- Download PDF Manual

-

Exterior Lamp

Bulb Number

Front Parking and Sidemarker Lamp Front Turn Signal Lamp Halogen Headlamps High-Beam Low-Beam Rear Turn Signal and Taillamps

194

3757 A

9005 HB3

9006 HB4

3057For replacement bulbs not listed here, contact your dealer.

4. Unclip the wiring harness (A) and remove the

three socket retaining screws (B).

5. Remove the socket by releasing the retaining tabs. 6. Holding the socket, pull the bulb to release it

from the socket.

7. Reinstall by reversing Steps 1 through 6.

5-50

Windshield Wiper Blade Replacement Windshield wiper blades should be inspected at least twice a year for wear or cracking. Notice: Allowing the wiper blade arm to touch the windshield when no wiper blade is installed could damage the windshield. Any damage that occurs would not be covered by your warranty. Do not allow the wiper blade arm to touch the windshield. 1. To remove the old wiper blades, lift the wiper arm

until it locks into a vertical position.

A. Blade Assembly B. Arm Assembly C. Locking Tab

D. Blade Pivot E. Hook Slot F. Arm Hook

2. Press down on the blade assembly pivot locking

tab. Pull down on the blade assembly to release it from the wiper arm hook.

3. Remove the insert from the blade assembly. The

insert has two notches at one end that are locked by the bottom claws of the blade assembly. At the notched end, pull the insert from the blade assembly.

5-51

4. To install the new wiper insert, slide the insert (D),

notched end last, into the end with two blade claws (A). Slide the insert all the way through the blade claws at the opposite end (B). The plastic caps (C) will be forced off as the insert is fully inserted.

5. Be sure that the notches are locked by the bottom claws. Make sure that all other claws are properly locked on both sides of the insert slots.

A. Claw in Notch B. Correct Installation C. Incorrect Installation

6. Put the blade assembly pivot in the wiper arm hook.

Pull up until the pivot locking tab locks in the hook slot.

7. Carefully lower the wiper arm and blade assembly

onto the windshield.

5-52

Backglass Wiper Blade Replacement See Windshield Wiper Blade Replacement on page 5-51

for instructions on how to change the backglass wiper blade. The backglass wiper blade will not lock in a vertical position like the windshield wiper blade, so care should be used when pulling it away from the vehicle. Tires Your new vehicle comes with high-quality tires made by a leading tire manufacturer. If you ever have questions about your tire warranty and where to obtain service, see your GM Warranty booklet for details. For additional information refer to the tire manufacturer’s booklet included with your vehicle’s Owner’s Manual.{CAUTION:

Poorly maintained and improperly used tires are dangerous.

(cid:127) Overloading your tires can cause

overheating as a result of too much friction. You could have an air-out and a serious accident. See Loading Your Vehicle on page 4-43.

(cid:127) Underinflated tires pose the same danger as overloaded tires. The resulting accident could cause serious injury. Check all tires frequently to maintain the recommended pressure. Tire pressure should be checked when your tires are cold. See Inflation - Tire Pressure on page 5-59. (cid:127) Overinflated tires are more likely to be cut, punctured or broken by a sudden impact —such as when you hit a pothole. Keep tires at the recommended pressure.

(cid:127) Worn, old tires can cause accidents. If your

tread is badly worn, or if your tires have been damaged, replace them.

5-53

Tire Sidewall Labelling Useful information about a tire is molded into the sidewall. The following illustrations are examples of a typical P-Metric and a LT-Metric tire sidewall.

Passenger (P-Metric) Tire

(A) Tire Size: The tire size code is a combination of letters and numbers used to define a particular tire’s width, height, aspect ratio, construction type and service description. See the “Tire Size” illustration later in this section for more detail.

5-54

(B) TPC Spec (Tire Performance Criteria Specification): Original equipment tires designed to GM’s specific tire performance criteria have a TPC specification code molded onto the sidewall. GM’s TPC specifications meet or exceed all federal safety guidelines.

(C) DOT (Department of Transportation): The Department of Transportation (DOT) code indicates that the tire is in compliance with the U.S. Department of Transportation Motor Vehicle Safety Standards.

(D) Tire Identification Number (TIN): The letters and numbers following DOT code are the Tire Identification Number (TIN). The TIN shows the manufacturer and plant code, tire size, and date the tire was manufactured. The TIN is molded onto both sides of the tire, although only one side may have the date of manufacture.

(E) Tire Ply Material: The type of cord and number of plies in the sidewall and under the tread.

(F) Uniform Tire Quality Grading (UTQG): Tire manufacturers are required to grade tires based on three performance factors: treadwear, traction and temperature resistance. For more information, see Uniform Tire Quality Grading on page 5-63.

(G) Maximum Cold Inflation Load Limit: Maximum load that can be carried and the maximum pressure needed to support that load. For information on recommended tire pressure see Inflation - Tire Pressure on page 5-59 and Loading Your Vehicle on page 4-43.

Light Truck (LT-Metric) Tire

(A) Tire Size: The tire size code is a combination of letters and numbers used to define a particular tire’s width, height, aspect ratio, construction type and service description. See the “Tire Size” illustration later in this section for more detail.

(B) TPC Spec (Tire Performance Criteria Specification): Original equipment tires designed to GM’s specific tire performance criteria have a TPC specification code molded onto the sidewall. GM’s TPC specifications meet or exceed all federal safety guidelines.

(C) Dual Tire Maximum Load: Maximum load that can be carried and the maximum pressure needed to support that load when used in a dual configuration. For information on recommended tire pressure see Inflation - Tire Pressure on page 5-59 and Loading Your Vehicle on page 4-43.

(D) DOT (Department of Transportation): The Department of Transportation (DOT) code indicates that the tire is in compliance with the U.S. Department of Transportation Motor Vehicle Safety Standards.

(E) Tire Identification Number (TIN): The letters and numbers following DOT code are the Tire Identification Number (TIN). The TIN shows the manufacturer and plant code, tire size, and date the tire was manufactured. The TIN is molded onto both sides of the tire, although only one side may have the date of manufacture.

(F) Tire Ply Material: The type of cord and number of plies in the sidewall and under the tread.

5-55

(G) Single Tire Maximum Load: Maximum load that can be carried and the maximum pressure needed to support that load when used as a single. For information on recommended tire pressure see Inflation - Tire Pressure on page 5-59 and Loading Your Vehicle on page 4-43. Tire Size The following examples show the different parts of a tire size.

Passenger (P-Metric) Tire

Light Truck (LT-Metric) Tire

5-56

(A) Passenger (P-Metric) Tire: The United States version of a metric tire sizing system. The letter P as the first character in the tire size means a passenger vehicle tire engineered to standards set by the U.S. Tire and Rim Association. (A) Light Truck (LT-Metric) Tire: The United States version of a metric tire sizing system. The letters LT as the first two characters in the tire size means a light truck tire engineered to standards set by the U.S. Tire and Rim Association. (B) Tire Width: The three-digit number indicates the tire section width in millimeters from sidewall to sidewall. (C) Aspect Ratio: A two-digit number that indicates the tire height-to-width measurements. For example, if the tire size aspect ratio is 75, as shown in item C of the light truck (LT-Metric) tire illustration, it would mean that the tire’s sidewall is 75% as high as it is wide. (D) Construction Code: A letter code is used to indicate the type of ply construction in the tire. The letter R means radial ply construction; the letter D means diagonal or bias ply construction; and the letter B means belted-bias ply construction. (E) Rim Diameter: Diameter of the wheel in inches.

