- Download PDF Manual

-

holes are worn oversize or damaged. Do not attempt to salvage a worn fork. Replace shift fork roll pins if necessary or if doubt exists about their condition.

The all bearings for wear, roughness, flat spots, pitting or other damage. Replace the bearings if nec- essary.

Inspect the blocker rings and fiction cones. replace either part if worn or damaged in any way. Replace if the friction material is burned, flaking off or worn.

Inspect synchro components wear or damage.

Replace parts if worn, cracked or distorted.

Inspect all of the thrust washers and locating pins. Replace the pins if bent or worn. Replace the wash- ers if worn or the locating pin notches are distorted. Inspect the case and housing/adapter sealing and mating surfaces are free of burrs and nicks. Inspcet

MANUAL TRANSMISSION - NV4500

21 - 61

DR MANUAL TRANSMISSION - NV4500 (Continued)

the alignment dowels in the case top surface and in the housing/adapter are tight and in good condition. Replace the gear case or housing/adapter if cracked or broken.

ASSEMBLY

NOTE: Gaskets are not used in the transmission. Use Mopar Silicone Sealer or equivalent on all gear case and extension housing sealing surfaces.

COUNTERSHAFT AND REVERSE IDLER GEAR

(1) Install countershaft front bearing cup in case

with Handle C-4171 and Installer 6061-1.

(2) Install

front bearing on countershaft with

Installer C-4340 (Fig. 66).

Fig.67COUNTERSHAFTINGEARCASE

1 - GEAR CASE 2 - COUNTERSHAFT

(6) Lubricate reverse idler gear bearings with petroleum jelly and install first bearing and second bearing (Fig. 68).

(7) Install idler gear front thrust washer on boss in gear case (Fig. 68). Coat thrust washer with lib- eral quantity of petroleum jelly to hold it in place.

Fig.66COUNTERSHAFTFRONTBEARING

1 - FRONT BEARING 2 - INSTALLER 3 - COUNTERSHAFT

(3) Lubricate countershaft front bearing cup and

cone with petroleum jelly.

(4) Position gear case on end with rear of case fac-

ing up (Fig. 67).

(5) Install countershaft in gear case (Fig. 67).

NOTE: Do not install rear countershaft bearing on countershaft at this time.

Fig.68IDLERGEARFRONTTHRUSTWASHER

1 - IDLER GEAR FRONT THRUST WASHER ON BOSS

21 - 62 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)(8) Install reverse idler gear in case (Fig. 69). (9) Install idler gear rear thrust washer between

idler gear and case boss (Fig. 69).

DR

Fig.69IDLERGEAR

1 - REAR THRUST WASHER 2 - REVERSE IDLER GEAR 3 - FRONT THRUST WASHER

(10) Align idler gear bearings and thrust washers

with a drift.

(11) Install reverse idler shaft with notched end of

shaft facing countershaft (Fig. 70).

Fig.70REVERSEIDLERSHAFT

1 - COUNTERSHAFT 2 - SHAFT NOTCH 3 - REVERSE IDLER SHAFT

(12) Lift countershaft upward and position wood

block between front of shaft and case (Fig. 71).

(13) Install rear bearing cone on countershaft with

Installer C-4040 (Fig. 72).

(14) Remove wood block from under countershaft and lower countershaft front bearing into front bear- ing cup.

Fig.71SUPPORTINGCOUNTERSHAFT

1 - COUNTERSHAFT 2 - WOOD BLOCK

Fig.72COUNTERSHAFTREARBEARING

1 - INSTALLER 2 - REAR BEARING 3 - COUNTERSHAFT

(15) Lubricate countershaft rear bearing cup and

cone with petroleum jelly.

(16) Install countershaft rear bearing cup in gear case and over rear bearing (Fig. 73). Tap cup into place with plastic mallet if necessary.

(17) Install countershaft rear bearing plate (Fig.

74).

NOTE: Verify plate is seated in notch in reverse idler shaft before tightening bearing plate bolts.

DR MANUAL TRANSMISSION - NV4500 (Continued)

MANUAL TRANSMISSION - NV4500

21 - 63

Fig.73COUNTERSHAFTREARBEARINGCUP

1 - COUNTERSHAFT REAR BEARING CUP

Fig.75COUNTERSHAFTFRONTBEARINGCAP

1 - FRONT BEARING CAP

Fig.74COUNTERSHAFTREARBEARINGPLATE 1 - COUNTERSHAFT 2 - REAR BEARING PLATE 3 - IDLER SHAFT

(18) Apply Mopar silicone adhesive/sealer or equiv- alent to flange and lip of new cap. Install new front bearing cap in gear case (Fig. 75) with Handle C-4171 and Installer C-3972-A.

COUNTERSHAFT END PLAY

Fig.76MEASURINGCOUNTERSHAFTENDPLAY 1 - DIAL INDICATOR 2 - COUNTER SHAFT 3 - INDICATOR MOUNTING ARM AND BASE

(1) Rotate countershaft 4-5 times to seat bearings. (2) Mount dial indicator on case. Then position indicator plunger on end of countershaft and zero dial indicator (Fig. 76).

(3) Raise countershaft with screwdriver and note end play reading on dial indicator. End play should be 0.051 - 0.15 mm (0.002 - 0.006 in.).

(4) Remove countershaft rear bearing plate. (5) Install a end play shim that will provide mini- mum countershaft end play. Position shim on rear bearing cup (Fig. 77).

Fig.77COUNTERSHAFTENDPLAYSHIM

1 - REAR BEARING CUP 2 - END PLAY SHIM (SELECTIVE)

21 - 64 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)DR

NOTE: Four of these snap rings are used to secure various components on the mainshaft 1-2 synchro hub. The snap rings are all the same size and are interchangeable.

(6) Install countershaft rear bearing plate (Fig.

74).

NOTE: Verify plate is seated in reverse idler shaft notch and end play shims are still in position before installing bolts.

(7) Apply 1-2 drops Mopar Loc N’ Seal or equiva- lent to threads of rear bearing plate bolts. Then install and tighten bearing plate bolts to 23 N·m (200

in. lbs.).SHIFT LUG AND RAIL

(1) Lubricate shift lug and rail with Castrolt Syn-

torq or equivalent.

(2) Insert shift lug rail part way into case. (3) Install shift lug on rail. (4) Position shift rail so roll pin notches are

toward outside of case (Fig. 78).

(5) Install roll pin that secures lug to rail (Fig. 78).

Fig.79FIRSTGEARBEARINGANDSNAPRING

1 - SNAP RING 2 - FIRST GEAR BEARING 3 - MAINSHAFT SYNCHRO HUB

(2) Install first gear clutch cone on mainshaft 1-2

synchro hub with recessed side of cone facing front (Fig. 80). Verify cone is seated against snap ring on hub.Fig.78SHIFTLUGANDRAIL

1 - NOTCHES (FOR 5TH GEAR SHIFT FORK ROLL PINS) 2 - LUG RAIL 3 - ROLL PIN HOLE 4 - SHIFT LUG

MAINSHAFT AND GEARTRAIN

CAUTION: The reverse, 1-2 and 3-4 synchro compo- nents can be assembled and installed incorrectly. Follow assembly procedures for component identi- fication and location.

Lubricate mainshaft bearing surfaces and all bear- ing assemblies with Castrolt Syntorq or with petro- leum jelly.

(1) Install first snap ring in rear most groove of mainshaft hub (Fig. 79). This snap ring locates first gear clutch gear on shaft.

