- 2006 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2009 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2012 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2011 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2005 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2007 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2016 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2004 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2015 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2010 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- 2008 GMC Canyon Owners Manuals

- GMC Canyon Owners Manuals

- Download PDF Manual

-

To avoid the possibility of the vehicles rolling, set the parking brake firmly on both vehicles involved in the jump start procedure.

Put an automatic transmission in PARK (P) or a manual transmission in NEUTRAL before setting the parking brake. If you have a four-wheel-drive vehicle, be sure the transfer case is not in NEUTRAL.

Notice: If you leave your radio or other accessories on during the jump starting procedure, they could be damaged. The repairs would not be covered by your warranty. Always turn off your radio and other accessories when jump starting your vehicle. 3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette lighter or the accessory power outlets. Turn off the radio and all lamps that are not needed. This will avoid sparks and help save both batteries. And it could save the radio!

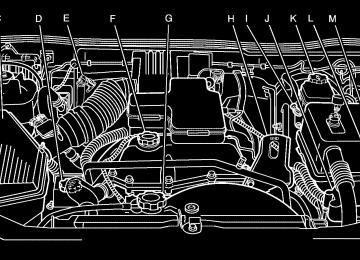

4. Open the hoods and locate the positive (+) and negative (−) terminal locations on the other vehicle. Your vehicle has a remote positive (+) and a remote negative (−) jump starting terminal. See Engine Compartment Overview on page 324 for more information on the terminal locations.

{CAUTION:

Using a match near a battery can cause battery gas to explode. People have been hurt doing this, and some have been blinded. Use a flashlight if you need more light. Be sure the batteries have enough water. You do not need to add water to the ACDelco® battery (or batteries) installed in your new vehicle. But if a battery has filler caps, be sure the right amount of fluid is there. If it is low, add water to take care of that first. If you do not, explosive gas could be present. Battery fluid contains acid that can burn you. Do not get it on you. If you accidentally get it in your eyes or on your skin, flush the place with water and get medical help immediately.

355

{CAUTION:

Fans or other moving engine parts can injure you badly. Keep your hands away from moving parts once the engine is running.

5. Check that the jumper cables do not have loose or missing insulation. If they do, you could get a shock. The vehicles could be damaged too. Before you connect the cables, here are some basic things you should know. Positive (+) will go to positive (+) or to a remote positive (+) terminal if the vehicle has one. Negative (−) will go to a heavy, unpainted metal engine part or to a remote negative (−) terminal if the vehicle has one. Do not connect positive (+) to negative (−) or you will get a short that would damage the battery and maybe other parts too. And do not connect the negative (−) cable to the negative (−) terminal on the dead battery because this can cause sparks.

356

6. Connect the red positive (+) cable to the positive (+) terminal of the dead battery. Use a remote positive (+) terminal if the vehicle has one.

7. Do not let the other end touch metal. Connect

it to the positive (+) terminal of the good battery. Use a remote positive (+) terminal if the vehicle has one.

8. Now connect the black negative (−) cable to the negative (−) terminal of the good battery. Use a remote negative (−) terminal if the vehicle has one. Do not let the other end touch anything until the next step. The other end of the negative (−) cable does not go to the dead battery. It goes to a heavy, unpainted metal engine part, or to a remote negative (−) terminal on the vehicle with the dead battery.

9. Connect the other end of the negative (−) cable at least 18 inches (45 cm) away from the dead battery, but not near engine parts that move. The electrical connection is just as good there, and the chance of sparks getting back to the battery is much less. Your vehicle has a remote negative (−) terminal for this purpose.

10. Now start the vehicle with the good battery

and run the engine for a while.

11. Try to start the vehicle that had the dead

battery. If it will not start after a few tries, it probably needs service.

357

To disconnect the jumper cables from both vehicles, do the following: 1. Disconnect the black negative (−) cable from

the vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from

the vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the

other vehicle.

Notice: If the jumper cables are connected or removed in the wrong order, electrical shorting may occur and damage the vehicle. The repairs would not be covered by your warranty. Always connect and remove the jumper cables in the correct order, making sure that the cables do not touch each other or other metal.

Jumper Cable Removal

A. Heavy, Unpainted Metal Engine Part or

Remote Negative (−) Terminal

B. Good Battery or Remote Positive (+) and

Remote Negative (−) Terminals

C. Dead Battery or Remote Positive (+) Terminal

358

Rear Axle When to Check and Change Lubricant It is not necessary to regularly check rear axle fluid unless you suspect there is a leak or you hear an unusual noise. A fluid loss could indicate a problem. Have it inspected and repaired. How to Check Lubricant

To get an accurate reading, the vehicle should be on a level surface.

The proper level is from 0 to 3/8 inch (0 mm to 10 mm) below the bottom of the filler plug hole, located on the rear axle. What to Use See Recommended Fluids and Lubricants on page 447 to determine which kind of lubricant to use. Four-Wheel Drive Lubricant checks in this section apply to this vehicle. There are two additional systems that need lubrication. Transfer Case When to Check Lubricant Refer to the Maintenance Schedule to determine how often to check the lubricant. See Additional Required Services on page 440. How to Check Lubricant To get an accurate reading, the vehicle should be on a level surface.

359

Front Axle When to Check and Change Lubricant It is not necessary to regularly check your front axle fluid unless you suspect there is a leak or you hear an unusual noise. A fluid loss could indicate a problem. Have it inspected and repaired. How to Check Lubricant

To get an accurate reading, the vehicle should be on a level surface.

A. Drain Plug B. Filler Plug If the level is below the bottom of the filler plug hole, located on the transfer case, you’ll need to add some lubricant. Remove the plug and add enough lubricant to raise the level to the bottom of the filler plug hole. Use care not to overtighten the plug. What to Use Refer to the Maintenance Schedule to determine what kind of lubricant to use. See Recommended Fluids and Lubricants on page 447.

360

If the level is below the bottom of the filler plug hole, located on the front axle, you may need to add some lubricant. When the differential is cold, add enough lubricant to raise the level to 1/2 inch (12 mm) below the filler plug hole. When the differential is at operating temperature (warm), add enough lubricant to raise the level to the bottom of the filler plug hole. What to Use See Recommended Fluids and Lubricants on page 447 to determine what kind of lubricant to use.

Bulb Replacement For the proper type of replacement bulbs, see Replacement Bulbs on page 366. For any bulb changing procedure not listed in this section, contact your dealer.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside and can burst if you drop or scratch the bulb. You or others could be injured. Be sure to read and follow the instructions on the bulb package.

361

Headlamps

A. Low-Beam Headlamp/Daytime Running

Lamps (DRL)

B. High-Beam Headlamp To replace one of these bulbs, do the following: 1. Open the hood. See Hood Release on

page 323 for more information.

2. Reach in and access the bulb sockets from

inside the engine compartment.

362

3. Turn the bulb socket counterclockwise to

remove it from the headlamp assembly and pull it straight out.

4. Unplug the electrical connector from the old

bulb by releasing the clips on the bulb socket.

5. Replace with a new bulb socket. 6. Plug in the electrical connector to the new

bulb socket.

7. Reinstall the new bulb socket into the

headlamp assembly and turn it clockwise to secure.

8. Close the hood.

Front Turn Signal, Parking and Daytime Running Lamps (DRL) To replace one of these bulbs, do the following: 1. Open the hood. See Hood Release on

page 323 for more information.

3. Turn the bulb socket counterclockwise and

remove it from the lamp assembly.

4. Holding the socket, pull the old bulb to

release it from the bulb socket.

5. Push the new bulb into the socket until it

clicks.

6. Insert the bulb socket into the lamp assembly

and turn it clockwise to secure.