(F) Service Description: The service description indicates the load range and speed rating of a tire. The load index can range from 1 to 279. Speed ratings range from A to Z.

Tire Terminology and Definitions

Air Pressure: The amount of air inside the tire pressing outward on each square inch of the tire. Air pressure is expressed in pounds per square inch (psi) or kilopascal (kPa).

Accessory Weight: This means the combined weight of optional accessories. Some examples of optional accessories are, automatic transmission, power steering, power brakes, power windows, power seats, and air conditioning.

Aspect Ratio: The relationship of a tire’s height to its width.

Belt: A rubber coated layer of cords that is located between the plies and the tread. Cords may be made from steel or other reinforcing materials.

Bead: The tire bead contains steel wires wrapped by steel cords that hold the tire onto the rim.

Bias Ply Tire: A pneumatic tire in which the plies are laid at alternate angles less than 90 degrees to the centerline of the tread.

Cold Inflation Pressure: The amount of air pressure in a tire, measured in pounds per square inch (psi) or kilopascals (kPa) before a tire has built up heat from driving. See Inflation - Tire Pressure on page 5-59.

Curb Weight: This means the weight of a motor vehicle with standard and optional equipment including the maximum capacity of fuel, oil and coolant, but without passengers and cargo.

DOT Markings: A code molded into the sidewall of a tire signifying that the tire is in compliance with the U.S. Department of Transportation (DOT) motor vehicle safety standards. The DOT code includes the Tire Identification Number (TIN), an alphanumeric designator which can also identify the tire manufacturer, production plant, brand and date of production.

GVWR: Gross Vehicle Weight Rating, see Loading Your Vehicle on page 4-43.

GAWR FRT: Gross Axle Weight Rating for the front axle, see Loading Your Vehicle on page 4-43.

GAWR RR: Gross Axle Weight Rating for the rear axle, see Loading Your Vehicle on page 4-43.

Intended Outboard Sidewall: The side of an asymmetrical tire, that must always face outward when mounted on a vehicle.

Kilopascal (kPa): The metric unit for air pressure.

Light Truck (LT-Metric) Tire: A tire used on light duty trucks and some multipurpose passenger vehicles.

5-57

Load Index: An assigned number ranging from 1 to 279 that corresponds to the load carrying capacity of a tire.

Passenger (P-Metric) Tire: A tire used on passenger cars and some light duty trucks and multipurpose vehicles.

Maximum Inflation Pressure: The maximum air pressure to which a cold tire may be inflated. The maximum air pressure is molded onto the sidewall.

Maximum Load Rating: The load rating for a tire at the maximum permissible inflation pressure for that tire.

Maximum Loaded Vehicle Weight: The sum of curb weight; accessory weight; vehicle capacity weight; and production options weight.

Normal Occupant Weight: The number of occupants a vehicle is designed to seat multiplied by 150 lbs (68 kg). See Loading Your Vehicle on page 4-43.

Occupant Distribution: Designated seating positions.

Outward Facing Sidewall: The side of an asymmetrical tire that has a particular side that faces outward when mounted on a vehicle. The side of the tire that contains a whitewall, bears white lettering or bears manufacturer, brand, and/or model name molding that is higher or deeper than the same moldings on the other sidewall of the tire.

Recommended Inflation Pressure: Vehicle manufacturer’s recommended tire inflation pressure and shown on the tire placard. See Inflation - Tire Pressure on page 5-59 and Loading Your Vehicle on page 4-43.

Radial Ply Tire: A pneumatic tire in which the ply cords that extend to the beads are laid at 90 degrees to the centerline of the tread.

Rim: A metal support for a tire and upon which the tire beads are seated.

Sidewall: The portion of a tire between the tread and the bead.

Speed Rating: An alphanumeric code assigned to a tire indicating the maximum speed at which a tire can operate.

Traction: The friction between the tire and the road surface. The amount of grip provided.

Tread: The portion of a tire that comes into contact with the road.

5-58

Treadwear Indicators: Narrow bands, sometimes called “wear bars,” that show across the tread of a tire when only 1/16 inch (1.6 mm) of tread remains. See When It Is Time for New Tires on page 5-62.

UTQGS (Uniform Tire Quality Grading Standards): A tire information system that provides consumers with ratings for a tire’s traction, temperature, and treadwear. Ratings are determined by tire manufacturers using government testing procedures. The ratings are molded into the sidewall of the tire. See Uniform Tire Quality Grading on page 5-63.

Vehicle Capacity Weight: The number of designated seating positions multiplied by 150 lbs (68 kg) plus the rated cargo load. See Loading Your Vehicle on page 4-43.

Vehicle Maximum Load on the Tire: Load on an individual tire due to curb weight, accessory weight, occupant weight, and cargo weight.

Vehicle Placard: A label permanently attached to a vehicle showing the vehicle’s capacity weight and the original equipment tire size and recommended inflation pressure. See “Tire and Loading Information Label” under Loading Your Vehicle on page 4-43.

Inflation - Tire Pressure Tires need the correct amount of air pressure to operate effectively. Notice: Do not let anyone tell you that under-inflation or over-inflation is all right. It is not. If your tires do not have enough air (under-inflation), you can get the following:

Too much flexing Too much heat Tire overloading

(cid:127) Premature or irregular wear (cid:127) Poor handling (cid:127) Reduced fuel economy If your tires have too much air (over-inflation), you can get the following: (cid:127) Unusual wear (cid:127) Poor handling (cid:127) Rough ride (cid:127) Needless damage from road hazards

5-59

(cid:127) (cid:127) (cid:127) A Tire and Loading Information label is attached to the vehicle’s center pillar (B-pillar), below the driver’s door latch. This label shows your vehicle’s original equipment tires and the correct inflation pressures for your tires when they are cold. The recommended cold tire inflation pressure, shown on the label, is the minimum amount of air pressure needed to support your vehicle’s maximum load carrying capacity. For additional information regarding how much weight your vehicle can carry, and an example of the tire and loading information label, see Loading Your Vehicle on page 4-43. How you load your vehicle affects vehicle handling and ride comfort, never load your vehicle with more weight than it was designed to carry. When to Check Check your tires once a month or more. Also, check the tire pressure of the spare tire. How to Check Use a good quality pocket-type gage to check tire pressure. You cannot tell if your tires are properly inflated simply by looking at them. Radial tires may look properly inflated even when they’re underinflated. Check the tire’s inflation pressure when the tires are cold. Cold means your vehicle has been sitting for at least three hours or driven no more than 1 mile (1.6 km).

Remove the valve cap from the tire valve stem. Press the tire gage firmly onto the valve to get a pressure measurement. If the cold tire inflation pressure matches the recommended pressure on the tire and loading information label, no further adjustment is necessary. If the pressure is low, add air until you reach the recommended amount. If you overfill the tire, release air by pushing on the metal stem in the center of the tire valve. Recheck the tire pressure with the tire gage. Be sure to put the valve caps back on the valve stems. They help prevent leaks by keeping out dirt and moisture.

Tire Inspection and Rotation Tires should be rotated every 5,000 to 8,000 miles (8 000 to 13 000 km). Any time you notice unusual wear, rotate your tires as soon as possible and check wheel alignment. Also check for damaged tires or wheels. See When It Is Time for New Tires on page 5-62 and Wheel Replacement on page 5-65 for more information. Make sure the spare tire is stored securely. Push, pull, and then try to rotate or turn the tire. If it moves, use the wheel wrench to tighten the cable. For information on storing or removing the spare tire, see Changing a Flat Tire on page 5-69.