Fig.80FIRSTGEARCLUTCHCONE

1 - MAINSHAFT 1-2 SYNCHRO HUB 2 - FIRST GEAR CLUTCH CONE

DR MANUAL TRANSMISSION - NV4500 (Continued)

(3) Install snap ring on mainshaft 1-2 synchro hub to secure clutch cone (Fig. 81). Verify snap ring is seated in hub groove and against clutch cone.

MANUAL TRANSMISSION - NV4500

21 - 65

Fig.821-2SYNCHROSLEEVEONHUB

1 - ALIGN WIDE SLOT IN SLEEVE WITH WIDE SPLINE OF HUB 2 - 1-2 SLEEVE AND HUB

Fig.81FIRSTGEARCLUTCHCONESNAPRING

1 - FIRST GEAR CLUTCH CONE 2 - MAINSHAFT 1-2 SYNCHRO HUB 3 - CLUTCH CONE SNAP RING

(4) Support mainshaft in upright position to install remaining gears, snap rings and synchro compo- nents. Shaft can be supported in gear case or hole can be cut in workbench to support shaft.

(5) If 1-2 synchro hub and sleeve were disassem- bled for service, reassemble hub, sleeve, struts and springs as follows:

(a) Align and install sleeve on hub. Rotate sleeve until it slides onto hub. Sleeve only fits one way and will easily slide onto hub when long slot in sleeve, aligns with long shoulder on hub (Fig. 82). (b) Place wood blocks under hub that will raise hub about 3.5 cm (1.375 in.) above surface of work- bench. Then allow sleeve to drop down on hub (Fig. 83).

(c) Install springs and struts in hub (Fig. 83). Use lots of petroleum jelly to hold them in place. Then compress struts with your fingers and move sleeve upward until struts are started in sleeve. Verify that struts are engaged in sleeve before pro- ceeding.

(d) Turn synchro assembly upright. Then move sleeve into neutral position on hub and work struts into sleeve at same time. Be sure struts are seated and springs are not displaced during assembly.

Fig.831-2SYNCHROSTRUTSANDSPRINGS

1 - WOOD BLOCKS 2 - HUB 3 - SLEEVE 4 - STRUTS AND SPRINGS (4 EACH)

21 - 66 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)DR

(6) Install first gear stop ring in 1-2 synchro hub and sleeve (Fig. 84). Verify stop ring is seated and engaged in hub and sleeve.

(8) Install snap ring that secures 1-2 synchro on mainshaft hub (Fig. 86). Verify snap ring is seated in groove in mainshaft hub.

Fig.84FIRSTGEARSTOPRINGINSYNCHROHUB (7) Install 1-2 synchro assembly and stop ring on mainshaft with the taper on the sleeve facing for- ward. (Fig. 85).

Fig.861-2SYNCHROSNAPRING

1 - SYNCHRO SNAP RING 2 - 1-2 SYNCHRO ASSEMBLY 3 - MAINSHAFT HUB

(9) Assemble second gear clutch cone, clutch ring

and stop ring (Fig. 87).

Fig.851-2SYNCHRO

1 - MAINSHAFT HUB 2 - 1-2 SYNCHRO ASSEMBLY 3 - TAPERED SIDE OF SLEEVE

Fig.87SECONDGEARCLUTCHCONE,CLUTCH

RINGANDSTOPRING

1 - STOP RING 2 - CLUTCH RING 3 - CLUTCH CONE

DR MANUAL TRANSMISSION - NV4500 (Continued)

MANUAL TRANSMISSION - NV4500

21 - 67

(10) Install assembled second gear clutch cone and rings on mainshaft and in 1-2 synchro hub (Fig. 88).

(12) Install second gear bearing on mainshaft (Fig.

90).

Fig.88SECONDGEARCLUTCHCONE,CLUTCH

Fig.90SECONDGEARBEARING

RINGANDSTOPRING

1 - SECOND GEAR BEARING

1 - CLUTCH CONE 2 - STOP RING 3 - CLUTCH RING

(11) Install snap ring that secures second gear clutch cone on mainshaft (Fig. 89). Use narrow blade screwdriver to work snap ring into hub groove as shown. Verify snap ring is seated in mainshaft groove.

NOTE: If snap ring will not fit in groove, clutch cone is slightly misaligned.

(13) Install second gear on mainshaft and bearing. Rotate gear until tabs of second gear clutch ring are seated in tab slots in gear (Fig. 91).

Fig.91SECONDGEAR

1 - SECOND GEAR 2 - CLUTCH RING TABS 3 - TAB SLOTS (IN GEAR)

Fig.89SECONDGEARCLUTCHCONESNAPRING 1 - SCREWDRIVER 2 - MAINSHAFT HUB 3 - SNAP RING 4 - SECOND GEAR CLUTCH CONE

21 - 68 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)(14) Install thrust washer pin in shaft (Fig. 92).

DR

Fig.92THRUSTWASHERPIN

1 - THRUST WASHER PIN 2 - SECOND GEAR

(15) Install second gear

thrust washer. Verify

washer is seated on gear and pin (Fig. 93).

Fig.94SNAPRINGANDTHIRD

1 - SECOND GEAR THRUST WASHER 2 - THRUST WASHER SNAP RING 3 - THIRD GEAR BEARING SPACER

Fig.93SECONDGEARTHRUSTWASHER

1 - THIRD GEAR BEARING

Fig.95THIRDGEARBEARING

1 - SECOND GEAR 2 - SECOND GEAR THRUST WASHER 3 - LOCATING PIN IN WASHER NOTCH

(16) Install second gear thrust washer snap ring (Fig. 94). Verify snap ring is seated in mainshaft groove.

(17) Install third gear bearing spacer on shaft and

seat it against thrust washer snap ring (Fig. 94).

(18) Install third gear bearing on mainshaft (Fig.

95). Bearing should be flush with mainshaft hub.

NOTE: If bearing is not flush with hub, the bearing spacer or snap ring was not installed.

(19) Install third gear over bearing and onto main-

shaft (Fig. 96).

Fig.96THIRDGEAR

1 - THIRD GEAR

DR MANUAL TRANSMISSION - NV4500 (Continued)

MANUAL TRANSMISSION - NV4500

21 - 69

(20) Install synchro stop ring on third gear (Fig.

97). Verify stop ring is seated on cone taper.

(22) Start 3-4 synchro assembly on mainshaft with the hub groove and sleeve groove both facing for- ward. Tap assembly onto shaft splines until hub is about 3 mm (0.125 in.) away from third gear stop ring. Then align stop ring with synchro sleeve and hub and seat synchro assembly with Installer C-4040

(Fig. 99).Fig.97THIRDGEARSTOPRING

1 - SYNCHRO STOP RING 2 - THIRD GEAR

(21) If 3-4 synchro was disassembled for service,

reassemble synchro components as follows:

(a) Align and install synchro sleeve on hub (Fig. 98). Front side of hub has a narrow groove machined in it. (b) Insert all

three synchro struts

in slots

machined in sleeve and hub (Fig. 98).

(c) Install and seat synchro springs (Fig. 98). Use screwdriver to compress springs and seat them in struts and hub as shown.

Fig.98SYNCHROASSEMBLY(3-4)

1 - STRUT (3) 2 - SPRING (3) 3 - 3-4 SLEEVE 4 - 3-4 HUB

Fig.99SEATING3-4SYNCHROASSEMBLYON

MAINSHAFT

1 - 3-4 SYNCHRO HUB 2 - HUB GROOVE 3 - INSTALLER C-4040

(23) Verify 3-4 synchro hub is seated on shaft with approximately 3 mm (0.125 in.) of shaft spline visi- ble.