7. Close the hood.

2. Reach in to access either one of the bulb

sockets in the engine compartment.

363

Center High-Mounted Stoplamp (CHMSL) To replace the CHMSL bulb, do the following: 1. Remove the two screws and lift off the lamp

assembly from the vehicle.

Taillamps, Turn Signal, Stoplamps and Back-up Lamps

A. Stoplamp/Taillamp B. Turn Signal/Taillamp C. Back-up Lamp

2. Turn the bulb socket counterclockwise and

remove it from the lamp assembly.

3. Holding the socket, pull the bulb to release it

from the socket.

4. Push the new bulb into the socket until it

clicks.

5. Insert the bulb socket into the lamp assembly

and turn it clockwise to secure.

6. Reinstall the lamp assembly and tighten the

screws.

364

To replace one of these bulbs, do the following:

1. Open the tailgate. See Tailgate on page 108

for more information.

2. Remove the two

rear lamp assembly screws near the tailgate latch.

3. Pull the lamp assembly away from the

vehicle.

4. Turn the bulb socket counterclockwise to

remove it from the taillamp assembly. 5. Holding the socket, pull the old bulb to

release it from the socket.

6. Push the new bulb into the socket until it

clicks.

7. Insert the bulb socket into the taillamp

assembly and turn it clockwise to secure.

8. Reinstall the taillamp assembly and tighten

the screws.

9. Close the tailgate.

365

License Plate Lamp To replace one of these bulbs, do the following:

Replacement Bulbs

Exterior Lamp

Bulb Number

Center High-Mounted Stoplamp (CHMSL) License Plate Bulb Headlamps

High-beam Low-beam/Daytime Running Lamp (DRL)

Parking/Front Turn Signal Parking Lamp (Inboard) Stoplamp, Rear Turn Signal, Taillamp, and Back-up Lamp

912

W5W

9005

9006

3757KA 3157A

3057

For replacement bulbs not listed here, contact your dealer.

1. Reach under the rear bumper for the bulb

socket.

2. Turn the bulb socket counterclockwise and

pull the bulb socket out of the connector. 3. Pull the old bulb straight out from the bulb

socket.

4. Push the new bulb straight in until it clicks to

secure it.

5. Reverse Steps 1 through 3 to reinstall the

license plate lamp.

366

Windshield Wiper Blade Replacement Windshield wiper blades should be inspected for wear and cracking. See Scheduled Maintenance on page 437 for more information. Replacement blades come in different types and are removed in different ways. For proper type and length, see Normal Maintenance Replacement Parts on page 449. Allowing the wiper blade arm to touch the windshield when no wiper blade is installed could damage the windshield. Any damage that occurs would not be covered by your warranty. Do not allow the wiper blade arm to touch the windshield. 1. To remove the old wiper blades, lift the wiper

arm until it locks into a vertical position.

A. Blade Assembly B. Arm Assembly C. Locking Tab 2. Press down on the blade assembly pivot

D. Blade Pivot E. Hook Slot F. Arm Hook

locking tab. Pull down on the blade assembly to release it from the wiper arm hook.

3. Remove the insert from the blade assembly.

The insert has two notches at one end that are locked by bottom claws of the blade assembly. At the notched end, pull the insert from the blade assembly.

367

4. To install the new wiper insert, slide the insert (D), notched end last, into the end with two blade claws (A). Slide the insert all the way through the blade claws at the opposite end (B). The plastic caps (C) will be forced off as the insert is fully inserted.

5. Be sure that the notches are locked by the

bottom claws. Make sure that all other claws are properly locked on both sides of the insert slots.

A. Claw in Notch B. Correct Installation C. Incorrect Installation

6. Put the blade assembly pivot in the wiper arm

hook. Pull up until the pivot locking tab locks in the hook slot.

7. Carefully lower the wiper arm and blade

assembly onto the windshield.

368

Tires Your new vehicle comes with high-quality tires made by a leading tire manufacturer. If you ever have questions about your tire warranty and where to obtain service, see your GM Warranty booklet for details. For additional information refer to the tire manufacturer’s booklet included with your vehicle.

{CAUTION:

Poorly maintained and improperly used tires are dangerous.

(cid:127) Overloading your vehicle’s tires can cause overheating as a result of too much friction. You could have an air-out and a serious accident. See Loading Your Vehicle on page 286.

CAUTION:

(Continued)

CAUTION:

(Continued)

(cid:127) Underinflated tires pose the same

danger as overloaded tires. The resulting accident could cause serious injury. Check all tires frequently to maintain the recommended pressure. Tire pressure should be checked when your vehicle’s tires are cold. See Inflation - Tire Pressure on page 377. (cid:127) Overinflated tires are more likely to be cut, punctured, or broken by a sudden impact — such as when you hit a pothole. Keep tires at the recommended pressure.

(cid:127) Worn, old tires can cause accidents. If the tire’s tread is badly worn, or if your vehicle’s tires have been damaged, replace them.

369

Tire Sidewall Labeling Useful information about a tire is molded into its sidewall. The examples below show a typical passenger vehicle tire and a compact spare tire sidewall.

Passenger Vehicle Tire Example

370

(A) Tire Size: The tire size is a combination of letters and numbers used to define a particular tire’s width, height, aspect ratio, construction type and service description. See the “Tire Size” illustration later in this section for more detail.

(B) TPC Spec (Tire Performance Criteria Specification): Original equipment tires designed to GM’s specific tire performance criteria have a TPC specification code molded onto the sidewall. GM’s TPC specifications meet or exceed all federal safety guidelines.

(C) DOT (Department of Transportation): The Department of Transportation (DOT) code indicates that the tire is in compliance with the U.S. Department of Transportation Motor Vehicle Safety Standards.

(D) Tire Identification Number (TIN): The letters and numbers following DOT code are the Tire Identification Number (TIN). The TIN shows the manufacturer and plant code, tire size, and date the tire was manufactured. The TIN is molded onto both sides of the tire, although only one side may have the date of manufacture.

(E) Tire Ply Material: The type of cord and number of plies in the sidewall and under the tread.

(F) Uniform Tire Quality Grading (UTQG): Tire manufacturers are required to grade tires based on three performance factors: treadwear, traction and temperature resistance. For more information see Uniform Tire Quality Grading on page 389.

(G) Maximum Cold Inflation Load Limit: Maximum load that can be carried and the maximum pressure needed to support that load.

Compact Spare Tire Example

(A) Temporary Use Only: The compact spare tire or temporary use tire has a tread life of approximately 3,000 miles (5 000 km) and should not be driven at speeds over 65 mph (105 km/h). The compact spare tire is for emergency use when a regular road tire has lost air and gone flat. See “Compact Spare Tire” under Spare Tire on page 413 for additional information.

371

(B) Tire Ply Material: The type of cord and number of plies in the sidewall and under the tread.

(C) Tire Identification Number (TIN): The Tire Identification Number (TIN). The TIN shows the manufacturer and plant code, tire size, and date the tire was manufactured. The TIN is molded onto both sides of the tire, although only one side may have the date of manufacture.

(D) Maximum Cold Inflation Load Limit: Maximum load that can be carried and the maximum pressure needed to support that load.

(E) Tire Inflation: The temporary use tire or compact spare tire should be inflated to 60 psi (420 kPa). For more information on tire pressure and inflation see Inflation - Tire Pressure on page 377.

(F) Tire Size: A combination of letters and numbers define a tire’s width, height, aspect ratio, construction type and service description. The letter T as the first character in the tire size means the tire is for temporary use only.

(G) TPC Spec (Tire Performance Criteria Specification): Original equipment tires designed to GM’s specific tire performance criteria have a TPC specification code molded onto the sidewall. GM’s TPC specifications meet or exceed all federal safety guidelines.

