronic key from steering lock and reinsert.

Important! When towing the vehicle, please, note the following: With the automatic central locking activated and the electronic key in steering lock position 2, the vehicle doors lock if the left front wheel as well as the right rear wheel are turning at vehicle speeds of approx. 9 mph (15 km/h) or more. To prevent the vehicle door locks from locking, deactivate the automatic central locking, see page 36.

P88.20-2026-26

The rear towing eye is located at the right, below the bumper. The front towing eye is located on the passenger side behind a cover in the bumper panel.

Cover removal: Insert finger in recess of cover and pull cover out. Cover installation: Engage cover at bottom and press in top securely.

253

Note: To signal turns while being towed with hazard warning flasher in use, turn electronic key in steering lock to position 2 and activate combination switch for left or right turn signal in usual manner – only the selected turn signal will operate. Upon canceling the turn signal, the hazard warning flasher will operate again.

Caution! If the vehicle is towed with the front axle raised, the engine must be shut off (electronic key in steering lock position 0 or 1). Otherwise, the ESP will immediately be engaged and will apply the rear wheel brakes. Switch off the tow-away alarm as well as the ESP.

We recommend that the vehicle be transported using flat bed equipment. This method is preferable to other types of towing. The vehicle may be towed with all wheels on the ground and the selector lever in position “N” for distances up to 30 miles (50 km) and at a speed not to exceed 30 mph (50 km/h). The electronic key must be in steering lock position 2. To be certain to avoid a possibility of damage to the transmission, however, we recommend the drive shaft be disconnected at the rear axle drive flange for any towing beyond a short tow to a nearby garage. Do not tow with sling-type equipment. Towing with sling-type equipment over bumpy roads will damage radiator and supports. Use wheel lift, dolly, or flat bed equipment, with electronic key in steering lock turned to position 0.

Warning! With the engine not running, there is no power assistance for the braking and steering systems. In this case, it is important to keep in mind that a considerably higher degree of effort is necessary to brake and steer the vehicle.

Towing

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

254

Index

Transmission selector lever, manually unlocking

To do so, insert a pin (1), e.g. ball point pen, into the covered opening below the position “D” of the shift pattern. While pushing the pin down, move selector lever from position “P”. After removal of the pin from the opening, the cover will not close fully. Only after moving the selector lever to positions “D+” and “D–” does the cover return to its closed position.

In the case of power failure the transmission selector lever can be manually unlocked, e.g. to tow the vehicle.

Towing

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

255

Index

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Exterior lamps

Bulbs

Headlamp adjustment Correct headlamp adjustment is extremely important. Check and readjust headlamps at regular intervals and when a bulb has been replaced. For adjusting headlamp aim see page 261.

Replacing bulbs

Warning! Bulbs and bulb holders can be very hot. Allow the lamp to cool down before changing a bulb. Halogen lamps contain pressurized gas. A bulb can explode if you:

• touch or move it when hot, • drop the bulb, • scratch the bulb.

Wear eye and hand protection.

Notes: To prevent a possible electrical short circuit, switch off lamp prior to replacing a bulb. When replacing bulbs, install only 12 volt bulbs with the specified watt rating. When replacing halogen bulbs do not touch glass portion of bulb with bare hands. Use plain paper or a clean cloth.

Warning! Because of high voltage in Xenon lamps, it is dangerous to replace the bulb or repair the lamp and its components. We recommend that you have such work done by a qualified technician.

256

Headlamp assembly (Halogen)

Headlamp assembly (Xenon)

P82.10-2394-26

P82.10-2395-26

1 Headlamp vertical adjustment screw 2 Cover for low beam headlamp 3 Cover for high beam headlamp, parking and

standing lamp

4 Bulb socket for turn signal lamp 5 Electrical connector for low beam headlamp bulb 6 Electrical connector for high beam headlamp bulb 7 Bulb socket for parking and standing lamp

Exterior lamps

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

257

Index

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Exterior lamps

Bulbs for low or high beam H7 (55 W) Open hood. Rotate cover (2 or 3) counterclockwise and remove. Pull off electrical connector (5 or 6). Unhook clamping ring and remove bulb. Insert new bulb (seating properly in cutouts of bulb socket), mount clamping ring. Reinstall and push electrical connector on securely. Reinstall cover (2 or 3).

Xenon (optional) Bulb for low beam

Warning! Because of high voltage in Xenon lamps, it is dangerous to replace the bulb or repair the lamp and its components. We recommend that you have such work done by a qualified technician.

Turn signal lamp 1156 NA (26.9/5 W/32/4 cp bulb) Open hood. Twist bulb socket (4) counterclockwise and pull out. Push bulb into socket, turn counterclockwise and remove. Insert new bulb in socket, push in and twist clockwise. Reinstall bulb socket. Reinstall lamp assembly until properly seated.

Parking and standing lamp H 6W (6 W bulb) Open hood. Rotate cover (3) counterclockwise and remove. Twist bulb socket (7) counterclockwise and pull out. Push bulb into socket, turn counterclockwise and remove. Insert new bulb in socket, push in and twist clockwise. Reinstall bulb socket. Reinstall lamp assembly until properly seated. Reinstall cover (3).

258

Taillamp assemblies

P82.10-2080-26

P82.10-2083-26

Open trunk lid. Swing cover aside (bulbs 1, 2 and 3).

1 Turn signal lamp (21 W/24 cp bulb) 2 Stop, tail, parking, and side marker lamp

(21/4 W bulb)

3 Tail and parking lamp (5 W/4 cp bulb)

4 Driver’s side:

Rear fog lamp (21 W/32 cp bulb) 5 Backup lamp (21 W/32 cp bulb)

Twist bulb socket counterclockwise and pull out. Push bulb into socket, turn counterclockwise and remove. Insert new bulb in socket, push in and twist clockwise. Reinstall bulb socket. Close cover (bulbs 1, 2 and 3).

Exterior lamps

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

259

Index

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

Index

Exterior lamps

Side marker lamp, front (5 W/4 cp bulb)

Carefully slide lamp towards front (arrow), and remove back and first. Twist bulb socket counterclockwise and pull out. Push bulb socket, turn counterclockwise and remove. Insert new bulb in socket, push in and twist clockwise. Reinstall bulb socket, push in and twist clockwise. To reinstall lamp, set front end of lamp in bumper and let back end snap into place.

260

High mounted stop lamp, Additional turn signals on the exterior mirror The high mounted stop lamp (3rd brake lamp), and the additional turn signals on the exterior mirrors are equipped with LEDs. Have the system checked at an authorized Mercedes-Benz Center if a fault or defect occurs.

Adjusting headlamp aim Correct headlamp adjustment is extremely important. To check and readjust a headlamp, follow steps 1 through 5. Please note: • Low beam adjustments simultaneously aim the high

beam.

• Vehicle should have a normal trunk load.

1. Park vehicle on level surface approximately 25 ft. (7.6 m) from a vertical test screen or wall. The centerline of the vehicle must be at a 90° angle to the test screen.

Exterior lamps

Instruments and controls

Operation

Driving

Instrument cluster display

Practical hints

Car care

Technical

data

261

Index

Instruments and controls

Exterior lamps

Operation

Driving

Instrument cluster display

Practical hints