NOTE: If hub is not seated, stop ring lugs are mis- aligned. Rotate ring until lugs are engaged in 3-4

hub slots.(24) Verify that second and third gear rotate freely at this point. If not, determine the cause and correct.

(25) Invert mainshaft in case or bench. (26) Install first gear bearing on mainshaft. (27) Install first gear on shaft with clutch hub side of gear facing the front of shaft (Fig. 100). Verify tabs on clutch ring are aligned and seated in first gear hub.

NOTE: 1-2 synchro hub will not seat properly if clutch ring tabs are misaligned.

21 - 70 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)DR

(28) Install reverse clutch gear on first gear (Fig.

100). Verify clutch gear is seated on shaft splines.

(29) Install reverse clutch gear snap ring with heavy duty snap ring pliers (Fig. 100). Verify snap ring is seated in groove.

NOTE: Reverse gear will not fit properly if snap ring is not seated.

Fig.102REVERSEGEARBEARINGANDSPACER 1 - REVERSE GEAR BEARING 2 - BEARING SPACER 3 - FIRST GEAR

CAUTION: The reverse sleeve will fit either way on the hub. Verify tapered side of the sleeve faces rearward.

Fig.100FIRSTGEARANDCLUTCHGEAR

1 - FIRST GEAR 2 - REVERSE CLUTCH GEAR SNAP RING 3 - REVERSE CLUTCH GEAR

(30) Install stop ring on clutch cone (Fig. 101). Ver-

ify stop ring is seated on cone taper.

Fig.101CLUTCHGEARSTOPRING

1 - REVERSE GEAR STOP RING 2 - CLUTCH GEAR 3 - FIRST GEAR

(31) Install reverse gear bearing spacer on main- shaft and seat against reverse clutch gear snap ring (Fig. 102).

(32) Install reverse gear bearing on mainshaft

(Fig. 102).

(33) If reverse gear sleeve and struts were disas- sembled for service, reassemble sleeve, struts and springs as follows:

(a) Position sleeve on hub so tapered side of

sleeve faces rearward. (Fig. 103).

(b) Rotate sleeve to align teeth on sleeve and hub. Sleeve will slide easily into place on hub when properly aligned.

(c) Install springs in gear hub (Fig. 103). Use petroleum jelly to hold springs in place if desired. (d) Compress first spring with flat blade screw- driver and slide strut into position in hub slot. Then work spring into seat in strut with small hooked tool or screwdriver.

Fig.103REVERSEGEARSYNCHROASSEMBLY

1 - REVERSE GEAR 2 - SLEEVE 3 - SPRING (3) 4 - STRUT (3) 5 - HUB

DR MANUAL TRANSMISSION - NV4500 (Continued)

MANUAL TRANSMISSION - NV4500

21 - 71

(e) Install second and third struts in same man-

ner as described in step (d).

(f) Work sleeve upward on hub until struts are centered and seated in sleeve. Sleeve should be in neutral position after seating struts. (34) Install reverse gear and synchro assembly on mainshaft (Fig. 104). Rotate assembly until stop ring lugs engage in hub slots and gear drops into seated position.

Fig.106MAINSHAFTREARBEARING

1 - INSTALLER 2 - MAINSHAFT REAR BEARING

Fig.104REVERSEGEAR 1 - REVERSE GEAR AND SYNCHRO ASSEMBLY

(35) Install reverse gear thrust washer (Fig. 105).

Fig.107FOURTHGEARSTOPRING

1 - 3-4 SYNCHRO SLEEVE 2 - FOURTH SPEED STOP RING

Fig.105REVERSEGEARTHRUSTWASHER

1 - THRUST WASHER 2 - REVERSE GEAR

(36) Install

on mainshaft with Installer 6446. Seat bearing on output shaft and against thrust washer (Fig. 106).

rear bearing

(37) Install fourth gear stop ring in 3-4 synchro

(38) Install fourth gear clutch gear in stop ring

sleeve (Fig. 107).

(Fig. 108).

(39) Roll gear case onto its left side. (40) Grip mainshaft at pilot bearing hub and just behind reverse gear. Then lift assembly and guide rear of shaft through bearing bore at rear of case.

(41) Continue holding front of shaft but switch grip at rear to shaft output splines. Lift mainshaft assembly slightly, align gears and seat assembly in case.

Fig.108FOURTHGEARCLUTCHGEAR

1 - FOURTH SPEED CLUTCH GEAR

21 - 72 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)(42) Set transmission case upright (Fig. 109).

DRIVE GEAR AND RETAINER

DR

(1) Install bearing on drive gear with Installer

6448 (Fig. 111).

Fig.111FRONTBEARINGONDRIVEGEAR

1 - INSTALLER 2 - BEARING 3 - DRIVE GEAR

(2) Lubricate pilot bearing with petroleum jelly

and install it in drive gear bore.

(3) Install drive gear on mainshaft. Work gear rearward until mainshaft hub is seated in pilot bear- ing.

(4) Install bearing cup in front retainer with Han-

dle C-4171 and Installer C-4308 (Fig. 112).

Fig.109MAINSHAFTANDGEARTRAININCASE

1 - MAINSHAFT AND GEARTRAIN 2 - FOURTH SPEED CLUTCH GEAR

(43) Install drive gear thrust bearing on mainshaft (Fig. 110). Use plenty of petroleum jelly to hold bear- ing in place.

(44) Check alignment and mesh of mainshaft gears. If gears are not aligned, roll case on side and realign shaft and gears in case.

Fig.110DRIVEGEARTHRUSTBEARING

1 - MAINSHAFT 2 - DRIVE GEAR THRUST BEARING

Fig.112FRONTBEARINGCUPINRETAINER

1 - INSTALLER 2 - HANDLE 3 - WOOD BLOCKS 4 - RETAINER

DR MANUAL TRANSMISSION - NV4500 (Continued)

MANUAL TRANSMISSION - NV4500

21 - 73

(5) Install new oil seal in front bearing retainer with Installer 6052 (Fig. 113). Use one or two wood blocks to support retainer as shown. Lubricate seal lip with petroleum jelly after installation.

(10) Align front bearing retainer bolt holes and tap retainer into place with plastic mallet. Install new retainer bolts and tighten to 30 N·m (22 ft. lbs.) (Fig. 115).

NOTE: Never reuse the old bolts.

Fig.113BEARINGRETAINEROILSEAL

MAINSHAFT END PLAY

Fig.115FRONTBEARINGRETAINER

1 - DRIVE GEAR 2 - FRONT BEARING RETAINER

1 - INSTALLER 2 - RETAINER 3 - WOOD BLOCK

(6) Clean contact surfaces of gear case and front

bearing retainer with a wax and grease remover.

(7) Apply Mopar Silicone Sealer or equivalent to

flange surface of front bearing retainer (Fig. 114).

(8) Install front bearing retainer over drive gear

and start it into case.

(9) Start front bearing retainer in gear case. Verify (12

the top-center

is at

retainer O’clock) position (Fig. 114).

lube channel

Fig.114LOCATIONOFFRONTRETAINERLUBE

CHANNEL

1 - LUBE CHANNEL 2 - FRONT RETAINER 3 - APPLY GASKET MAKER HERE

(1) Install mainshaft rear bearing cup in case and over bearing. Tap bearing cup into place with plastic mallet.