372

Tire Size The following illustration shows an example of a typical passenger vehicle tire size.

(A) P-Metric Tire: The United States version of a metric tire sizing system. The letter P as the first character in the tire size means a passenger vehicle tire engineered to standards set by the U.S. Tire and Rim Association.

(B) Tire Width: The three-digit number indicates the tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio: A two-digit number that indicates the tire height-to-width measurements. For example, if the tire size aspect ratio is 70, as shown in item C of the illustration, it would mean that the tire’s sidewall is 70 percent as high as it is wide.

(D) Construction Code: A letter code is used to indicate the type of ply construction in the tire. The letter R means radial ply construction; the letter D means diagonal or bias ply construction; and the letter B means belted-bias ply construction.

(E) Rim Diameter: Diameter of the wheel in inches.

(F) Service Description: These characters represent the load range and speed rating of the tire. The load index represents the load carry capacity a tire is certified to carry. The load index can range from 1 to 279. The speed rating is the maximum speed a tire is certified to carry a load. Speed ratings range from A to Z.

373

Tire Terminology and Definitions

Air Pressure: The amount of air inside the tire pressing outward on each square inch of the tire. Air pressure is expressed in pounds per square inch (psi) or kilopascal (kPa).

Accessory Weight: This means the combined weight of optional accessories. Some examples of optional accessories are, automatic transmission/ transaxle, power steering, power brakes, power windows, power seats, and air conditioning.

Aspect Ratio: The relationship of a tire’s height to its width.

Belt: A rubber coated layer of cords that is located between the plies and the tread. Cords may be made from steel or other reinforcing materials.

Bead: The tire bead contains steel wires wrapped by steel cords that hold the tire onto the rim.

Bias Ply Tire: A pneumatic tire in which the plies are laid at alternate angles less than 90 degrees to the centerline of the tread.

374

Cold Tire Pressure: The amount of air pressure in a tire, measured in pounds per square inch (psi) or kilopascals (kPa) before a tire has built up heat from driving. See Inflation - Tire Pressure on page 377.

Curb Weight: This means the weight of a motor vehicle with standard and optional equipment including the maximum capacity of fuel, oil, and coolant, but without passengers and cargo.

DOT Markings: A code molded into the sidewall of a tire signifying that the tire is in compliance with the U.S. Department of Transportation (DOT) motor vehicle safety standards. The DOT code includes the Tire Identification Number (TIN), an alphanumeric designator which can also identify the tire manufacturer, production plant, brand, and date of production.

GVWR: Gross Vehicle Weight Rating. See Loading Your Vehicle on page 286.

GAWR FRT: Gross Axle Weight Rating for the front axle. See Loading Your Vehicle on page 286.

GAWR RR: Gross Axle Weight Rating for the rear axle. See Loading Your Vehicle on page 286.

Intended Outboard Sidewall: The side of an asymmetrical tire, that must always face outward when mounted on a vehicle.

Kilopascal (kPa): The metric unit for air pressure.

Light Truck (LT-Metric) Tire: A tire used on light duty trucks and some multipurpose passenger vehicles.

Load Index: An assigned number ranging from 1 to 279 that corresponds to the load carrying capacity of a tire.

Maximum Inflation Pressure: The maximum air pressure to which a cold tire may be inflated. The maximum air pressure is molded onto the sidewall.

Maximum Load Rating: The load rating for a tire at the maximum permissible inflation pressure for that tire.

Maximum Loaded Vehicle Weight: The sum of curb weight, accessory weight, vehicle capacity weight, and production options weight.

Normal Occupant Weight: The number of occupants a vehicle is designed to seat multiplied by 150 lbs (68 kg). See Loading Your Vehicle on page 286.

Occupant Distribution: Designated seating positions.

Outward Facing Sidewall: The side of an asymmetrical tire that has a particular side that faces outward when mounted on a vehicle. The side of the tire that contains a whitewall, bears white lettering, or bears manufacturer, brand, and/or model name molding that is higher or deeper than the same moldings on the other sidewall of the tire.

Passenger (P-Metric) Tire: A tire used on passenger cars and some light duty trucks and multipurpose vehicles.

Recommended Inflation Pressure: Vehicle manufacturer’s recommended tire inflation pressure as shown on the tire placard. See Inflation - Tire Pressure on page 377 and Loading Your Vehicle on page 286.

375

Radial Ply Tire: A pneumatic tire in which the ply cords that extend to the beads are laid at 90 degrees to the centerline of the tread.

Rim: A metal support for a tire and upon which the tire beads are seated.

Sidewall: The portion of a tire between the tread and the bead.

Speed Rating: An alphanumeric code assigned to a tire indicating the maximum speed at which a tire can operate.

Traction: The friction between the tire and the road surface. The amount of grip provided.

Tread: The portion of a tire that comes into contact with the road.

Treadwear Indicators: Narrow bands, sometimes called wear bars, that show across the tread of a tire when only 1/16 inch (1.6 mm) of tread remains. See When It Is Time for New Tires on page 385.

UTQGS (Uniform Tire Quality Grading Standards): A tire information system that provides consumers with ratings for a tire’s traction, temperature, and treadwear. Ratings are determined by tire manufacturers using government testing procedures. The ratings are molded into the sidewall of the tire. See Uniform Tire Quality Grading on page 389.

Vehicle Capacity Weight: The number of designated seating positions multiplied by 150 lbs (68 kg) plus the rated cargo load. See Loading Your Vehicle on page 286.

Vehicle Maximum Load on the Tire: Load on an individual tire due to curb weight, accessory weight, occupant weight, and cargo weight.

Vehicle Placard: A label permanently attached to a vehicle showing the vehicle’s capacity weight and the original equipment tire size and recommended inflation pressure. See “Tire and Loading Information Label” under Loading Your Vehicle on page 286.

376

Inflation - Tire Pressure Tires need the correct amount of air pressure to operate effectively. Notice: Do not let anyone tell you that under-inflation or over-inflation is all right. It is not. If your tires do not have enough air (under-inflation), you can get the following: (cid:127) Too much flexing (cid:127) Too much heat (cid:127) Tire overloading (cid:127) Premature or irregular wear (cid:127) Poor handling (cid:127) Reduced fuel economy If your tires have too much air (over-inflation), you can get the following: (cid:127) Unusual wear (cid:127) Poor handling (cid:127) Rough ride (cid:127) Needless damage from road hazards

A Tire and Loading Information label is attached to the vehicle’s center pillar (B-pillar), below the driver’s door latch. This label shows your vehicle’s original equipment tires and the correct inflation pressures for your tires when they are cold. The recommended cold tire inflation pressure, shown on the label, is the minimum amount of air pressure needed to support your vehicle’s maximum load carrying capacity. For additional information regarding how much weight your vehicle can carry, and an example of the Tire and Loading Information label, see Loading Your Vehicle on page 286. How you load your vehicle affects vehicle handling and ride comfort, never load your vehicle with more weight than it was designed to carry. When to Check Check your tires once a month or more. Also check the tire pressure of the spare tire. If you have a compact spare tire, it should be at 60 psi (420 kPa). See Spare Tire on page 413 for additional information.

377

Tire Pressure Monitor System Your vehicle has a Tire Pressure Monitor System (TPMS). This system uses radio and sensor technology to check tire pressure levels. TPMS sensors are mounted onto each tire and wheel assembly on your vehicle, except the spare tire. The TPMS sensors monitor the air pressure in your vehicle’s tires and transmit the tire pressure readings to a receiver located in the vehicle. When a low tire pressure condition is detected, the TPMS will illuminate the low tire pressure warning light located in the instrument panel cluster, and at the same time display the LOW TIRE warning message on the Driver Information Center (DIC). The low tire pressure warning light and the LOW TIRE warning message appear at each ignition cycle until the tires are inflated to the correct inflation pressure.