5-60

The purpose of regular rotation is to achieve more uniform wear for all tires on the vehicle. The first rotation is the most important. See Scheduled Maintenance on page 6-4.

{CAUTION:

When rotating your tires, always use the correct rotation pattern shown here. After the tires have been rotated, adjust the front and rear inflation pressures as shown on the Tire and Loading Information label. See Loading Your Vehicle on page 4-43, for an example of the label and its location on your vehicle. Make certain that all wheel nuts are properly tightened. See “Wheel Nut Torque” under Capacities and Specifications on page 5-102.

Rust or dirt on a wheel, or on the parts to which it is fastened, can make wheel nuts become loose after a time. The wheel could come off and cause an accident. When you change a wheel, remove any rust or dirt from places where the wheel attaches to the vehicle. In an emergency, you can use a cloth or a paper towel to do this; but be sure to use a scraper or wire brush later, if needed, to get all the rust or dirt off. See Changing a Flat Tire on page 5-69.

5-61

Buying New Tires To find out what kind and size of tires you need, look at the Certification/Tire label or the Tire and Loading Information label. For examples of these labels and their location on your vehicle, see Loading Your Vehicle on page 4-43. The tires installed on your vehicle when it was new had a Tire Performance Criteria Specification (TPC Spec) number on each tire’s sidewall. When you get new tires, General Motors recommends that you get tires with that same TPC Spec number. That way your vehicle will continue to have tires that are designed to give proper endurance, handling, speed rating, load range, traction, ride and other things during normal service on your vehicle. If your tires have an all-season tread design, the TPC number will be followed by an “MS” (for mud and snow). If you replace your tires with those not having a TPC Spec number, make sure they are the same size, load range, speed rating and construction type (bias, bias-belted or radial) as your original tires.

When It Is Time for New Tires

One way to tell when it’s time for new tires is to check the treadwear indicators, which will appear when your tires have only 1/16 inch (1.6 mm) or less of tread remaining. Some commercial truck tires may not have treadwear indicators.

You need a new tire if any of the following statements are true: (cid:127) You can see the indicators at three or more places

around the tire.

(cid:127) You can see cord or fabric showing through the

tire’s rubber. The tread or sidewall is cracked, cut or snagged deep enough to show cord or fabric. The tire has a bump, bulge or split. The tire has a puncture, cut or other damage that can’t be repaired well because of the size or location of the damage.

5-62

(cid:127) (cid:127) (cid:127) {CAUTION:

Mixing tires could cause you to lose control while driving. If you mix tires of different sizes or types (radial and bias-belted tires) the vehicle may not handle properly, and you could have a crash. Using tires of different sizes may also cause damage to your vehicle. Be sure to use the same size and type tires on all wheels.

{CAUTION:

If you use bias-ply tires on your vehicle, the wheel rim flanges could develop cracks after many miles of driving. A tire and/or wheel could fail suddenly, causing a crash. Use only radial-ply tires with the wheels on your vehicle.

Uniform Tire Quality Grading Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width. For example: Treadwear 200 Traction AA Temperature A The following information relates to the system developed by the United States National Highway Traffic Safety Administration, which grades tires by treadwear, traction and temperature performance. (This applies only to vehicles sold in the United States.) The grades are molded on the sidewalls of most passenger car tires. The Uniform Tire Quality Grading system does not apply to deep tread, winter-type snow tires, space-saver or temporary use spare tires, tires with nominal rim diameters of 10 to 12 inches (25 to 30 cm), or to some limited-production tires. While the tires available on General Motors passenger cars and light trucks may vary with respect to these grades, they must also conform to federal safety requirements and additional General Motors Tire Performance Criteria (TPC) standards.

5-63

Treadwear The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear one and a half (1.5) times as well on the government course as a tire graded 100. The relative performance of tires depends upon the actual conditions of their use, however, and may depart significantly from the norm due to variations in driving habits, service practices and differences in road characteristics and climate. Traction – AA, A, B, C The traction grades, from highest to lowest, are AA, A, B, and C. Those grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance. Warning: The traction grade assigned to this tire is based on straight-ahead braking traction tests, and does not include acceleration, cornering, hydroplaning, or peak traction characteristics. Temperature – A, B, C The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel. Sustained high temperature can cause the

5-64

material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 109. Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law. Warning: The temperature grade for this tire is established for a tire that is properly inflated and not overloaded. Excessive speed, underinflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.

Wheel Alignment and Tire Balance The tires and wheels on your vehicle were aligned and balanced carefully at the factory to give you the longest tire life and best overall performance. Adjustments to wheel alignment and tire balancing will not be necessary on a regular basis. However, if you notice unusual tire wear or your vehicle pulling to one side or the other, the alignment may need to be checked. If you notice your vehicle vibrating when driving on a smooth road, your tires and wheels may need to be rebalanced. See your dealer for proper diagnosis.

Wheel Replacement Replace any wheel that is bent, cracked or badly rusted or corroded. If wheel nuts keep coming loose, the wheel, wheel bolts and wheel nuts should be replaced. If the wheel leaks air, replace it (except some aluminum wheels, which can sometimes be repaired). See your dealer if any of these conditions exist. Your dealer will know the kind of wheel you need. Each new wheel should have the same load-carrying capacity, diameter, width, offset and be mounted the same way as the one it replaces. If you need to replace any of your wheels, wheel bolts or wheel nuts, replace them only with new GM original equipment parts. This way, you will be sure to have the right wheel, wheel bolts and wheel nuts for your vehicle.

{CAUTION:

Using the wrong replacement wheels, wheel bolts or wheel nuts on your vehicle can be dangerous. It could affect the braking and handling of your vehicle, make your tires lose air and make you lose control. You could have a collision in which you or others could be injured. Always use the correct wheel, wheel bolts and wheel nuts for replacement.

Notice: The wrong wheel can also cause problems with bearing life, brake cooling, speedometer or odometer calibration, headlamp aim, bumper height, vehicle ground clearance and tire or tire chain clearance to the body and chassis. See Changing a Flat Tire on page 5-69 for more information.

5-65

Used Replacement Wheels

Tire Chains

{CAUTION:

{CAUTION:

Putting a used wheel on your vehicle is dangerous. You can’t know how it’s been used or how far it’s been driven. It could fail suddenly and cause a crash. If you have to replace a wheel, use a new GM original equipment wheel.

Do not use tire chains. There is not enough clearance. Tire chains used on a vehicle without the proper amount of clearance can cause damage to the brakes, suspension or other vehicle parts. The area damaged by the tire chains could cause you to lose control of your vehicle and you or others may be injured in a crash. Use another type of traction device only if its manufacturer recommends it for use on your vehicle and tire size combination and road conditions. Follow that manufacturer’s instructions. To help avoid damage to your vehicle, drive slowly, re-adjust or remove the device if it is contacting your vehicle, and do not spin your wheels. If you do find traction devices that will fit, install them on the rear tires.

5-66

Accessory Inflator Your vehicle may be equipped with an accessory inflator system. You can inflate things like basketballs and bicycle tires. You can also use it to bring your tire pressure up to the proper pressure. It is not designed to inflate large objects which will require more than five minutes to inflate, such as an air mattress.