(2) Install rear bearing plate to hold mainshaft

and rear bearing in position (Fig. 116).

NOTE: Do not install any end play shims at this time.

(3) Tighten rear bearing plate bolts securely. (4) Place gear case in upright position on bench. Either cut hole in bench to accept drive gear and front retainer or use C-clamps to secure transmission on bench.

NOTE: Do not leave transmission unsupported.

(5) Install Extension Rod 8161 into a suitable

threaded hole in rear of case.

(6) Mount dial indicator on extension rod and posi-

tion indicator plunger against end of mainshaft.

(7) Move mainshaft forward to remove all play

then zero dial indicator.

(8) Move mainshaft upward and record dial indica- tor reading. Move mainshaft with pry tool positioned between drive gear and case.

(9) End play should be 0.051-0.15 mm (0.002-0.006

in.). Select fit shims are available to adjust end play. If end play adjustment is required, remove bearing plate and install necessary shim.(10) Reinstall rear bearing plate with oil hole in

bearing plate at the top (Fig. 116).

(11) Apply Mopar Lock N’ Seal or equivalent to bearing plate bolt threads. Install and tighten bolts to 23 N·m (200 in. lbs.).

21 - 74 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)DR

Fig.118FIFTHGEARTHRUSTWASHERPIN

1 - THRUST WASHER PIN 2 - COUNTERSHAFT

Fig.116REARBEARINGPLATE

1 - BEARING PLATE OIL HOLE (AT TOP) 2 - MAINSHAFT REAR BEARING PLATE

(12) Install mainshaft

fifth gear with Installer 6446 (Fig. 117). Gear is seated when it contacts rear bearing.

Fig.119FIFTHGEARTHRUSTWASHER

1 - PIN 2 - THRUST WASHER

Fig.117MAINSHAFTFIFTHGEAR

1 - MAINSHAFT FIFTH GEAR 2 - INSTALLER

COUNTERSHAFT FIFTH GEAR SYNCHRO

(1) Install thrust washer pin in countershaft (Fig.

118).

(2) Install thrust washer on countershaft. Turn washer until pin engages in washer notch (Fig. 119).

NOTE: The flat side of washer faces the rear and cone side faces the front.

(3) Lubricate and install

countershaft (Fig. 120).

fifth gear bearing on

Fig.120COUNTERSHAFTFIFTHGEARBEARING 1 - COUNTERSHAFT 2 - FIFTH GEAR NEEDLE BEARING

DR MANUAL TRANSMISSION - NV4500 (Continued)

(4) Install synchro sleeve on hub of countershaft fifth gear with tapered side of sleeve facing front and the flat side facing rear (Fig. 121).

MANUAL TRANSMISSION - NV4500

21 - 75

Fig.121SYNCHROSLEEVEONCOUNTERSHAFT

FIFTH

1 - GEAR HUB 2 - SYNCHRO SLEEVE 3 - COUNTERSHAFT FIFTH GEAR

(5) Install shift fork in synchro sleeve (Fig. 122).

Fig.123COUNTERSHAFTFIFTHGEAR,SHIFT

FORKANDSYNCHROSLEEVE

1 - SHIFT FORK AND SLEEVE 2 - FIFTH GEAR HUB 3 - SHIFT FORK ROLL PINS

Fig.122FIFTHGEARSHIFTFORKINSYNCHRO

SLEEVE

1 - SYNCHRO SLEEVE 2 - SHIFT FORK

(6) Install assembled fifth gear, synchro sleeve and shift fork (Fig. 123). Align fork with shift lug rail and align gear with bearings and countershaft. Start components onto shaft and rail, then tap gear and fork into place with plastic or rawhide mallet.

(7) Install fifth gear synchro struts and springs

(Fig. 124).

Fig.124FIFTHGEARSYNCHROSTRUTSAND

SPRINGS

1 - FIFTH GEAR HUB 2 - SYNCHRO SPRING (3) 3 - SYNCHRO STRUT (3)

21 - 76 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)DR

(8) Assemble and install fifth synchro clutch gear and stop ring in fifth gear hub (Fig. 125). Verify parts are seated in fifth gear hub.

Fig.125FIFTHSYNCHROCLUTCHGEARAND

STOPRING

1 - STOP RING 2 - CLUTCH GEAR

(9) Install clutch gear snap ring (Fig. 126).

Fig.126FIFTHSYNCHROCLUTCHSNAPRING

1 - CLUTCH GEAR RING 2 - FIFTH SYNCHRO CLUTCH GEAR

(10) Align roll pin holes in shift fork with notches in shift lug rail. Then install roll pins from top side of fork (Fig. 123).

NOTE: Roll pins only fit one way due to small shoulder at one end of each pin.

FIFTH GEAR NUT

(1) Install belleville washer onto the mainshaft. (2) Install fifth gear nut over the mainshaft. (3) Tighten the clamp bolt until the gap in the

clamp nut assembly is closed.

(4) Back the clamp bolt off one full turn.

(5) Place 10-15 drops of Loctite 272 onto the main- threads where the fifth gear nut will be

shaft engaged.

(6) Install fifth gear nut on mainshaft (Fig. 127).

Fig.127FIFTHGEARNUT

1 - FIFTH GEAR 2 - FIFTH GEAR NUT

(7) Hold mainshaft Socket 6993 4X2 or Socket

6984 4X4 while installing the fifth gear nut.

(8) Tighten fifth gear nut as much as possible with Wrench 6743, long handle ratchet, breaker bar and applicable socket wrench (Fig. 128).

Fig.128FIFTHGEARNUT

1 - WRENCH 2 - FIFTH GEAR NUT 3 - SOCKET

(9) Lock mainshaft gears by shifting all synchro

sleeves into engaged position.

DR MANUAL TRANSMISSION - NV4500 (Continued)

MANUAL TRANSMISSION - NV4500

21 - 77

(10) Tighten fifth gear nut with Nut Wrench 6743

and high capacity torque wrench. Tighten nut to 366- 380 N·m (270-280 ft. lbs.). Have helper hold trans- mission steady if necessary.(11) Torque the fifth gear clamp nut clamping bolt

to 13.5 N·m (10 ft. lbs.).

(12) Unlock the mainshaft gears by shifting all

synchro sleeves out of the engaged position.

EXTENSION/ADAPTER HOUSING

(1) Clean mating surfaces of extension/adapter housing and gear case with a wax and grease remover.

(2) Check alignment dowels in gear case and hous- ing or adapter. Be sure dowels are in position and seated.

(3) Apply Mopar Silicone Sealer or equivalent to

gear case and housing mating surfaces.

(4) Align and install extension/adapter housing on

gear case (Fig. 129).

Fig.129INSTALLINGEXTENSION/ADAPTER

HOUSING

1 - GEAR CASE 2 - EXTENSION HOUSING

(5) Apply Mopar Lock N’ Seal or equivalent to

threads of extension/adapter housing bolts.

(6) Install and tighten housing bolts to 54 N·m (40

ft. lbs.).

SHIFT MECHANISM

(1) Clean mating surfaces of shift cover and gear

case with wax and grease remover.

(2) Apply a small amount of Mopar silicone sealer

or equivalent to sealing surface of shift cover.

CAUTION: Do not over-apply an excesive amount sealer. Excess can squeezed into gear case and could block lubricant feed holes in time.