How to Check Use a good quality pocket-type gage to check tire pressure. You cannot tell if your tires are properly inflated simply by looking at them. Radial tires may look properly inflated even when they are underinflated. Check the tire’s inflation pressure when the tires are cold. Cold means your vehicle has been sitting for at least three hours or driven no more than 1 mile (1.6 km). Remove the valve cap from the tire valve stem. Press the tire gage firmly onto the valve to get a pressure measurement. If the cold tire inflation pressure matches the recommended pressure on the Tire and Loading Information label, no further adjustment is necessary. If the inflation pressure is low, add air until you reach the recommended amount. If you overfill the tire, release air by pushing on the metal stem in the center of the tire valve. Recheck the tire pressure with the tire gage. Be sure to put the valve caps back on the valve stems. They help prevent leaks by keeping out dirt and moisture.

378

For additional information and details about the DIC operation and displays see DIC Controls and Displays on page 194 and DIC Warnings and Messages on page 198. You may notice, during cooler weather conditions, that the low tire pressure warning light and the DIC LOW TIRE message may come on when the vehicle is first started, and then turn off as you start to drive. This may be an early indicator that the air pressure in the tire(s) is getting low and needs to be inflated to the proper pressure. Each tire, including the spare (if provided), should be checked monthly when cold and inflated to the inflation pressure recommended by the vehicle manufacturer on the vehicle placard or tire inflation pressure label. (If your vehicle has tires of a different size than the size indicated on the vehicle placard or tire inflation pressure label, you should determine the proper tire inflation pressure for those tires.)

As an added safety feature, your vehicle has been equipped with a tire pressure monitoring system (TPMS) that illuminates a low tire pressure telltale when one or more of your tires is significantly under-inflated.

Accordingly, when the low tire pressure telltale illuminates, you should stop and check your tires as soon as possible, and inflate them to the proper pressure. Driving on a significantly under-inflated tire causes the tire to overheat and can lead to tire failure. Under-inflation also reduces fuel efficiency and tire tread life, and may affect the vehicle’s handling and stopping ability. Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driver’s responsibility to maintain correct tire pressure, even if under-inflation has not reached the level to trigger illumination of the TPMS low tire pressure telltale.

379

Your vehicle has also been equipped with a TPMS malfunction indicator to indicate when the system is not operating properly. The TPMS malfunction indicator is combined with the low tire pressure telltale. When the system detects a malfunction, the telltale will flash for approximately one minute and then remain continuously illuminated. This sequence will continue upon subsequent vehicle start-ups as long as the malfunction exists. When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure as intended. TPMS malfunctions may occur for a variety of reasons, including the installation of replacement or alternate tires or wheels on the vehicle that prevent the TPMS from functioning properly. Always check the TPMS malfunction telltale after replacing one or more tires or wheels on your vehicle to ensure that the replacement or alternate tires and wheels allow the TPMS to continue to function properly.

A Tire and Loading Information label, attached to your vehicle, shows the size of your vehicle’s original equipment tires and the correct inflation pressure for your vehicle’s tires when they are cold. See Loading Your Vehicle on page 286, for an example of the Tire and Loading Information label and its location on your vehicle. Also see Inflation - Tire Pressure on page 377 for additional information. Your vehicle’s TPMS can warn you about a low tire pressure condition but it does not replace normal tire maintenance. See Tire Inspection and Rotation on page 383, When It Is Time for New Tires on page 385, and Tires on page 369. Notice: Do not use a tire sealant if your vehicle has Tire Pressure Monitors. The liquid sealant can damage the tire pressure monitor sensors.

380

TPMS Sensor Identification Codes Each TPMS sensor has a unique identification code. Any time you replace one or more of the TPMS sensors or rotate your vehicle’s tires, the identification codes will need to be matched to the new tire/wheel position. The sensors are matched to the tire/wheel positions in the following order: driver’s side front tire, passenger’s side front tire, passenger’s side rear tire, and driver’s side rear tire using a TPMS diagnostic tool. See your dealer for service. The TPMS sensors may also be matched to each tire/wheel position by increasing or decreasing the tire’s air pressure. If increasing the tire’s air pressure, do not exceed the maximum inflation pressure indicated on the tire’s sidewall. You will have one minute to match the first tire/wheel position, and five minutes overall, to match all four tire/wheel positions.

If it takes longer than one minute, to match the first tire and wheel, or more than five minutes to match all four tire and wheel positions the matching process stops and you will need to start over. The TPMS sensor matching procedure is outlined below: 1. Set the parking brake. 2. Turn the ignition switch to ON with the

engine off.

3. Turn the exterior lamp switch from AUTO to

OFF four times within three seconds. A double horn chirp will sound and the TPMS low tire warning light starts flashing. The double horn chirp and flashing TPMS warning light indicates the TPMS matching process has started. The TPMS warning light should continue flashing throughout the matching procedure. The LOW TIRE message displays on the Driver Information Center (DIC).

4. Start with the driver’s side front tire.

381

5. Remove the valve cap from the valve cap

stem. Activate the TPMS sensor by increasing or decreasing the tire’s air pressure for 10 seconds, then stop and listen for a single horn chirp. The single horn chirp should sound within 15 seconds, confirming that the sensor identification code has been matched to this tire and wheel position. If you do not hear the confirming single horn chirp, turn the ignition switch to LOCK and start over beginning with Step 2. To let air-pressure out of a tire you can use the pointed end of the valve cap, a pencil-style air pressure gage, or a key.

6. Proceed to the passenger’s side front tire, and

repeat the procedure in Step 5.

7. Proceed to the passenger’s side rear tire, and

repeat the procedure in Step 5.

8. Proceed to the driver’s side rear tire, and

repeat the procedure in Step 5.

9. After hearing the confirming horn chirp for the driver side rear tire, check to see if the TPMS low tire warning light and the DIC LOW TIRE messages have turned off. If yes, the TPMS sensors have been relearned. Turn the ignition switch to LOCK. If the low tire warning light and the DIC SERV TPM messages are on after completing Step 5 for the driver side rear tire, the sensor relearn process has not been successful. Turn the ignition switch to LOCK and repeat the matching process beginning with Step 2.

10. Set all four tires to the recommended

air pressure level as indicated on the Tire and Loading Information label.

11. Put the valve caps back on the valve stems.

382

Federal Communications Commission (FCC) and Industry and Science Canada The Tire Pressure Monitor System (TPMS) operates on a radio frequency and complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: 1. This device may not cause harmful

interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

The Tire Pressure Monitor System (TPMS) operates on a radio frequency and complies with RSS-210 of Industry and Science Canada. Operation is subject to the following two conditions: 1. This device may not cause interference. 2. This device must accept any interference received, including interference that may cause undesired operation of the device.

Changes or modifications to this system by other than an authorized service facility could void authorization to use this equipment.

Tire Inspection and Rotation Tires should be rotated every 5,000 to 8,000 miles (8 000 to 13 000 km). Any time you notice unusual wear, rotate your tires as soon as possible and check wheel alignment. Also check for damaged tires or wheels. See When It Is Time for New Tires on page 385

and Wheel Replacement on page 390 for more information. Make sure the spare tire is stored securely. Push, pull, and then try to rotate or turn the tire. If it moves, use the wheel wrench to tighten the cable. See Changing a Flat Tire on page 394. The purpose of regular rotation is to achieve more uniform wear for all tires on the vehicle. The first rotation is the most important, see Scheduled Maintenance on page 437.383

{CAUTION:

Rust or dirt on a wheel, or on the parts to which it is fastened, can make wheel nuts become loose after time. The wheel could come off and cause an accident. When you change a wheel, remove any rust or dirt from places where the wheel attaches to the vehicle. In an emergency, you can use a cloth or a paper towel to do this; but be sure to use a scraper or wire brush later, if needed, to get all the rust or dirt off. See Changing a Flat Tire on page 394.