The accessory inflator is located in the rear compartment on the driver’s side of the vehicle behind an access cover, near the liftgate opening.

To remove the cover, push in on the tab to access the inflator. You may have an air inflator kit that is located in the glove compartment. It includes a 22 ft (6.7 m) hose with three nozzle adapters.

To use the accessory inflator, do the following:

1. Attach the appropriate nozzle adapter to the end of

the hose if required.

2. Attach that end of the hose to the object you wish

to inflate.

3. Attach the other end of the hose to the outlet. 4. Press and release the switch to turn the air inflator

on. The indicator light will remain on when the inflator is running. The system has an internal clock to prevent overheating. The system will allow about five minutes of running time, then the compressor will stop. The indicator light will then begin to flash. When the indicator is off, the inflator can be started again by pressing the switch. If the compressor is still hot, it may only run for a short time before shutting off again.

5. Press and release the switch to turn the inflator off. Place the inflator kit tools in the pouch and store it in its proper location. Remove the inflator hose from the outlet during loading and unloading. Load leveling will not function with the inflator hose attached to the inflator outlet. See “Electronically Controlled Air Suspension System” under Loading Your Vehicle on page 4-43

5-67

To reinstall the cover, line up the tabs at the back of the cover, put it in place and latch the tabs. A continuous flashing indicator light may also indicate a malfunction in the air suspension system. See “Electronically Controlled Air Suspension System” under Loading Your Vehicle on page 4-43 for more information.

{CAUTION:

Inflating something too much can make it explode, and you or others could be injured. Be sure to read the inflator instructions, and inflate any object only to its recommended pressure.

If a Tire Goes Flat It’s unusual for a tire to “blowout” while you’re driving, especially if you maintain your tires properly. If air goes out of a tire, it’s much more likely to leak out slowly. But if you should ever have a “blowout,” here are a few tips about what to expect and what to do: If a front tire fails, the flat tire will create a drag that pulls the vehicle toward that side. Take your foot off the accelerator pedal and grip the steering wheel firmly. Steer to maintain lane position, and then gently brake to a stop well out of the traffic lane. A rear blowout, particularly on a curve, acts much like a skid and may require the same correction you’d use in a skid. In any rear blowout, remove your foot from the accelerator pedal. Get the vehicle under control by steering the way you want the vehicle to go. It may be very bumpy and noisy, but you can still steer. Gently brake to a stop, well off the road if possible.

5-68

{CAUTION:

{CAUTION:

Lifting a vehicle and getting under it to do maintenance or repairs is dangerous without the appropriate safety equipment and training. The jack provided with your vehicle is designed only for changing a flat tire. If it is used for anything else, you or others could be badly injured or killed if the vehicle slips off the jack. Use the jack provided with your vehicle only for changing a flat tire.

If a tire goes flat, the next part shows how to use your jacking equipment to change a flat tire safely.

Changing a Flat Tire If a tire goes flat, avoid further tire and wheel damage by driving slowly to a level place. Turn on your hazard warning flashers.

Changing a tire can be dangerous. The vehicle can slip off the jack and roll over or fall on you or other people. You and they could be badly injured or even killed. Find a level place to change your tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly. 2. Put the shift lever in PARK (P). 3. Turn off the engine and do not restart

while the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

To be even more certain the vehicle will not move, you should put blocks at the front and rear of the tire farthest away from the one being changed. That would be the tire, on the other side, at the opposite end of the vehicle.

5-69

When you have a flat tire, use the following example as a guide to assist you in the placement of wheel blocks.

Removing the Spare Tire and Tools

The following information will tell you next how to use the jack and change a tire.

The jacking equipment you will need is stored under the rear seat on the passenger’s side of the vehicle. See Rear Seat Operation on page 1-5 for more information. To release the jack from its holder, turn the knob on the jack counterclockwise to lower the jack head.

5-70

The tools you’ll be using include the wheel wrench (A), wheel blocks (B), extension(s) (socket end) (C), handle (jack end) (D), and jack (E). The following instructions explain how to remove the underbody-mounted spare underneath your vehicle. Notice: storage position under the vehicle when it is supported by a jack, you could damage the tire and/or your vehicle. Always remove or restow a tire when the vehicle is on the ground.

If you remove or restow a tire from/to the

1. Insert the socket end of the extension on a

45 degree angle downward into the hoist drive shaft hole. It will be exposed when the rear gate is open and is just above the rear bumper. Be sure the socket end of the extension connects to the hoist shaft.

2. Turn the wheel wrench counterclockwise to lower the spare tire. Keep turning the wheel wrench until the spare tire can be pulled out from under the vehicle. If the spare tire does not lower to the ground, the secondary latch is engaged causing the tire not to lower. See Secondary Latch System on page 5-77 for more information.

5-71

3. Tilt the retainer at the end of the cable when the

tire has been completely lowered, and pull it through the wheel opening.

If you drive away before the spare tire or

4. Pull the tire out from under the vehicle. Notice: secondary latch system cable has been reinstalled, you could damage your vehicle. Always reinstall this cable before driving your vehicle. 5. Put the spare tire near the flat tire.

Removing the Flat Tire and Installing the Spare Tire

1. Using the wheel

wrench, loosen all the wheel nuts. Don’t remove them yet.

2. Turn the jack adjusting knob clockwise by hand to

raise the jack lift head.

3. Place the handle, extension and wheel wrench onto

the jack.

6. Position the chisel end of your wheel wrench in the notch of the center cap and pry off the center cap.

5-72

Front

Rear

A. Front Frame/Rear Axle B. Jack C. Handle D. Extension(s) E. Wheel Wrench

4. Place the jack in the appropriate position nearest

the flat tire.

{CAUTION:

Getting under a vehicle when it is jacked up is dangerous. If the vehicle slips off the jack you could be badly injured or killed. Never get under a vehicle when it is supported only by a jack.

{CAUTION:

Raising your vehicle with the jack improperly positioned can damage the vehicle and even make the vehicle fall. To help avoid personal injury and vehicle damage, be sure to fit the jack lift head into the proper location before raising the vehicle.

5-73

{CAUTION:

Rust or dirt on the wheel, or on the parts to which it is fastened, can make the wheel nuts become loose after a time. The wheel could come off and cause an accident. When you change a wheel, remove any rust or dirt from the places where the wheel attaches to the vehicle. In an emergency, you can use a cloth or a paper towel to do this; but be sure to use a scraper or wire brush later, if you need to, to get all the rust or dirt off.

5. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the ground so there is enough room for the spare tire to fit.

6. Remove all the wheel nuts and take off the flat tire.

5-74

7. Remove any rust or dirt

from the wheel bolts, mounting surfaces and spare wheel.

9. Put the nuts on by

hand. Make sure the rounded end is toward the wheel.

8. Place the spare on the wheel-mounting surface.

{CAUTION:

Never use oil or grease on studs or nuts. If you do, the nuts might come loose. Your wheel could fall off, causing a serious accident.

10. Tighten each nut by hand until the wheel is held against the hub. If a nut can’t be turned by hand, use the wheel wrench and see your dealer as soon as possible.

5-75

{CAUTION:

Incorrect wheel nuts or improperly tightened wheel nuts can cause the wheel to come loose and even come off. This could lead to an accident. Be sure to use the correct wheel nuts. If you have to replace them, be sure to get new GM original equipment wheel nuts. Stop somewhere as soon as you can and have the nuts tightened with a torque wrench to the proper torque specification. See Capacities and Specifications on page 5-102 for wheel nut torque specification.