(3) Lubricate synchro sleeves with Castrolt Syn- torq gear lubricant or equivalent. Then apply light coat of petroleum jelly to shift fork contact surfaces.

(4) Verify shift fork pads (Fig. 130) are secure.

Fig.130SHIFTFORKPAD

1 - SHIFT FORK PADS 2 - FIFTH-REVERSE FORK

(5) Verify 1-2 and 3-4 synchro sleeves and forks in

shift cover are in neutral position.

(6) Align and seat shift cover on transmission.

NOTE: If cover will not seat, it may not be aligned on gear case dowels or shift forks are not aligned with sleeves and shift lug.

(7) Apply Mopar Lock N’ Seal or equivalent to

threads of shift cover bolts.

(8) Install shift cover bolts and tighten to 27-31

N·m (216-276 in. lbs.).

(9) Apply sealer to backup lamp switch. Install switch into cover and tighten to 22-34 N·m (193-265

in. lbs.).(10) Install vent assembly if removed. Apply an adhesive/sealer to vent tube to help secure it in cover.

INSTALLATION

NOTE: If a new transmission is being installed, use all components supplied with the new transmission. For example, if a new shift tower is supplied with the new transmission, do not re-use the original shift tower.

(1) Apply light coat of Mopar high temperature bearing grease or equivalent to contact surfaces of the following components: †input shaft splines. †release bearing slide surface of front retainer. †release bearing bore. †release fork.

DR

FOUR WHEEL DRIVE

(1) Install transfer case shift mechanism on trans-

(2) Install

transfer case on transmission jack.

Secure transfer case to jack with safety chains.

(3) Raise jack and align transfer case input gear

with transmission mainshaft.

(4) Move transfer case forward and seat it on

adapter.

(5) Install transfer case nuts and tighten to: †If 3/8 studs 41-47 N·m (30-35 ft. lbs.). †If 5/16 studs 30-41 N·m (22-30 ft. lbs.). (6) Install transfer case shift mechanism to side of

transfer case.

on transfer case.

(7) Connect transfer case shift lever to range lever

(8) Align and connect propeller shafts. (9) Fill

transmission with required lubricant. Check lubricant level in transfer case and add lubri- cant if necessary.

(10) Install transfer case skid plate, if equipped and crossmember. Tighten attaching bolts/nuts to 41

N·m (30 ft. lbs.).(11) Install exhaust system components. (12) Lower vehicle. (13) Clean the mating surfaces of shift tower, iso- lator plate and shift cover with suitable wax and grease remover.

(14) Apply Mopar Gasket Maker or equivalent to the sealing surface of the shift cover. Do not over apply sealant.

(15) Install the isolator plate onto the shift cover,

metal side down.

(16) Install the shift tower onto the isolator plate. No sealant is necessary between the shift tower and the isolator plate.

(17) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(18) Install the bolts to hold the shift tower to the isolator plate and the shift cover. Tighten the shift tower bolts to 10.2-11.25 N·m (7.5-8.3 ft. lbs.).

(19) Install the shift lever extension onto the shift

tower and lever assembly.

(20) Install shift lever boot and bezel. (21) Connect battery negative cable.

21 - 78 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued) †release fork ball stud. †propeller shaft slip yoke. (2) Apply sealer to threads of bottom PTO coverbolt and install bolt in case.

(3) Mount transmission on jack and position trans-

mission.

mission under vehicle.

(4) Raise transmission until input shaft is centered

in release bearing and clutch disc hub.

(5) Move transmission forward and start input shaft in release bearing, clutch disc and pilot bush- ing.

(6) Work transmission forward until seated against clutch housing. Do not allow transmission to remain unsupported after input shaft has entered clutch disc.

(7) Install transmission bolts and tighten to 108

N·m (80 ft. lbs.).

rear crossmember.

fixture.

on shift cover.

(8) Install transmission mount on transmission or

(9) Install rear crossmember. (10) Remove transmission jack and engine support

(11) Position transmission harness wires in clips

(12) Install clutch slave cylinder and install slave

cylinder shield, if equipped.

(13) Connect speed sensor and backup light switch

wires.

TWO WHEEL DRIVE

(1) Fill transmission with recommended lubricant.

Correct fill level is bottom edge of fill plug hole.

(2) Align and install propeller shaft. (3) Lower vehicle. (4) Clean the mating surfaces of shift tower, isola- tor plate and shift cover with suitable wax and grease remover.

(5) Apply Mopar Gasket Maker or equivalent to the sealing surface of the shift cover. Do not over apply sealant.

(6) Install the isolator plate onto the shift cover,

metal side down.

(7) Install the shift tower onto the isolator plate. No sealant is necessary between the shift tower and the isolator plate.

(8) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(9) Install the bolts to hold the shift tower to the isolator plate and the shift cover. Tighten the shift tower bolts to 10.2-11.25 N·m (7.5-8.3 ft. lbs.).

(10) Install the shift lever extension onto the shift

tower and lever assembly.

(11) Install shift boot and bezel. (12) Connect battery negative cable.

DR MANUAL TRANSMISSION - NV4500 (Continued) SPECIFICATIONS

MANUAL TRANSMISSION - NV4500

21 - 79

TORQUE SPECIFICATIONS

DESCRIPTION

Switch, Back-up Lamp

Countershaft Bearing Plate Bolts

Fifth Gear Nut

Fifth Gear Nut Clamp Bolt

Drain and Fill Plug

Front Bearing Retainer Bolts Mainshaft Bearing Plate Bolts

PTO Cover Bolts

Extension/Adapter Housing Bolts

Shift Mechanism Cover Bolts

Transmission Bolts

SPECIAL TOOLS

N·m 22-34

19-26

366-38013.5

34-47

27-34

19-26

27-54

41-68

27-31

108Ft. Lbs. 16-25

14-19

270-28010

25-35

20-25

14-19

20-40

30-50

20-2380

In. Lbs.

170-230

235-305

170-230REMOVERC-3985-B

INSTALLERBUSHING6951

BUSHINGREMOVER6957

INSTALLERBUSHING8156

REMOVERBUSHING8155

HANDLEC-4171

21 - 80 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)DR

INSTALLERSEALC-3972-A

INSTALLERSEAL8154

INSTALLERSEALC-3860-A

SOCKET6441

SOCKET6442

SOCKET6993

WRENCH6443

SOCKET6984

WRENCH6743

PULLER6444

DR MANUAL TRANSMISSION - NV4500 (Continued)

MANUAL TRANSMISSION - NV4500

21 - 81

JAWS6459

JAWS6451

JAWS6820

REMOVER6454

JAWS&INSERT6453

JAWS6447

JAWS6449

INSTALLER6061

INSTALLERC-4340

21 - 82 MANUAL TRANSMISSION - NV4500

MANUAL TRANSMISSION - NV4500 (Continued)DR

INSTALLERC-4040

RODEXTENSION8161

INSTALLER6448

INSTALLER6446

INSTALLERC-4308

JAWS6445

INSTALLER6052

DR

MANUAL TRANSMISSION - NV4500

21 - 83

ADAPTER HOUSING SEAL REMOVAL

(1) Raise and support vehicle. (2) Mark the propeller shafts and yokes for instal-

lation reference and remove the shafts.

(3) Support transmission with a transmission jack. (4) Remove engine rear support. (5) Remove transfer case. (6) Remove adapter housing seal with a pry tool or

slide hammer mounted screw (Fig. 131).

(3) Remove extension housing seal (Fig. 132) using

Remover C-3985-B.