Any time you rotate the vehicle’s tires the Tire Pressure Monitor System (TPMS) will need to be reset. The TPMS identification codes will need to be matched to the tire and wheel position. See “TPMS Sensor Identification Codes” under Tire Pressure Monitor System on page 378.

When rotating your tires, always use one of the correct rotation patterns shown here. If your vehicle has a compact spare tire or a spare tire that does not match your vehicle’s road tires and wheels, in size and type, do not include the spare in the tire rotation. After the tires have been rotated, adjust the front and rear inflation pressures as shown on the Tire and Loading Information label. For the location of the Tire and Loading Information label see Loading Your Vehicle on page 286. Make certain that all wheel nuts are properly tightened, see “Wheel Nut Torque” under Capacities and Specifications on page 430 for the proper wheel nut torque specification.

384

When It Is Time for New Tires

One way to tell when it is time for new tires is to check the treadwear indicators, which will appear when your tires have only 1/16 inch (1.6 mm) or less of tread remaining. Some commercial truck tires may not have treadwear indicators.

You need a new tire if any of the following statements are true: (cid:127) You can see the indicators at three or more

places around the tire.

(cid:127) You can see cord or fabric showing through

the tire’s rubber.

(cid:127) The tread or sidewall is cracked, cut or

snagged deep enough to show cord or fabric.

(cid:127) The tire has a bump, bulge, or split. (cid:127) The tire has a puncture, cut, or other damage

that cannot be repaired well because of the size or location of the damage.

385

Buying New Tires GM has developed and matched specific tires for your vehicle. The original equipment tires installed on your vehicle, when it was new, were designed to meet General Motors Tire Performance Criteria Specification (TPC spec) system rating. If you need replacement tires, GM strongly recommends that you get tires with the same TPC Spec rating. This way, your vehicle will continue to have tires that are designed to give the same performance and vehicle safety, during normal use, as the original tires. GM’s exclusive TPC Spec system considers over a dozen critical specifications that impact the overall performance of your vehicle, including brake system performance, ride and handling, traction control, and tire pressure monitoring performance. GM’s TPC Spec number is molded onto the tire’s sidewall by the tire manufacturer. If the tires have an all-season tread design, the TPC spec number will be followed by an MS for mud and snow. See Tire Sidewall Labeling on page 370 for additional information.

386

{CAUTION:

Mixing tires could cause you to lose control of your vehicle while driving. If you mix tires of different sizes, brands, or types (radial and bias-belted tires), the vehicle may not handle properly, and you could have a crash. Using tires of different sizes, brands, or types may also cause damage to your vehicle. Be sure to use the correct size, brand, and type of tires on all wheels. Your vehicle may have a compact spare tire and wheel assembly. If the vehicle has a compact spare tire and wheel, they have the same overall diameter as your vehicle’s full-size tires and wheels.

CAUTION:

(Continued)

If you must replace your vehicle’s tires with those that do not have a TPC Spec number, make sure they are the same size, load range, speed rating, and construction type (radial and bias-belted tires) as your vehicle’s original tires. Your vehicle’s original equipment tires are listed on the Tire and Loading Information Label. This label is attached to the vehicle’s center pillar (B-pillar). See Loading Your Vehicle on page 286, for more information about the Tire and Loading Information Label and its location on your vehicle.

CAUTION:

(Continued)

Because they were designed and developed for use on your vehicle, it is all right to drive your vehicle with the compact spare installed properly. Compact spare tires are designed for temporary use only. See Spare Tire on page 413.

{CAUTION:

If you use bias-ply tires on your vehicle, the wheel rim flanges could develop cracks after many miles of driving. A tire and/or wheel could fail suddenly, causing a crash. Use only radial-ply tires with the wheels on your vehicle.

387

Different Size Tires and Wheels If you add wheels or tires that are a different size than your original equipment wheels and tires, this may affect the way your vehicle performs, including its braking, ride and handling characteristics, stability, and resistance to rollover. Additionally, if your vehicle has electronic systems such as, anti-lock brakes, traction control, and electronic stability control, the performance of these systems can be affected.

{CAUTION:

If you add different sized wheels, your vehicle may not provide an acceptable level of performance and safety if tires not recommended for those wheels are selected. You may increase the chance that you will crash and suffer serious injury. Only use GM specific wheel and tire systems developed for your vehicle, and have them properly installed by a GM certified technician.

See Buying New Tires on page 386 and Accessories and Modifications on page 316 for additional information.

388

Uniform Tire Quality Grading Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width. For example: Treadwear 200 Traction AA Temperature A The following information relates to the system developed by the United States National Highway Traffic Safety Administration (NHTSA), which grades tires by treadwear, traction, and temperature performance. This applies only to vehicles sold in the United States. The grades are molded on the sidewalls of most passenger car tires. The Uniform Tire Quality Grading (UTQG) system does not apply to deep tread, winter-type snow tires, space-saver, or temporary use spare tires, tires with nominal rim diameters of 10 to 12 inches (25 to 30 cm), or to some limited-production tires. While the tires available on General Motors passenger cars and light trucks may vary with respect to these grades, they must also conform to federal safety requirements and additional General Motors Tire Performance Criteria (TPC) standards.

Treadwear The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear one and a half (1.5) times as well on the government course as a tire graded 100. The relative performance of tires depends upon the actual conditions of their use, however, and may depart significantly from the norm due to variations in driving habits, service practices, and differences in road characteristics and climate. Traction – AA, A, B, C The traction grades, from highest to lowest, are AA, A, B, and C. Those grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance. Warning: The traction grade assigned to this tire is based on straight-ahead braking traction tests, and does not include acceleration, cornering, hydroplaning, or peak traction characteristics.

389

Temperature – A, B, C The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel. Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 109. Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law. Warning: The temperature grade for this tire is established for a tire that is properly inflated and not overloaded. Excessive speed, under-inflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.

Wheel Alignment and Tire Balance The tires and wheels on your vehicle were aligned and balanced carefully at the factory to give you the longest tire life and best overall performance. Adjustments to wheel alignment and tire balancing will not be necessary on a regular basis. However, if you notice unusual tire wear or your vehicle pulling to one side or the other, the alignment may need to be checked. If you notice your vehicle vibrating when driving on a smooth road, your tires and wheels may need to be rebalanced. See your dealer for proper diagnosis.

Wheel Replacement Replace any wheel that is bent, cracked, or badly rusted or corroded. If wheel nuts keep coming loose, the wheel, wheel bolts, and wheel nuts should be replaced. If the wheel leaks air, replace it (except some aluminum wheels, which can sometimes be repaired). See your dealer if any of these conditions exist.

390

Your dealer will know the kind of wheel you need. Each new wheel should have the same load-carrying capacity, diameter, width, offset and be mounted the same way as the one it replaces. If you need to replace any of your wheels, wheel bolts, or wheel nuts, replace them only with new GM original equipment parts. This way, you will be sure to have the right wheel, wheel bolts, and wheel nuts for your vehicle.

Notice: The wrong wheel can also cause problems with bearing life, brake cooling, speedometer or odometer calibration, headlamp aim, bumper height, vehicle ground clearance, and tire or tire chain clearance to the body and chassis. See Changing a Flat Tire on page 394 for more information. Used Replacement Wheels

{CAUTION:

Using the wrong replacement wheels, wheel bolts, or wheel nuts on your vehicle can be dangerous. It could affect the braking and handling of your vehicle, make your tires lose air and make you lose control. You could have a collision in which you or others could be injured. Always use the correct wheel, wheel bolts, and wheel nuts for replacement.