Improperly tightened wheel nuts can lead

Notice: to brake pulsation and rotor damage. To avoid expensive brake repairs, evenly tighten the wheel nuts in the proper sequence and to the proper torque specification. See Capacities and Specifications on page 5-102 for the wheel nut torque specification.

11. Lower the vehicle by turning the jack handle counterclockwise. Lower the jack completely.

5-76

12. Use the wrench to

tighten the wheel nuts firmly in a crisscross sequence as shown.

{CAUTION:

Secondary Latch System Your vehicle has an underbody-mounted tire hoist assembly equipped with a secondary latch system. It is designed to stop the spare or flat road tire from suddenly falling off your vehicle if the cable holding the spare tire is damaged. For the secondary latch to work, the tire must be stored with the valve stem pointing up. See Storing a Flat or Spare Tire and Tools on page 5-80 for instructions on storing the spare or flat tire correctly.

Before beginning this procedure read all the instructions. Failure to read and follow the instructions could damage the hoist assembly and you and others could get hurt. Read and follow the instructions listed below.

{CAUTION:

Someone standing too close during the procedure could be injured by the jack. If the spare tire does not slide off the jack completely, make sure no one is behind you or on either side of you as you pull the jack out from the spare.

5-77

To release the spare tire from the secondary latch, do the following:

5. Turn the wrench counterclockwise until

approximately 6 inches (15 cm) of cable is exposed.

1. Check under the

vehicle to see if the cable is visible.

If it is not visible, proceed to Step 6.

2. If visible, first try to tighten the cable by turning the wheel wrench clockwise until you hear two clicks or feel it skip twice. You cannot overtighten the cable.

3. Loosen the cable by turning the wheel wrench

counterclockwise three or four turns.

4. Repeat this procedure at least two times.

If the spare tire lowers to the ground, continue with Step 2 of Removing the Spare Tire and Tools on page 5-70.

5-78

6. Attach the jack handle, extension(s) and the wheel

wrench to the jack and place it under the vehicle towards the front of the rear bumper. Position the center lift point of the jack under the center of the spare tire.

7. Turn the wrench clockwise to raise the jack until it

lifts the end fitting.

8. Continue raising the jack until the spare tire stops

moving upward and is held firmly in place. The secondary latch has released and the spare tire is balancing on the jack.

9. Lower the jack by turning the wheel wrench

counterclockwise. Keep lowering the jack until the spare tire slides off the jack or is hanging by the cable.

10. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push against the spare while firmly pulling the jack out from under the spare tire with the other hand.

11. Tilt the retainer at the end of the cable and pull it through the wheel opening. Pull the tire out from under the vehicle.

If you drive away before the spare tire or

Notice: secondary latch system cable has been reinstalled, you could damage your vehicle. Always reinstall this cable before driving your vehicle. 12. Turn the wheel wrench clockwise to raise the cable

back up if the cable is hanging under the vehicle.

Have the hoist assembly inspected as soon as you can. You will not be able to store a spare or flat tire using the hoist assembly until it has been repaired or replaced.

If the spare tire is hanging from the cable, insert the socket end of the extension connected to the wheel wrench into the hoist shaft hole in the bumper on a 45 degree angle downward. Turn the wheel wrench counterclockwise to lower the spare the rest of the way.

5-79

Storing a Flat or Spare Tire and Tools

{CAUTION:

{CAUTION:

Storing a jack, a tire, or other equipment in the passenger compartment of the vehicle could cause injury. In a sudden stop or collision, loose equipment could strike someone. Store all these in the proper place.

The underbody-mounted spare tire needs to be stored with the valve stem pointing up. If the spare tire is stored with the valve stem pointing downward, its secondary latch won’t work properly and the spare tire could loosen and suddenly fall from your vehicle. If this happened when your vehicle was being driven, the tire might contact a person or another vehicle, causing injury and, of course, damage to itself as well. Be sure the underbody-mounted spare tire is stored with its valve stem pointing up.

Notice: An aluminum wheel with a flat tire should always be stored under the vehicle with the hoist. However, storing it that way for an extended period could damage the wheel. To avoid this, always stow the wheel properly with the valve stem pointing up and have the wheel repaired as soon as possible.

5-80

Follow this diagram to store the underbody-mounted spare.

A. Wheel Wrench B. Hoist Shaft C. Extension D. Retainer E. Spare or Flat

Tire (Valve Stem Pointed Up)

1. Put the tire on the ground at the rear of the vehicle,

with the valve stem pointed up and to the rear.

2. Pull the retainer (D) through the wheel. 3. Put the socket end of the extension (C), on a

45 degree angle downward, through the hole in the rear bumper and into the hoist shaft (B).

4. Raise the tire fully against the underside of the

vehicle by turning the wheel wrench (A) clockwise until you hear two clicks or feel it skip twice. The spare tire hoist cannot be overtightened.

5. Make sure the tire is stored securely. Push, pull (A),

and then try to turn (B) the tire. If the tire moves, use the wheel wrench and socket end of the extension to tighten the cable.

Return the jack, wheel blocks and tools to the proper location under the rear seat of the vehicle. Return the rear seat to its proper position.

5-81

Spare Tire Your vehicle, when new, had a fully-inflated spare tire. A spare tire may lose air over time, so check its inflation pressure regularly. See Inflation - Tire Pressure on page 5-59 and Loading Your Vehicle on page 4-43

for information regarding proper tire inflation and loading your vehicle. For instruction on how to remove, install or store a spare tire, see Removing the Flat Tire and Installing the Spare Tire on page 5-72 and Storing a Flat or Spare Tire and Tools on page 5-80. After installing the spare tire on your vehicle, you should stop as soon as possible and make sure the spare is correctly inflated. Have the damaged or flat road tire repaired or replaced as soon as you can and installed back onto your vehicle. This way, a spare tire will be available in case you need it again.A. Handle B. Wheel Wrench C. Instruction Label

D. Extension E. Wheel Blocks

and Jack

5-82

Appearance Care Cleaning products can be hazardous. Some are toxic. Other cleaning products can burst into flames if a match is struck near them or if they get on a hot part of the vehicle. Some are dangerous if their fumes are inhaled in an enclosed space. When anything from a container is used to clean the vehicle, be sure to follow the manufacturer’s warnings and instructions. Always open the doors or windows of the vehicle when cleaning the inside. Never use these to clean the vehicle: (cid:127) Gasoline (cid:127) Benzene (cid:127) Naphtha (cid:127) Carbon Tetrachloride (cid:127) Acetone (cid:127) Paint Thinner

Turpentine Lacquer Thinner

(cid:127) Nail Polish Remover They can all be hazardous — some more than others — and they can all damage the vehicle, too.

Do not use any of these products unless this manual says you can. In many uses, these will damage the vehicle: (cid:127) Alcohol

Laundry Soap

(cid:127) Bleach (cid:127) Reducing Agents

Fabric/Carpet Use a vacuum cleaner often to get rid of dust and loose dirt. Wipe vinyl, leather, plastic, and painted surfaces with a clean, damp cloth. GM-approved cleaning products can be obtained from your dealer. Here are some cleaning tips: (cid:127) Always read the instructions on the cleaner label. (cid:127) Clean up stains as soon as you can before they set. (cid:127) Carefully scrape off any excess stain. (cid:127) Use a clean cloth or sponge, and change to a clean

area often. A soft brush may be used if stains are stubborn. To avoid forming a ring on fabric after spot cleaning, clean the entire area immediately or it will set.