(4) On heavy duty 4X2 vehicles, remove extension housing seal with a pry tool or a slide hammer mounted screw.

Fig.132EXTENSIONHOUSINGANDSEAL(4X2)

1 - EXTENSION HOUSING 2 - SEAL

(5) On light duty transmissions, remove the exten-

sion housing bushing with Remover 6957.

(6) On heavy duty transmissions,

remove the

extension housing bushing with Remover 8155.

Fig.131AdapterHousing(4–WheelDriveModels) 1 - ADAPTER HOUSING 2 - SEAL

INSTALLATION

INSTALLATION

(Fig. 133) and Installer.

(1) Install housing bushing with Handle C-4171

†Light Duty - Installer 6951

†Heavy Duty - Installer 8161(1) Install adapter housing seal with Installer

C-3860-A and Handle C-4171.

(2) Install transfer case. (3) Install propeller shafts with reference marks

(4) Fill transfer case and transmission to proper

aligned.

level.

(5) Remove support and lower vehicle.

EXTENSION HOUSING SEAL REMOVAL

(1) Mark the propeller shaft and yoke for installa-

tion reference.

(2) Remove the propeller shaft.

Fig.133ExtensionHousingBushing

1 - HANDLE 2 - INSTALLER 3 - EXTENSION HOUSING

21 - 84 MANUAL TRANSMISSION - NV4500

EXTENSION HOUSING SEAL (Continued)(2) Install housing seal with Handle C-4171 (Fig. 134) and Installer. †Light Duty - Installer C-3972-A †Heavy Duty - Installer 8154

DR

(3) Pry up shift mechanism cover at slots provided

in cover (Fig. 136).

Fig.134PinionSeal

Fig.136LOOSENSHIFTMECHANISM

1 - HANDLE 2 - INSTALLER

1 - SHIFT MECHANISM COVER SLOT 2 - PRY TOOL

(3) Install propeller shaft with reference marks

aligned.

(4) Check and fill transmission.

(4) Raise cover enough to disengage it from align-

ment dowels in gear case (Fig. 137).

SHIFT MECHANISM REMOVAL

(1) Remove transmission from vehicle. (2) Remove shift mechanism cover bolts (Fig. 135).

Fig.137SHIFTMECHANISMCOVER

1 - SHIFT MECHANISM COVER 2 - ALIGNMENT DOWELS

(5) Raise front of shift mechanism cover and lift

cover up and off gear case (Fig. 137).

Fig.135SHIFTMECHANISMBOLTS

1 - SHIFT MECHANISM COVER 2 - BOLTS

DR SHIFT MECHANISM (Continued) FIFTH-REVERSE SHIFT FORK PADS

Three shift pads on the forks are held in place by

tension and a small locating tang (Fig. 138).

MANUAL TRANSMISSION - NV4500

21 - 85

INSTALLATION

EXPANSION PLUG

(1) Apply small bead of Mopar silicone sealer or

equivalent to outer edge of each new plug.

(2) Position each plug in bore and tap into place

with hammer and punch or socket.

FIFTH-REVERSE SHIFT FORK PADS

(1) Align pad locating tab. (2) Snap pads into place and verify locating tabs

are locked-in.

SHIFT COVER

(1) Clean mating surfaces of shift mechanism

cover and gear case with wax and grease remover.

(2) Apply a small amount of Mopar silicone sealer or equivalent to sealing surface of shift mechanism cover.

Fig.138SHIFTFORKPADLOCATIONS

1 - SHIFT FORK PADS 2 - FIFTH-REVERSE FORK

To remove the pads, grasp a pad with hand and tilt it out and off the fork. If pad is difficult to remove by hand, insert a screwdriver blade between the pad and fork and pry the pad off.

EXPANSION PLUG

The expansion plugs at the rear of the shift rail

bores (Fig. 139) can be replaced if loose/leaking.

CAUTION: Do not use an excessive amount sealer. Excess can squeezed into gear case and could block lubricant feed holes in time.

(3) Lubricate synchro sleeves with Castrolt Syn- torq gear lubricant or equivalent. Then apply light coat of petroleum jelly to shift fork contact surfaces.

(4) Verify shift fork pads (Fig. 140) are secure.

Fig.139EXPANSIONPLUGLOCATION

1 - EXPANSION PLUGS

(1) Drill 6 mm (1/4 in.) diameter hole in center of

the plug to be removed.

(2) Pry plug out of cover with tapered punch. (3) Clean all chips from shift cover and plug bores. Then clean plug bores with solvent and dry with clean shop towel.

Fig.140SHIFTFORKPAD

1 - SHIFT FORK PADS 2 - FIFTH-REVERSE FORK

(5) Verify 1-2 and 3-4 synchro sleeves and forks in

shift cover are in neutral position.

(6) Align and seat shift mechanism cover on trans-

mission.

NOTE: If cover will not seat, it may not be aligned on gear case dowels or shift forks are not aligned with sleeves and shift lug.

21 - 86 MANUAL TRANSMISSION - NV4500

SHIFT MECHANISM (Continued)DR

(7) Apply Mopar Lock N’ Seal or equivalent to

INSTALLATION

threads of shift cover bolts.

(8) Install shift cover mechanism bolts and tighten

to 27-31 N·m (216-276 in. lbs.).

(9) Apply sealer to backup lamp switch. Install switch into cover and tighten to 22-34 N·m (193-265

in. lbs.).(10) Install vent assembly if removed. Apply an adhesive/sealer to vent tube to help secure it in cover.

(11) Install transmission.

SHIFT COVER REMOVAL

(1) Shift transmission into Neutral. (2) Unscrew and remove the shift lever extension

from the shift

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(4) Remove the bolts holding the shift tower to the

isolator plate and transmission shift cover.

(5) Remove the shift tower and isolator plate from

the transmission shift cover.

(1) Clean the mating surfaces of shift tower, isola- tor plate and shift cover with suitable wax and grease remover.

(2) Apply Mopar Gasket Maker or equivalent to the sealing surface of the shift cover. Do not over apply sealant.

(3) Install the isolator plate onto the shift cover,

metal side down.

(4) Install the shift tower onto the isolator plate. No sealant is necessary between the shift tower and the isolator plate.

(5) Verify shift tower, isolator plate and shift tower

bushings are properly aligned.

(6) Install bolts to hold the shift tower to the iso- lator plate and the shift cover. Tighten the shift tower bolts to 10.2-11.25 N·m (7.5-8.3 ft. lbs.).

(7) Install shift lever extension, shift boot and

bezel.

DR

MANUAL TRANSMISSION - NV5600

21 - 87

MANUAL TRANSMISSION - NV5600

TABLE OF CONTENTS

page

page

MANUAL TRANSMISSION - NV5600

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . 122

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 87

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

DIAGNOSIS AND TESTING . . . . . . . . . . . . . . . . 89

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 90

CLEANING - TRANSMISSION . . . . . . . . . . . . . 104

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . 104

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . 122

SPECIFICATIONS - NV5600MANUAL TRANSMISSION - NV5600

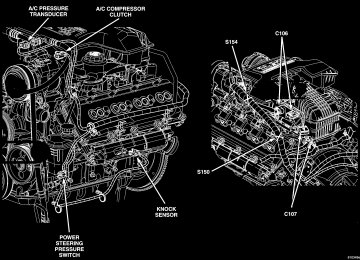

DESCRIPTIONThe NV5600 is a six speed constant mesh manual transmission (Fig. 1). All gear ranges including reverse are synchronized. First and second gears uti- lize dual cone synchronizers in order to aid shifting. Sixth gear is an overdrive range. The transmission uses cast iron for the gear case and extension/ adapter housing and aluminum for the clutch hous- ing.