{CAUTION:

Putting a used wheel on your vehicle is dangerous. You cannot know how it has been used or how far it has been driven. It could fail suddenly and cause a crash. If you have to replace a wheel, use a new GM original equipment wheel.

391

Tire Chains

{CAUTION:

If your vehicle has P225/75R15, P265/75R15, P235/75R15, or P235/50R18

size tires, do not use tire chains. They can damage your vehicle because there is not enough clearance. Tire chains used on a vehicle without the proper amount of clearance can cause damage to the brakes, suspension, or other vehicle parts. The area damaged by the tire chains could cause you to lose control of your vehicle and you or others may be injured in a crash. Use another type of traction device only if its manufacturer recommends it for use on your vehicle and tire size combination and road conditions.CAUTION:

(Continued)

392

CAUTION:

(Continued)

Follow that manufacturer’s instructions. To help avoid damage to your vehicle, drive slowly, readjust, or remove the device if it is contacting your vehicle. Do not spin the vehicle’s wheels. If you do find traction devices that will fit, install them on the rear tires.

If your vehicle has a tire size other

Notice: than P225/75R15, P265/75R15, P235/75R15 or P235/50R18 use tire chains only where legal and only when you must. Use chains that are the proper size for your tires. Install them on the tires of the rear axle. Do not use chains on the tires of the front axle. Tighten them as tightly as possible with the ends securely fastened. Drive slowly and follow the chain manufacturer’s instructions. If you can hear the chains contacting your vehicle, stop and retighten them. If the contact continues, slow down until it stops. Driving too fast or spinning the wheels with chains on will damage your vehicle.

If a Tire Goes Flat It is unusual for a tire to blowout while you are driving, especially if you maintain your vehicle’s tires properly. If air goes out of a tire, it is much more likely to leak out slowly. But if you should ever have a blowout, here are a few tips about what to expect and what to do: If a front tire fails, the flat tire will create a drag that pulls the vehicle toward that side. Take your foot off the accelerator pedal and grip the steering wheel firmly. Steer to maintain lane position, and then gently brake to a stop well out of the traffic lane. A rear blowout, particularly on a curve, acts much like a skid and may require the same correction you would use in a skid. In any rear blowout remove your foot from the accelerator pedal. Get the vehicle under control by steering the way you want the vehicle to go. It may be very bumpy and noisy, but you can still steer. Gently brake to a stop, well off the road if possible.

{CAUTION:

Lifting a vehicle and getting under it to do maintenance or repairs is dangerous without the appropriate safety equipment and training. The jack provided with your vehicle is designed only for changing a flat tire. If it is used for anything else, you or others could be badly injured or killed if the vehicle slips off the jack. Use the jack provided with your vehicle only for changing a flat tire.

If a tire goes flat, the next part shows how to use the jacking equipment to change a flat tire safely.

393

CAUTION:

(Continued)

3. If you have a four-wheel-drive vehicle, be sure the transfer case is in a drive gear – not in NEUTRAL.

4. Turn off the engine and do not restart

while the vehicle is raised.

5. Do not allow passengers to remain in

the vehicle.

To be even more certain the vehicle will not move, put blocks at the front and rear of the tire farthest away from the one being changed. That would be the tire on the other side, at the opposite end of the vehicle.

Changing a Flat Tire If a tire goes flat, avoid further tire and wheel damage by driving slowly to a level place. Turn on your hazard warning flashers. See Hazard Warning Flashers on page 158 for more information.

{CAUTION:

Changing a tire can be dangerous. The vehicle can slip off the jack and roll over or fall on you or other people. You and they could be badly injured or even killed. Find a level place to change your tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly. 2. Put an automatic transmission shift lever in PARK (P), or shift a manual transmission to FIRST (1) or REVERSE (R).

CAUTION:

(Continued)

394

When your vehicle has a flat tire, use the following example as a guide to assist you in the placement of the wheel blocks.

Removing the Spare Tire and Tools The tools you will need are located under the passenger’s seat.

The following information will tell you next how to use the jack and change a tire.

Crew Cab

For crew cab models, the jack and wheel blocks are located under the driver’s side rear seat.

395

For regular and extended cab vehicles, the jack and wheel blocks are located under the cover at the center of the vehicle behind the front seats.

Regular/Extended Cab

To access the tools, do the following:

1. Move the seats

forward to access the cover.

Extended/Regular Cab

396

2. Turn the wing nut on the cover counterclockwise to remove it. For crew cab models, reach under the rear seat to access the jack and wheel blocks. To reinstall the jack and wheel block assembly in the mounting bracket, insert the tabs into the jack base by pushing the blocks up into the assembly. The outer hole in the jack base aligns with the tab on the bracket. When reinstalling, make sure the jack is secure, but do not overtighten the jack in the bracket. 3. Remove the wheel blocks and the wheel

block retainer by turning the wing nut counterclockwise.

4. Put the wheel blocks at the front and rear of

the tire farthest away from the one being changed. That would be the tire on the other side, at the opposite end of the vehicle.

5. Locate the wing nut used to retain the storage

bag and tools which is under the front passenger’s seat. Remove it by turning the wing nut counterclockwise.

You will use the jack handle extensions and the wheel wrench to remove the underbody-mounted spare tire.

A. Jack Handle Extensions B. Jack C. Extension Tool D. Wheel Wrench E. Wheel Blocks

1. Assemble the wheel wrench (D) and the jack

handle extensions (A).

2. Insert the hoist end (chiseled end) of the extension tool (C) through the hole in the rear bumper and into the funnel-shaped guide. The chiseled end of the extension is used to lower the spare tire.

397

3. Turn the wheel wrench (D) counterclockwise

to lower the spare tire to the ground. Continue to turn the wheel wrench until the spare tire can be pulled out from under the vehicle. If the spare tire does not lower to the ground, the secondary latch is engaged causing the tire not to lower. See Secondary Latch System on page 406.

Removing the Flat Tire and Installing the Spare Tire Use the following pictures and instructions to remove the flat tire and raise the vehicle.

The tools you will be using include the jack (A), the wheel blocks (B), the extension tool (C), the jack handle extensions (D), and the wheel wrench (E).

4. Tilt the retainer

when the tire has been lowered, and slide it up the cable so it can be pulled up through the wheel opening.

5. Put the spare tire near the flat tire.

398

1. Remove the center cap by placing the chisel end of the wheel wrench (E) into one of the slots on the wheel and gently prying the cap out.

2. Use the wheel wrench to loosen all the wheel

nuts by turning it counterclockwise. Do not remove the wheel nuts yet.

399

{CAUTION:

Getting under a vehicle when it is jacked up is dangerous. If the vehicle slips off the jack you could be badly injured or killed. Never get under a vehicle when it is supported only by a jack.

{CAUTION:

Raising your vehicle with the jack improperly positioned can damage the vehicle and even make the vehicle fall. To help avoid personal injury and vehicle damage, be sure to fit the jack lift head into the proper location before raising the vehicle.

400

Front Position

3. Position the jack (A) under the vehicle as

shown for the front or rear locations.

Front Position

Rear Position

If the flat tire is on the front of the vehicle, position the jack to the rear of the front tire in the pocket off of the frame.

If the flat tire is on the rear, position the jack under the rear axle and get as close as possible to the shock absorber.

4. Make sure the jack head is positioned so that the rear axle is resting securely between the grooves that are on the jack head.

5. Turn the wheel wrench clockwise to raise the vehicle. Raise the vehicle far enough off the ground so there is enough room for the spare tire to fit under the wheel well.