5-83

(cid:127) (cid:127) (cid:127) (cid:127) Most stains can be removed with club soda water. To clean, use the following instructions: 1. For liquids: blot with a clean, soft, white cloth. For

solids: remove as much as possible and then vacuum or brush.

2. Apply club soda water to a clean, soft, white cloth.

Do not over-saturate; the cloth should not drip water.

3. Clean the entire area. Avoid getting the fabric

too wet.

4. Start cleaning from the seams into the stain to

avoid a ring effect.

5. Continue cleaning, using a clean area of the cloth

each time it becomes soiled.

6. When the stain is removed, blot the cleaned area

with another dry, clean, soft, white cloth.

Using Cleaner on Fabric 1. First, try the cleaner on an area of the fabric that is not easily seen to make sure the cleaner does not affect the color of the fabric.

2. For liquids: blot with a clean, soft, white cloth. For

solids: remove as much as possible and then vacuum or brush.

5-84

3. Spray a small amount of the cleaner onto a clean soft, white, cloth. Do not apply spray directly to the fabric.

4. Start cleaning from the seams into the stain to

avoid a ring effect.

5. Continue cleaning, using a clean area of the cloth

each time it becomes soiled.

6. When the stain is removed, blot the cleaned area

with another dry, clean, soft, white cloth.

7. If the cleaner leaves a ring effect, follow up with the

club soda water instructions given earlier in this section.

Special Fabric Cleaning Problems Stains caused by such things as catsup, black coffee, egg, fruit, fruit juice, milk, soft drinks, vomit, urine, and blood can be removed using the club soda water instructions given earlier in this section. If an odor lingers after cleaning vomit or urine, treat the area with a water and baking soda solution: 1 teaspoon (5 ml) of baking soda to 1 cup (250 ml) of lukewarm water. Let dry.

Stains caused by oil and grease can be cleaned with an approved GM cleaner and a clean, white cloth. 1. Carefully scrape off excess stain. 2. Clean with cool water and allow to dry completely. 3. If a stain remains, follow the “Using Cleaner on

Fabric” instructions described earlier.

Instrument Panel Use only mild soap and water to clean the top surfaces of the instrument panel. Sprays containing silicones or waxes may cause annoying reflections in the windshield and even make it difficult to see through the windshield under certain conditions.

Vinyl Use warm water and a clean cloth. (cid:127) Rub with a clean, damp cloth to remove dirt. This

may have to be done more than once. Things like tar, asphalt, and shoe polish will stain if they are not removed quickly. Use a clean cloth and vinyl cleaner. See your dealer for this product.

Leather Use a soft cloth with lukewarm water and a mild soap or saddle soap and wipe dry with a soft cloth. Then, let the leather dry naturally. Do not use heat to dry.

For stubborn stains, use a leather cleaner.

(cid:127) Never use oils, varnishes, solvent-based or abrasive cleaners, furniture polish, or shoe polish on leather.

(cid:127) Soiled or stained leather should be cleaned

immediately. If dirt is allowed to work into the finish, it can harm the leather.

Interior Plastic Components Use only a mild soap and water solution on a soft cloth or sponge. Commercial cleaners may affect the surface finish.

Glass Surfaces Glass should be cleaned often. GM Glass Cleaner or a liquid household glass cleaner will remove normal tobacco smoke and dust films on interior glass. See Vehicle Care/Appearance Materials on page 5-90. Notice: glass surfaces on your vehicle, you could scratch the glass. When cleaning the glass on your vehicle, use only a soft cloth and glass cleaner.

If you use abrasive cleaners when cleaning

5-85

(cid:127) (cid:127) Care of Safety Belts Keep belts clean and dry.

{CAUTION:

Do not bleach or dye safety belts. If you do, it may severely weaken them. In a crash, they might not be able to provide adequate protection. Clean safety belts only with mild soap and lukewarm water.

Weatherstrips Silicone grease on weatherstrips will make them last longer, seal better, and not stick or squeak. Apply silicone grease with a clean cloth. During very cold, damp weather frequent application may be required. See Recommended Fluids and Lubricants on page 6-12.

Washing Your Vehicle The paint finish on the vehicle provides beauty, depth of color, gloss retention, and durability. The best way to preserve the vehicle’s finish is to keep it clean by washing it often with lukewarm or cold water. Do not wash the vehicle in the direct rays of the sun. Use a car washing soap. Do not use strong soaps or chemical detergents. Be sure to rinse the vehicle well, removing all soap residue completely. GM-approved cleaning products can be obtained from your dealer. See Vehicle Care/Appearance Materials on page 5-90. Do not use cleaning agents that are petroleum based, or that contain acid or abrasives. All cleaning agents should be flushed promptly and not allowed to dry on the surface, or they could stain. Dry the finish with a soft, clean chamois or an all-cotton towel to avoid surface scratches and water spotting. High pressure car washes may cause water to enter the vehicle.

5-86

Cleaning Exterior Lamps/Lenses Use only lukewarm or cold water, a soft cloth and a car washing soap to clean exterior lamps and lenses. Follow instructions under Washing Your Vehicle on page 5-86.

Finish Care Occasional waxing or mild polishing of your vehicle by hand may be necessary to remove residue from the paint finish. You can get GM-approved cleaning products from your dealer. See Vehicle Care/Appearance Materials on page 5-90. If your vehicle has a “basecoat/clearcoat” paint finish. The clearcoat gives more depth and gloss to the colored basecoat. Always use waxes and polishes that are non-abrasive and made for a basecoat/clearcoat paint finish. Notice: Machine compounding or aggressive polishing on a basecoat/clearcoat paint finish may damage it. Use only non-abrasive waxes and polishes that are made for a basecoat/clearcoat paint finish on your vehicle.

Foreign materials such as calcium chloride and other salts, ice melting agents, road oil and tar, tree sap, bird droppings, chemicals from industrial chimneys, etc., can damage your vehicle’s finish if they remain on painted surfaces. Wash the vehicle as soon as possible. If necessary, use non-abrasive cleaners that are marked safe for painted surfaces to remove foreign matter. Exterior painted surfaces are subject to aging, weather and chemical fallout that can take their toll over a period of years. You can help to keep the paint finish looking new by keeping your vehicle garaged or covered whenever possible. Protecting Exterior Bright Metal Parts Bright metal parts should be cleaned regularly to keep their luster. Washing with water is all that is usually needed. However, you may use chrome polish on chrome or stainless steel trim, if necessary. Use special care with aluminum trim. To avoid damaging protective trim, never use auto or chrome polish, steam or caustic soap to clean aluminum. A coating of wax, rubbed to high polish, is recommended for all bright metal parts.

5-87

Windshield, Backglass, and Wiper Blades If the windshield is not clear after using the windshield washer, or if the wiper blade chatters when running, wax, sap or other material may be on the blade or windshield. Clean the outside of the windshield with a full-strength glass cleaning liquid. The windshield is clean if beads do not form when you rinse it with water. Grime from the windshield will stick to the wiper blades and affect their performance. Clean the blade by wiping vigorously with a cloth soaked in full-strength windshield washer solvent. Then rinse the blade with water. Check the wiper blades and clean them as necessary; replace blades that look worn.