ADAPTER HOUSING SEAL

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 127EXTENSION HOUSING SEAL

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 127SHIFT COVER

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 128To drain the trans remove the bottom PTO cover bolt. Fill the trans through the plug to the rear of the PTO cover (Fig. 1). Dry fill is approximately 4.5 liters (9.5 pints) or to the bottom edge of the fill plug hole.

The gear ratios are:

GEAR RATIOS

GEAR FIRST

SECOND

THIRD FOURTH

FIFTH SIXTH

REVERSE

RATIO 5.63:1

3.38:1

2.04:1

1.39:1

1.00:1

0.73:1

5.63:121 - 88 MANUAL TRANSMISSION - NV5600

MANUAL TRANSMISSION - NV5600 (Continued)DR

Fig.1NV5600MANUALTRANSMISSION

DR MANUAL TRANSMISSION - NV5600 (Continued) IDENTIFICATION

The transmission has

two identification tags attached to the driver side upper clutch housing (Fig. 2). One tag provides the transmission part number. The second tag provides sequencing and build date information. The information on the tags are essen- tial to correct parts ordering.

MANUAL TRANSMISSION - NV5600

21 - 89

before checking. These recommendations will ensure an accurate check and avoid an underfill or overfill condition. Always check the lubricant level after any addition of fluid to avoid an incorrect lubricant level condition.

Leaks can occur at the mating surfaces of the gear case, adaptor or extension housing, or from the front/ rear seals. A suspected leak could also be the result of an overfill condition. Leaks at the rear of the extension or adapter housing will be from the hous- ing oil seals. Leaks at component mating surfaces will probably be the result of inadequate sealer, gaps in the sealer, incorrect bolt tightening or use of a non-recommended sealer. A leak at the front of the transmission will be from either the front bearing retainer or retainer seal. Lubricant may be seen drip- ping from the clutch housing after extended opera- tion. If the leak is severe, it may also contaminate the clutch disc causing the disc to slip, grab and or chatter.

Fig.2IDENTIFICATIONTAGLOCATION

1 - IDENTIFICATION TAGS

OPERATION

The driver selects a particular gear by moving the shift lever to the desired gear position. As the shift lever moves the selected shift rail, the shift fork attached to that rail begins to move. The fork is posi- tioned in a groove in the outer circumference of the synchronizer sleeve. As the shift fork moves the syn- chronizer sleeve, the synchronizer begins to speed-up or slow down the selected gear (depending on whether we are up-shifting or down-shifting). The synchronizer does this by having the synchronizer hub splined to the mainshaft or the countershaft in some cases, and moving the blocker ring into contact with the gear’s friction cone. As the blocker ring and friction cone come together, the gear speed is brought up or down to the speed of the synchronizer. As the two speeds match, the splines on the inside of the synchronizer sleeve become aligned with the teeth on the blocker ring and friction cone and eventually will slide over the teeth, locking the gear to the main- shaft or countershaft through the synchronizer.

DIAGNOSIS AND TESTING

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the result of a leak, inadequate lubricant fill or an incor- rect lubricant level check. A correct lubricant level check can only be made when the vehicle is level. Also allow the lubricant to settle for a minute or so

HARD SHIFTING

Hard shifting is usually caused by a low lubricant level, improper or contaminated lubricants. The con- sequence of using non-recommended lubricants is noise, excessive wear, internal bind and hard shift- ing. Substantial lubricant leaks can result in gear, shift rail, synchro, and bearing damage. If a leak goes undetected for an extended period, the first indi- cations of component damage are usually hard shift- ing and noise.

Component damage, incorrect clutch adjustment or damaged clutch pressure plate or disc are additional probable causes of increased shift effort. Incorrect adjustment or a worn/damaged pressure plate or disc can cause incorrect release. If clutch problem is advanced, gear clash during shifts can result. Worn or damaged synchro rings can cause gear clash when shifting into any forward gear. In some new or rebuilt transmissions, new synchro rings may tend to stick slightly causing hard or noisy shifts. In most cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur- ing normal operation. Rotating gears generate a mild whine that is audible, but generally only at extreme speeds. Severe highly audible transmission noise is generally the initial indicator of a lubricant problem. improper or contaminated lubricant will promote rapid wear of gears, synchros, shift rails, forks and bearings. The overheating caused by a lubricant problem, can also lead to gear breakage.

Insufficient,

REMOVAL

(1) Shift transmission into Neutral.

21 - 90 MANUAL TRANSMISSION - NV5600

MANUAL TRANSMISSION - NV5600 (Continued)DR

(2) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(3) Remove the bolts holding the shift tower to the

isolator plate and transmission gear case.

(4) Remove the shift tower and isolator plate from

the transmission gear case.

(5) Raise and support vehicle. (6) Remove skid plate, if equipped. (7) Mark propeller shaft/shafts and axle yokes for

installation reference.

(8) Remove propeller shaft. (9) Disconnect and remove exhaust system as nec-

essary.

(10) Disconnect wires at backup light switch. (11) Support engine with adjustable safety stand

and wood block.

(12) If

transmission is to be disassembled for repair, remove drain bolt at bottom of PTO cover and drain lubricant from transmission (Fig. 3).

FOUR WHEEL DRIVE

fer case range lever.

(1) Disconnect transfer case shift linkage at trans-

(2) Support and secure transfer case with safety

chains to a transmission jack.

(3) Remove transfer case mounting nuts. (4) Move transfer case rearward until input gear

clears transmission mainshaft.

(5) Lower transfer case assembly and move it from

under vehicle.

(6) Support and secure transmission with safety

chains to a transmission jack.

(7) Remove

bolts/nuts

attaching

transmission

mount to rear crossmember.

(8) Remove rear crossmember bolts and pry out

crossmember.

the engine block.

clears clutch disc.

vehicle.

(9) Remove transmission clutch housing bolts at

(10) Move transmission rearward until input shaft

(11) Lower transmission and remove it from under

DISASSEMBLY

NOTE: Use Fixture 8241 for moving and handling the transmission. The fixture supports the transmis- sion at the center of gravity in order to ease mount- ing the transmission into the build fixture.

(1) Mount the transmission into Fixture 8230 (Fig. 4).

Fig.3NV5600DRAINBOLT

1 - PTO COVER 2 - DRAIN BOLT

(13) Remove clutch slave cylinder splash shield, if

equipped.

(14) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

(15) Remove wire harness from clips on transmission.

TWO WHEEL DRIVE

the rear mount.

(1) Remove bolts/nuts mounting transmission to

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember bolts and pry out

crossmember.

the engine block.

(4) Remove transmission clutch housing bolts at

(5) Slide transmission and jack rearward until

input shaft clears clutch disc and pressure plate.

(6) Lower transmission jack and remove transmis-

sion from under vehicle.

Fig.4TRANSMISSIONFIXTURE

1 - FIXTURE 2 - TRANSMISSION

DR MANUAL TRANSMISSION - NV5600 (Continued)

MANUAL TRANSMISSION - NV5600

21 - 91

(4) Remove primary shift rail detent plug (Fig. 7).

Fig.7PRIMARYSHIFTRAILDETENTPLUG

1 - DETENT PLUG

(5) Remove primary shift rail detent spring (Fig.