401

CAUTION:

(Continued)

The wheel could come off and cause an accident. When you change a wheel, remove any rust or dirt from the places where the wheel attaches to the vehicle. In an emergency, you can use a cloth or a paper towel to do this; but be sure to use a scraper or wire brush later, if needed, to get all the rust or dirt off.

7. Remove any rust or dirt from the wheel bolts, mounting surfaces and spare wheel.

6. Remove all the

wheel nuts and take off the flat tire.

{CAUTION:

Rust or dirt on the wheel, or on the parts to which it is fastened, can make the wheel nuts become loose after time.

CAUTION:

(Continued)

402

8. Install the spare tire.

{CAUTION:

Never use oil or grease on studs or nuts. If you do, the nuts might come loose. Your wheel could fall off, causing a serious accident.

9. Put the wheel nuts

back on with the rounded end of the nuts toward the wheel. Tighten each wheel nut by hand. Then use the wheel wrench to tighten the nuts until the wheel is held against the hub.

Front Position

403

{CAUTION:

Incorrect wheel nuts or improperly tightened wheel nuts can cause the wheel to come loose and even come off. This could lead to an accident. Be sure to use the correct wheel nuts. If you have to replace them, be sure to get new GM original equipment wheel nuts. Stop somewhere as soon as you can and have the nuts tightened with a torque wrench to the proper torque specification. See Capacities and Specifications on page 430

for wheel nut torque specification.Rear Position

10. Turn the wheel wrench counterclockwise to

lower the vehicle. Lower the jack completely.

404

Improperly tightened wheel nuts can

Notice: lead to brake pulsation and rotor damage. To avoid expensive brake repairs, evenly tighten the wheel nuts in the proper sequence and to the proper torque specification. See Capacities and Specifications on page 430 for the wheel nut torque specification.

When you reinstall the regular wheel and tire, you must also reinstall the center cap. Place the cap on the wheel and tap it into place until it seats flush with the wheel. The cap only goes on one way. Be sure to line up the tab on the center cap with the indentation on the wheel.

11. Tighten the wheel

nuts firmly in a crisscross sequence as shown by turning the wheel wrench clockwise.

405

Secondary Latch System Your vehicle has an underbody-mounted tire hoist assembly that has a secondary latch system. It is designed to stop the spare tire from suddenly falling off your vehicle. For the secondary latch to work, the spare must be installed with the valve stem pointing down. See Storing a Flat or Spare Tire and Tools on page 410.

{CAUTION:

Before beginning this procedure read all the instructions. Failure to read and follow the instructions could damage the hoist assembly and you and others could get hurt. Read and follow the instructions listed next.

406

To release the spare tire from the secondary latch, do the following:

1. Check under the

vehicle to see if the cable end fitting is visible.

2. If the cable end fitting is not visible, proceed

to Step 6. If it is visible, first try to tighten the cable by turning the wheel wrench clockwise until you hear two clicks or feel it skip twice. You cannot overtighten the cable.

3. Loosen the cable by turning the wheel wrench

counterclockwise three or four turns.

4. Repeat this procedure at least two times. If the spare tire lowers to the ground, continue with Step 5 under Removing the Spare Tire and Tools on page 395.

5. Turn the wrench counterclockwise until approximately 6 inches (15 cm) of cable is exposed.

6. Stand the wheel blocks on their shortest ends,

with the backs facing each other.

7. Place the bottom

edge of the jack (A) on the wheel blocks (B), separating them so that the jack is balanced securely.

8. Attach the jack handle, extension, and wheel

wrench to the jack and place it (with the wheel blocks) under the vehicle towards the front of the rear bumper. Position the center lift point of the jack under the wheel.

9. Turn the wheel wrench clockwise to raise the

jack until it lifts the tire.

10. Continue raising the jack until the tire stops moving upward and is held firmly in place, the secondary latch has released, and the tire is balancing on the jack.

407

12. Reinsert the jack handle into the jack.

Lower the jack by turning the wheel wrench counterclockwise. Keep lowering the jack until the spare tire slides off the jack or is hanging by the cable.

{CAUTION:

Someone standing too close during the procedure could be injured by the jack. If the spare tire does not slide off the jack completely, make sure no one is behind you or on either side of you as you pull the jack out from the under spare.

11. Remove the jack handle and insert the hoist end of the extension through the hole in the rear bumper. Turn the wheel wrench counterclockwise one turn or until the wheel retainer assembly is disengaged.

408

13. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push against the spare while firmly pulling the jack out from under the spare tire with the other hand. If the spare tire is hanging from the cable, insert the hoist end of the extension into the hoist shaft hole in the bumper and turn the wheel wrench counterclockwise to lower the spare the rest of the way.

14. Tilt the tire retainer at the end of the cable and pull it through the wheel opening. Pull the tire out from under the vehicle.

15. If the cable is hanging under the vehicle, turn

the wheel wrench clockwise to raise the cable. Have the hoist assembly inspected as soon as you can. You will not be able to store a spare or flat tire using the hoist assembly until it has been replaced.

To continue changing the flat tire, see Removing the Flat Tire and Installing the Spare Tire on page 398.

409

Storing a Flat or Spare Tire and Tools

{CAUTION:

Storing a jack, a tire, or other equipment in the passenger compartment of the vehicle could cause injury. In a sudden stop or collision, loose equipment could strike someone. Store all these in the proper place.

Notice: Storing an aluminum wheel with a flat tire under your vehicle for an extended period of time or with the valve stem pointing up may damage the wheel. Always stow the wheel with the valve stem pointing down and have the wheel/tire repaired as soon as possible.

410

Store the tire under the rear of the vehicle in the spare tire carrier. Use the following art and text to help you. 1. Put the tire on the ground at the rear of the

vehicle with the valve stem pointed down.

2. Tilt the retainer downward and through the

wheel opening. Make sure the retainer is fully seated across the underside of the wheel.

3. Attach the wheel wrench and extensions

together as shown.

4. Insert the hoist end of the extension through

the hole in the rear bumper and into the funnel-shaped guide.

5. Turn the wheel wrench clockwise to raise the

tire part way up. Make sure the retainer is seated in the wheel opening and the valve stem is pointed down.

6. Raise the tire fully against the underside of

the vehicle by turning the wheel wrench clockwise until you feel it skip twice. You cannot overtighten the cable.

411

To store the tools, do the following: 1. Return the wheel wrench, jack extensions and

the storage bag to the locations described under Removing the Spare Tire and Tools on page 395.

2. Install the wheel blocks first. Then install

the jack.

3. Secure the items in the vehicle as shown next.

7. Make sure the tire is stored securely. Push,

pull (A), and then try to turn (B) the tire. If the tire moves, check to make sure the tire valve stem is pointing down, then use the wheel wrench to loosen and then tighten the cable.

412

Crew Cab

A. Jack B. Wheel Blocks C. Wing Nut

A. Jack B. Wheel Blocks C. Wing Nut

Regular/Extended Cab

Spare Tire Compact Spare Tire Your vehicle may have a compact spare tire. Although the compact spare tire was fully inflated when your vehicle was new, it can lose air over time. Check the inflation pressure regularly. It should be 60 psi (420 kPa). Notice: and the compact spare tire is installed on your vehicle, do not drive in four-wheel drive until you can have your flat tire repaired and/or

If your vehicle has four-wheel drive

replaced. You could damage your vehicle, and the repair costs would not be covered by your warranty. Never use four-wheel drive when the compact spare tire is installed on your vehicle. After installing the compact spare on your vehicle, you should stop as soon as possible and make sure your vehicle’s spare tire is correctly inflated. The compact spare is made to perform well at speeds up to 62 mph (100 km/h) for distances up to 500 miles (804 km).For heavy payloads or towing, and for low traction or four-wheel-drive conditions, repair or replace the full-size tire. Of course, it is best to replace your vehicle’s spare with a full-size tire as soon as you can. The spare tire will last longer and be in good shape in case you need it again. Notice: When the compact spare is installed, do not take your vehicle through an automatic car wash with guide rails. The compact spare can get caught on the rails. That can damage the tire and wheel, and maybe other parts of your vehicle. Do not use your compact spare on other vehicles.