If you use strong soaps, chemicals,

Aluminum Wheels Notice: abrasive polishes, cleaners, brushes, or cleaners that contain acid on aluminum or chrome-plated wheels, you could damage the surface of the wheel(s). The repairs would not be covered by your warranty. Use only GM-approved cleaners on aluminum or chrome-plated wheels.

5-88

Keep the wheels clean using a soft clean cloth with mild soap and water. Rinse with clean water. After rinsing thoroughly, dry with a soft clean towel. A wax may then be applied. Notice: Using chrome polish on aluminum wheels could damage the wheels. The repairs would not be covered by your warranty. Use chrome polish on chrome wheels only. The surface of these wheels is similar to the painted surface of the vehicle. Do not use strong soaps, chemicals, abrasive polishes, abrasive cleaners, cleaners with acid, or abrasive cleaning brushes on them because the surface could be damaged. Do not use chrome polish on aluminum wheels. Notice: automatic car wash that has silicone carbide tire cleaning brushes, you could damage the aluminum or chrome-plated wheels. The repairs would not be covered by your warranty. Never drive a vehicle equipped with aluminum or chrome-plated wheels through an automatic car wash that uses silicone carbide tire cleaning brushes. Do not take the vehicle through an automatic car wash that has silicone carbide tire cleaning brushes. These brushes can also damage the surface of these wheels.

If you drive your vehicle through an

Tires To clean the tires, use a stiff brush with tire cleaner. Notice: Using petroleum-based tire dressing products on your vehicle may damage the paint finish and/or tires. When applying a tire dressing, always wipe off any overspray from all painted surfaces on your vehicle.

Sheet Metal Damage If the vehicle is damaged and requires sheet metal repair or replacement, make sure the body repair shop applies anti-corrosion material to parts repaired or replaced to restore corrosion protection. Original manufacturer replacement parts will provide the corrosion protection while maintaining the warranty.

Finish Damage Any stone chips, fractures or deep scratches in the finish should be repaired right away. Bare metal will corrode quickly and may develop into major repair expense. Minor chips and scratches can be repaired with touch-up materials available from your GM dealer. Larger areas of finish damage can be corrected in your GM dealer’s body and paint shop.

Underbody Maintenance Chemicals used for ice and snow removal and dust control can collect on the underbody. If these are not removed, corrosion and rust can develop on the underbody parts such as fuel lines, frame, floor pan, and exhaust system even though they have corrosion protection. At least every spring, flush these materials from the underbody with plain water. Clean any areas where mud and debris can collect. Dirt packed in close areas of the frame should be loosened before being flushed. Your GM dealer or an underbody car washing system can do this for you.

Chemical Paint Spotting Some weather and atmospheric conditions can create a chemical fallout. Airborne pollutants can fall upon and attack painted surfaces on the vehicle. This damage can take two forms: blotchy, ring-shaped discolorations, and small, irregular dark spots etched into the paint surface. Although no defect in the paint job causes this, GM will repair, at no charge to the owner, the surfaces of new vehicles damaged by this fallout condition within 12 months or 12,000 miles (20 000 km) of purchase, whichever occurs first.

5-89

Vehicle Care/Appearance Materials See your GM dealer for more information on purchasing the following products.

Description

Polishing Cloth Wax-Treated Tar and Road Oil Remover Chrome Cleaner and Polish White Sidewall Tire Cleaner

Vinyl Cleaner

Glass Cleaner

Chrome and Wire Wheel Cleaner

Finish Enhancer

Usage

Interior and exterior polishing cloth. Removes tar, road oil, and asphalt. Use on chrome or stainless steel. Removes soil and black marks from whitewalls. Cleans vinyl tops, upholstery, and convertible tops. Removes dirt, grime, smoke and fingerprints. Removes dirt and grime from chrome wheels and wire wheel covers. Removes dust, fingerprints, and surface contaminants. Spray on and wipe off.

5-90

Description

Usage

Cleaner Wax

Swirl Remover Polish

Wash Wax Concentrate

Foaming Tire Shine Low Gloss

Removes swirl marks, fine scratches, and other light surface contamination. Removes light scratches and protects finish. Cleans, shines, and protects in one step. No wiping necessary. Medium foaming shampoo. Cleans and lightly waxes. Biodegradable and phosphate free. Quickly removes spots and stains from carpets, vinyl, and cloth upholstery. Odorless spray odor eliminator used on fabrics, vinyl, leather and carpet. See your General Motors parts department for these products. See Recommended Fluids and Lubricants on page 6-12.

Odor Eliminator

Spot Lifter

Vehicle Identification

Vehicle Identification Number (VIN)

This is the legal identifier for your vehicle. It appears on a plate in the front corner of the instrument panel, on the driver’s side. You can see it if you look through the windshield from outside your vehicle. The VIN also appears on the Vehicle Certification and Service Parts labels and the certificates of title and registration.

Engine Identification The eighth character in your VIN is the engine code. This code will help you identify your engine, specifications and replacement parts.

Service Parts Identification Label You will find this label on the inside of the glove box. It is very helpful if you ever need to order parts. On this label, you will find the following: (cid:127) VIN (cid:127) Model designation (cid:127) Paint information (cid:127) Production options and special equipment Be sure that this label is not removed from the vehicle.

5-91

Electrical System

Add-On Electrical Equipment Notice: Don’t add anything electrical to your vehicle unless you check with your dealer first. Some electrical equipment can damage your vehicle and the damage wouldn’t be covered by your warranty. Some add-on electrical equipment can keep other components from working as they should. Your vehicle has an airbag system. Before attempting to add anything electrical to your vehicle, see Servicing Your Airbag-Equipped Vehicle on page 1-60.

Headlamps The headlamp wiring is protected by four fuses. An electrical overload will cause a lamp to go on and off. If this happens, have your headlamp wiring checked right away.

Windshield Wiper Fuses The windshield wiper motor is protected by a circuit breaker and a fuse. If the motor overheats due to heavy snow or ice, the wiper will stop until the motor cools. If the overload is caused by some electrical problem, be sure to get it fixed.

Power Windows and Other Power Options Circuit breakers protect the power windows and other power accessories. When the current load is too heavy, the circuit breaker opens and closes, protecting the circuit until the problem is fixed or goes away.

5-92

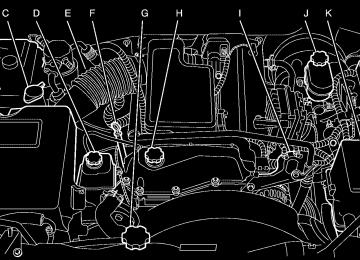

Engine Compartment Fuse Block

Fuses and Circuit Breakers The wiring circuits in your vehicle are protected from short circuits by a combination of fuses and circuit breakers. This greatly reduces the chance of fires caused by electrical problems. Look at the silver-colored band inside the fuse. If the band is broken or melted, replace the fuse. Be sure you replace a bad fuse with a new one of the identical size and rating. If you ever have a problem on the road and don’t have a spare fuse, you can borrow one that has the same amperage. Just pick some feature of your vehicle that you can get along without — like the radio or cigarette lighter— and use its fuse, if it is the correct amperage. Replace it as soon as you can.

The fuse block is located under the hood in the engine compartment on the driver’s side of the vehicle. See Engine Compartment Overview on page 5-12 for more information on location. Remove the primary cover by pressing the two locking tabs. Remove the secondary cover by snapping off while lifting. To reinstall the fuse panel cover, reverse the sequence.