8).

Fig.8PRIMARYSHIFTRAILDETENTSPRING

1 - DETENT SPRING

(2) Rotate the transmission to the horizontal posi-

(3) Remove the shift tower (Fig. 5) and isolator

tion, if necessary.

plate (Fig. 6).

Fig.5REMOVESHIFTTOWER

1 - SHIFT TOWER 2 - TRANSMISSION

Fig.6SHIFTTOWERISOLATORPLATE

1 - ISOLATOR PLATE 2 - TRANSMISSION

21 - 92 MANUAL TRANSMISSION - NV5600

MANUAL TRANSMISSION - NV5600 (Continued)(6) Remove primary shift rail detent plunger (Fig.

9).

DR

Fig.9PRIMARYSHIFTRAILDETENTPLUNGER

1 - DETENT PLUNGER

(7) Remove clutch housing bolts (10) (Fig. 10) from

inside the housing.

Fig.11SHIFTRAILBLOCKERBOLT

1 - BLOCKER BOLT

(2) Remove extension/adapter housing from the

transmission gear case with Puller 8244 (Fig. 12).

NOTE: It may be necessary to straighten the hous- ing during removal due to the tendency for the reverse idler shaft the housing.

to bind into one side of

Fig.10CLUTCHHOUSINGBOLTS

1 - BOLTS (10)

(8) Remove shift rail blocker bolt (Fig. 11) from the

side of the transmission gear case.

EXTENSION/ADAPTER HOUSING

(1) Remove bolts holding the extension/adapter

housing onto the transmission gear case.

Fig.12TRANSMISSIONCASEPULLER

1 - PULLER 2 - EXTENSION/ADAPTER HOUSING

DR MANUAL TRANSMISSION - NV5600 (Continued)

MANUAL TRANSMISSION - NV5600

21 - 93

(3) Remove crossover detent plug, spring and plunger from the extension/adapter housing (Fig. 13).

NOTE: Tag all countershaft pre-load shims from between the bearing race and the housing (Fig. 16).

(8) Remove crossover cam bushing from the exten-

sion/adapter housing with Remover 8240.

Fig.13CROSSOVERCAMDETENTPLUG

1 - DETENT PLUG 2 - EXTENSION HOUSING

(4) Remove bolt and washer holding the crossover

cam to the extension/adapter housing (Fig. 14).

(5) Remove crossover cam from the extension/

adapter housing.

Fig.14CROSSOVERCAMBOLT

1 - CROSSOVER CAM 2 - BOLT 3 - EXTENSION HOUSING

(6) Remove back-up lamp switch from the exten-

sion/adapter housing.

(7) Remove countershaft rear bearing race from the extension/adapter housing with Remover L-4518

(Fig. 15).Fig.15COUNTERSHAFTREARBEARINGRACE

1 - REMOVER

Fig.16COUNTERSHAFTREARBEARINGRACE

ANDSHIM

1 - PRE-LOAD SHIM 2 - BEARING RACE

(9) On 4X2 vehicles, remove extension housing

seal with a pry tool or a slide hammer and screw.

(10) On 4X4 vehicles, remove adapter housing seal

with a pry tool or a slide hammer and screw.

21 - 94 MANUAL TRANSMISSION - NV5600

MANUAL TRANSMISSION - NV5600 (Continued)DR

REVERSE GEAR

(1) Remove crossover cam rollers and pin (Fig. 17).

(4) Remove reverse idler gear rear bearing, bear- ing spacer, front bearing and front thrust washer from the idler gear shaft.

(5) Remove reverse countershaft rear bearing from the countershaft reverse gear assembly with Puller C-293-PA and Adapters C-293-52 (Fig. 19).

Fig.17CROSSOVERCAMROLLERSANDPIN

1 - CROSSOVER CAM PIN 2 - CROSSOVER CAM ROLLERS

(2) Remove reverse idler thrust washer from the

reverse idler.

(3) Remove reverse idler and reverse countershaft

gears together (Fig. 18).

Fig.19COUNTERSHAFTREARBEARINGPULLER 1 - PULLER 2 - ADAPTERS

(6) Seperate countershaft reverse gear and sleeve. (7) Remove output shaft nut with Wrench 8226 on the shaft nut and Socket 6993 or 6984 to hold the shaft (Fig. 20). Discard output shaft nut from the output shaft.

NOTE: If necessary strike the flat side area of Wrench 8226 with a hammer to break the nut loose.

Fig.18REVERSEIDLERANDCOUNTERSHAFT

GEARS

1 - REVERSE IDLER GEAR 2 - COUNTERSHAFT REVERSE GEAR

Fig.20LOOSENOUTPUTSHAFTNUT

1 - WRENCH 2 - SOCKET

DR MANUAL TRANSMISSION - NV5600 (Continued)

MANUAL TRANSMISSION - NV5600

21 - 95

(8) Remove output shaft ball bearing assembly and reverse thrust washer from the output shaft (Fig. 21).

(10) Remove reverse gear bearing sleeve from the

output shaft (Fig. 23).

NOTE: If necessary heat the sleeve slightly with a heat gun. Do not use a torch to heat the sleeve or damage to the output shaft may occur.

Fig.21OUTPUTSHAFTBEARINGANDTHRUST

WASHER

1 - OUTPUT SHAFT BALL BEARING 2 - THRUST WASHER

(9) Remove reverse gear, reverse gear synchronizer cone, reverse gear outer blocker ring and reverse gear bearing (Fig. 22).

Fig.23REVERSEBEARINGSLEEVE

1 - REVERSE GEAR BEARING SLEEVE

(11) Remove roll-pin securing the reverse shift fork to the reverse shift rail with a 6 mm (7/32 in.) punch and hammer.

Fig.22REVERSEGEARCOMPONENTS

1 - REVERSE GEAR 2 - REVERSE BEARING 3 - BLOCKER RING 4 - FRICTION CONE

21 - 96 MANUAL TRANSMISSION - NV5600

MANUAL TRANSMISSION - NV5600 (Continued)(12) Remove reverse shift fork and synchronizer as an assembly from the reverse shift rail and the out- put shaft (Fig. 24).

DR

Fig.25TRANSMISSIONCASELIFTFIXTURE

1 - FIXTURE 2 - TRANSMISSION CASE

Fig.24REVERSESHIFTFORKANDSYNCHRO

1 - REVERSE SYNCHRO 2 - REVERSE SHIFT FORK

TRANSMISSION GEAR CASE

(1) Remove remaining bolts holding the transmis-

sion gear case to the clutch housing.

(2) Remove the shift socket roll pin with a 6 mm

(7/32 in.) punch and hammer.

(3) Turn shift socket so it won’t catch the case

when lifting it up.

case.

(4) Install Fixture 8232 to the transmission gear

(5) Attach an engine crane or equivalent to Fixture 8232 and remove the transmission gear case from the clutch housing (Fig. 25).

(6) Remove rear output shaft and countershaft bearing races from the transmission gear case with a brass drift and hammer.

GEARTRAIN

(1) Remove bolts holding the 5-6 crossover bracket

to the clutch housing (Fig. 26).

Fig.265-6CROSSOVERBRACKETBOLTS

1 - 5-6 CROSSOVER BRACKET

DR MANUAL TRANSMISSION - NV5600 (Continued)

(2) Attach Fixture 8232 to the output shaft and

countershaft (Fig. 27).

MANUAL TRANSMISSION - NV5600