413

And do not mix your compact spare tire or wheel with other wheels or tires. They will not fit. Keep your spare tire and its wheel together. Notice: Tire chains will not fit your compact spare. Using them can damage your vehicle and can damage the chains too. Do not use tire chains on your compact spare. Full-Size Spare Tire Your vehicle may have a full-size spare tire, which, when new, was fully inflated. A spare tire may lose air over time, so check its inflation pressure regularly. See Inflation - Tire Pressure on page 377 and Loading Your Vehicle on page 286

for information regarding proper tire inflation and loading your vehicle. For instruction on how to remove, install, or store a spare tire, see Removing the Flat Tire and Installing the Spare Tire on page 398 and Storing a Flat or Spare Tire and Tools on page 410.If your vehicle has four-wheel drive

Your vehicle may have a different size spare tire than the road tires originally installed on your vehicle. This spare was developed for use on your vehicle, so it is alright to drive on it. If your vehicle has four-wheel drive and the different size spare tire is installed, keep the vehicle in two-wheel drive. Notice: and the different size spare tire is installed on your vehicle, do not drive in four-wheel drive until you can have your flat tire repaired and/or replaced. You could damage your vehicle, and the repair costs would not be covered by your warranty. Never use four-wheel drive when the different size spare tire is installed on your vehicle. After installing the spare tire on your vehicle, you should stop as soon as possible and make sure the spare is correctly inflated. The spare tire is made to perform well at speeds up to 62 mph (100 km/h) for distances up to 500 miles (804 km).

414

For heavy payloads or towing, and for low traction or four-wheel-drive conditions, repair or replace the full-size tire. Have the damaged or flat road tire repaired or replaced as soon as you can and installed back onto your vehicle. This way, the spare tire will be available in case you need it again. Do not mix tires and wheels of different sizes, because they will not fit. Keep your spare tire and its wheel together. Appearance Care

Cleaning the Inside of Your Vehicle Your vehicle’s interior will continue to look its best if it is cleaned often. Although not always visible, dust and dirt can accumulate on your upholstery. Dirt can damage carpet, fabric, leather, and plastic surfaces. Regular vacuuming is recommended to remove particles from your upholstery. It is important to keep your upholstery from becoming and remaining heavily soiled. Soils should be removed as quickly as possible. Your vehicle’s interior may experience extremes of heat that could cause stains to set rapidly.

Lighter colored interiors may require more frequent cleaning. Use care because newspapers and garments that transfer color to your home furnishings may also transfer color to your vehicle’s interior. When cleaning your vehicle’s interior, only use cleaners specifically designed for the surfaces being cleaned. Permanent damage may result from using cleaners on surfaces for which they were not intended. Use glass cleaner only on glass.Remove any accidental over-spray from other surfaces immediately. To prevent over-spray, apply cleaner directly to the cleaning cloth. Notice: cleaning glass surfaces on your vehicle, you could scratch the glass. When cleaning the glass on your vehicle, use only a soft cloth and glass cleaner. Many cleaners contain solvents that may become concentrated in your vehicle’s breathing space. Before using cleaners, read and adhere to all safety instructions on the label. While cleaning your vehicle’s interior, maintain adequate ventilation by opening your vehicle’s doors and windows.

If you use abrasive cleaners when

415

Dust may be removed from small buttons and knobs using a small brush with soft bristles. Your GM dealer has a product for cleaning your vehicle’s glass. Should it become necessary, you can also obtain a product from your GM dealer to remove odors from your vehicle’s upholstery. Do not clean your vehicle using the following cleaners or techniques: (cid:127) Never use a knife or any other sharp object to

remove a soil from any interior surface.

(cid:127) Never use a stiff brush. It can cause damage

to your vehicle’s interior surfaces. (cid:127) Never apply heavy pressure or rub

aggressively with a cleaning cloth. Use of heavy pressure can damage your interior and does not improve the effectiveness of soil removal.

(cid:127) Use only mild, neutral-pH soaps. Avoid

laundry detergents or dishwashing soaps with degreasers. Using too much soap will leave a residue that leaves streaks and attracts dirt. For liquid cleaners, about 20 drops per gallon (3.78 L) of water is a good guide.

416

(cid:127) Do not heavily saturate your upholstery while

cleaning.

(cid:127) Damage to your vehicle’s interior may result from the use of many organic solvents such as naptha, alcohol, etc.

Fabric/Carpet Use a vacuum cleaner with a soft brush attachment frequently to remove dust and loose dirt. A canister vacuum with a beater bar in the nozzle may only be used on floor carpet and carpeted floor mats. For soils, always try to remove them first with plain water or club soda. Before cleaning, gently remove as much of the soil as possible using one of the following techniques: (cid:127) For liquids: gently blot the remaining soil

with a paper towel. Allow the soil to absorb into the paper towel until no more can be removed.

(cid:127) For solid dry soils: remove as much as

possible and then vacuum.

Leather A soft cloth dampened with water may be used to remove dust. If a more thorough cleaning is necessary, a soft cloth dampened with a mild soap solution can be used. Allow the leather to dry naturally. Do not use heat to dry. Never use steam to clean leather. Never use spot lifters or spot removers on leather. Many commercial leather cleaners and coatings that are sold to preserve and protect leather may permanently change the appearance and feel of your leather and are not recommended. Do not use silicone or wax-based products, or those containing organic solvents to clean your vehicle’s interior because they can alter the appearance by increasing the gloss in a non-uniform manner. Never use shoe polish on your leather.

To clean, use the following instructions: 1. Saturate a lint-free, clean white cloth with

water or club soda.

2. Wring the cloth to remove excess moisture. 3. Start on the outside edge of the soil and gently

rub toward the center. Continue cleaning, using a clean area of the cloth each time it becomes soiled.

4. Continue to gently rub the soiled area until the

cleaning cloth remains clean.

5. If the soil is not completely removed, use a mild soap solution and repeat the cleaning process that was used with plain water.

If any of the soil remains, a commercial fabric cleaner or spot lifter may be necessary. When a commercial upholstery cleaner or spot lifter is to be used, test a small hidden area for colorfastness first. If the locally cleaned area gives any impression that a ring formation may result, clean the entire surface. After the cleaning process has been completed, a paper towel can be used to blot excess moisture from the fabric or carpet.

417

Instrument Panel, Vinyl, and Other Plastic Surfaces A soft cloth dampened with water may be used to remove dust. If a more thorough cleaning is necessary, a clean soft cloth dampened with a mild soap solution can be used to gently remove dust and dirt. Never use spot lifters or removers on plastic surfaces. Many commercial cleaners and coatings that are sold to preserve and protect soft plastic surfaces may permanently change the appearance and feel of your interior and are not recommended. Do not use silicone or wax-based products, or those containing organic solvents to clean your vehicle’s interior because they can alter the appearance by increasing the gloss in a non-uniform manner. Some commercial products may increase gloss on your instrument panel. The increase in gloss may cause annoying reflections in the windshield and even make it difficult to see through the windshield under certain conditions.

Care of Safety Belts Keep belts clean and dry.

{CAUTION:

Do not bleach or dye safety belts. If you do, it may severely weaken them. In a