5-93

L6 Engine

5-94

Fuses

Usage

Fuses

Usage

10

11

12

13

14

15Electrically-Controlled Air Suspension Passenger’s Side High-Beam Headlamp Passenger’s Side Low-Beam Headlamp Back-Up-Trailer Lamps Driver’s Side High-Beam Headlamp Driver’s Side Low-Beam Headlamp Rear Window Washer Automatic Transfer Case Windshield Washer Powertrain Control Module B Fog Lamps Stoplamp Cigarette Lighter Ignition Coils Electric Adjustable Pedal

16

17

18

19

20

21

22

2324

25

26

27

28

29

30

31Truck Body Controller, Ignition 1

Crank Airbag Trailer Electric Brake Cooling Fan Horn Ignition E Electronic Throttle Control Instrument Panel Cluster, Driver Information Center Automatic Shift Lock Control System Engine 1

Back-Up Powertrain Control Module 1

Oxygen Sensor Air Conditioning Truck Body Controller5-95

Fuses

Usage

Fuses

Usage

32

33

34

35

36

50

51

52

53

54

56Trailer Anti-lock Brakes (ABS) Ignition A Blower Motor Ignition B Passenger’s Side Trailer Turn Driver’s Side Trailer Turn Hazard Flashers Headlamp Driver Module Air Injection Reactor (AIR) Solenoid Air Injection Reactor (AIR) Pump

39

40

41

42

43

44

45

46

47

49

55Fog Lamps Horn Fuel Pump Windshield Washer High-Beam Headlamp Air Conditioning Cooling Fan Headlamp Driver Module Starter Electric Adjustable Pedal Air Injection Reactor (AIR) Solenoid

Relays

37

38Usage

Blank or Headlamp Washer Rear Window Washer

Miscellaneous

Usage

48

Instrument Panel Battery

5-96

V8 Engine

5-97

Fuses

Usage

Fuses

Usage

10

11

12

13

14

15

16

17

18

19

20

21Electrically-Controlled Air Suspension Passenger’s Side High-Beam Headlamp Passenger’s Side Low-Beam Headlamp Back-Up-Trailer Lamps Driver’s Side High-Beam Headlamp Driver’s Side Low-Beam Headlamp Rear Window Washer Automatic Transfer Case Windshield Washer Powertrain Control Module B Fog Lamps Stoplamp Cigarette Lighter Ignition Coils Canister Vent Truck Body Controller, Ignition 1

Crank Airbag Trailer Electric Brake Cooling Fan Horn5-98

22

2324

25

26

27

28

29

30

31

32

33

34

35

36

50

51

52

53

54

55

56

57Ignition E Electronic Throttle Control Instrument Panel Cluster, Driver Information Center Automatic Shift Lock Control System Engine 1

Back-Up Powertrain Control Module 1

Powertrain Air Conditioning Injector Bank A Trailer Anti-lock Brakes (ABS) Ignition A Blower Motor Ignition B Passenger’s Side Trailer Turn Driver’s Side Trailer Turn Hazard Flashers Transmission Oxygen Sensor Bank B Oxygen Sensor Bank A Injector Bank B Headlamp Driver ModuleRear Underseat Fuse Block

Fuses

58

59Relays

37

38

39

40

41

42

43

44

45

46

47

49

60Usage

Truck Body Controller 1

Electric Adjustable PedalUsage

Headlamp Washer Rear Window Washer Fog Lamps Horn Fuel Pump Windshield Wipers/Washer High-Beam Headlamp Air Conditioning Cooling Fan Headlamp Driver Module Starter Electric Adjustable Pedal Powertrain

Miscellaneous

Usage

48

Instrument Panel Battery

5-99

Fuses

Usage

01

02

03

04

05

06

07

08

09

10

11

12

13

14

1516

17

18

19

20

21

23

24Right Door Control Module Left Door Control Module Endgate Module 2

Truck Body Controller 3

Rear Fog Lamps Blank Truck Body Controller 2

Power Seats Rear Wiper Driver Door Module Amplifier Passenger Door Module Rear Climate Controls Left Rear Parking Lamps Blank Vehicle Center High-Mounted Stop Lamp Right Rear Parking Lamps Locks Liftgate Module/Driver Seat Module Blank Lock Blank Unlock5-100

Fuses

Usage

Fuses

Usage

25

2627

28

29

30

31

32

33

34

35

36

37

38Blank Blank OnStar® Overhead Battery, OnStar® System Sunroof Rainsense™ Wipers Parking Lamps Truck Body Controller Accessory Truck Body Controller 5

Front Wipers Vehicle Stop Transmission Control Module Heat Ventilation Air Conditioning B Front Parking Lamps Left Turn Signal39

40

41

42

43

44

45

46

47

48

49

50

51

52Heat Ventilation Air Conditioning I Truck Body Controller 4

Radio Trailer Park Right Turn Signal Heat Ventilation Air Conditioning Rear Fog Lamps Auxiliary Power 1

Ignition 0

Four-Wheel Drive Blank Truck Body Controller Ignition Brakes Truck Body Controller Run5-101

Capacities and Specifications The following approximate capacities are given in English and metric conversions. See Recommended Fluids and Lubricants on page 6-12 for more information.

Application

Air Conditioning Refrigerant R134a Cooling System

4200 L6

5300 V8Differential Fluid – Front Differential Fluid – Rear

4200 L6

5300 V8Capacities

English 1.9 lbs

10.8 quarts 12.2 quarts 1.7 pints

3.6 pints 4.3 pints

Metric

0.85 kg

10.2 L 11.6 L 0.8 L

1.7 L 2.0 L

Engine Oil with Filter

4200 L6

6.6 L 5.7 L 5300 V8

82.2 L Fuel Tank 4.7 L Transmission (Drain and Refill) 140 Y Wheel Nut Torque All capacities are approximate. When adding, be sure to fill to the appropriate level, as recommended in this manual. Recheck the fluid level after filling.7.0 quarts 6.0 quarts 21.7 gallons 5.0 quarts 100 ft lb

5-102

Engine Specifications

Engine

VIN Code

Transmission

Spark Plug Gap

VORTEC™ 4200 L6

VORTEC™ 5300 V8Automatic Automatic

0.042 inches (1.07 mm) 0.040 inches (1.01 mm)

5-103

✍ NOTES

5-104

Section 6

Maintenance Schedule

Maintenance Schedule ......................................6-2

Introduction ...................................................6-2

Maintenance Requirements ..............................6-2

Your Vehicle and the Environment ....................6-2

Using Your Maintenance Schedule ....................6-2

Scheduled Maintenance ...................................6-4

Additional Required Services ............................6-6

Maintenance Footnotes ...................................6-7Owner Checks and Services ............................6-9

At Each Fuel Fill ............................................6-9

At Least Once a Month ...................................6-9

At Least Once a Year ...................................6-10

Recommended Fluids and Lubricants ...............6-12

Normal Maintenance Replacement Parts ..........6-14

Maintenance Record .....................................6-156-1

Maintenance Schedule

Introduction Important: Keep engine oil at the proper level and change as recommended.

Have you purchased the GM Protection Plan? The Plan supplements your new vehicle warranties. See your Warranty and Owner Assistance booklet or your dealer for details.

Maintenance Requirements Notice: Maintenance intervals, checks, inspections, replacement parts and recommended fluids and